0 ratings0% found this document useful (0 votes)

171 viewsNaca Report 1368

Naca Report 1368

Uploaded by

Adam GordonNaca Report 1368

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Naca Report 1368

Naca Report 1368

Uploaded by

Adam Gordon0 ratings0% found this document useful (0 votes)

171 views86 pagesNaca Report 1368

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Naca Report 1368

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

171 views86 pagesNaca Report 1368

Naca Report 1368

Uploaded by

Adam GordonNaca Report 1368

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 86

REPORT: 1368

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA 65-SERIES COMPRESSOR

BLADES AT LOW SPEEDS *

By Jans C. Euupy, L. Joseeu Hunero, Joux R. Ban, and A, Riowanp Fours

SUMMARY

The performance of NACA 65-series compressor blade

sections in cascade has been investigated syetematically in a

low-speed eascade tunnel. Porous test-section vide walls and,

Sor high-preseure-rise conditions, porous flecble end walls were

‘employed to establish conditions closely simulating two-dimen

sional flow. Blade sections of design lift coeficients from

0 to 2.7 were tested over the usable angle-of-atiack range for

tarious combinations of inletglow angle P of 80°, 45°, 60°,

and 70°, and. solidity © of 0.50, 0.76, 1.00, 1.85, and 1.50.

Design points were chosen on the basis of optimum high-speed

operation. A suficient number of combinations were tested

to permit interpolation and extrapolation of the data to all

conditions within the usual range of application.

The results of this investigation indicate a continuous varia

tion of blade-section performance as the major cascade param-

ters, lade eamber, inlet angle, and solidity were varied over the

test range. Summary curces of the results have been prepared

to enable compressor designers to select the proper blade camber

and angle of attack when the compressor velocity diagram and

desired solidity have been determined.

At a few test conditions, an upper limit to the design lift co-

effvient that could provide satisfactory performance was found.

‘These results provide information as to the mazimum value of

the loading parameter, expressed a8 the product of solidity and

section lift coeficient based on the vector mean velocity, that ean

be used effectively in compressor design. Analysis of the trends

indicated. that the common practice of employing « constant

mazimum value of the loading parameter for all inlet angles

and solidities fails to define the obserced performance of the

compressor blades sludied in this investigation.

Ar indes that the positive and negative limits of useful angle-

of-attack range occurred when the section drag coeficient reached.

twice the minimum ealue tons used to estimate the operating

range of the compressor Blade sections studied. A broad oper-

ating range for these sections was obserced, except for conditions

of highest pressure rise across the cascade corresponding to high

cambers at high inlet angles. These conditions are not typical

of usual design practice and no dificulty should ordinarily be

encountered in employing these Blade sections. In general, the

obsereed performance of NACA 66-series compressor blades in

cascade is considered to be very satisfactory.

INTRODUCTION

The design of an axial-flow compressor of high perform-

ance involves three-dimensionel high-speed flow of com-

ppressible viscous gases through successive rows of closely

spaced blades. No adequate theoretical solution for this

complete problem has yet appeared nor, from consideration

of the complexity of the problem, does it seem likely that

complete relationships will be established for some time.

Various aspects of the problem have been treated theore

cally, and the results of those studies aro quite usoful in

design caleulations. All such studies, howover, havo been

Dased on idealized flow, with effects of one or more such

physical realities as compressibility, finite blado spacing,

and viscosity neglected. Consideration of viscosity effects

hhas been particularly difficult. Tt appears, thereforo, that

in spito of advances in theoretical methods, theory ‘must

‘be supplemented by experimental data for some time (0

come.

Some of the information required can be obtained only.

by experiment in single-stage and multistage compressors.

‘Much of the information, however, can be obtained more

easily by isolating tho effects of each parameter for detailed

measurement. The effects of inlet angle, blede shape,

angle of attack, and solidity on tho turing angle and drag

produced can be studied by tests of compressor blades in

‘two-dimensional cescade tunnels. Cascade tests can pro-

vide many basic data concorning the performance of com-

pressors under widely varying conditions of operation with

relative easo, rapidity, and low cost. A number of success-

ful high-speed axiaLfiow compressors have been designed

by using low-speed cascade data directly. A moro refined

procedure, however, would uso cascade data, not as the

final answer, but as a broad base from which to work out

the threo-dimensfonal relations.

‘Date from a large number of two-dimensional cascade

tests have been available in this end other. countries for

*sopeades NAOA Techn Noe 216 dormarly NACA HO LALO) by T. Jeph Her, Tames 0, Beery, and Jobe en, 878 NAOA Tene Note 38 (one

[AOR HAC Léa) by A, lad Fl, 0,

ns

m4

somo years. Although the cascade configurations used in

these investigations were geometrically two dimensional, in

no ease except that of the porous-wall cascade of reference 1

was the flow believed to be two dimensional. This situa-

tion is ordinarily accepted on the grounds that the flow in

the compressor is slso subject to three-dimensional end

cffects. ‘That similar end conditions would exist in. ste-

tionary cascades and rotating blade rows seems unlikely.

As discussed in reference 1, there is evidence, however,

thet the flow through typical axial compressor blades is more

nearly like that in aerodynamically two-dimensional cas-

cades than like that in cascades which are only geometri-

cally two dimensional. Excellent correlation between

porous-wall cascade and rotor-blade pressure-distribution

‘and turning-angle values is shown for the design conditions

‘of the compressor investigation reported in reference 2.

‘Pho proper basic approach to the compressor design prob-

lem, therefore, would seem to be to separate the two-

dimensional effects from tho threo-dimonsional. This ap-

proach should also aid in the evaluation of the separete

affects of tip clearance and secondary fiow in axial com-

pressors. Therefore, systematic series of low-speed

cascade tests of the NACA 65-series compressor blade

sections were made by means of the porous-wall technique

to insure two dimensionality of the flow. ‘These results

and an analysis of the data aro presented, as well as sum-

marized data in the form of carpet plots for use in specific

design problems.

syMBoLs

a mean-line loading designation

‘ blade height or span, feet

© Dlade chord, feet

on seotion drag coefficient

o resultant-force coefficient

¢ section lift coefficient

fue camber, expressed as design lift coefficient of

isolated airfoil -

ew section normel-fores coefficient,

evar section normal-force coefficient. obtained by cal-

culation of momentum and pressure changes

across blade row

exe section normal-forco coefficient obtained « by

integration of blade-surface pressure distribution

& wake momentum difference coefficient

F force on blades, pounds

Fy foreo on blades due to momentum change through

blade row, pounds

F, oreo on blades due to pressure change through

Dlade row, pounds

Fz foro on blades due to momentum difference in

‘wake, pounds

® tangential spacing between blades, feet

Ud ratio of section lift to section drag

Mo Mach number

P total pressure, pounds per square foot

P statie pressure, pounds per square foot

‘Ap _ static pressure rise across cascade, pounds per

‘square foot

‘REPORT 1368—NATIONAL ADVISORY COMAUTTER FOR AERONAUTICS

dynamic presure, pounds per square foote

pla, nondimensional static-prescuresiso peramter

Reynolds number based on blade chord

pressure coefficient (Fe)

rotor-blade rotational speed, fest per second

flow velocity, feet per second

flow velocity relative to blades, feot per second

chordwise distance from blade leading edge, feot

sealed value substituted for 6, 0+50(cr.—0.4)

perpendicular distance from blade chord line, fect

angle between flow direction and blade chord,

degrees

tangle between flow direction and a perpendicular

to the cascade axis, degroes

flow turing angle, degrees (8,~8.)

angle between resultant-foree direction and tan-

gential direction, degrees

mass density of flow, slugs per cubic foot

solidity, e/g

subscripts:

‘component in axial direction

design value, excopt in drag coefficient

local

referred to veotor-mean velocity, Wn

flow outside wake

component in tangential direction

upstream of blade row

downstream of blade row

APPARATUS, TEST PROGRAM, AND PROCEDURE

DESCRIPTION OF TEST EQUIPMENT

‘The test facility used in this investigation was the Langley

S-inch low-speed, porous-wall cascade tunnel described in

reference 1 and shown in figures 1 and 2. During the course

of this program some further improvements wore required to

establish proper testing conditions at higher pressure rise

conditions. In particular, the boundary-layer buildup

behind the slot on the convex flexible end wall with high

pressure rise cascades was sufficient to cause separation and

destroy simulation of the infinite cascade even though the

blade flow was not separated. ‘This condition was corrected

by replacing the end wall with a porous flexible wall and

suction chamber. In addition tho large difference in flow

Jongth from the entrance cone to the side-wall slots between

the tunnel ends at the higher inlet air angles gavo quite

different boundary-layer thickness along the length of tho

side-wall slots and made uniform flow entering tho test

section difficult to obtain. This condition was improved

by making the changeable side plates porous and drawing

small emount of air through them. ‘The concave flexible,

‘end wall was made porous to provide a further control of

flow conditions through the test section.

‘The porous material found to be most satisfactory is com~

mercial woven monel filter cloth. ‘This cloth is available

in various meshes in widths up to 36 inches and can bo

calendered at the factory to reduce porosity and improve

surface smoothness. ‘The combination found most suitable

for the present work wes e Dutch twill double weave of 30

Gee 2s w REE GG & HBO

vueegeae

SYSTEMATIC TWO-DIMENSIONAL CASCADE THSTS OF NACA 65-SERIES COMPRESSOR BLADES AT LOW SPEEDS

by 250 mesh with warp wire diameter of 0.010 inch and fill

wiro diameter of 0.008 inch. ‘The original thickness of

about 0.026 inch was reduced to 0.018 inch by calendering.

‘Tho resulting material has the porosity characteristics shown

in figure 3. ‘The primary advantages of this material over

others tried previously are its uniformity, flexibility, strength,

surface smoothness, and relatively low cost.

‘Tho blade family used in this investigation is formed by

combining basic thickness form with cambered mean

lines. ‘The basic thickness form used is the NACA 65(216)~

010 thickness form with the ordinates increased by 0.0015,

times tho chordwise stations to provide slightly increased

thickness toward the trailing edge. This thickness form

hhas been designated the 65-010 blower blade section in

references 3 and 4. It wos not derived for 10-percent

thickness but was sealed down from tho NACA 65,2-016

airfoil given in reference 8. As discussed in reference 5, the

scaling procedure gives the best results when it is restricted

to maximum thickness changes of afew percent. Subsequent

to the enscade studies of reference 3, in which the NACA

65-010 blower blade was first introduced, the basic thickness

form for the NACA 65-010 airfoil section was derived and

ineluded in reference 5. ‘The ordinates for the basic thick-

ness form of tho blower blade in reference 3 differ slightly

from the airfoil ordinates in reference & but are considered

interchangeable within the accuracy of the results reported

herein, Ordinates for both the sealed thickness form (ref.

3) and derived thickness form (ref. 5) are given in table I.

TABLET

ORDINATES FOR NACA 65-010 BASIC THICKNESS FORMS

[Stations and ondinates in pereent chord)

Ondinates, y

Station, | 65@216)-010 | Derived

fitfoil ome | 05-010

bined wath | ‘sito

peoooise

0 °

152 me

300 a3

rh 1189

ait iar

2m au

2709 pai

ain 2040

ae 3.068

221s 4143

i500 50a

Sau 4780

4 ose Som

‘Base £000

3020 oa

4570 aan

S50 £530

cia rar

Sear ‘082

ons ais

Rast 2 bea

Lar Los

136 1385

49 B10

Tat 308

150

60 687

715

‘The basic meen line used is the a=1.0 mean line given on

page 97 of reference 5. ‘The amount of camber is expressed

in reference 5 as design lift edeffcient cx» for the isolated air-

foil, and that system has been retained. Ordinates and slopes,

for the a=1.0 mean line aro given in table II for c,.—1.

Both ordinates and slopes are sealed directly to obtain

other cambers. Cambered blade sections aro obtained by

applying the thickness perpendicular to the mean line at

stations laid out along the chord line. The blade sections

tested are shown in figure 4. In the designation tho camber

x is given by the first number after the dash in tenths,

For example, the NACA 65-810 and NACA 65-(12)10

Blade sections are cambered for c=0.8 and 2,

respectively.

[TRET PROGRAM AND PROCEDURE

‘Test program—The test program was planned to provide

sofficient information to satisfy any conventional vector

diagram of the type shown in figure 5. ‘Tests of seven-

blade cascades were run with various combinations of inlet

air angle 6; of 30°, 45°, 60°, and 70°, solidity « of 0.50, 0.75,

1.00, 1.25, and 1.50, and eumbers from cx, of 0 to 2.7 over

the useful anglo-of-attack range. ‘The most complete test

sories wer run at solidities of 1.00 and 1.50; suflicient tests,

were made at the other solidities to guide interpolation and

extrapolation, ‘Tho combinations of 6, 0, and blade sec-

tion which were tested are tebulated in table TIT. The

camber range covered at solidties of 1.00 and 1.50 was

determined by one of two limitations. At the higher inlet

angles. progressively higher cambers were used until tho

limit loading had been reached, that is, until the design

condition coincided with stall; at lower inlet angles, how-

ever, design turning angle exceeded inlet anglo before the

limit loading had beon reached and the tests were terminated

‘TABLE TL

ORDINATSS FOR THE NACA a=1.0 MEAN LINE, ey=10

[Stations and ordinates in percent chord]

ni ome

280 | 593150,

‘TABLE II

CASCADE COMBINATIONS TESTED

ow Hilde] Bib

eign] Sins

| ee

Eine | SR

ae [oe apse

eae | ese | ae |

Bb io| Hi ng| Hite | Wile

| ER) Ae

RR | CURE

at

at

em | Se. Se

vs Ee| Ei | ae

#8) HB8| Bb

eg ae at as

i ie | Hae | eae

ve | Bib) ie] Ete) Bib

eine] eepe) tine) BiB

SSE] RH Su

ee) ae

SHER | SEAN

“No design point was obtained for this combination,

there, Limit conditions were attained at 670°, «1.00,

41.25, and 1.50, and at ,=60°, o=1.00 and 1.50.

‘Test procedure.—It was shown in reference 1 that two-

dimensional flow can be achieved by controlling the removal

of boundary-layer air through porous test-section side walls

so that the downstream static pressure equals the ideal

value, corresponding to the turning angle, corrected for the

Dlocking effect of the wake. This criterion wag accordingly

used in these tests. Tn addition, the flexiblo end-wvall shapes,

and suetion-flow quantitios were adjusted to obtain uniform

‘upstream flow direction end wall static pressures, criteria,

of tivo-dimensional flow simulating an infinite cascade.

‘This proceduro necessitated an approximate meesurement,

of turning angle and wake size and an estimate of the correct

iso before the final settings could bo made.

Initially, this system requived some cut-and-try procedure

but after the initial tests at each combination of f and «a

chart similar to figure 5 of reference 1 could be drawn to

assist in estimating the pressure rise. An experienced

operator could make the required estimates and settings

very quickly by this procedure. Spot calculations of the

correct pressure rises were made after completion of tests

to check the accuracy of the values used.

‘Tests wero made at each cascade combination shown in

tablo IIT over a range of angles of attack at intervals of 2°

to 3°, In general, the tests covered the interval from nega-

tive to positive stall, where stall was determined by a large

{ncreaso in wake size. ‘The principal exeoptions occurred for

Tow cambered blades where negative stall would have

REPORT 1368—NATIONAL ADVISORY COMMITTEE POR ABRONAUTICS

occurred at negative turning. It was found that the small

wall boundary-layer buildup for negative turning angles and

hence negative pressure rises would heve required a less

porous material than that normally used, to avoid excess air

removal while maintaining sufficient suction pressure diff

ential to avoid local reverse flow through the porous material,

Te was not deemed worthwhile to change the porous material

to obtein data in this relatively uninteresting range. For the

NACA 65-010 section at i=80°, however, the diffieulty

persisted well above 0° turning, and this combination was

tested with both porous and solid walls.

Tho tests wore entirely within a speed rango considered

incompressible. ‘Tho Bulk of the tests at solidities of 1.00

and 1,50 wore run at an entering velocity of 95 feot per

second. For tho usual 5-inch blade chord, the Reynolds

number was 245,000. Some information near the design

point was obtained at higher effective Reynolds number for

‘most cascade combinations by adding roughness to the blade

Teading edges in the form of ¥einch-wide strips of masking

tape draped around the leading edges from wall to wall.

In addition, some tests near design conditions were run at

speed of 135 feet per second and a Reynolds number of

346,000 with and without roughness. ‘Two cascade com-

binations were tested at design conditions over a rango of

Reynolds numbers from 160,000 to 470,000 to assist in esti-

mating performance at Reynolds numbers other than the

usual test value. In order to provide further information on

sealo effects, two cascade combinations wero tested through

the range with leading-edge roughness at the standard

Reynolds number and in the smooth conditions at a Reynolds

number of 445,000. For solidities of 0.50 and 0.76 the tunnel

could not accommodate seven blades of 5-inch chord; the

blade chord was reduced to 2.5 inches and the Reynolds num-

ber to approximately 200,000 for those tests. Tests with

roughness were made near the design point for solidities

below 1.00, but Reynolds numbers higher than 200,000

could not be obtained with the existing equipment

Test measurements.—The blade pressure distribution was

measured at the midspan position of the central airfoil at

cach angle of attack. In addition, surveys of wako total-

pressure loss and turning angle were made downstream of the

cascade. ‘The total-pressure surveys were made with a non-

integrating multitube rake approximately 1 chord down-

stream of the blade trailing edges. ‘Turning anglo surveys

‘wore made by the “null method” with a claw-type yaw hond;

since the yaw dovieo was mounted on track at the rear of

the tunnel the distance from tho blades varied from about

1 to 8 chords in tho flow direetion depending upon the inlet~

and turning-angle combination. Flow discharge angle

readings were taken at a number of points downstream of

several blade passages along the tunnel center line. These

readings were averaged to obtain the final value, Sinco the

angle readings in the wake deviated several degrees from the

average reading, and the direction of tho deviation varied

consistently with the direction of the total pressure gradient,

tho accuracy of readings in the wake was questioned. ‘There-

fore, the values obtained when the wake readings wore

included and excluded in the averaging process wore com-

pared for a number of tests. ‘The resulting turning-angle

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA 65-SHRIRS COMPRESSOR BLADES AT LOW SPREDS

curves compared very wel, but scatter was considerably less

‘when only the readings outside the wake were used to obtain

the turning-angle value. This latter procedure has been

‘adopted as the standard method of measuring the flow dis-

chargo direction. Static pressure and upstream flow angles

wre measured approximately 1 chord upstream of the

blade row. ‘Total pressure was measured in the settling

chamber. Pressures were obtained by orifices with pressure

leads to manometer boards, Angles of flow were again

obtained by use of a claw-type yaw head by the null method.

Csloulations —Pressure distribution and wake-survey data

were recorded and force values calculated nondimensionally

3 coefficients based numerically on the upstream dynemic

pressure q1. This choice was dictated partly for convenience

in reducing tho data (standardization of g, permits use of

manometer scales which give nondimensional values directly)

‘and partly because information based on entering flow was

considered most convenient for design use, particularly when

critical speed is important.

All forces due to pressure and momentum changes across

the blade row were summed to obtain the resultant blade

{oree coefficient ér.. In this process the wake total-pressure

deficit was converted to an integrated momentum difference

by the method given for the drag caleulation in the appendix

of reference 5. ‘This wake momentum difference, expressed

nondimensionally, is designated tho wake coellicient cus; it

represents the momentum difference between the wake and

the stream outside the wake, and is based on q, numerically.

‘The wake coeficient is not considered to be a true drag

cooficient, but is used merely for convenience jn assessing

tho contribution of the wake in the summation of forces.

‘The resultant-force coefficient: was resolved into compo-

nents perpendicular and parallel to the vector mean velocity

Wr (Gee fig. 6) to obtain the lift coefficient cx, and the drag

coefficient a1, respectively. ‘The mean velocity was cal-

culated as the vector average of tho velocities far upstream

and far downsiream. The velocity far downstream was

obtained from measurements just behind the blades by using

a momentum-weighted average of the velocity just behind

the blades, ‘This rather detailed mothod was found neces-

sary to give consistent drag values, Since the resultant

force is very nearly perpendicular to the mean velocity, the

value of the component parallel to the mean velocity is quite

sensitive to mean-velocity direction. Attempts at using the

downstream velocity outside tho wake for averaging rather

than the momentum-average velocity gave very erratic drag

results and indicated that mean velocity directions obtained

in that manner were not reliable, Tn addition to the lift and

dvag, the section normal-force coefficient ey xr. Was obtained

by computing the component of the resultant-force coefficient

perpendicular to the blade chord line. ‘This normal-forco

coefficient was compared with the normal-force coefficient

év.ra obtained by integration of the blade surface pressure

distribution os a check on the accuracy of individual tests.

A detailed derivation of the method of calculating the foree

coefficients is given in appendix A.

Accuracy of results.—In general tho tuming-angle values

measured are believed to be accurate within +£0.5° near the

design values. ‘The correlation procedure used is believed

nT

to have improved further the accuraey of the design values

in the final results. For tests far from design, that is, near

positive or negative stall, the accuracy was reduced some-

what. Tn addition, at an inlet angle of 70° with sections of

zero camber, satisfactory measurements were very difficult

to obtain and the accuracy was reduced.

‘As noted in the section describing calculation methods, the

Dlade normal-force coefficient cy a, calculated from pressure-

rise and momentum considerations was compared with the

normal-force coefficient cy.p. obtained from the pressure

distribution as a check on the overall accuracy of individual

tests. Since these values would be affected by error in

tuming-angle, surface pressure or wake-survey readings, or

by failure to achieve two dimensionality of the flow, this

‘comparison is a check on the overall acceptability of the

results, A difference of 5 percent between the two normal-

force couffcients was set as the outside limit for acceptance

of individual tests for lift coefficients above 0.2; below lift

cooflicients of 0.2 a direct numerical comparison was made

using a limit of +£0.01. Tho agreement was well within

‘the 5-pereent limit for most of the tests as originally run, and

only a few conditions had to be repeated. ‘The accuracy of

the lift coeficients is directly comparable to that of the

normal-force coefficients. Tho accuracy of wake-cocfficient

and dreg-coeflicient values will be discussed Inter under

‘Reynolds number effects

PRESENTATION OF RESULTS

Detailed blade-performance data for all cascade combina-

tions tested are presented in the form of surface-pressure

distributions and blede-section-characteristic plots in figures,

6 to 84. The represuntative pressure distributions presented

havo been selected to illustrate the variation through the

angle-of-attack range for each combination, The section

characteristics presented through the angle-of-attack range

are turning angle 6, lift coellicient cis, wake coefficient ew.1,

drag coefficient cg,, and liftdrag ratio Ud. ‘Tho effects of

‘changes in Reynolds number end blede-surface condition on

section characteristics are given in figure 85.

‘Trends of section operating range, in terms of angle-of-

attack range, with eamber for the four inlet angles of the

tests are presented in figure 86. Variation of ideal and

actual dynamic-pressure ratio across tho cascade with

turning anglo and inlet angle is presented in figure 87.

Figure 88 gives the relation between inlet dynamic pressure

and mean dynamic pressure for convenience in converting

coefficients from one reference velocity to the other. Limi

loading information is summarized in figure 89. Comparison

‘of the present porous-wall-cascade tuming-angle data with

those of the solid-wall cascade of reference 3 is made in

figure 90 for a typical inlet angle and solidity combination

‘The information which is most useful for choosing the

blade sections to fulfill compressor design vector diagrams

is summarized in figures 91 to 111. The variation of turning

angle with angle of attack for the blade sections tested is,

presented for one combination of inlet angle and solidity in

each of the figures 91 to 106. ‘Trends of the slopes of the

curves of turning angle against angle of attack near design

are given in figure 107. Figures 108 to 111 are design and

correlation charts; the variation of design turning angle and

718

design anglo of attack with the parameters, eamber, inlet

angle, and solidity, is presented for several combinations of

the parameters so that interpolation to the conditions of a

design velocity dingram is relatively easy.

‘The selection of the blade section and the blade setting

required to fulfil a given velocity diagram at design condi-

tions requires several interpolations and cross plots of the

date presented in figures 6 to 84, In order to facilitate these

interpolations, a carpet plotting technique described in

reference 6 has been used to correlate the date, This

technique, for whieh details are explained in appendix B,

permits a function of several variables to be presented on @

single graph and such a graph lends itself readily to interpola-

tions for intermediate values of the variables plotted.

Carpet plots summarizing the present date are presented in

figures 112 to 116, and an example illustrating their use is

included in appendix B.

DISCUSSION

DESIGN CONDITIONS

‘The values and shape of the blade-surface pressure distribu-

tion aro important eriteria for predicting the conditions of

best operation at high Mach numbers. Velocity peaks oc-

curring on either surface in low-speed tests would be ac-

centuated at high speeds, and supersonic velocities with at-

tendant shock losses would occur at relatively low entering

‘Mech numbers. ‘The selection of the angle of attack desig-

nated as “design” for each combination of inlet angle,

solidity, and camber is based on the premise that the blade

section Will be required to operate at Mach numbers near tho

critical value. ‘The trend of pressure-distribution shape over

the anglo-of-attack range was examined for each cascade

combination, and the angle for which no velocity peaks

occurred on either surfece was selected as being optimum

from the standpoint of high-speed usage. In general, the

design angle so selected is near the middlo of tho low-drag.

range thus indicating efficient section operation for angles,

a fow degrees higher or lower than the design condition. ‘The

choices of design angle of attack are indicated by an arrow

on the bladesection-characteristic plots of figures 6 to 84.

‘The design angles are also shown by cross bars on the turning-

angle summary curves in figures 91 to 108.

Correlation of the design angles of attack and design turn-

ing angles over the rango of camber, solidity, and inlet angle

is given by figures 108 to 111 in 2 manner convenient for

design use. ‘The correlation is excellent; smooth curves re-

sult when any two of the three parameters aro used as inde-

pendent variables.

‘The section-characteristic curves of figures 6 to 84 indicate

that, in general, the design points chosen do not give maxi-

‘mum lift-drag ratios for low- and medium-speed operation.

For designs which will not operate near eritieal speed, there-

fore, higher efficiency could be obtained by using angles of

attack several degrees higher than the design points pre-

sented. ‘This procedure must be used with caution, however,

at the higher camber and inlet-angle combinations since the

section operating range becomes quite narrow for combina-

tions of highest camber and inlet angle corresponding to

REPORT 1308—NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

tho highest values of Apia. It is recommended tht the

individual pressuro distributions and soction-characteristio,

ccurves bo examined before departure from the specified design

points is made.

Pressure distribution and boundary leyers.—Vor many of

the tests at angles of attack near and below design, there is

evidence that a region of laminar separation of the boundar

layer flow occurred on the convex blade surface; this sopa-

rated boundary layer then became turbulent and reattached

to the blade surface as a relatively thick turbulent boundary

layer. The mechanism of such a flow sequence is deseribed

for the isolated airfoil in reference 7. ‘Tho laminar separation

is indicated by a relatively flat region in tho pressure distri-

bution on the convex surface and tho turbulent reattachment

is characterized by erapid pressure recovery just downstream

of the separated region. ‘This low pattorn can be seen clearly

‘in many of tho figures but is particularly evident in figures

42 (a), 42 (0), 65 (b) to 56 (d), and 60 (a) to 66 (@). For

some tests, Inminar separation appeared to occur on the

concavesurfaceaswell. This is noticeable in figures 42 (b),

42 (@), 42 (¢), 66 (6), and 66 (€).

‘The extent of laminar boundary-layer flow which occurs on

‘an airfoil surface is affected by Roynolds number, stream

turbulence level, airfoil surface condition, and surface pros-

sure gradient. Increases in Reynolds number, stream turbu-

once, and surface roughness would promote earlier transitio

Qualitatively a gradient of decreasing surfaco pressure would

be required to maintain laminar flow if the Reynolds number,

stream turbulence, surface roughness, or the combination of

these, which might be referred to as “effective Reynolds

number,” were high enough to favor transition. At the

turbulence level of the S-inch cascade tunnel, however,

aminar flow and laminer seperation on the convex surface

persisted to Reynolds numbers up to 248,000 even when the

surface pressure gradient was slightly unfavorable. ‘Tho

addition of leading-edge roughness, as described in the section

“Test Procedure” reduced the extent of the laminar separa~

tion region, but did not eliminate it in somo eases. In view

of the thick boundary liyer which results from laminar

separation and reattachment, it appears thet the minimum

final boundary-layer thickness and section drag coefficient

‘would result if the Reynolds number and turbuleneo values

were such as to cause transition before laminar separation

occurred. Use of leading-edge roughness to reduce an ex-

tended laminar separation region would probably result in a

thinner final boundary layer than that for the smooth blade

at tho same Reynolds number but would probably result in a

thicker boundary layer than that for the smooth blade at

hhigh Reynolds number. A thick turbulent boundary layer

would be expected to promote turbulent separation near the

trailing edge of compressor blades which produce a signifieant

‘pressure rise.

Wake coefficient and drag coefiicient—As noted pro-

viously, the wake coefficient o., expresses the momentum

difference between the wake flow and the downstream flow

outside the wake in manner convenient for use in summing

blade forces. ‘The wake cosffcient is, of course, directly

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA 65-ERIES COMPRESSOR BLADES AT LOW SPEEDS

dependent upon boundary-layer thickness and shape, and

changes in the boundary layor with changes in effective

Reynolds number are refleoted in the wake-coefficient values.

Furthermore, if the effective Reynolds number is neer the

condition where laminar separation may or may not occur,

the change in surface pressure gradient with change in angle

of attack would control the presence and extent of Jeminar

separation on either blade surface. Obviously erratic varia

tions in the value of the wake coefficients would result under

those circumstences. ‘The blade-section-characteristic curves

of figures 6 to 84 show that in most cases the wake-coeflicient

values woro irregular as the angle of attack was varied in

the region near design at the usual test Reynolds number of

246,000. With either higher Reynolds number or leeding-

edge roughness, or both, the rapid local pressure recovery

associnted with boundary-layer reattachment was less evi-

dent, in tho surface pressure distributions and the wake

cocflicient usually was reduced. For a few cases, notably

those of figures 34 (), 35 (g), 68 (g), and 8¢ (¢), leading-edgo

roughness increased the wake coefficient, however; in those

cases the roughness apparently produced a more severe

turbulent boundary leyer than laminar separation and re-

attachment did.

‘The trend of deag coefficient c41, defined as the component

of resultant force parallel to the mean velocity, was similar

to that of wake coefficient. ‘The drag curves were quite

irregular near design angle of attack and the values measured

varied as much as 30 pereent with Reynolds number and

roughness. Obviously the values of both drag coefficient and

lift-drag ratio near design are not sufficiently reliable to use

direetly in design analysis. ‘These values should be of

some use for comparison purposes, however. ‘The large

drag rise associated with positive and negative stall should

be relatively insensitive to Reynolds number effects, because

tho pressure gradients on the critical surfaces are then un-

favorable to laminar flow and therefore should be useful for

determining offective operating range.

‘The trend of drag coefficient with Reynolds number nest

the design condition for the NACA 65-(12)10 blade section

at By of 60°, ¢ of 1.00, and A, of 45°, « of 1.50 shown in figure

85 (a) sorves to indiente the magnitude of the Reynolds

number effect. Increasing the stream turbulence by the use

of a }inch-mesh sereen upstream of the test section lowered

the drag coefficients at low Reynolds number, and reduced

the Reynolds number at which the drag coefficients become

essentially constant with Reynolds number. The compari

son of eg, values through the angle-of-attack range for the

samo easeade combinations at two Reynolds numbers in

figures 85 (b) and 85 (0) gives some further indicetion of

Reynolds number effect. For R of 445,000, tho drag cooffi-

cients are lower and the curves are smoother than for 7 of,

245,000. ‘The addition of leading-edge roughness in figure

86 (b) smoothed the drag curve but did not give the same

deorense in drag that the high R did. ‘There appears to be

some effect on the angle of attack at which the drag rises

rapidly in figure 85 (c) but since the effect: was not the same

in figure 85 (b) no conclusions can be drawn.

‘Turning angle and lift—Figure 85 (x) shows that the

effect of Reynolds number on turning angle near design ay is

20507-0048

79

almost insignificant for R between 220,000 and 470,000.

‘This is borne out by the fect that throughout figures 6 to 84

changes in @ with Reynolds number and roughness were, in

general, within the limits of measuring accuracy. Below R

of 220,000 a decrease of design turning angle ean be expected.

Reynolds number appears to have some effect on tuming

angle near stall in figure 85 (c), but again the effect has not

been definitely established. Tt can bo concluded that, the

design turning angles presented are correct for R above

220,000, but that the effect of near stall is unknown.

‘Laminer separation hed no appreciable effect on the

measured lift. ‘The lift-coofficient values for a given test,

agreed well at low and high Reynolds numbers and with

and without roughness. ‘The normal-force coefficients ob-

tained by integration of the pressure distributions also

changed very little with changes in Reynolds number and

roughness,

In order to estimate the useful operating angle-of-attack

range of the various sections at the several solidity and inlet

angle conditions tested, Howell's index of twice tho mini-

‘mum drag (ref. 8) was used to select the upper and lower

limits of angle of attack. As discussed previously in the

section concerning Reynolds number effects, the accuracy

of the measured values of drag coefficient near design angle

of attack suffered due to laminar-flow separation. The

minimum value of drag coefficient could not be determined

exactly end an approximate value was used to determine the

operating range. For most of the test configurations, the

drag coefficient changed rapidly with angle of attack near

the ends of the useful range, so an error in the value of mini-

‘mum drag used would have only small effect on tho operat

ing range value. Some scatter in the results was evident,

however.

No significant effect of solidity was observed. Most values

at constant camber and inlet angle fell within the scatter of

the points. A tendency for the range to increase slightly as

tho solidity was increased seas detectable at p,=45°, but this

was not evident for other inlet angles. ‘The results plotted

in figure 86 indicate that the major determinant of the oper-

ating range is inlet angle. As the inlet angle is increased,

the usable range of angle of attack is decreased, with greater

changes indicated for angles above design than for angles

below design. ‘The camber of the section affects the oper-

‘ating range in the following manner for angles of attack

above design: at an inlet angle of 30°, tho range increased

with increasing camber; at inlet angles of 45°, 60°, and 70°,

the opposite trend occured. For values of a less than

design, little change in range with camber was indicated for

:=30°; at higher inlet angles, the range decreased as the

section camber incressed.

With high entering velocities, the section operating range

would be reduced because of a more rapid increase of drag

‘at angles of attack well above or below design. Further,

the comparison between sections of different camber, at

constant inlet angle and solidity, would be altered es the

flow velocities relative to the blado surfaces exceed the local

velocity of sound.

720

‘Tho ideal, nondimensional pressure rise Ap/gy across a. two-

dimensional cascade is specified when the inlet angle and

turning angle aro known, since the ratio of the flow areas

determines the pressure rise. Since the mass flow is con-

stant, the actual pressure riso is less than the ideal because

of the “blocking” effect of the wake on the downstream flow

area. For given inlet and turning angles, the blocking effect

‘would be more severe for higher solidity, tince the unaffected

flow area is reduced. For incompressible flow the nondi-

‘mensional pressure rise is equal to one minus the dynamic-

pressure ratio, thet ia, S21, ‘Tho actual dynamic.

a 4%

pressure ratio becomes higher than the ideal because of the

wake blocking effect. ‘The ideal dynamic-pressure ratios,

and the actual ratios at design turning angles for two solid~

ities, aro summarized in figure 87 for the range of inlet and

turning angles of the tests. ‘The dynamie-pressure ratios for

individual tests aro given by the short bars at the 100-

percent points of the pressure-distribution plots in figures 6

to 84, Wake blocking effeots would be changed by the same

Reynolds number and roughness factors which change the

wake coefficient; however, the percentage change in dynamic-

pressure ratio would be small.

Tnformation on the maximum Ioading which can be

achieved in a compressor blade row is important in tho

design of high performance axial-low compressors. As noted

viously, the high pressure riso associated with large turn-

ing at high inlet angles promotes turbulent separation so

that at inlet angles of 60° and 70° the stall angle of attack

moved progressively closer to tho design value with inereas-

ing section camber. ‘The limit turning is reached when the

‘maximum turning angle is no greater than design turning

angle. The practical limit would be somewhat lower to

sive a reasonable operating range.

Approximate limit turning was reached at 6, of 60°, ¢ of

1,00 and 1.50, and at 6, of 70°, ¢ of 1.00, 1.25, and 1.

Information from those tests is given in terms of s commonly

‘used loading parameter, o¢im) in figure 89. Both the actual

test values of the parameter, and the ideal values calculated

using the test inlet and turning angles are presented. Nota

that the lift coefficient is here based, numerically, on the

mean velocity, to conform to the usual form of the parameter.

Arbitrarily chosen constant values of cin have often been

used os maximum allowable values in design analyses. ‘Tho

fallacy of using any constant value as a limit is clesely shown

in figure 89; the true limiting value increases with increasing

solidity and decreases with increasing inlet angle. “Since no

limits were reached for inlet angles of 45° and 30°, itis clear

that the limitation bas very little significance there except,

pethaps, at very low solidities. ‘The phenomenon is not yet

‘well enough understood to permit the choice of parameter

which could define the overall limitation as e single value.

REPORT 1363—NATIONAL ADVISORY COMMUTER FOR AERONAUTICS

COMPARISON WITH SOLID-WALL CASCADE DATA

‘The comparison between pressure-distribution and turn-

ing-angle data for a solid-wall cascade tunnel and for the

present porous-wall cascade tunnel is given in vefereneo 1 for

the NACA 65-(12)10 blade section at 6; of 60° and o of 1.00.

‘The comparison has been extended in figure 90 to include

turning-angle date for all the cambers reported for 6; of 60°

and ¢ of 1.00 in reference 3. ‘The turaing-angle curves com-

pare fairly well for cambers up to ex,» of 0.8, but for the

airfoils of higher camber the deta of reference 3 doviate

significantly from the present results. Comparisons at other

conditions would show similar trends.

Summaries of the relationships between turning angle and

angle of attack through the camber range are given for each

inlet angle and solidity in figures 91 to 106. ‘The variations

are quite consistent for most of the range. Some ineonsist-

‘ney in the shapo of the curves at stall isa result of reduced.

accuracy of measurement there. For combinations giving

moderate pressure rises straight-line relationships aro indi-

catod for considerable portions of tho curves. For the high-

est pressure rises, however, no definite straight-line relation-

ships exist. ‘The variation of the slopes near design is given

in figure 107 to assist in estimating relationships at conditions

other than those tested. ‘These slopes aro average slopes for

tho camber range, and do not apply for the highest eambers.

‘They must be used with particular caution for inlet angles

near 70°, since very nazrow straight-line regions axe prevalent

there.

‘The usuel procedure in blade-section selection is to deter

mine the camber ei, which is required for a given design

velocity diagram at a selected solidity. Figure 112 gives

carpet plots of ‘the data at five solidity conditions. ‘The

carpet plots indicate the variation of camber ¢,», at design

angle of attack «,, with required values of inlet-air angle 8,

and design turning angle 0. Ench carpet plot is spaced from

the next by a number of grid units proportional to the differ-

ence in solidities. Since design angle of attack is independent

of inlet-air angle, it is possible to present a carpet plot (Gg.

118) showing design angle of attack ay a3 a funtion of

camber ¢,, and solidity «.

‘The tesis were mado at fixed inlot-air angles with the angl

of-attack variation produced by changing the blade setting.

Although date of this type facilitated the determination of

design conditions for the various combinations of inlet-nir

angle, solidity, and camber, it does not lend itself casily, as

presented, to obtaining off-design performance of a blade

section as regards operation of this section in a compressor

in which blade setting is fixed and the angle of attack varied

by changing the inlet-air angle. However, if.tho date. are

plotted as an off-design carpet, itis a simple matter to draw

in curves of constant blade setting and thus to predict the

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA O5-SERIES COMPRESSOR BLADES AT LOW SPEEDS

variation in turning angle with angle of attack for all inter~

mediate conditions of solidity, eamber, and blade setting.

Such off-design carpet plots showing turning angle as a fune-

mn of solidity, inlet-air angle, angle of attack, and camber

aro presented in figure 114. Off-design data are presonted

for the following sections:

NACA 65-(4)10

NACA 65-(8)10

NACA 65-(12)10 :

NACA 65-(15)10

NACA 65-(18)10

Pressure rise as a percentage of inlet dynamic pressure

play, called pressure-rise coefficient, has been used a3 2

cascade londing-limit parameter. It is known thet cascade

losses increnso rapidly above certain limiting values of

Aplq. However, in view of the physical meaning of the

pressure-tise coefficient, particularly in reference to the inner

nd outer casings, it is considered to be a useful parameter.

If the inlet-air angle, the turning angle, and the entering

Mach number aro known, calculations of an isentropic

pressure-tise coefficient. is possible, provided some relation-

ship is assumed between the entering and leaving stream-

tube areas. Therefore, tivo carpet plots were made in order

to show the variation of the pressure-rise coefficient. with

inlet-nir angle 6, turning angle @, and entering Mach number

My. The first of these plots (fg. 116 (a)) was calculated by

‘assuming constant stream-tube area; the second (fig. 116 (b))

‘was calculated by assuming that the stream-tube area varied

so that constant axial velocity would be produced across

the blade passage. Pressure-rise coefficients obtained from

721

these two plots very often bracket the value associated with

the actual three-dimensional condition being examined.

SUMMARY OF RESULTS

‘Tho systematic investigation of NACA 65-series compressor

blade sections in a low-speed cascade tunnel has provided

design data for all conditions within the usual range of

application. ‘The results of this investigation indicate a

continuous variation of blade-section performance as the

important, cascade parameters blade camber, inlet angle,

‘and solidity are varied over the useful range. Summary

curves have been prepared to facilitate selection of blade

sections and sottings for compressor-design velocity diagrams

for optimum high-speed operation.

‘Upper limits for the loading parameter aja have been

established for some conditions, and the invalidity of using

‘constant value of the parameter has been shown.

‘The variation of the useful section operating range with

camber, inlet angle, end solidity has been shown. ‘The

‘operating range was found to be broad except for the highest

pressure-rise conditions.

Compressor-blade cascade data have been presented in

the form of design carpet plots, which greatly facilitate the

selection of compressor blade sections required to fulfill

‘velocity diagrams. Plots of this type also are shown to

increase greatly the usefulness of available cascade data by

iding a simple method of obtaining the off-design varia

in turning angle with angle of attack.

Lanouey Awnonavricat Lanonavony,

‘Namtowat, Apvisony Cosnurrse Fon AERONAUTICS,

Laxauer Frau, Va., January 31, 1958.

APPENDIX A

CALCULATION OF BLADE FORCE COEFFICIENTS,

‘The two-dimensional resultant force on a blade in cascade

i the veetor sum of all tho pressure and momentum forces

exerted by the fluid. At any appreciable distance behind

the blade row the static pressure is constant along a line

parallel to the blade row, since any prior pressure gradients,

‘would have been converted to momentum changes. On tho

assumption that pressure foree acting inthe upstream ditec-

tion is positive,

P= Odio @

sum the momentum forees in the exial end tangential direc-

tions. Assume that the axial momentum forces are positive

if the force on the blade is in the upstream direction and

that the tangential momentum forces are positive if the

tangential velocity change is in the usual direction shown in

figure 5. ‘Tho axial momentum foree then is

Pam fnVoas(Voa.s—Voadb dg ®

and the tangential momentum fores is

Fae [Vases Wea db tg ®

Sineo momentum values in the wako can be obtained most

easily as differences between the wake values and the down-

stream value outside the wake, it is convenient to rewrite

equations (2) and (3)

Vas Paaa—Faadbat f Ve

Fe, 1Weas-Vaaadbdg (4)

Foren VesWos—Wescdb0+ f piVeas(lFeaa—Wia,db dg

@)

Howover, the wake momentom force, as ealeulated from

wake surveys, is

= fav

Pr

Uf, now, the flow direction in the wake can be assumed to

be the same as the average downstream flow direction, the

‘wake foreo can bo resolved into components in the axial

and tangential directions. Using the same sign convention

as before

(Ws = Wb dg O}

cos m= f nVeasVoss—Vaasdbdg

®

‘These are the integral terms in equations (4) and (5). Sub-

stituting equation (7) in equation (4) and equation (8) in

‘equation (6) yields the axial and tangential force components,

m2

1s follows:

Pet Para= (D221) 69+ Vea Vase Vea)bg~ Fe 008 fa

Fea Fare= 0.0 Wea Weanbgt Fe sin By

For convenience coefficients based on 9; are used and

teeyey Fag a} [AP Ves Vane~Ved |,

Se seep Pe 0 Be

oF 1 Va

Taibo

or,

trata

If is used to denote the angle between the resultant foreo

and the tangential direction

‘Tho lift coofficiont es, and drag coofficiont e, ara the

components of cr, perpendicular and parallel, respectively,

to tho veotor mean velocity Wa, where Wn is the vector

average of the velocities far upstream and far downstream.

‘The upstream velocity can be easily measured. ‘Tho velocity.

far downstream is obtained by proper averaging of the

velocities just behind the blades. Sinco the axial area con-

trols the axial velocity, conservation of mass determines the

axial component of the velocity far downstream. Inasmuch

as there are no physical boundaries in the tangential direction

to support pressure gradients, conservation of momentum

controls the tangential component far downstream. ‘The

discussion up to this point applies to compressible as woll as

incompressible flow.

For compressible flow the effect of wake mixing on pres-

sures and densities makes accurate determination of the

axial velocity far downstream rather tedious. In tho i

compressible, two-dimensional case the downstream axial

component is Vea, and the downstream tangontial com-

ponent is the momentum-weighted everage of Wx ‘This

tangential component can be obtained by adding to the

tangential momentum of the discharge free stream tho

integrated tangential momentum of the wake. ‘The inte

grated tangential momentum of the wake can be determined

from the tangential component of the wake coefficient.

Having the correct velocity far downstream, the vector

mean-velocity direction Wx can bo easily obtained. ‘Tho

direction of Wm should bo determined accurately since ¢,y

is very nearly perpendicular to Wq, and the value of the drag

component ¢,; is sensitive to small changes in the direction

of Wa:

APPENDIX B

CARPET-PLOTTING TECHNIQUE

Sinco the earpet-plotting technique is not too well known,

‘a description of this technique will be helpful. examine

first figure 114 (a). Tt will be noted thet this figure is

‘composed of five similar and separate plots. Each of these

plots shows the variation of the turning sngle @ with tho

angle of attack a and the inlet-air angle é for a given solidity

a and a camber cx, of 0.40. Tt might be here pointed out

that the tests were made at four inlet-air angles, 30°, 45°,

60°, and 70°, The leftmost plot, which ropresonts a solidity

of 1.50, is constructed by plotting turning angle @ as ordinate

‘against angle of attack a as abscisse for f,=30°. Then,

for a A, of 45°, the a; scale is shifted to the right a number of

grid units proportional to the 15° increment in ® and the

turning angles are plotted as before. ‘This procedure of

shifting the a scale is followed until the range of &; values

for which test deta are available hes been completed.

Curves of constant angle of attack may then bo drown

between the several curves of a against 6,50 thet the removal

of the a abscissa seales is possible. At this point, curves

of a against @ may be filled in at 5° intervals of & by using

tho proper abscisen increment, ‘The plot thus constructed

is called 0 GaisB: carpet.

A b,au6, carpet is constructed for the next solidity of 1.25

by shifting the angle-of-attack scales to the right a number

of grid units proportional to the solidity increment of 0.25

and sufficient to keep any overlapping of the 8a,2 carpets

to a minimum. ‘This procedure previously described in

constructing the first @a,8: carpet is then repeated. ‘The

full range of solidities for which test data aro available

(0.60 to 1.50) may be presented by spacing and constructing

the 0,8: eaxpets on this plot called a 6,au,8,¢ carpet plot.

Similar G,a,81,¢ carpet plots are then made for each of the

other cambers, namely, ¢1o=0.8, 1.2, 1.5, and 1.8 shown in

figures 114 (b), 114 (@), 114 (@), and 114 (0), respeetively.

‘For intermediate camber conditions, linear interpolations

between G,a;,,0 carpets could be used or these #,c,Bi¢

plots could be combined into # single carpet plot to make

possible a single graphical interpolation. For example,

figure 114 (a) may be combined with figure 114 (b) by again

shifting the angle-of-attack scales to the right a number of

grid units proportional to the camber increment of 0.40.

Overlapping of the 04,61, carpets can be avoided by shift-

ing also the 6 ordinate seale vertically a number of grid units

proportional to the camber increment of 0.49. ‘This com-

bination of a vertical and a horizontal shift is facilitated by

‘tho uso of register points labeled “AB” on both plots 114 (a)

and 114 (b). ‘The AB register points ean be superimposed

and the grids alined. In like manner, if all of the register

points are used, figures 114 (a), 114 (b), 114 (c), 114), and

114 (¢) may be assembled into a single carpet plot. Figure

115 was made by combining plots 114 (a), 114 (¢), and 114

(©) representing cambers of 04, 1.2, and 1.8, respectively.

On this carpet, the design angle of attack is indicated by a

dotted line and the approximate occurrence of twice mini-

mum drag is indicated by a dashed line. Since the origins

of tho @ sosles for cambers of 1.2 and 1.8 are shifted ver-

tically a number of grid units proportional to the camber

increment, the ordinate scale is no longer a truo @ scale for

these higher eambers and is called Y. When an interpola~

tion is made for any camber above 0.4, the @ value may be

obtained by substituting Y in the following expression:

0=Y—50(e1,.—0.4)

Figures 114 (b) and 114 (@) representing eambers of 0.8 and

1.5 wore omitted from figure 118 in order to reduce the size

of the plot. It-will also be noted that date are availeble for

cambers of 0.8 and 1.5 at only two solidities, 1.00 and 1.50.

In view of the necessity for shifting the separate plots to

provide for combinations of the several variables, as ilus-

trated in figure 115, the carpet plots assembled in the present

bound copy are useful only as a means of demonstrating this

technique. For this reason, larger separate plots for use in

compressor design have been prepared and aro obtainable

on request from NACA Headquarters, Washington, D. C.

‘Tho use of the carpet plots presented ean be shown best

by use of an example. Generally, from a velocity-diagram

calculation, the inlet-air angle, turning angle, and inlet

‘Mach number are known, and some value of solidity has

been decided upon. The problem is to find the eamber ¢,.,

tho design angle of attack a. the pressure-riso coefficient

Ap/q (one-dimensional flow being assumed), and the off-

design varietion in @ with a at a constant blade setting.

‘The following design conditions are essumed:

Bia55°

6°

10

85

Figuro 112 is used to locate first the intersection of the

curves for 6:=55° and 24=15° on each of the four carpets

representing solidities of 1.25, 1.00, 0.75, and 0.50; then a

smooth curve is drawn connecting these four points which

aro labeled “A,” “B,” “0,” and “D.” If the 8; and @ values

hand fallen between thoso represented on the curves, these

intermediate values could be located by measuring the in-

crements along the abscissa, Although the design solidity

- Ey

12h

of 1.10 falls between points A and B representing solidities

of 1.25 and 1.00, respectively, points C and D for soliities

of 0.75 and 0.50 are included to define more accurately the

shape of the curve between points A and B. Sinco the hor-

‘zontal interval from A to B represents a solidity increment

of 0.25 from 1.25 to 1.00, the point corresponding too

solidity of 1.10 may be obtained by locating on the ABOD

curve the point B, which has a horizontal distance from

point B equal to a solidity increment of 0.10. Point E thus

located indicates camber cy» of 0.87 on the ordinate scale.

Next, the solidity of 1.10 and the newly found camber

ex, of 0.87 are used in conjunction with figure 113 to find

the design angle of attack. ‘Tho point for a camber of 0.87

is located on the e=1.10 curve between the camber of 0.8

and 0.9 curves by reading the proper horizontal increment

0f.0,07.. ‘This point indicates on the ordinate scale a design

angle of attack of 10.5°.

‘The pressure-rise coefficient Ap/q, is found from figure

116 (a) by using the values M=0.65, 6=55°, and 0==15°,

In figure 116 (a), the Ap/a, was caleulated on a one-dimen-

sional basis, whereas in figure 116 (b) the Ap/q: was ealen-

lated for a constant axial velocity. Since one-dimensional

flow was assumed in this example, figure 116 (a) should be

used. Employing the proper horizontal , increment, of

10° and starting at the B=45° curve, locate the Ai=55°

point on the @=15° curve for each of the carpet plots rep-

resenting Mach numbers of 0.60, 0.60, 0.70, and 0.80. ‘The

four points thus located are designated “WF,” “G,” “H,” and

“[ and are connected by a smooth curve. Next, locate on

this curve point J whose horizontal distance from point @

is equal to a Mach number increment of 0.05. Point J

indicates on the ordinate scale pressure-rise coefficient of

0.590.

REPORT 1368—NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

‘Tho last step in this sample problem is the prediction of an

af curve. at a constant blade setting. ‘Tho offlesign

carpet (Bg. 115) is used to predict this a,0 curve for the

blade seotion having a camber oy. of 0.87, a solidity e of 1.10,

and a. blade setting of 44.5°, ‘The blade sotting is the differ-

ence between the inlet-air angle and the angle of attack,

or 55°—10.5°=44.5° at the design condition. In figure

116, curves labeled “a” and “b” representing this constant

blade sotting of 44.5° are drawn on the éai,8: plots for ex.

of 0.4 at the solidities of 1.25 and 1.00, respectively. Curve

¢ is then interpolated for the solidity of 1.10 by the use of

the correct solidity ineremont along the abscissa. As can

bbe seen in the example, this interpolation is aided by drawing

Ddotwweon curves « and b lines of constant angle of attack at

values of 6°, 8°, 10°, 12°, and 14°. A similar interpolation

is then accomplished for a camber of 1.2, which produces

curves d, e, and f. A linear interpolation for the intermedi-

ate camber of 0.87 is mado between curves ¢ and f to obtain

curve g, which shows tho variation of ¥ with a for the

design camber and solidity. ‘The ¥ values may be converted

to @ values by using the relationship

¥—50(¢,.-0.4)

It has been found that linear interpolations between any

‘two cambers of figure 116 produce design turning angles

which agreo with the design carpot plot within 1.0°. If

greater accuracy is desired, a faired curve between tho

threo cambers should be used. In figuro 116, tho design

angle of attack is indicated by a short-dashed line and the

approximate occurrence of twice minimum drag is indicated

by a long-dashed line.

REFERENCES

1. Bria, Jobn R., and Emery, James C.: Effect of Tunnel Contigura-

on and Testing Technique on Cascade Performance. NACA

Rep. 1016, 1951. Supersedes NACA TN 2028)

2, Westphal, Willard R., and Godwin, Wiliam TR Comparison of

NACA’ 65-Serias Compressor-Blade Pressure Disteibutions and

Performance ina Rotor and in Cascade, NAGA TN 3808, 1958.

(upersedes NACA RAC 51820)

8, Bogdonoff, Seymour M., and Bogdonol, Hacriet B.: Blade Design

‘Data fot Asial-Flow Fans and Compressors, NACA WR 1-635,

1045, (Formerly NACA ACR L5¥07a)

4, Bogdonoff, Seymour AL, and Hess, Eugene E.: Asial-Flow Fan

‘and Compressor Blade Design Data at 62.5" Stogger and Further

‘Verifeation of Cascade Data by Rotor Tests. NACA 'TN 1271,

oi,

5. Abbott, Im HL, von Doenhol, Albert

‘Suminary of Alrfll Data. "NACA Rep. 824, 1045,

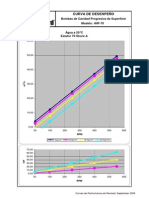

NACA WR 1-560),

©. Yates, A Hs ‘Cumpets’ and ‘Lattices’

vol. XVIII, no. 208, Jun, 1946, pp. 8-9.

7, Bursoall, Wiliam J., and Loftin, Laureneo 1, Jr: Exporimontal

Investigation of Localized Regions of Laminia-Boundary-Layer

Separation. NACA TN 2898, 1051,

8, Howell, A. R: Design of Axial Compressors. Lectures on the

Development of the British Gas Turbino Jet Unit Published in

War Bmorgeney Issue No. 12 of tho Institution of Mochanioal

Engineors. ASME, Reprint, Jun. 647, pp. 452-462.

and Stivers, Louis 8, Jn

(Guportedes

Aircraft. Bnglneoring,

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA 65-SHRIUS COMPRESSOR BLADES AT LOW SPEEDS

Epo.

'

Baio

corel se

Seting chamber

Frovae 1-

-Vertial cross section of to-dimensional low-epeed

casoade tunnel.

Fes arora.

j eae

\

Fravas 2—Photograph of Langley Sinch cascade tunnel with

‘portions of one side removed to show porous surfaces,

i

Foarsl

3

C

° a a 12 1g 20 2a 28

Presid, bq

Fraums 3.—Porosity characterstion of the ealendered mone iter

loth used In this investigntion.

725

tea 65-150 roe

oe

nach 65-1010

Short Qos

p30 i :

T “Sons Gone

oe nica 65-210 org

ert Stent

“me

ica 65-810 Nac 65 (2010 vga

s

Toop

@) NAGA 65~ (12110 (o) NACA 65- (2710 “Tangent

(@) Lower cambered sections. Angle between chord line and tangent

to lower surface as shown for tho various soetions.

Frovaz 4.—Blade teotions tasted in this investigation.

() Higher cambered sections, Chord line and tangent lino

soineldont,

Figure 4—Coneluded.

‘Fiune 5—Typieal vector diagram for a compressor rotor.

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA 65-SERIES COMPRESSOR BLADES AT LOW SPEEDS 727

2 Comat sree

a 2 Geren race

3 Cina oan

a

4 s roy

(0) ay = 30%, 02.4" 5 {

- ma eo

2a oe | fm a-30, 0-8

eal

u

s

Ss

s pao

(d) a+ 8.0%; 8+6.9° a

en 7an, 8-99 Bsn

aq ACen

49

aa

ql

; J

s . t

1d .

@ gethr, 6-934

0% 40-25 85 100

in) ays170r; @=143°

02 a0 65 60 100

ceed

or sy 40.307

wt | 20 {06

| 2 +05

ft 2 10, 40445

Bde Fy 44 ow

| 0° doses

o of J-t0 -Jo2

“t 1-20 or

i

O48 6 20

oy oa

26

( Section characteristios; flagged symbol indicates

Teading-edge roughness

Fravns 6.—Dladesurfaco pressure distributions and blade

section characteristics for the easeade combination, 6:=30°,

7=1.00, and blade seetion, NACA 65-010.

© ayr150y Or16.6"

06 ao 20 80 100

a

i) aj-210%; 02210"

080 a0 65 80 05

cat crt

ep 7 60 05

vat ol Iso os

al si 40. fos

‘ba 30, 402 ey

aes Fe +

abs 120” 01 ey

of 2 w Jo

al ° 401

4}

ne

oa 8 ee 20

09

@) Scotion characteristics; laggod aymbol indicates

Tending edge roughness.

Fiavns 7.—Blade-surfaco pressure distributions and blade

‘seotion charactriaties for the eascade combination, Bi=30",

(721.00, and biade seotion, NACA 05~10.

REPORT 136§—NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

3 Genel aries T

ap ee

| 2 Corer arTece

a ea} | [eee

°

ve

= le }

2a a 28 ‘88°

. 2a

s aero i

al ry "

. | h.

@ aah ee ana7 Geter

@ sere t

2 @ alin Oe2ur

Fy 40

2 sq a

: KJ

1 2a Ly

ehred “p P

e187; 8-205" 0 ej2217%; 64280" TN

0-85 40-65 8 G9 -a a a0 80 16S ‘|

Pacer See

= 20-08 eae 20, O32

feta q ot a aoe oa OD BO WD

2a ro. for oF

ele alee i eo 507

ats wo Sau Lo

fees Fray sel sls ay leo

_ . so

c cog bey

q aa eo

ot | 0 J E

jzo. oe ae so hoe

ab oa Lee 10 Fou ae a e leo “Jor

ot ol oto = wl 4 jo to

So ae 1S Ie 20 a 04 8 ie 16 2 2 os oe

dey onsen

(@ Section characteristics; lagged aymbol indicates

leading-edge roughness.

Provan 8—Disdesurface pressure distributions and blade

‘section characteristics for the eagcade combination,

7m 1.00, and blade section, NACA 65-810,

A= 80%,

Fiauns 0.—Bindesurfaco prossure distributions and blade

tion charactersties for the easeade combination, f= 30°,

(@ Seotion cheraotorster; lagged ayinbol indicates

Tening-edge roughness

1.00, and blado section, NACA 65~(12)10.

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA 65-SERIES COMPRESSOR BLADES AT Low SPEEDS 729

3 Gina

—— ea “ae

| Sena

1.6 —

tot fod e f

s }— 3y—F

‘| tS @ @ ayri6.0% 06297

d

fe) 0-50", O15 a rihor, 8-232" 2a

al

ve

1 + s fA

: is ‘

(0) a, "81"; B= We arly 02250" (0) y+ 12.0%;

al aa

ue 16 Ps

. ‘ cee i

a i

s | 1

‘ in |

Osan beer | nas ewer fo) arty 0-008 | [fin «j-38a0, Braco

eee E ore age | fee ee

ree Ee,

to 245 i ro or aal 9f 24 70 Jos

Gy f on

die doe Be alse ie

ad Sa Sad

a po ee - 36] 7 eat jong

sd 2 fetes sat eo” os

A low

aE fo ee

a ie

16} Al 10 or a 4) zo 08

pie le Ne

2 3 ee 16 20 24 28 Be 36° _ _ 3S 1 20 et es 8 36° °

(@) Seotion characteristics; flagged symbol indicates: (g) Seotion characteristics; flagged symbol indicates

os ster

Figunn 18—Blado-surface pressure distributions and blade

‘seotion charactoritics for tho cascade combination, 6,30",

‘7=11.60, and blade evotion, NACA 85-(19)10.

Fiounz 19.—Bisdo-eurface pressure distributions and blade

‘seotion characteristics for the cascade combination, f;=30°,

‘71.50. and blade section, NACA 65-(15)10.

734, ‘REPORT 1368—NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

3 Sier action

2 Gina atten

eal 8 Gene tatote

(@19)= 00%, 6+ 05"

|

laa ooee

aa

9

ad 2

: Pee

ad rk

ea

s

\ jo son, b65| | floss, boos

oa ae oe ao eg 8 ae Bo

Becet Ser

FY 5 or

d

{e) 0*25.0%; 0+ 41.6" Uf) @y# 31.0%; 847.3" ae ia

oe 85-05 80 tot ae a

Panes ec d os

ar 10 co 306

a

aat shel loa so 405 4 |°* on

ee 8400 Fay 4 ons

wok ss so, ote A los %

asst a, 44 es

sot so os 2

ob le

st 20 doe

28] 5] 10 01 ‘xe

kee 0 |

a ge 20 ee se? Se a + e 2, 6° °

ons ane

(e Seton charset; tagged symbol Insts () Seolion caracteratn tagged pmb ndaten

Icadingedge rupisees icadingodgs ropes,

‘Frovan 20.—Blade-curface preasure distributions and blade

‘section cheracterlaties for the eassade combination, pi=20%,

{50, and blade section, NACA 65-(18)10

Fravaz 21.—Blade-aurfaco pressure distributions and blade

‘section characteistieg for the easeade combination, B.=46%,

7=0.50, and blade section, NACA 65-10,

SYSTEMATIC TWO-DIMENSIONAL CASCADE TESTS OF NACA 6§-SERINS COMPRESSOR BLADES AT LOW SPEEDS 735,

eae ae

2.4} 2 a

\

s

rear; Bae

zal

s

4 L

49

Fe

al

s

me

u

othe f AL

fo ss ota | Pita, 9a

0 AOC 80 0a a0 aD

Poca ch

sr 13 90 08

es

wt ule LA leo jor

ak if ot Lo os

a leo. fos

Sy

840g 20} 4} {504-404 ent

%

rc lio os

8 fso. foe

q bo {ou

a

© Mae ee a?

eyes

@) Section characteristics.

Fiounn 22—Biadewurface pressure distributions and blade

seetion characteristics for tho eascade combination, £1=45%,

‘#=0.50, and blade section, NACA 65-(12)10

2 Care ats

2a

a

108"

Re

7 !

(oar for ayer Gaia

“

aa

ahaa!

s

oe

‘thay 2U7%, 0-184

‘0 20 40 65 80 105

020-405-080 10,

Pacer et

Br may 708

x ee Heo or

oa

2a 70 os

a 0 os

Bde Fay, Fy ont

20 20° losers

a

re 10} 20 Jos

i 30 oe

4 20 or

al wo to

ee eee

809

@ Section cheractorstes; Aagged symbol indicates

leading-edge roughness,

Fravas 28.—Bladesurfaco pressure disteibutions and blade