J-T Expander Bypass: Application Discussion AD122 June 15, 2003

J-T Expander Bypass: Application Discussion AD122 June 15, 2003

Uploaded by

KorichiKarimCopyright:

Available Formats

J-T Expander Bypass: Application Discussion AD122 June 15, 2003

J-T Expander Bypass: Application Discussion AD122 June 15, 2003

Uploaded by

KorichiKarimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

J-T Expander Bypass: Application Discussion AD122 June 15, 2003

J-T Expander Bypass: Application Discussion AD122 June 15, 2003

Uploaded by

KorichiKarimCopyright:

Available Formats

J-T Expander Bypass

Application Discussion

AD122

June 15, 2003

In the production of natural gas products, turboexpanders are sometimes used in

Natural Gas Liquids (NGL). A turboexpander consists of alternate sets of nozzles

through which vapor or gas flows in a steady-state expansion process. The use o

large capital investment, but can offer significant power savings. Along with the n

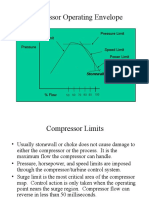

devices are typically used in processes with high feed gas pressures (greater tha

plant layout, varying feed products and where a large amount (greater than 30%

desired.

Turboexpanders are used to recover cryogenic liquids from lean natural gas or to

a gas stream into mechanical work as the gas or vapor expands through the exp

are what are commonly referred to as NGL such as propane, butane and ethane

objective of the turboexpander is to conserve energy and the mechanical work p

considered a byproduct.

When a gas or vapor passes through a turboexpander, the gas expands as it flow

blades and cools through the isentropic (constant Entropy) gas expansion proce

process, hydrocarbon gas temperatures drop through the respective dew points

constituents. As the temperatures of the gases drop below the dew point, they co

and can be recovered. As these gases have a higher BTU content than methane

selling price depending on demand. At this point, the lean gas is used to cool the

several heat exchangers and is then recompressed and sent back to the pipeline

shows a cross section of this process where the mechanical work created by the

the drive the lean gas compressor.

Figure 1: Natural Gas Process Including Turboexpander and Expander

The turboexpander replaces the Joule-Thompson expansion valve used in a con

system. The expansion valve is isenthalpic (constant Enthalpy, no work or heat t

turboexpander takes work out of the system making it isentropic. Isentropic expa

temperature of the expanded gases at the same pressure reduction than that of

The use of turboexpanders, however, does not eliminate the need for the Joule T

typically referred to as the expander bypass valve (See Figure 1), but operates u

Thompson effect. The valve is used to enable a more efficient startup and shutdo

turboexpander. It is also used to continue the process should the expander go of

beyond the full speed capacity of the turboexpander.

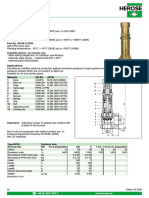

There are many factors that must be taken into account when selecting the prop

application. As inlet pressures vary between 700 and 1500 psig and outlet press

and 700 psig, the effects of damaging noise and vibration need to be addressed.

that at the low temperatures (-150F) experienced, proper body and trim material

In order to protect the expander in the event of a system upset, the valve must o

valve will possess the same capacity and characteristic as the expander to provi

transition between the devices. The final concern is tight shutoff. As previously s

turboexpander is a much more efficient device than the valve so energy could be

if shutoff is not maintained.

The main concern when looking at product selection in this application is to ensu

selected are compatible with the cryogenic temperatures and that the valve trim

issues with noise that are common at these pressure drops. Also of concern is th

that control stroking speed.

Another concern that must be explored is the possibility of hydrate formation in t

solid compounds formed by the chemical combination of gas and water under pr

deposits to form in the pipe and valve trim. Most facilities utilize dehydration unit

formation and the expanders are usually installed at the end of the process. How

explored when selecting the expander bypass valve. If hydrates are present trim

can plug and render the valve useless.

For many applications, the Fisher Ebody with 316 SST body and trim materials c

applications where the temperature can reach as low as 325F, Fisher develope

It should also be noted that an extension type bonnet is recommended at these t

frosting on the stem and instruments. Depending upon the pressure drop, noise

the Whisper I, Whisper III or WhisperFlo solutions in 316 SST materials may be

pressure drop applications, standard trim can be used. These solutions can also

the control characteristic of the expander providing a smooth transition between

accessories necessary to obtain fast stroking speeds will include volume booste

valves.

You might also like

- LM2500 Course PDFDocument86 pagesLM2500 Course PDFKorichiKarim100% (13)

- Pneumatic Reciprocating Powere Hacksaw Machine - Docx FinalDocument11 pagesPneumatic Reciprocating Powere Hacksaw Machine - Docx FinalARVIND DARLING100% (3)

- Gaskell 6th SolutionsDocument229 pagesGaskell 6th Solutionsrogue20200429No ratings yet

- Gas Turbine Operation & Maintenance CourseDocument100 pagesGas Turbine Operation & Maintenance CourseMohammed El-Shahat89% (9)

- Sample VOC PlanDocument18 pagesSample VOC PlanbharatNo ratings yet

- Jet Pump Technical DataDocument11 pagesJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- Rotor Dynamic Response of A Centrifugal Compressor Due To Liquid Carry Over: A Case StudyDocument14 pagesRotor Dynamic Response of A Centrifugal Compressor Due To Liquid Carry Over: A Case Studymariamalloney1730No ratings yet

- Turbo ExpanderDocument17 pagesTurbo ExpanderFathy CaceresNo ratings yet

- Article Turboexpander ProtectionDocument3 pagesArticle Turboexpander ProtectionAnonymous Rn6JarNo ratings yet

- Gas Turbine Working PrincipleDocument7 pagesGas Turbine Working PrincipleAhmed Mohamed SalihNo ratings yet

- Compressor Choke: by TMI Staff & Contributors On August 27, 2019Document5 pagesCompressor Choke: by TMI Staff & Contributors On August 27, 2019Tusar Kole100% (1)

- Filosofia de ControlDocument40 pagesFilosofia de Controlejzuppelli8036No ratings yet

- Siemens PDFDocument10 pagesSiemens PDFejzuppelli8036No ratings yet

- Compressor Surge ControlDocument8 pagesCompressor Surge ControlihllhmNo ratings yet

- Electric Drive Vs Gas Turbines: January 2006Document10 pagesElectric Drive Vs Gas Turbines: January 2006Adool FighterNo ratings yet

- 05 Cylinder Performance (Compressed)Document43 pages05 Cylinder Performance (Compressed)Somen MukherjeeNo ratings yet

- Frequency Detuning in Vertical Pumps - Pumps & Systems PDFDocument9 pagesFrequency Detuning in Vertical Pumps - Pumps & Systems PDFskakerNo ratings yet

- Steam Turbine-Part III - Trip and Throttle ValveDocument7 pagesSteam Turbine-Part III - Trip and Throttle ValveAahmer Hasan100% (1)

- Chap 6 Reaction TurbineDocument10 pagesChap 6 Reaction TurbineSourabh Salunkhe100% (1)

- Performance Prediction of Axial Flow Compressors Using Stage Characteristics PDFDocument10 pagesPerformance Prediction of Axial Flow Compressors Using Stage Characteristics PDFgready64100% (1)

- Compressor C65Document1 pageCompressor C65frdnNo ratings yet

- CenssorsDocument106 pagesCenssorsChandraSekaranBm100% (1)

- OP16 Gas Turbine OPRA Turbines 1.85MWDocument11 pagesOP16 Gas Turbine OPRA Turbines 1.85MWAminovic MostafaNo ratings yet

- Novel Method of Detection of Surge - Gas Machinery Journal Q2 - 13Document16 pagesNovel Method of Detection of Surge - Gas Machinery Journal Q2 - 13mantosh_bhattacharyaNo ratings yet

- Turbo Expander Compressor - Natural Gas Turboexpander - L.ADocument3 pagesTurbo Expander Compressor - Natural Gas Turboexpander - L.Adr_kh_ahmedNo ratings yet

- Turboexpander Compressors 2Document5 pagesTurboexpander Compressors 2Lidia Jara50% (2)

- PEP Session On Steam TurbinesDocument35 pagesPEP Session On Steam Turbinesdanish moinNo ratings yet

- Lube Oil SystemDocument12 pagesLube Oil Systemkareemaa589No ratings yet

- Operating Dry Screw CompressorsDocument3 pagesOperating Dry Screw Compressorskamal arabNo ratings yet

- 11-Regine Mowill (荷兰QPPA Turbines)Document38 pages11-Regine Mowill (荷兰QPPA Turbines)邢焕震No ratings yet

- Dynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene BlendsDocument11 pagesDynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene Blendspickpocket27No ratings yet

- 4 1-Lat Exceptions To API 614Document5 pages4 1-Lat Exceptions To API 614remsorNo ratings yet

- Centifugal CompressorDocument23 pagesCentifugal CompressorSubhash Padmanabhan100% (2)

- Centrifugal Compressor Operation and MaintenanceDocument16 pagesCentrifugal Compressor Operation and MaintenanceNEMS100% (1)

- Compressive Fan BlowerDocument58 pagesCompressive Fan BlowerKiraNo ratings yet

- Masters Rotorsol ForDocument50 pagesMasters Rotorsol ForVILLANUEVA_DANIEL2064No ratings yet

- Dry Gas Seals and Support Systems: Benefits and Options: Plant Safety and EnvironmentDocument5 pagesDry Gas Seals and Support Systems: Benefits and Options: Plant Safety and EnvironmentMuzammil SaleemNo ratings yet

- Influence of The Number of Blades of Miniature Centrifugal Impeller On Compressor PerformanceDocument6 pagesInfluence of The Number of Blades of Miniature Centrifugal Impeller On Compressor PerformanceSuherman MuktiNo ratings yet

- New Cardrige Design - BRXsealDocument15 pagesNew Cardrige Design - BRXsealobumuyaemesi100% (2)

- TB KeyPerformanceEvaluation PDFDocument2 pagesTB KeyPerformanceEvaluation PDFvcharles100% (1)

- Rotating Equipment Classifications: By: Eng. Abobakrelsedik MohamedDocument97 pagesRotating Equipment Classifications: By: Eng. Abobakrelsedik Mohamedaalipour967No ratings yet

- Dry Gas Seal System ManualDocument44 pagesDry Gas Seal System ManualGeorge J Alukkal100% (1)

- 01 Compressed Air FundamentalsDocument38 pages01 Compressed Air FundamentalsWill MorrisonNo ratings yet

- Bhel Turbine Block 3 PresentationDocument29 pagesBhel Turbine Block 3 Presentationnischal100% (1)

- Hydro ComDocument18 pagesHydro ComOmprakash_janaNo ratings yet

- Radial Flow Gas TurbinesDocument20 pagesRadial Flow Gas TurbinesAnggita Dwi LiestyosiwiNo ratings yet

- Selecting Screw CompressorsDocument3 pagesSelecting Screw Compressorsli xianNo ratings yet

- ADRE DatasheetDocument16 pagesADRE DatasheetAhmad Musaddiq MohammadNo ratings yet

- RG Integrally Geared Compressors PDFDocument6 pagesRG Integrally Geared Compressors PDFJaswindersingh Bhatia100% (1)

- DGS - 2. JCDocument15 pagesDGS - 2. JCfjafarvand100% (1)

- Installation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMDocument3 pagesInstallation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMjose luis rattiaNo ratings yet

- Oil MistDocument14 pagesOil MistazisyuswandiNo ratings yet

- Anti-Surge - Valve - ROI - REXA - 2Document10 pagesAnti-Surge - Valve - ROI - REXA - 2Hash LalaNo ratings yet

- Aerodynamic Design of Centrifugal CompressorDocument7 pagesAerodynamic Design of Centrifugal CompressorJun GWan ParkNo ratings yet

- Subsonic Ejector RamjetDocument99 pagesSubsonic Ejector Ramjetmarco20874No ratings yet

- SteamDocument24 pagesSteamsanju_17100% (2)

- Trapped Fluid in Compressor Coupling SpacerDocument26 pagesTrapped Fluid in Compressor Coupling SpacerHamid JNo ratings yet

- Screw Compression 101Document61 pagesScrew Compression 101fitobNo ratings yet

- Rod Load MoweryDocument7 pagesRod Load Mowerymoudar72No ratings yet

- Shaft Alignment PracticeDocument2 pagesShaft Alignment Practicekamal arabNo ratings yet

- Stonewall ControlDocument3 pagesStonewall ControlDiana Catalina Molano Bayona100% (1)

- Pre-Heater of Nat GasDocument12 pagesPre-Heater of Nat GasStl JoseNo ratings yet

- Gas Compression HysysDocument6 pagesGas Compression HysysMusa Mohammed100% (2)

- Tutorial On Turbo ExpanderDocument0 pagesTutorial On Turbo ExpanderMajid Sattar100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- 3641-Ge Frame 9e Turbines PDFDocument5 pages3641-Ge Frame 9e Turbines PDFKorichiKarim100% (1)

- GEA32129A Heavy Duty Gas Turbine Monitoring Protection - R1 PDFDocument48 pagesGEA32129A Heavy Duty Gas Turbine Monitoring Protection - R1 PDFramkrishnaNo ratings yet

- Appendix: Writing A Doctoral DissertationDocument8 pagesAppendix: Writing A Doctoral DissertationKorichiKarimNo ratings yet

- Week 8: 2.16 - Lubricating Oil Specification 2.17 - Types of Lubricating Oil 2.9 & 2.10 - Types of Journal BearingDocument18 pagesWeek 8: 2.16 - Lubricating Oil Specification 2.17 - Types of Lubricating Oil 2.9 & 2.10 - Types of Journal BearingKorichiKarimNo ratings yet

- Sonatrach Antisurge PDFDocument214 pagesSonatrach Antisurge PDFKorichiKarim100% (3)

- 02 Technical Report Corrosion and Mitigation in Fire Systems FM Research Jul 2014Document98 pages02 Technical Report Corrosion and Mitigation in Fire Systems FM Research Jul 2014KorichiKarim100% (1)

- 505c PiecesDocument347 pages505c PiecesKorichiKarimNo ratings yet

- CC General DescriptionDocument40 pagesCC General DescriptionKorichiKarim100% (2)

- Vadodara Institute of Engineering: Surging and ChokingDocument16 pagesVadodara Institute of Engineering: Surging and ChokingKorichiKarimNo ratings yet

- Control FundamentalDocument82 pagesControl FundamentalKorichiKarim100% (2)

- Centrifugal Compressor: Gas PathDocument49 pagesCentrifugal Compressor: Gas PathKorichiKarim100% (4)

- Compressor Surge and Operation Rev1Document28 pagesCompressor Surge and Operation Rev1KorichiKarim100% (2)

- 05 CC Off Designe Operating OverviewDocument8 pages05 CC Off Designe Operating OverviewKorichiKarim100% (2)

- Plant Start-Up - 1111Document5 pagesPlant Start-Up - 1111KorichiKarim100% (1)

- Exfire360 Fire&Gas Control PanelDocument6 pagesExfire360 Fire&Gas Control PanelKorichiKarim100% (1)

- Sonatrach Antisurge PDFDocument214 pagesSonatrach Antisurge PDFKorichiKarimNo ratings yet

- Gas Turbine 3Document45 pagesGas Turbine 3KorichiKarim100% (2)

- Wheelspace 150212063314 Conversion Gate02Document15 pagesWheelspace 150212063314 Conversion Gate02KorichiKarim100% (1)

- Bernoulli Equation: Z P P V G HLDocument2 pagesBernoulli Equation: Z P P V G HLKorichiKarimNo ratings yet

- CATAPANG, Jamiel S. - Experiment 4 (Air Properties - A4)Document25 pagesCATAPANG, Jamiel S. - Experiment 4 (Air Properties - A4)Jamiel CatapangNo ratings yet

- Kenr8379kenr8379-03 SisDocument6 pagesKenr8379kenr8379-03 SisqwureyquweryNo ratings yet

- Laporan Harian TurbineDocument18 pagesLaporan Harian TurbineoksaNo ratings yet

- Topic 3 - Reservoirs and Appraisal DrillingDocument4 pagesTopic 3 - Reservoirs and Appraisal DrillingwevansNo ratings yet

- Guidance Notes - Descaling Plate Heat Exchangers - FWF - 15iDocument2 pagesGuidance Notes - Descaling Plate Heat Exchangers - FWF - 15iOmid LarkiNo ratings yet

- Hydraulic Jump PDFDocument5 pagesHydraulic Jump PDFS KIRAN KUMARNo ratings yet

- Gas DynamicsDocument17 pagesGas DynamicsAmrMashhourNo ratings yet

- How Can I Store Methane Gas in A Gas CylinderDocument2 pagesHow Can I Store Methane Gas in A Gas CylinderJonathan AssefaNo ratings yet

- 150-2372 Unitrol 7000 - Low ResDocument4 pages150-2372 Unitrol 7000 - Low ResGary Fernando Gomez CantosNo ratings yet

- Basics of Well ComplitionDocument15 pagesBasics of Well ComplitionSunny Bba100% (1)

- Engineering Page - Heat Exchangers - Typical Overall Heat Transfer Coefficients PDFDocument2 pagesEngineering Page - Heat Exchangers - Typical Overall Heat Transfer Coefficients PDFJahidul IslamNo ratings yet

- Cabezales Stream FloDocument8 pagesCabezales Stream FlorovalanoNo ratings yet

- Heat Transfer. Finned Tubes. Heat Flow - U Factor - Fin EfficiencyDocument79 pagesHeat Transfer. Finned Tubes. Heat Flow - U Factor - Fin EfficiencyvyrgoNo ratings yet

- Drag Force Word DocumentDocument31 pagesDrag Force Word Documentamber19995No ratings yet

- Airware FRLs CatalogDocument39 pagesAirware FRLs CatalogA Warsi WarsiNo ratings yet

- Anna Todd Dupa Ce Ne Am CertatDocument1 pageAnna Todd Dupa Ce Ne Am CertatLaviNo ratings yet

- G11 - LP Fluid Mechanics DraftDocument14 pagesG11 - LP Fluid Mechanics DraftbocadojerrylloydNo ratings yet

- SLV Air Producuts - Project Report - KIADBDocument16 pagesSLV Air Producuts - Project Report - KIADBpk84427No ratings yet

- Passive Safety SystemDocument3 pagesPassive Safety SystemSimon SimonNo ratings yet

- Model 42 Operator ManualDocument28 pagesModel 42 Operator ManualMuzammil AbbasNo ratings yet

- MAE 333 SyllabusDocument4 pagesMAE 333 SyllabusastrobarbyNo ratings yet

- Assignment 4Document2 pagesAssignment 4challamjNo ratings yet

- Boiler Log BookDocument3 pagesBoiler Log BookSarah Frazier100% (1)

- Introduction To Afterburner PDFDocument16 pagesIntroduction To Afterburner PDFthamizh100% (3)

- Type 06198: Overflow ValvesDocument2 pagesType 06198: Overflow ValvesabdulfetahNo ratings yet

- Labyrinth Seals - A Literature Review: January 2018Document8 pagesLabyrinth Seals - A Literature Review: January 2018Matias RiedelNo ratings yet

- Buat Download AjaDocument10 pagesBuat Download AjaFazriatu AuliaNo ratings yet