1664

1664

Uploaded by

engineer.mmCopyright:

Available Formats

1664

1664

Uploaded by

engineer.mmCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1664

1664

Uploaded by

engineer.mmCopyright:

Available Formats

AS 16641979

This is a free 6 page sample. Access the full version online.

Australian Standard

SAA Aluminium Structures Code

The following scientific, industrial and governmental organizations and departments

were officially represented on the committee entrusted with the preparation of this

standard:

Aluminium Development Council

Department of Labour and Industry, N.S.W.

Department of Public Works, N.S.W.

National Association of Australian State Roads Authorities

This is a free 6 page sample. Access the full version online.

Railways of Australia Committee

This standard, prepared by Committee BD/50, Aluminium Structures, was approved

on behalf of the Council of the Standards Association of Australia on 9 March 1979,

and was published on 1 June 1979.

The rules are intended to include the technical provisions necessary for design and

fabrication of aluminium alloy load-carrying members, but do not purport to comprise

all the necessary provisions of a contract.

Review of Australian Standards. To keep abreast of progress in industry, Australian Standards are subject

to periodic review and are kept up to date by the issue of amendments or new editions as necessary. It is

important therefore that Standards users ensure that they are in possession of the latest ed ition, and any

amendments thereto.

Full details of all Australian Standards and related publications will be found in the Standards Australia

Catalogue of Publications; this information is supplemented each month by the magazine The Australian

Standard, which subscribing members receive, and which gives details of new publications, new editions

and amendments, and of withdrawn Standards.

Suggestions for improvements to Australian Standards, addressed to the head office of Standards Australia,

are welcomed. Notification of any inaccuracy or ambiguity found in an Australian Standard should be made

without delay in order that the matter may be investigated and appropriate action taken.

AS 16641979

This is a free 6 page sample. Access the full version online.

Australian Standard

RULES FOR

THE USE OF ALUMINIUM IN

STRUCTURES

known as the

SAA ALUMINIUM STRUCTURES

CODE

First published . . . . . . . . . . . . . . . . . . . . . . . .

Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1975

1979

Incorporating:

Interp 1 1985

PUBLISHED BY STANDARDS AUSTRALIA

(STANDARDS ASSOCIATION OF AUSTRALIA)

1 THE CRESCENT, HOMEBUSH, NSW 2140

ISBN 0 7262 0567 2

AS 16641979

This is a free 6 page sample. Access the full version online.

PREFACE

This standard, which is a revision of AS 16641975

was prepared by the Associations Committee on

Aluminium Structures. It is based on the Aluminium

Construction ManualSection 1: Specifications for

Aluminium Structures (2nd Ed. 1971) published by

the Aluminium Association, New York and British

Standard CP 1181969, The Structural Use of

Aluminium. The committee gratefully acknowledges

the assistance received from these sources.

In the revision the principal changes have related

to data on the range of aluminium alloys which has

been generally extended. The standard does not now

provide for alloy Alclad 3004 in H16 temper.

The standard applies to the design and

fabrication of aluminium structures and is presented

in a similar format to AS 1250, SAA Steel Structures

Code; however it is emphasized that steel designs

should not be directly copied as many types of

welded connections used in steel fabrication are

entirely unsuitable for aluminium structures. For

welded aluminium structures particular attention shall

be given to the design of welded connections and the

possibility of failure of members by local buckling.

The committee has recommended that the

international designation system for wrought

aluminium and aluminium alloys used by the

Aluminium Development Council (ADC) be adopted

for all Australian standards. This designation system

is used throughout this standard and a detailed

explanation of the system can be found in the ADC

publication Aluminium Standards and DataThird

Edition.

The design sections of the standard (Section 5,

Maximum Permissible Stresses, and Section 6,

Combined Stresses) consist of a compilation of

methods to determine the maximum permissible

stresses for different types and combinations of

stress. The maximum permissible stresses for alloys

commonly used in structures are given in Tables A1

to A21 in Appendix A.

Aluminium alloys attain their strengths by heat

treatment or strain hardening, and welding causes

local overageing or annealing in heat-treatable and

non-heat-treatable alloys respectively, producing a

zone of lower strength along both sides of the weld

bead. To account for this decrease in strength,

permissible stresses for welded members are

determined as outlined in Rule 5.3.3.

Attention is drawn to the following Australian,

American and British standards and other documents

which may be required for use in connection with this

standard:

AS 1110

ISO Metric Hexagon Precision

Bolts and Screws

AS 1111

ISO Metric Hexagon Commercial

Bolts and Screws

AS 1112

ISO Metric Hexagon Nuts,

Including Thin Nuts, Slotted Nuts

and Castle Nuts

AS 1170

SAA Loading Code

Part 1Dead and Live Loads

Part 2Wind Forces

AS 1237

Flat Metal Washers for General

Engineering Purposes (Metric

Series)

AS 1250

AS 1275

SAA Steel Structures Code

Metric Screw Threads for

Fasteners (Based on ISO

Recommendations)

AS 1418

SAA Crane Code

AS 1449

Stainless and Heat-resisting Steel

Plate, Sheet and Strip (Coils and

Cut Lengths)

AS 1480

SAA Concrete Structures Code

AS 1511

SAA High-strength Structural

Bolting Code

AS 1538

SAA Cold-formed Steel

Structures Code

AS 1562

Code of Practice for the Design

and Instal lati on of Selfsupporti ng Met al R oofi ng

Without Transverse Laps

AS 1588

Filler Rods for Welding

AS 1627

Code of Practice for Preparation

and Pretreatment of Metal

Surfaces Prior to Protective

Coating

Part 1Degreasing of Metal

Surfaces Using Solvent or

Alkaline Solutions

AS 1665

SAA Aluminium Welding Code

AS 1734

Wrought Aluminium and

Aluminium Alloy Flat Sheet,

Coiled Sheet and Plate for

General Engineering Purposes

AS 1735

SAA Lift Code

AS 1866

Wrought Aluminium and

Aluminium Alloy Extruded Rod,

Bar, Solid Tubes and Hollow

Shapes for General Engineering

Purposes

AS 1867

Wrought Aluminium and

Aluminium Alloy Drawn Tubes

for General Engineering Purposes

AS K108

Metal Priming Paint, Anticorrosive

ASTM D 962 Specification for Aluminium

Pigments, Powder and Paste, for

Paints

U.S.A.

Federal Government

Specification TT-V-81F: Varnish,

Mixing for Aluminium Paints

BS 641

Dimensions of Small Rivets for

General Purposes

BS 1974

Large Aluminium Alloy Rivets:

1/2 in to 1 in Nominal Diameters

BS 2708

Unified Black Square and

Hexagon Bolts, Screws and Nuts

( U N C

a n d

U N F

Threads)Normal Series

BS CP118

The Structural Use of Aluminium

Aluminium Technology*

Book 2Forming Aluminium

Book 3Machining Aluminium

Book 4Joining Aluminium

* Published by Aluminium Development Council.

AS 16641979

CONTENTS

Page

SECTION

1.1

1.2

1.3

1.4

1.5

1.6

1. GENERAL

Scope . . . . . . . . . . . . . . .

Standards . . . . . . . . . . . .

New Materials or Methods

Design and Supervision . .

Definitions . . . . . . . . . . .

Notation . . . . . . . . . . . . .

SECTION

2.1

2.2

2.3

2. MATERIALS

Aluminium Alloys . . . . . . . . . . . . .

Fasteners and Filler Rods . . . . . . . .

Mechanical Properties of Aluminium

Alloys . . . . . . . . . . . . . . . . . . . . .

Buckling Constants . . . . . . . . . . . .

Steel . . . . . . . . . . . . . . . . . . . . . .

Concrete . . . . . . . . . . . . . . . . . . . .

This is a free 6 page sample. Access the full version online.

2.4

2.5

2.6

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

4

4

4

4

4

...

...

7

7

.

.

.

.

8

8

8

8

.

.

.

.

.

.

.

.

SECTION

3.1

3.2

3.3

3.4

3. GENERAL DESIGN REQUIREMENTS

Loads . . . . . . . . . . . . . . . . . . . . . . . . 14

Design . . . . . . . . . . . . . . . . . . . . . . . 14

Experimentally Based Designs . . . . . . 15

Weld Quality in Welded Structures . . . 15

SECTION

4.1

4.2

4.3

4.4

4. GEOMETRICAL PROPERTIES

Gross Section . . . . . . . . . . . . . . .

Effective Section . . . . . . . . . . . . .

Hole Effective Diameters . . . . . . .

Sectional Areas of Bolts and Rivets

SECTION

5.1

5.2

5.3

5.4

5.5

5. MAXIMUM PERMISSIBLE STRESSES

General . . . . . . . . . . . . . . . . . . . . . . 17

Minimum Mechanical Properties . . . . . 17

Maximum Permissible Stresses . . . . . . 17

Design Details . . . . . . . . . . . . . . . . . 26

Compression in Single Web Laterally

Unbraced Beams . . . . . . . . . . . . . . . . 27

Special Provisions for Thin Sections . . 27

5.6

SECTION

6.1

6.2

6.3

6.4

...

...

...

..

6. COMBINED STRESSES

General . . . . . . . . . . . . . . . . . . . .

Combined Compression and Bending

Combined Shear, Compression and

Bending . . . . . . . . . . . . . . . . . . . .

Torsion and Shear in Tubes . . . . . .

SECTION 7. DESIGN OF CONNECTIONS

7.1

Arrangements and Strength of

Connections . . . . . . . . . . . . . . .

7.2

Maximum Permissible Forces on

Rivets and Bolts . . . . . . . . . . . .

7.3

Design Details . . . . . . . . . . . . .

7.4

Alternative Fasteners . . . . . . . . .

16

16

16

16

..

..

30

30

..

..

30

30

....

31

....

....

....

31

31

32

Page

SECTION

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8. FABRICATION

Laying Out . . . . . . . . . . . . . . .

Cutting . . . . . . . . . . . . . . . . . .

Heating . . . . . . . . . . . . . . . . .

Punching, Drilling and Reaming

Bolting . . . . . . . . . . . . . . . . . .

Riveting . . . . . . . . . . . . . . . . .

Welded Structures . . . . . . . . . .

SECTION

9.1

9.2

9.3

9. PAINTING

General . . . . . . . . . . . . . . . . . . . . . .

Contact with Dissimilar Materials . . . .

Cleaning and Treatment of Metal

Surfaces . . . . . . . . . . . . . . . . . . . . . .

APPENDICES

A Maximum Permissible Stresses for

Aluminium Sections . . . . . . . . . .

B Fatigue . . . . . . . . . . . . . . . . . . .

C Struts . . . . . . . . . . . . . . . . . . . . .

D Constants for Lateral Buckling

of Beams . . . . . . . . . . . . . . . . . .

E References on the Elastic Flexural/

Torsional Buckling of Beams . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.....

.....

.....

33

33

33

33

33

33

33

34

34

34

35

78

96

. . . . . 100

. . . . . 103

TABLES

1. Aluminium Filler Alloys for General

Purpose Welding . . . . . . . . . . . . . . . . . . . 7

2. Minimum Mechanical Properties for

Aluminium Alloys . . . . . . . . . . . . . . . . . 8

3. Minimum Mechanical Properties for

Welded Aluminium Alloys . . . . . . . . . . . . 9

4. Formulas for Buckling Constants:

For Products Temper Designations O,

T1, T3, or T4 and Temper Designations

beginning with H . . . . . . . . . . . . . . . . . 10

5. Formulas for Buckling Constants:

For Products Temper Designations T5,

T6, T8, or T9 . . . . . . . . . . . . . . . . . . . . 11

6. Buckling Formula Constants for

Non-welded Aluminium Alloys . . . . . . . 12

7. Factors of Safety for Buildings and

Similar Structures . . . . . . . . . . . . . . . . . 14

8. Values of Coefficients kt and k c . . . . . . . 17

9. General Formulas for Determining

Maximum Permissible Stresses . . . . . . . . 22

10. Maximum Permissible Shear Stresses

in Fillet Welds . . . . . . . . . . . . . . . . . . . 24

11. Maximum Permissible Bearing Stresses . . 31

12. Maximum Permissible Shear Stresses in

Rivets . . . . . . . . . . . . . . . . . . . . . . . . . 31

13. Maximum Permissible Stresses in Bolts . 31

Copyright STANDARDS AUSTRALIA

Users of Standards are reminded that copyright subsists in all Standards Australia publications and software. Except where the

Copyright Act allows and except where provided for below no publications or software produced by Standards Australia may be

reproduced, stored in a retrieval system in any form or transmitted by any means without prior permission in writing from

Standards Australia. Permission may be conditional on an appropriate royalty payment. Requests for permission and information on

commercial software royalties should be directed to the head office of Standards Australia.

Standards Australia will permit up to 10 percent of the technical content pages of a Standard to be copied for use

exclusively in-house by purchasers of the Standard without payment of a royalty or advice to Standards Australia.

Standards Australia will also permit the inclusion of its copyright material in computer software programs for no royalty

payment provided such programs are used exclusively in-house by the creators of the programs.

Care should be taken to ensure that material used is from the current edition of the Standard and that it is updated whenever the

Standard is amended or revised. The number and date of the Standard should therefore be clearly identified.

The use of material in print form or in computer software programs to be used commercially, with or without payment, or in

commercial contracts is subject to the payment of a royalty. This policy may be varied by Standards Australia at any time.

AS 16641979

STANDARDS ASSOCIATION OF AUSTRALIA

Australian Standard Rules

for

THE USE OF ALUMINIUM IN STRUCTURES

This is a free 6 page sample. Access the full version online.

SECTION 1. GENERAL

1.1 SCOPE. These Rules (hereinafter referred to as this

Code) apply to the design and fabrication of aluminium

alloy load-carrying members.

1.2 STANDARDS. Unless otherwise noted, a Standard

referred to in this Code is the current edition thereof.

1.3 NEW MATERIALS OR METHODS. This Code

shall not be interpreted to prevent the use of materials,

methods of design or construction not specifically

referred to herein. If it is desired to seek the opinion of

the SAA Committee on Aluminium Structures as to

whether materials other than those specified, or methods

of design or construction not covered herein, are deemed

to comply with the intention of this Code, details of

such materials or methods, including relevant test

results, shall be submitted to the Committee.

NOTE: It will be necessary to seek approval from the appropriate

Authority for the use of new materials or methods.

1.4 DESIGN AND SUPERVISION.

1.4.1 Design. The design of a structure or the part of a

structure to which this Code is applied shall be the

responsibility of an engineer experienced in the design

of such structures.

For the purpose of this Code the term Design Engineer

shall mean the engineer responsible for design and shall

include his representative.

1.4.2 Supervision. All stages of construction of a

structure or the part of a structure to which this Code is

applied shall be adequately supervised to ensure that all

the requirements of the design are satisfied in the

completed structure, the supervision being the

responsibility of either

(a) the design engineer, or

(b) an engineer experienced in such supervision.

For the purposes of this Code, the term Supervising

Engineer shall mean the engineer responsible for

supervision of construction and shall include his

representative.

NOTE: Although the execution of design and supervision may be

delegated to other acceptable persons who need not necessarily be

qualified, Rule 1.4 requires that design and supervision must be the

responsibility of qualified and experienced persons.

Similarly, the Rule does not require the design engineer to be

responsible for supervision also unless he has been assigned this

responsibility specifically. The design engineer and the supervising

engineer need not be the same person.

1.5 DEFINITIONS.

1.5.1 General. For the purpose of this Code, the

definitions in Rules 1.5.2 and 1.5.3 shall apply.

NOTE: Other terms having special meanings are defined in the

Rule in which they occur.

Authority - a body having statutory powers to control

the design and erection of buildings or structures in

the area in which the building or structure

concerned is to be erected.

Contractor - the person, persons or organization

agreeing under a contract to execute the work.

Engineer - a person qualified for Corporate Membership

of the Institution of Engineers, Australia (see

Rule 1.4).

NOTE: This definition does not require that an engineer be a

Corporate Member of the Institution of Engineers, Australia.

1.5.3 Technical Definitions.

Beam or girder - a structural member, other than a

triangulated frame, which supports load primarily

by its internal resistance to bending.

Dead load - the actual mass of all permanent

construction and all permanently installed plant,

equipment, and services required for functional

purposes.

Earthquake forces - all forces on a structure caused by

earthquakes.

Gauge - the transverse spacing between parallel adjacent

lines of fasteners.

Live load - the load assumed to arise from the intended

use or purpose of a structure, including distributed,

concentrated, impact and inertial forces, but

excluding wind, snow and earthquake forces.

Pitch - the centre distance between individual fasteners

in a line of fasteners.

Strut - a compression member including a column or

stanchion.

Wind forces - all forces on a structure caused by wind

pressure.

1.6 NOTATION. The notation used in any of the Rules

of this Code shall have the following meanings with

respect to the structure, or member or condition to

which the Rule is applied, unless otherwise defined

elsewhere in this Code. Unless otherwise stated, a

dimension shall mean a specified dimension.

(a) Maximum permissible stresses.

= the maximum permissible compressive

Fac

stress in an axially loaded strut not

subjected to bending

Fat

Fbc

1.5.2 Administrative Definitions.

Approved - according to the context, approved either by

the Engineer or the appropriate Authority.

Fbt

= the maximum permissible tensile stress

in an axially loaded tension member not

subjected to bending

= the maximum permissible compressive

stress due to bending in a member not

subjected to axial force

= the maximum permissible tensile stress

due to bending in a member not

subjected to axial force

This is a free preview. Purchase the entire publication at the link below:

This is a free 6 page sample. Access the full version online.

AS 1664-1979 Rules for the use of aluminium in

structures (known as the SAA Aluminium

Structures Code) (incorporating Corrig.)

Looking for additional Standards? Visit SAI Global Infostore

Subscribe to our Free Newsletters about Australian Standards in Legislation; ISO, IEC, BSI and more

Do you need to Manage Standards Collections Online?

Learn about LexConnect, All Jurisdictions, Standards referenced in Australian legislation

Do you want to know when a Standard has changed?

Want to become an SAI Global Standards Sales Affiliate?

Learn about other SAI Global Services:

LOGICOM Military Parts and Supplier Database

Metals Infobase Database of Metal Grades, Standards and Manufacturers

Materials Infobase Database of Materials, Standards and Suppliers

Database of European Law, CELEX and Court Decisions

Need to speak with a Customer Service Representative - Contact Us

You might also like

- ASNZS3679.2-2016 Structural Steel - Part 2 Welded I SectionsDocument38 pagesASNZS3679.2-2016 Structural Steel - Part 2 Welded I Sectionsvajahatullahkhan100% (1)

- As-NZS 1252.1-2016 High-Strength Steel Fastener Assemblies For Structural EngineeringDocument56 pagesAs-NZS 1252.1-2016 High-Strength Steel Fastener Assemblies For Structural EngineeringRoan Chua100% (1)

- 化学成分表Document1 page化学成分表Duy NguyenNo ratings yet

- NZS 1664-1-1997 Aluminium Structures Limit State Design PDFDocument8 pagesNZS 1664-1-1997 Aluminium Structures Limit State Design PDFlaiju p b0% (2)

- MEMBRANES Installation Instructions To AS 42002 V1222Document43 pagesMEMBRANES Installation Instructions To AS 42002 V1222Stephen MaartenszNo ratings yet

- Australian/New Zealand Standard: Structural Design Actions Part 0: General PrinciplesDocument8 pagesAustralian/New Zealand Standard: Structural Design Actions Part 0: General PrinciplesMikeChan0% (4)

- As 1163 - Hollow Sections For Structural SteelDocument26 pagesAs 1163 - Hollow Sections For Structural SteelIrene Yu100% (1)

- As3678 2011Document41 pagesAs3678 2011Billy Brikz Yanis100% (1)

- Triton RTA200 SparesDocument2 pagesTriton RTA200 Sparesj_abendstern4688No ratings yet

- As 4912-2002 (Reference Use Only) General Conditions of Contract For The Periodic Supply of GoodsDocument7 pagesAs 4912-2002 (Reference Use Only) General Conditions of Contract For The Periodic Supply of GoodsSAI Global - APACNo ratings yet

- Australian/New Zealand Standard: Aluminium Structures Part 2: Allowable Stress DesignDocument8 pagesAustralian/New Zealand Standard: Aluminium Structures Part 2: Allowable Stress DesignSiddhant Agarwal100% (1)

- As 4750-2003 Electrogalvanized (Zinc) Coatings On Ferrous Hollow and Open SectionsDocument7 pagesAs 4750-2003 Electrogalvanized (Zinc) Coatings On Ferrous Hollow and Open SectionsSAI Global - APACNo ratings yet

- AS 1554 Part 3 Welding Reinforcing SteelDocument29 pagesAS 1554 Part 3 Welding Reinforcing SteelCarlos Velilla MNo ratings yet

- As 3826-1998 Strengthening Existing Buildings For EarthquakeDocument7 pagesAs 3826-1998 Strengthening Existing Buildings For EarthquakeSAI Global - APACNo ratings yet

- AS 1275-1985 Metric Screw Threads For FastnersDocument20 pagesAS 1275-1985 Metric Screw Threads For Fastnersnolan.melhartNo ratings yet

- As 1391-2007 (+a1)Document8 pagesAs 1391-2007 (+a1)Tuan DangNo ratings yet

- As 2334-1980 Steel Nails - Metric SeriesDocument7 pagesAs 2334-1980 Steel Nails - Metric SeriesSAI Global - APACNo ratings yet

- (1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsDocument88 pages(1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsMark Carroll-ChiltsNo ratings yet

- Welding Consumables and Design of Welds in AS 4100-1998 WITH AMENDMENT 1, 2012Document6 pagesWelding Consumables and Design of Welds in AS 4100-1998 WITH AMENDMENT 1, 2012fmboy700100% (1)

- As 1397-2001 Steel Sheet and Strip - Hot-Dipped Zinc-Coated or Aluminium Zinc-CoatedDocument7 pagesAs 1397-2001 Steel Sheet and Strip - Hot-Dipped Zinc-Coated or Aluminium Zinc-CoatedSAI Global - APAC0% (2)

- SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKDocument29 pagesSAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKtracyhopyNo ratings yet

- As Nzs 1252 1996Document29 pagesAs Nzs 1252 1996Khan NiNo ratings yet

- ColdSteel Manual V120Document87 pagesColdSteel Manual V120Terry CheukNo ratings yet

- Australian Standard: Guidelines For The Erection of Building SteelworkDocument0 pagesAustralian Standard: Guidelines For The Erection of Building SteelworkZoran MatevNo ratings yet

- Australian/New Zealand StandardDocument8 pagesAustralian/New Zealand Standardcris0% (1)

- ASI National Structural Steelwork Specification V2 Final PDFDocument44 pagesASI National Structural Steelwork Specification V2 Final PDFSamsuNo ratings yet

- High Strength Structural Bolt Assemblies To As/nzs 1252Document4 pagesHigh Strength Structural Bolt Assemblies To As/nzs 1252Josh Maizidian100% (1)

- CCEC Standards Regulations Guide ENDocument9 pagesCCEC Standards Regulations Guide ENHeru Pribadi100% (1)

- AS 1101.3 - 1987 Graphical Symbols For Engineering - WeldingDocument44 pagesAS 1101.3 - 1987 Graphical Symbols For Engineering - WeldingRobart JacobNo ratings yet

- As Standard ListDocument6 pagesAs Standard ListNguyen Duc DungNo ratings yet

- 1390-1997 Cup Head Bolts With ISO Metric Coarse Pitch ThreadsDocument19 pages1390-1997 Cup Head Bolts With ISO Metric Coarse Pitch ThreadsSean LiongNo ratings yet

- AS 4652.2 1012 Waterproofing Membranes For ExternalDocument6 pagesAS 4652.2 1012 Waterproofing Membranes For ExternalHaisen QinNo ratings yet

- As 3784.1-1990 Coatings For Fire Protection of Building Elements Guide To Selection and Installation of SprayDocument6 pagesAs 3784.1-1990 Coatings For Fire Protection of Building Elements Guide To Selection and Installation of SpraySAI Global - APACNo ratings yet

- BS 709Document17 pagesBS 709vuthuy94No ratings yet

- NZS 3404 (2009) Steel Structures Standard (Materials, Fabrication and Construction)Document163 pagesNZS 3404 (2009) Steel Structures Standard (Materials, Fabrication and Construction)Ba Thanh DinhNo ratings yet

- Previews-ANSI Z97!1!2009 PreDocument12 pagesPreviews-ANSI Z97!1!2009 PreMetzy Nieto SanchezNo ratings yet

- As 3996-2006 Access Covers and GratesDocument7 pagesAs 3996-2006 Access Covers and GratesSAI Global - APACNo ratings yet

- As 4600 Rel NoteDocument14 pagesAs 4600 Rel NoteDiana Ho WyNo ratings yet

- As 3750.18-2002 Paints For Steel Structures Moisture Cure Urethane (Single-Pack) SystemsDocument7 pagesAs 3750.18-2002 Paints For Steel Structures Moisture Cure Urethane (Single-Pack) SystemsSAI Global - APACNo ratings yet

- AS 4676-2000 UtilityPoleDesign PDFDocument8 pagesAS 4676-2000 UtilityPoleDesign PDFBert66Lim0% (1)

- Expansion Joints Seals Brochure Issue 03Document16 pagesExpansion Joints Seals Brochure Issue 03Andrew PetryszakNo ratings yet

- AS4055-1192 Wind Loads For HousingDocument24 pagesAS4055-1192 Wind Loads For Housingdipyaman_19No ratings yet

- As 4100-1998 Steel StructuresDocument11 pagesAs 4100-1998 Steel StructuresSAI Global - APAC0% (6)

- As 1111.1-2000 ISO Metric Hexagon Bolts and Screws - Product Grade C BoltsDocument10 pagesAs 1111.1-2000 ISO Metric Hexagon Bolts and Screws - Product Grade C BoltsSAI Global - APACNo ratings yet

- As 1170 (1) .0-2002 Amdt 1-2003 Structural Design Actions - General PrinciplesDocument1 pageAs 1170 (1) .0-2002 Amdt 1-2003 Structural Design Actions - General PrinciplesDrRat P RatanamalayaNo ratings yet

- Bolt ConnectionsDocument32 pagesBolt ConnectionsMatthew JohnstonNo ratings yet

- As 2867-1986 Farm Structures - General Requirements For Structural DesignDocument6 pagesAs 2867-1986 Farm Structures - General Requirements For Structural DesignSAI Global - APAC100% (1)

- AS 1735.1-2003 General RequirementsDocument48 pagesAS 1735.1-2003 General RequirementsMorten Pedersen100% (1)

- Ton Lanh Mau-Theo JIS 3322Document5 pagesTon Lanh Mau-Theo JIS 3322mrphongvnctNo ratings yet

- Australian StandardDocument33 pagesAustralian StandardJohn RainbirdNo ratings yet

- Australian/New Zealand StandardDocument36 pagesAustralian/New Zealand StandardKako DaNo ratings yet

- AS0908.2 (2000) Cellulose - Cement Products - Flat SheetsDocument22 pagesAS0908.2 (2000) Cellulose - Cement Products - Flat Sheetsjojo351No ratings yet

- As 3588-1996 Shower Bases and Shower ModulesDocument7 pagesAs 3588-1996 Shower Bases and Shower ModulesSAI Global - APACNo ratings yet

- Staad As4100Document28 pagesStaad As4100Amir IskandarNo ratings yet

- As 3495-1997 Authorization Requirements For Plumbing Products - Stainless Steel Non-Pressure Pipes and FittinDocument7 pagesAs 3495-1997 Authorization Requirements For Plumbing Products - Stainless Steel Non-Pressure Pipes and FittinSAI Global - APACNo ratings yet

- As 2577.1-1992 Australian Fire Incident Reporting System Description and ImplementationDocument7 pagesAs 2577.1-1992 Australian Fire Incident Reporting System Description and ImplementationSAI Global - APACNo ratings yet

- Gang-Nail Systems LTD: Top/C BTM/C WEB Wedge Member Grade DepthDocument9 pagesGang-Nail Systems LTD: Top/C BTM/C WEB Wedge Member Grade DepthcetinidrisNo ratings yet

- 4100 1998 - A1 2012Document30 pages4100 1998 - A1 2012Farid TataNo ratings yet

- 10210-10219 - Hollow SectDocument2 pages10210-10219 - Hollow SectBenedictus MurdonoNo ratings yet

- MP01P17Document16 pagesMP01P17MD Francis DuqmNo ratings yet

- Australian Standard: Design of Steel Lattice Towers and MastsDocument7 pagesAustralian Standard: Design of Steel Lattice Towers and Mastsalsager14No ratings yet

- Square and Rectangular HSS and Box-Shaped Members: Material Proper TiesDocument2 pagesSquare and Rectangular HSS and Box-Shaped Members: Material Proper Tiesengineer.mmNo ratings yet

- BL01Document1 pageBL01engineer.mmNo ratings yet

- 01 Ati AtihanDocument1 page01 Ati Atihanengineer.mmNo ratings yet

- SYP BrochureDocument38 pagesSYP Brochureengineer.mmNo ratings yet

- Robert Horne - Skybond Original Technical SheetsDocument1 pageRobert Horne - Skybond Original Technical Sheetsengineer.mmNo ratings yet

- Guidelines SeedplntmtrlDocument2 pagesGuidelines Seedplntmtrlengineer.mmNo ratings yet

- Z App. B.5 - ReactionsDocument1 pageZ App. B.5 - Reactionsengineer.mmNo ratings yet

- AISC Design Guide 1 Table 3.2 PDFDocument1 pageAISC Design Guide 1 Table 3.2 PDFamine ayari100% (1)

- LL LL: Uj Uj Uj I-Cfj (Cfji (1) 0 CyDocument1 pageLL LL: Uj Uj Uj I-Cfj (Cfji (1) 0 Cyengineer.mmNo ratings yet

- Technical Bulletin 11 1-8-30 11Document2 pagesTechnical Bulletin 11 1-8-30 11engineer.mmNo ratings yet

- Anchoring SystemsDocument63 pagesAnchoring Systemsengineer.mmNo ratings yet

- GLASS DESIGN - Monolithic Vision GlassDocument2 pagesGLASS DESIGN - Monolithic Vision Glassengineer.mmNo ratings yet

- NO T To Be Us Edf or PR Ofessi Onal Design Purposes.: Optima - 1 Gen - Alum 12.5 FT L Level52Document1 pageNO T To Be Us Edf or PR Ofessi Onal Design Purposes.: Optima - 1 Gen - Alum 12.5 FT L Level52engineer.mmNo ratings yet

- Materials and Design: Bekir Sadık Ünlü, Enver Atik, Sinan KöksalDocument5 pagesMaterials and Design: Bekir Sadık Ünlü, Enver Atik, Sinan KöksalVinay GopalNo ratings yet

- Mole ConceptDocument17 pagesMole ConceptRaju SinghNo ratings yet

- 06.7. Epd Ass 70 FD Sf2aDocument12 pages06.7. Epd Ass 70 FD Sf2aMoustafaNo ratings yet

- Puritan Medical SwabsDocument8 pagesPuritan Medical SwabsJuan Diego Zutta ArcosNo ratings yet

- CEE 9571 - Advanced Concrete TechnologyDocument3 pagesCEE 9571 - Advanced Concrete TechnologyabimalainNo ratings yet

- Artificial Retina Using Thin Film Transistors: Presented by Y.Mounisha 12W51A04A0Document20 pagesArtificial Retina Using Thin Film Transistors: Presented by Y.Mounisha 12W51A04A0Hemanth KumarNo ratings yet

- Research Paper in SAPDocument6 pagesResearch Paper in SAPMohammad Rahim RahimiNo ratings yet

- Chemistry Chemistry of of Polymers Polymers: Ingenierie Des Materiaux PolymeresDocument16 pagesChemistry Chemistry of of Polymers Polymers: Ingenierie Des Materiaux PolymeresAndri SomantriNo ratings yet

- Week 3 Video QuestionsDocument1 pageWeek 3 Video Questionsapi-254428474No ratings yet

- Entropy and The Second Law of Thermodynamics: Larry Brown Tom HolmeDocument50 pagesEntropy and The Second Law of Thermodynamics: Larry Brown Tom Holmemuhammad ali shakeelNo ratings yet

- Fuel Types Info & Burning StovesDocument33 pagesFuel Types Info & Burning StovesSkilledWizardNo ratings yet

- Washer-Disinfector G 7823 / G 7824: Operating InstructionsDocument56 pagesWasher-Disinfector G 7823 / G 7824: Operating InstructionsRichpleinNo ratings yet

- Five Day - Biochemical Oxygen DemandDocument21 pagesFive Day - Biochemical Oxygen DemandAG-Metal /Tretman Otpadnih Voda/Wastewater TreatmentNo ratings yet

- Genapol Ba 040Document1 pageGenapol Ba 040malek kaanicheNo ratings yet

- Dr.M.P.Bhatti Sehar Afzal 1009-BH-CHEM-16: Government College University LahoreDocument7 pagesDr.M.P.Bhatti Sehar Afzal 1009-BH-CHEM-16: Government College University LahoreAayat MughalNo ratings yet

- Revaluing Mine Waste Rock For Carbon Capture and StorageDocument17 pagesRevaluing Mine Waste Rock For Carbon Capture and StorageDedi Geo SetionoNo ratings yet

- Physical Properties of Some Common Refrigerants Are IndicatedDocument8 pagesPhysical Properties of Some Common Refrigerants Are IndicatedRajeshSekarNo ratings yet

- COMP.ahsbvamdhpDocument6 pagesCOMP.ahsbvamdhpLIYA B RAJENDRANNo ratings yet

- Che - F241 - 1180 - HT - Bits PilaniDocument4 pagesChe - F241 - 1180 - HT - Bits Pilanivan1234No ratings yet

- Exercise - III: Subjective Level-IDocument6 pagesExercise - III: Subjective Level-IRishabh AgarwalNo ratings yet

- 3.6.5 Bi-Metal Kwik-Flex Self-Drilling Screws (Pg. 168-170) - 2Document4 pages3.6.5 Bi-Metal Kwik-Flex Self-Drilling Screws (Pg. 168-170) - 2LauraMilenaHernándezTorresNo ratings yet

- Vapour Barrier NotesDocument46 pagesVapour Barrier NotesJANVI KRISHNo ratings yet

- Vapour Compression SystemDocument24 pagesVapour Compression SystemAbdullah100% (1)

- The Handbook of Hazardous Materials Spills Technology 39. Sodium CyanideDocument22 pagesThe Handbook of Hazardous Materials Spills Technology 39. Sodium CyanideJoelCristobal100% (1)

- Seismic Isolation Systems With Lead Rubber Bearings (LRB)Document9 pagesSeismic Isolation Systems With Lead Rubber Bearings (LRB)evil_jotNo ratings yet

- Advanced Construction Techniques and Materials: Unit 4Document169 pagesAdvanced Construction Techniques and Materials: Unit 4Bharath SrinivasanNo ratings yet

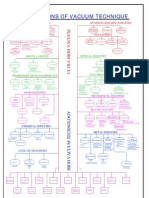

- Applications of Vacuum TechniqueDocument1 pageApplications of Vacuum Techniquesynayak100% (2)

- 9th Class Chemistry Test Paper 6Document1 page9th Class Chemistry Test Paper 6Amna ShakeelNo ratings yet

- Molecular Mechanisms of Ultrafiltration Membrane FoulingDocument10 pagesMolecular Mechanisms of Ultrafiltration Membrane FoulingtehtnicaNo ratings yet