Pressure Vessel Lifting Lugs

Pressure Vessel Lifting Lugs

Uploaded by

Arindam GhosalCopyright:

Available Formats

Pressure Vessel Lifting Lugs

Pressure Vessel Lifting Lugs

Uploaded by

Arindam GhosalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Pressure Vessel Lifting Lugs

Pressure Vessel Lifting Lugs

Uploaded by

Arindam GhosalCopyright:

Available Formats

Journal of

Pressure Vessel

Technology

Design Innovations

Proposed Design Criterion for Vessel

Lifting Lugs in Lieu of ASME B30.20

Dennis K. Williams

Sharoden Engineering Consultants, P.A.

P.O. Box 1336,

1153 Willow Oaks Trail,

Matthews, NC 28106-1336

e-mail: DennisKW@sharoden.com

This paper describes a method for evaluating the structural adequacy of various lifting lugs utilized in the erection and up righting of large pressure vessels. In addition, the analysis techniques

are described in detail and design guidelines for vessel lifting are

tendered. The statutory and provincial regulations in both the

United States and the province of Alberta, Canada are also reviewed and discussed with respect to the too often utilized phrase

factor of safety (FOS). The implied implications derived from

the chosen FOS are also outlined. A discussion is presented as to

the applicability of the ASME safety standard B30.20 entitled,

Below the Hook Lifting Devices (1999, ASME, New York) and

as to the severe shortcomings of the safety standard in its attempt

to delve into the design of lifting devices, especially when applied

to lifting lugs on large and heavy-weight pressure vessels. Exemplar lugs on vessels are defined and the finite element analyses

and closed form Hertzian contact problem solutions are presented

and interpreted in accordance with the proposed design criteria.

These results are compared against the very limited design information contained within ASME B30.20. Suggestions for the revision and applicability of the safety standard are presented and

discussed in light of the examples and technical justification presented in the following paragraphs. In addition, the silence of this

safety standard on the very large contact stresses that are well

known to exist between a lifting pin and clevis type geometry is

also discussed. Because of the limited number of repetitive loading cycles that vessel lifting lugs actually experience during the

service life of a vessel, a recommendation is made to either clearly

exclude vessel lifting lugs from the scope of ASME B30.20 or to

specifically include a separate design and analysis section within

this standard to properly address the mechanical and structural

design issues applicable to pressure vessel lifting lugs.

DOI: 10.1115/1.2716439

Introduction

The basic approach of the current study is to first define the

mode of failure against which any design criteria and/or standard

Contributed by the Pressure Vessel and Piping Division of ASME for publication

in the JOURNAL OF PRESSURE VESSEL TECHNOLOGY. Manuscript received January 23,

2006; final manuscript received September 7, 2006. Review conducted by David Raj.

Paper presented at the 2002 ASME Pressure Vessels and Piping Conference

PVP2002, Vancouver, British Columbia, Canada, August 59, 2002.

326 / Vol. 129, MAY 2007

must try to protect during the design phase of a vessel lifting lug.

Second, the approach selects a failure criteria from those commonly discussed in the literature, such as maximum shear stress

theory, maximum octahedral shear stress theory, and maximum

principal stress theory, that most closely matches the mode of

failure defined in the first step of the basic approach. Third, the

method adopts an achievable factor of safety based on the chosen failure theory from step two of the approach and applies the

FOS against the respective failure stress. Finally, a well-defined

design criterion for vessel lifting lugs is outlined based on the

basic approach presented herein and applied to the statutory and

provincial regulations contained within 29CFR1926 OSHA regulations 1 and the Occupational Safety and Health Act of the

Province of Alberta, Canada 2.

The purpose of this paper is to provide technical insight into the

applied mechanics evaluation of an exemplar pressure vessel lifting lug and proposed design criteria in lieu of the limited design

requirements contained within ASME B30.20 3. The current

work is restricted to the evaluation of the lug in the vicinity of the

lifting pin. The subject lifting lug of this paper is one whose

design load capacity is 700 metric tons 1,544,000 lbf. This

load capacity is not uncommon in the petroleum refinery industry

for a number of specialty types of ASME B&PV Code, Section

VIII 4 reactor vessels. On many project designs, there are at

least two types of imposed design bases for the lifting and handling equipment. The first of these design bases is an internally

generated or self-imposed design basis. The second of these design bases is one that may be classified as externally generated

design basis. For purposes of this discussion, internal and external refer to an organization within the design engineering organization hence internal or to an outside authority having jurisdiction hence external.

The internal design basis for the lifting lug can further be defined by either internally generated design and analysis criteria or

by externally generated codes and safety standards. The internally

generated criteria most often attempt to define an allowable set

of component stresses that restrict the computed bending, bearing,

and shear stresses within the lifting lug critical sections as determined by both experience and empirical data. Although there are

no uniform set of criteria among the numerous engineering design

professionals throughout the U.S. and Canada, it is this authors

experience that one guideline, which is often quoted, is the limitation of the bending stress to one third of the yield strength of the

lug material assuming a one-piece forged design. The additional

component stresses and the associated allowable stressess vary

widely across-the-board, depending on the particular design engineering group and their given experience. The externally generated or imposed design standard on lifting lugs often falls on the

limited criteria contained within the ASME safety standard

B30.20 3 entitled, Below the Hook Lifting Devices. This paper addresses the fallback position employed by many engineering organizations in attempting to utilize the design criteria contained therein and the inherent pitfalls of such a practice,

particularly when applied to large lifting lugs for pressure vessels.

The second major group of design basis criteria originates from

Copyright 2007 by ASME

Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 1 Lifting-lug geometry

an outside source and most often takes the form of regulatory

requirements defined by federal, state, and/or provincial authorities having jurisdiction. For the purposes of this paper, only the

regulations imposed in the U.S. and the Province of Alberta,

Canada are discussed, although the subject discussion is one that

has universal implications. This becomes even more apparent as

fabricators across the globe are providing ASME Code 4 pressure vessels intended for installation in both the U.S. and Canada.

The specific design lifting requirements imposed by the U.S. Department of Labor, 29CFR1926 OSHA regulations 1 are outlined and the implementation of a 5 to 1 factor of safety FOS

is also explored. Finally, the Provincial Regulations contained

within the Occupational Safety and Health Act of the Province of

Alberta, Canada 2 are also reviewed and discussed with further

interpretation of a very specific five-to-one factor of safety on the

ultimate tensile strength of the chosen lug material.

The analysis of the 700 metric ton lifting lug is conducted in

two separate manners. The first is the analysis and prediction of

the contact stresses, the general stress field within the critical sections of the lug, and the associated contact area between a close

tolerance fitting lifting bolt/pin utilizing the techniques presented

by Timoshenko and Goodier in the Theory of Elasticity 5 and

summarized for direct application by Young 6. The lug geometry

itself is a simple clevis type design of uniform thickness as shown

in Fig. 1. The second analysis utilizes the finite element method to

analyze the effects of the contact stresses within the lug and also

utilizes the calculated results to serve as a basis for the proposed

lug design criteria. The proposed lug design criteria must achieve

two goals. The first is to ensure a safe and practical design. The

second is to provide a design that is in full compliance with the

defined regulatory requirements defined herein. The technical

bases for achieving this two-fold objective are outlined in the

paragraphs that follow.

ASME B30.20: Below the Hook Lifting Devices

ASME B30.20 had its beginning in December 1916, when an

eight-page Code of Safety Standards for Cranes was presented to

the annual meeting of the ASME. Because of changes in design,

advancement in techniques, and the general interest of labor and

industry in safety, an American National Standards Committee

was formed under the joint sponsorship of ASME and Naval Facilities Engineering Command ASME 3. According to the

foreword provided within ASME B30.20 3, the Standard presents a coordinated set of rules that may serve as a guide to government and other regulatory bodies responsible for the guarding

and inspection of the equipment falling within its scope. Furthermore, the foreword to the referenced ASME Standard 3 urges

administrative and regulatory agencies to consult the B30 Committee prior to rendering decisions on disputed points. The foreJournal of Pressure Vessel Technology

word concludes with the protective remark that, revisions to the

Standard do not imply that previous editions were inadequate.

Within the Introduction to the ASME Standard 3, the Standards Committee states that they fully realize the importance of

proper design factors. In addition, the Standards Committee states

that, they will be glad to receive criticisms of this Standards

requirements and suggestions for its improvement, especially

those based on actual experience in application of the rules 3.

The purpose of this paper is to explore the design requirements

contained in the Standard 3 and to provide an exemplar of the

application of the suggested rules and some well defined and

quantitative criticisms of the Standard.

Within the scope of ASME B30.20 3 is the construction of

lifting devices. Some engineers interpret the 700 metric tons lifting lug under consideration to fall within the scope of the subject

Standard 3. Although Chapter 20-1 entitled Structural and Mechanical Lifting Devices 3 does not specifically categorize the

lifting lug under consideration, many design organizations cite

this chapter for use as a design guideline or requirement. In particular, paragraph 20-1.1.1 entitled General Construction, outlines the design requirements for a lifter as follows:

The load bearing structural components of a lifter shall be

designed to withstand stresses imposed by its rated load plus the

weight of the lifter, with a minimum design factor of three, based

upon yield strength of the material, and with stress ranges that do

not exceed the values given in ANSI/AWS D14.1 [7] for the applicable conditions [3].

Before proceeding, there are several observations that must be

highlighted concerning the preceding design requirement. First,

the placement of a design requirement under the heading of

Construction is not consistent with the organization of many

other ASME Codes and Standards 4 in that design criteria are

clearly labeled as such and are also segregated from the construction i.e., fabrication requirements. Second, the design requirement contained within the referenced Standard 3 only gives the

engineer a very vague idea at best as to which particular computed stresses must be compared against essentially the materials

yield stress divided by three. Third, the choice of an allowable

stress of sorts by the Standard 3 that is based on yield implies

some sort of failure criteria that would preclude the initiation of

yielding within the lug material when subjected to its maximum

rated load. Fourth, the selection of a yield based failure criteria

would most likely also imply that the anticipated failure mode

would be one of a ductile nature of course assuming the selection

of a linear, elastic, homogeneous, and isotropic lug material.

Fifth, the utilization of a large capacity vessel lifting lug will

typically only be subjected to a very limited number of lift

cycles, as once the vessel is moved from the fabricators shop

and uprighted in the field, it generally is there for the remainder of

its intended design life. Finally, the subject design problem clearly

involves contact stresses between a shackle pin and a clevis hole,

which obviously implies very large contact stresses that are highly

localized, which are not addressed by this or any other standard

known to this author. It is these implications in combination with

other regulatory requirements that are explored in some detail in

the paragraphs that follow.

OSHA Rigging Equipment Regulations in the United

States

The U.S. Department of Labor, through the regulations specified by its Occupational Health and Safety Administration

OSHA, specifies the general safety requirements for rigging

equipment for material handling. Throughout the U.S. Code of

Federal Regulations CFR, numerous references are made to

slings, wire rope, hooks, shackles, and other forms of material

handling and other forms of lifting equipment 1. In particular,

the regulations that are of most importance during the uprighting

and lifting of a pressure vessel are found in Title 29, Part 1926,

MAY 2007, Vol. 129 / 327

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Subpart 251 entitled Rigging Equipment for Material Handling

1. This and other OSHA Regulations may now be easily found

on the Internet at URL http://www.osha.gov.

Although there are numerous similarities between ASME

B30.20 3 and 29CFR1926.251 1 regarding the inspection of

the lifting equipment including, but not limited to lifting lugs

prior to use, there exists a striking difference in the design criteria for the handling devices. The OSHA requirements specifically define that the safe working loads of shackles and specific

identifiable products be designed with a safety factor of not less

than 5, although the safety factor is not explicitly defined therein

1. The FOS of 5 is repeatedly echoed throughout this and other

OSHA Regulations regarding handling equipment.

As in the proceeding section, there are several observations that

must be discussed concerning the preceding design requirement.

First, the OSHA design requirement 1 gives the engineer no

suggestion or proposal as to which particular computed stresses

must be compared against essentially the materials ultimate tensile stress divided by five. This assumes that the failure load,

however, is proportional to the ultimate tensile failure stress or

vice versa in the application of the FOS as recommended by

Boresi et al. 8. Second, the choice of an allowable stress of

sorts by the Regulation 1, which is based on what is assumed to

be a FOS of 5 applied to the ultimate tensile strength, implies

some sort of failure criteria that would be based on a predominant component stress or computed maximum principal stress

when subjected to its maximum rated load. Third, the selection of

an ultimate tensile strength based failure criteria would most

likely also imply that the anticipated failure mode would be one of

a brittle nature even though the lug material is most assuredly

classified as a ductile material under ordinary loading conditions.

Fourth, similar to the parley on ASME B30.20, the utilization of a

large-capacity vessel lifting lug will typically only be subjected to

a very limited number of lift cycles, for the reasons previously

cited. Finally, the subject design problem clearly involves contact

stresses between a shackle pin and a clevis hole, which obviously

implies very large contact stresses that are highly localized, which

are not addressed by this or any other regulation known to this

author.

Alberta Safety and Health Act Requirements

The Province of Alberta, Canada, through the regulations specified by its Occupational Health and Safety Act, Regulation 448/83

2, specifies the general safety requirements for rigging equipment for material handling. Similar to the OSHA Regulation 1

previously discussed, within the Alberta Regulation 2, numerous

references are made to slings, wire rope, hooks, shackles, and

other forms of material handling and other forms of lifting equipment. In particular, the regulations that are of most importance

during the up-righting and lifting of a pressure vessel are found in

Part 8, entitled, Rigging, paragraph 139 2. This and other Alberta Regulations may now be easily found on the Internet at URL

http://www.gov.ab.ca

Once again, there are numerous similarities between ASME

B30.20 3, 29CFR1926.251 1, and Alberta Regulation 448/83

2 AR 448/83 regarding the inspection of the lifting equipment

including, but not limited to lifting lugs prior to use. The Alberta

Regulation, however, begins to define the design criteria of the

handling devices more specifically than the OSHA regulations and

takes on a different basis for the FOS than even ASME B30.20

3. AR 448/83 requirements specifically state that the maximum

safe working load of rigging or rigging equipment must not exceed20% of the ultimate breaking strength of the weakest component of the rigging. As with the OSHA regulations, a FOS of 5

appears and is repeatedly echoed throughout this Regulation 2

regarding handling equipment.

The pertinent observations that must be discussed concerning

the preceding design requirement are as follows. The design requirement 2 gives the engineer the latitude to formulate a failure

328 / Vol. 129, MAY 2007

criteria based on the ultimate breaking strength, which suggests

at least an ultimate tensile strength divided by five allowable

stress. Again however, this assumes that the failure load is proportional to the ultimate tensile failure stress in the application of the

five-to-one FOS. Second, the choice of an allowable stress of

sorts by the Regulation 1 that is based on what is assumed to be

a FOS of 5 applied to the ultimate tensile strength implies some

sort of failure criteria that would be based on a predominant

component stress or computed maximum principal stress when

subjected to its maximum rated load. Third, the selection of an

ultimate tensile strength based failure criteria would most likely

also imply that the anticipated failure mode would be one of a

brittle nature. Fourth, similar to the discussion on ASME B30.20,

the utilization of a large capacity vessel lifting lug will typically

be subjected to only a very limited number of lift cycles, for the

reasons previously cited. Finally, as with all the other regulations

and standards previously cited, the very large contact stresses,

which are highly localized, are not addressed by this regulation as

well.

Classical Contact Stress Evaluations

The problem presented by the design of a vessel lifting lug is

first and foremost one created by the Hertzian contact of a lifting

pin supported by a shackle in this case with that of the lifting

hole in a clevis-type lifting lug. The resulting stresses of the greatest magnitude are indeed those created by the pressure exerted by

the pin on the clevis over a limited area of contact. The Hertzian

contact stress problem is treated and discussed in detail in Boresi

8 Chap. 14, Timoshenko 5 and Young 6. It is these contact

stresses that are not, however, addressed in any of the Standards

or Regulations previously discussed in the preceding paragraphs

of this paper 13. The only plausible justification for the silence

by these Standards and Regulations on the obvious existence of

the contact stresses may be as explained in the following by

Boresi 8:

Most load resisting members are designed on the basis of

stress in the main body of the member, that is, in portions of the

body not affected by the localized stresses at or near a surface of

contact between bodies. In other words, most failures (excessive

elastic deflection, yielding, and fracture) of members are associated with stresses and strains in portions of the body far removed

from the points of application of the loads.

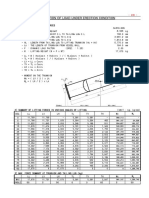

Appendix A contains a sample calculation for the

700 metric ton lifting lug contact stress evaluation. The geometric

and material properties are defined within the calculation proper.

The chosen material for the lifting lug is ASME 508 Grade 3

Class 2 with an ultimate tensile strength of 90,000 psi and yield

strength of 65,000 psi. The lifting lughole diameter is 8.543 in.

within which a pin diameter of 8.460 in. must be inserted. The

thickness of the lifting lug is 11.50 in.

The relatively simple evaluation of the contact stresses contained in Appendix A is not applicable close to the edges where

the contact boundary begins. This sharp interface area can produce highly localized stresses in excess of 100,000 psi 8 for the

700 metric tons loading under consideration. The depths at which

the effects of the contact stresses are significant range from the

surface of contact for the maximum principal stress to an approximate depth of 1.6 in. for the maximum shear stress and the

maximum octahedral shearing stress. Nevertheless, the results of

the contact stress evaluation contained in Appendix A reveal at

least two important pieces of information. The first is that the

average contact stress for the loading, geometry, and materials of

construction defined herein are 40,000 psi. Keeping in mind that

this is a compressive stress and that when compared to a yield

strength of at least 65,000 psi, this is far below those levels of

bearing and/or compressive stress allowed within other ASME

Codes 4. The second important piece of information is the calculated width of the assumed rectangular contact area. For the

subject design, this width is calculated to be 4.35 in., which

Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 2 Lifting-lug finite element mesh

equates to a half angle from top dead center of 30 deg for the

contact area. This value is and can be utilized in a more detailed

finite element analysis of the lifting lug and represents the angular

dimension over which the lifting load may be applied.

Classical Failure Theories and the Mystery of the Ulimate Factor of Safety

Clearly in the design and analysis of a lifting lug for a vessel

that weighs 700 metric tons, the engineer must have an exceptional understanding of the possible ways by which the lug may

fail to perform its function. In determining the possible modes of

failure, the engineer must also establish the failure criteria by

which the design will be judged. In the present study, the modes

of failure for the lug must include not only the common static

causes, such as bending, shear, and bearing, but also the effects of

a dynamic or shock loading due to the lift itself. It is this consideration of a potential dynamic load generated as a result of the

sudden loss of tension in a cable or sling that drives the need for

some form of a FOS to be employed to the applied static load or

resulting computed stress. Furthermore, the selection of a failure

criteria for the lifting lug must be predicated based on this dynamic load consideration and not the initiation of yield per se, as

the lug will only be utilized a very few number of times in its

design life i.e., certainly no more than ten times. As will be

shown, it is not only the mere specification of a single FOS but

also the failure criterion that determines the ultimate factor of

safety of a given lifting lug design.

Boresi 8 states, There is considerable but not necessarily

conclusive evidencethat when a member fails by general yielding at ordinary temperatures, the significant quantity associated

with the failure is shearing stress. Two of the most widely utilized failure criteria that address general yielding include the

maximum shearing stress Trescas criterion and the maximum

octahedral stress von Mises criterion theories. A third criterion to

be considered is the maximum principal stress theory of failure

Rankines criterion. Before proceeding, however, the engineer

must remember that in a uniaxial state of stress, the critical failure values for each of the defined theories are achieved simultaneously in a simple tensile test.

Journal of Pressure Vessel Technology

Trescas criterion states that inelastic action in any point in a

part initiates when the computed maximum shearing stress

reaches one-half of the materials yield strength. Although the

maximum shear stress failure theory is best suited for ductile material behavior in which relatively large shearing stresses are developed 8, for the problem at hand, the maximum shearing stress

would be limited to no more than 32,500 psi prior to the application of any FOS.

The maximum octahedral shear stress failure theory states that

inelastic action in any point in a part initiates when the computed

octahedral shearing stress reaches 0.471 times the materials yield

strength. In many ductile materials utilized within the pressure

vessel industry, the octahedral shearing stress criterion predicts the

initiation of yield better and with less conservatism than does the

Tresca criterion. For the problem at hand, the maximum octahedral shearing stress would be limited to no more than 30,641 psi

prior to the application of any FOS.

The maximum principal failure theory is one that may be easily

employed to establish either the initiation of yield for a brittle

material or one that may be employed to establish a guard against

fracture through the use of the ultimate tensile strength UTS and

an imposed FOS. In fact, even though the chosen material for a

vessel lifting lug should be one of high ductility and possess good

impact properties, the failure mechanism due to a sudden acceleration i.e., a dynamic load in most cases will be one of a brittle

nature. Therefore, Rankines criterion, when modified to utilize

the UTS, provides both an easy to use criterion and one that is

consistent with the expected mode of failure. For the problem at

hand, the maximum principal stress would be limited to 90,000 psi

divided by the chosen FOS. This also implies that the minimum

principal stress must be addressed as a separate matter. This is

because the failure mode that must be guarded against is one, first

and foremost, that would be tensile in nature and tend to open any

preexisting cracks in the lifting lug material.

Criteria for Consideration in the Design and Analysis of

Pressure Vessel Lifting Lugs

In an effort to more fully understand the stress field within the

700 metric tons lifting lug, a finite element analysis was perMAY 2007, Vol. 129 / 329

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 3 Stress-intensity contour

formed. The lug geometry was as shown in Fig. 1, and the refined

element mesh was as shown in Fig. 2. The base of the lug was

fixed against translation in all three coordinate directions, as the

elements chosen to model the geometry were a three-dimensional

solid with three-degrees of freedom at each node i.e., translations

in the x, y, and z directions. The 700 metric tons load was evenly

distributed within a 30 deg half angle from top dead center on

each side of the symmetry plane and continued through the thickness of the lifting lug. The chosen contact area was confirmed

independently by the calculations presented in Appendix A of this

paper, which was previously discussed. Several mesh densities

were employed until the stress results converged to within 3% of

the more course mesh density.

The results of the finite element analysis were decomposed into

all of the constituent component stresses. In addition, the results

were also reviewed in light of the three failure criteria previously

defined and outlined above. The stress contours showing the calculated maximum stress intensities i.e., twice the value of the

maximum shear stresses, the von Mises stresses and the maximum principal stresses are included in Figs. 35, respectively. All

of the contours reflect a highly concentrated respective combined

stress at the geometric discontinuity between the lug hole bore and

orthogonal outside surface. This is both attributed to the contact

load discontinuity and the reality of the geometric/load combination. This area is very small and is not anticipated to reflect the

overall load carrying capacity of the lug, regardless of the failure

criterion employed.

The calculated maximum shear stress as shown in Fig. 3 is

40,000 psi i.e., one-half of the calculated stress intensity.

When compared to the Tresca criterion allowable stress of onehalf of yield i.e., 32,500 psi, this represents an overage of 25%

without employing any factor of safety. As the distance from the

applied contact load increases, the stress contour reveals that an

overall maximum shear stress throughout the body of the lifting

lug quickly decreases to a value of 13,400 17,800 psi. In order

to fully evaluate the FOS for this criterion, these values must be

compared to one-half of the yield, which results in a FOS of as

low as 1.82 on the initiation of yield a short distance away from

330 / Vol. 129, MAY 2007

the proximity of the contact load application. It is recognized that

the subject lifting lug design would have a much higher load

carrying capacity than that predicted by this criterion due to the

strain hardening capacity of the chosen forging material.

The calculated equivalent stress i.e., von Mises as shown in

Fig. 4 is 69,194 psi. When compared to the equivalent allowable stress of 1.0 times yield i.e., 65,000 psi, this represents an

overage of 6.5% without employing any factor of safety. As the

distance from the applied contact load increases, the stress contour

reveals that an overall maximum equivalent stress throughout the

body of the lifting lug quickly decreases to a value of

23,100 30,800 psi. In order to fully evaluate the FOS for this

criterion, these values must be compared to the one times yield,

which results in a FOS of as low as 2.11 on the initiation of yield

a short distance away from the proximity of the contact load application. As before, it is recognized that the subject lifting lug

design would have a much higher load carrying capacity than that

predicted by this criterion due to the strain hardening capacity of

the chosen forging material.

The calculated maximum principal stress as shown in Fig. 5 is

53,276 psi. When compared to the equivalent allowable stress

of 1.0 times yield i.e., 65,000 psi, this represents a margin of

18% without employing any factor of safety. As the distance

from the applied contact load increases, the stress contour reveals

that an overall maximum principal stress throughout the body of

the lifting lug quickly decreases to a value of 16,400 psi. In

order to fully evaluate the FOS for this criterion, these values may

be compared to the one-time yield, which results in a FOS of

3.96 on the initiation of yield. As stated previously however,

this is not a good predictor of yield and is most well suited for use

with the ultimate tensile strength in this case. Proceeding on this

basis, these values must be compared to the UTS, which results in

a FOS of 5.49 on the ultimate failure load assuming totally

elastic response, which is a conservative predictor. In contrast,

the calculated minimum principal stress, as shown in Fig. 6, is

found to be approximately 61,292 psi, which is reflective of the

compressive contact stress between the lifting pin and lug hole.

Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 4 Von Mises stress Contour

Again it is recognized that the subject lifting lug design would

have a much higher load carrying capacity than that predicted by

this criterion due to the reasons previously stated.

Based on the results of the detailed finite element analysis of

the 700 metric ton lifting lug, the following design criterion is

tendered for consideration. First, in an effort to align the chosen

failure criterion with the most significant mode of failure i.e.,

from a dynamic load, the maximum principal stress failure crite-

ria should be utilized. Although attempts by the ASME B30.20

Safety Standard highlights the use of a one-third yield criterion,

there is no single published failure criterion known to this author

that can address all of the aspects of the lug design with this

method. In this authors opinion, the simple limitation of a single

type of component stress for example, a bending stress to some

allowable value hardly defines a failure criterion for use in the

current or future design of lifting lugs. Furthermore, applying this

Fig. 5 Max principal Stress Contour

Journal of Pressure Vessel Technology

MAY 2007, Vol. 129 / 331

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 6 Min. Principal Stress Contour

limitation i.e., the one-third yield criterion on the compressive

stresses present in the contact area, simply does not work nor will

it work in a triaxial state of stress. Second, in conjunction with the

chosen criterion, the maximum principal stresses should be calculated for the given working load and lug geometry. The load

should be distributed over a contact area as determined by either

an acceptable contact stress technique such as that presented in

Appendix A or by a nonlinear finite element contact stress analysis

procedure. The resulting maximum principal stresses in the body

of the lug that are located slightly beyond the area of load application should then be compared to an allowable stress value equal

to 20% of the UTS of the lug material. This will be consistent

with both domestic and Canadian regulations regarding the implementation of a well defined FOS of 5 on fracture and ultimate

breaking strength. Finally, the minimum principal stresses should

be computed and compared to simply one times the specified

minimum yield strength of the lug material. This allowable is

consistent with those specified in other ASME Codes 4 and the

compressive stresses do not pose the same crack opening hazard

found in purely tensile stresses. Utilizing this method of analysis

not only achieves a clear utilization of a highly recognized FOS,

but also addresses the issue of contact stresses about which the

Regulations and Standards identified herein have remained forever silent.

Summary and Conclusions

A method for evaluating the structural adequacy of various lifting lugs utilized in the erection and uprighting of large pressure

vessels was presented. The analysis techniques were described in

detail and design guidelines for vessel lifting lugs were tendered.

The statutory and provincial regulations in both the United States

and the province of Alberta, Canada, were also reviewed and discussed with respect to the too often utilized phrase factor of

safety FOS. Hopefully, the introduction of a clearly defined

FOS of 5, when utilized with the maximum principal stress failure

criterion, will serve as a constructive criticism to the very limited

design criterion given in the current ASME safety standard

B30.20 3 entitled, Below the Hook Lifting Devices and may

332 / Vol. 129, MAY 2007

be applied to lifting lugs for large and heavyweight pressure vessels in future design standards. Because of the limited number of

repetitive loading cycles that vessel lifting lugs actually experience during the service life of a vessel, a recommendation is made

to either clearly exclude vessel lifting lugs from the scope of

ASME B30.20 3 or to address the design aspects in a separate

standard to be developed at a later date. Based on the results

presented herein, it is hoped that a more realistic assessment of the

failure modes and the proper selection of a failure criterion will be

further studied and revised as necessary by the ASME B30.20

Committee, thereby leaving less to chance for the less experienced

design engineer of rigging and materials handling equipment.

Nomenclature

CE

D1

D2

E1

E2

KD

L

P

bb

p

1

2

cmax

material constant for contacting bodies

diameter of lifting lug hole

diameter of lifting shackle pin

modulus of elasticity for lifting lug

modulus of elasticity for lifting shackle pin

geometric constant for contacting bodies

length of contact; thickness of lifting lug

load to be lifted; maximum safe working load

width of rectangular contact area

load per unit length of contact

Poissons ratio for lifting lug

Poissons ratio for lifting shackle pin

maximum calculated contact stress

Appendix A: A Proposed Design Criterion for Vessel

Lifting Lugs in Lieu of ASME B30.20

First, we will evaluate the contact stresses in the lifting lug

based upon the one-fifth of the ultimate tensile strength design

criteria contained within the Alberta OS&H Act.

Lifting Cover Contact Stresses, SA-508 Gr 3 Cl 2.

Cylinder in a Cylindrical SocketTable 33, Case 2c, Formulas

for Stress & Strain [6].

Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Width of rectangular contact area:

bb 1.60 p KD CE

Provides an explanation of Table 33 and the notation used.

Diameter of top cylinder:

D2 8.46 in

Poissons ratio for

the top cylinder:

2 0.3

Modulus of elasticity

for the top cylinder:

E2 29.7 106

Diameter of bottom socket:

D1 8.543 in

Poissons ratio for

the bottom socket:

1 0.3

Modulus of elasticity

for the bottom socket:

cmax 0.798

lbf

in2

Length of cylinder:

L 11.50 in

1 21 1 22

+

E1

E2

Load per unit length:

CE

P

L

E1 27.8 106

KD = 870.768 in

CE = 6.337 108

p = 1.342 105

Journal of Pressure Vessel Technology

p

KD CE

cmax = 39354

lbf

in2

References

Loading:

D2 D1

D1 D2

With the UTS of SA-508 Gr 3 Cl 2 of 90000 psi, this is an

acceptable material for the lifting lug.

Note: See Timoshenko 5 and Sague 9 for technique and

formulas utilized above. ASME Paper Lifting Lug.mcd

lbf

in2

P 1.54338 106 lbf

KD

Stress:

bb= 4.354 in

in2

lbf

lbf

in

1 U. S. Department of Labor, Occupational Safety & Health Administration,

2002, Code of Federal Regulations, Title 29, Part 1926, Safety & Health

Regulations for Construction, Subpart 251, U. S. Government Printing Office,

Washington, DC.

2 Province of Alberta, Canada, 2000, Alberta Regulation 448/83, Occupational

Health & Safety Act, Queens Printer for Alberta, Edmonton, Alberta, Canada.

3 ASME, 1999, Below-the-Hook Lifting Devices, ASME, New York, ASME

B30.201999.

4 ASME, 2001, ASME Boiler & Pressure Vessel Code, Rules for Construction of

Pressure Vessels, Division 2-Alternate Rules, ASME, New York.

5 Timoshenko, S. P. and Goodier, J. N., 1970, Theory of Elasticity, 3rd ed.,

McGraw-Hill, New York.

6 Young, W. C., 1989, Roarks Formulas for Stress & Strain, 6th ed., McGrawHill, New York.

7 AWS, 1997, Specification for Welding Industrial and Mill Cranes & Other

Material Handling Equipment, American Welding Society, Miami ANSI/AWS

D14.11997.

8 Boresi, A. P., Sidebottom, O. M., Seely, F. B., and Smith, J. O., 1978, Advanced Mechanics of Materials, 3rd ed., Wiley, New York.

9 Sague, J. E., 1978, The Special Way Big Bearings Can Fail, Mach. Des.

5021, 113117.

MAY 2007, Vol. 129 / 333

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 08/31/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

You might also like

- Bednar - Pressure Vessel Design HandbookDocument230 pagesBednar - Pressure Vessel Design HandbookceballosingNo ratings yet

- Asme B30.5 2011Document46 pagesAsme B30.5 2011solserengsa100% (3)

- Asme B29.1M 1993 (R1999)Document59 pagesAsme B29.1M 1993 (R1999)J Ferreyra Libano100% (5)

- ASME B30.2 Lifting LugDocument8 pagesASME B30.2 Lifting LugEliza Nightry De Large100% (1)

- Dupont Design of Trunnions 1979Document26 pagesDupont Design of Trunnions 1979mjjanowski100% (1)

- Design of Lifting Beams PDFDocument10 pagesDesign of Lifting Beams PDFAnonymous x9STa9No ratings yet

- Evaluation For VesselDocument10 pagesEvaluation For VesselEngineering ESIINo ratings yet

- Steel Stacks Desing GuideDocument23 pagesSteel Stacks Desing GuideKhaled Eid100% (7)

- Nelson Curve - Model For Predicting Hydrogen AttackDocument2 pagesNelson Curve - Model For Predicting Hydrogen AttackDries VandezandeNo ratings yet

- Cycle Life Analysis Pressure VesselDocument29 pagesCycle Life Analysis Pressure VesselRicardo Paz Soldan100% (1)

- DVM BT p2pDocument4 pagesDVM BT p2panuashkNo ratings yet

- Desa Gandusari, 11-11-12Document19 pagesDesa Gandusari, 11-11-12Lia Hanisa Rahmawati0% (1)

- Introductie Weichai WHM6160 EngelsDocument40 pagesIntroductie Weichai WHM6160 EngelsParAld100% (2)

- Pan Ultra Operations ManualDocument33 pagesPan Ultra Operations ManualAbsoluto 補劑No ratings yet

- Lifting Lug DesignDocument7 pagesLifting Lug DesignJens SøndergaardNo ratings yet

- Lifting Analysis - TrunnionDocument3 pagesLifting Analysis - TrunnionMudasir MughalNo ratings yet

- Nozzle AnalysisDocument6 pagesNozzle AnalysisVaraprasad EthaNo ratings yet

- Nozzles-On External Loads and Internal PressureDocument18 pagesNozzles-On External Loads and Internal PressureFelipeNo ratings yet

- Lecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfDocument29 pagesLecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfAriHara SudhanNo ratings yet

- Creeps Analysis of ThermoplasticsDocument7 pagesCreeps Analysis of ThermoplasticsIgor AlarcónNo ratings yet

- Rectangular Tubesheet Design Guideline by HEIDocument6 pagesRectangular Tubesheet Design Guideline by HEIm5416No ratings yet

- TrunnionDocument20 pagesTrunnionGowtham JayaprakashNo ratings yet

- Use of Asme Code Case 2695Document2 pagesUse of Asme Code Case 2695G.SWAMINo ratings yet

- Lifting Lug TutorialDocument20 pagesLifting Lug Tutorialmontie3No ratings yet

- Loaded Flat PlatesDocument7 pagesLoaded Flat PlatesGanesh.MahendraNo ratings yet

- Design and Verification of Lifting LugsDocument3 pagesDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- Allowable Nozzle LoadingsDocument3 pagesAllowable Nozzle Loadingskemo10No ratings yet

- Aa Design and Analysis of Saddle SupportDocument11 pagesAa Design and Analysis of Saddle Supportparthidurairaj100% (1)

- Vertical Pressure VesselDocument5 pagesVertical Pressure VesselEnriqueGDNo ratings yet

- Lifting Lug DesignDocument17 pagesLifting Lug Designguravdr100% (2)

- Lifting Lug SampleDocument1 pageLifting Lug Sampleabdul marpaung0% (1)

- WRC Load AnalysisDocument5 pagesWRC Load Analysisyogacruise100% (1)

- Nozzle LoadsDocument8 pagesNozzle LoadsGovindan KrishnamoorthybashyamNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Tutorial of WRC 107 For TrunnionDocument9 pagesTutorial of WRC 107 For TrunnionAlvin SmithNo ratings yet

- 18 Desing of Support For Pressure VesselDocument27 pages18 Desing of Support For Pressure VesselAmit KananiNo ratings yet

- VVD Info PDFDocument6 pagesVVD Info PDFVicky Gautam100% (1)

- Tail Lifting Lug Calculation MS WordDocument11 pagesTail Lifting Lug Calculation MS WordWijayanto BekasiNo ratings yet

- Pressure VesselDocument8 pagesPressure VesselHector Javier Cruz CampaNo ratings yet

- Design of Saddle Support For Horizontal Pressure VesselDocument5 pagesDesign of Saddle Support For Horizontal Pressure Vesselsebastian9033100% (1)

- 4DMechanical VesselDocument26 pages4DMechanical VesselBowo Edhi WibowoNo ratings yet

- WRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)Document3 pagesWRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)naim100% (1)

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- PV Elite ResultDocument18 pagesPV Elite ResultVeny MartianiNo ratings yet

- Boiler PressureDocument51 pagesBoiler Pressurekeshav44100% (1)

- Joint Efficiency DeterminationDocument3 pagesJoint Efficiency DeterminationKlusnerKlusnerKlusnerNo ratings yet

- A Critical Review of ASME BTH-1-2005 in The Design and Analysis of Vessel Lifting LugsDocument10 pagesA Critical Review of ASME BTH-1-2005 in The Design and Analysis of Vessel Lifting LugsfostbarrNo ratings yet

- Vessels For High Pressure Dust CollectorsDocument4 pagesVessels For High Pressure Dust CollectorsWade ColemanNo ratings yet

- BS 7910Document12 pagesBS 7910ggsachary0% (1)

- BS 7910Document12 pagesBS 7910Mas Arman Tewo67% (3)

- Public Review Draft 2134Document15 pagesPublic Review Draft 2134Miguel Angel Soto SaenzNo ratings yet

- Design of Pressure VesselDocument137 pagesDesign of Pressure VesselCaptainToniesNo ratings yet

- Design of Pressure VesselDocument136 pagesDesign of Pressure VesselHarshal JadhavNo ratings yet

- The API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadDocument32 pagesThe API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadthiagopontualNo ratings yet

- Merging ASME and API Design Methods For Subsea Equipment Up To 25,000 PSI Working Pressure Otc23063Document10 pagesMerging ASME and API Design Methods For Subsea Equipment Up To 25,000 PSI Working Pressure Otc23063chau nguyenNo ratings yet

- Production Planning and Design in The PRDocument25 pagesProduction Planning and Design in The PRabryant633777No ratings yet

- Pressure VesselDocument6 pagesPressure VesselThiruThirunavukkarasuNo ratings yet

- Final Published Paper IJRMEJune 2016Document11 pagesFinal Published Paper IJRMEJune 2016akiramartianNo ratings yet

- Fire Rated Design BulletinDocument6 pagesFire Rated Design Bulletinclam2014No ratings yet

- Preprints202305 1449 v1Document27 pagesPreprints202305 1449 v1Pawel ButkiewiczNo ratings yet

- The Performance of Mechanical Splices: Steven L MCCABEDocument8 pagesThe Performance of Mechanical Splices: Steven L MCCABEEvello MercanoNo ratings yet

- DESIGN OF PRESSURE VESSEL Full Report DEDocument48 pagesDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (2)

- Estimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesFrom EverandEstimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesNo ratings yet

- Ratnamani BrochureDocument16 pagesRatnamani BrochureArindam GhosalNo ratings yet

- Selecting Positive Displacement PumpsDocument4 pagesSelecting Positive Displacement PumpsArindam GhosalNo ratings yet

- Bearings For PumpsDocument23 pagesBearings For PumpsArindam GhosalNo ratings yet

- Pneumatic Vs Electric Cost CalculatorDocument7 pagesPneumatic Vs Electric Cost CalculatorArindam GhosalNo ratings yet

- Fire Fighting SystemDocument1 pageFire Fighting SystemArindam GhosalNo ratings yet

- Sample Problem - NPSHA Calculation For PumpsDocument6 pagesSample Problem - NPSHA Calculation For PumpsArindam GhosalNo ratings yet

- IEEE 802.1ad Support On Provider BridgesDocument14 pagesIEEE 802.1ad Support On Provider BridgesUser NameNo ratings yet

- Zigbee Technology:19-3-2010: Seminor Title DateDocument21 pagesZigbee Technology:19-3-2010: Seminor Title Dateitdep_gpcet7225No ratings yet

- User Manual USC 2600 THDocument51 pagesUser Manual USC 2600 THAlan SNo ratings yet

- Bermad Combination Air Valve C70 - Product-Page - English - 9-2018Document4 pagesBermad Combination Air Valve C70 - Product-Page - English - 9-2018M MNo ratings yet

- Chery S11 PDFDocument91 pagesChery S11 PDFtiffany0% (1)

- Software Defined Traffic Engineering For Improving QoSDocument14 pagesSoftware Defined Traffic Engineering For Improving QoSVanessaKichiNo ratings yet

- Hilti Site Testing Brochure For Customers (Britain)Document4 pagesHilti Site Testing Brochure For Customers (Britain)Suzaikumar R SanglikarNo ratings yet

- 96A0379Document88 pages96A0379flotterotterNo ratings yet

- BPM and BpelDocument14 pagesBPM and BpelSOA TrainingNo ratings yet

- ISO4.HSE.34 - HSE Internal Audit Checklist - Rev. 02Document5 pagesISO4.HSE.34 - HSE Internal Audit Checklist - Rev. 02OGHENETEGA KEDIENHONNo ratings yet

- Puesta Tierra EngDocument6 pagesPuesta Tierra EngTy's HouseNo ratings yet

- Nokia HDM 5.1 Data SheetDocument5 pagesNokia HDM 5.1 Data SheetLuis Angel ReyesNo ratings yet

- Plan Training Session CHSDocument51 pagesPlan Training Session CHSAnnabelle Reyes SucgangNo ratings yet

- Method Statement Template N GuidelinesDocument2 pagesMethod Statement Template N Guidelinesmkashkooli_scribdNo ratings yet

- CP R70 Smart View Monitor Admin GuideDocument106 pagesCP R70 Smart View Monitor Admin Guideoorhan41No ratings yet

- Using Metric Conversions To Solve ProblemsDocument11 pagesUsing Metric Conversions To Solve ProblemsAnonymous V7wNdod6MNo ratings yet

- SyslogdDocument210 pagesSyslogdPakaphol Buathon GuideNo ratings yet

- Mn00144e - NMS5LX OPERATOR MANUAL PDFDocument420 pagesMn00144e - NMS5LX OPERATOR MANUAL PDFBossNo ratings yet

- TQMDocument42 pagesTQMJetesh Devgun0% (1)

- Iso 898-1Document1 pageIso 898-1iyomasaNo ratings yet

- EDGM-0 Purpose & Need - IntroductionDocument6 pagesEDGM-0 Purpose & Need - IntroductionmrminchanmonNo ratings yet

- Bto RCD1 R V21 MpoeDocument10 pagesBto RCD1 R V21 MpoeZori ClarkNo ratings yet

- CVDocument5 pagesCVNewaz KabirNo ratings yet

- DocLib 4660 170 InverterDocument1 pageDocLib 4660 170 InverterSun SunNo ratings yet

- LEEDv4 Fellow HandbookDocument8 pagesLEEDv4 Fellow HandbookfactonniNo ratings yet

- Power Front Disc Conversion Instructions MDC62DCDocument11 pagesPower Front Disc Conversion Instructions MDC62DCandrakin8No ratings yet