Mpu 6000 Ev Board1

Mpu 6000 Ev Board1

Uploaded by

Muhammad Firza AsharCopyright:

Available Formats

Mpu 6000 Ev Board1

Mpu 6000 Ev Board1

Uploaded by

Muhammad Firza AsharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Mpu 6000 Ev Board1

Mpu 6000 Ev Board1

Uploaded by

Muhammad Firza AsharCopyright:

Available Formats

Document Number: AN-MPU-6000EVB-00

MPU-6000/MPU-6050 EV Board User Guide Revision: 01

Release Date: 1/12/2011

MPU-6000/MPU-6050

9-Axis Evaluation Board

User Guide

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 1 AN-MPU-6000EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Document Number: AN-MPU-6000EVB-00

MPU-6000/MPU-6050 EV Board User Guide Revision: 01

Release Date: 1/12/2011

Table of Contents

1. REVISION HISTORY ................................................................................................................................... 3

2. PURPOSE ................................................................................................................................................... 4

2.1 USAGE................................................................................................................................................ 4

2.2 RELATED DOCUMENTS ........................................................................................................................ 4

3. MPU-6000 9-AXIS EV BOARD OVERVIEW .............................................................................................. 4

3.1 MPU-6000 KEY FUNCTION AND PIN-OUTS ........................................................................................... 5

3.2 MPU-6000 VS. MPU-6050 ................................................................................................................. 5

3.3 MPU-6000 BUS CONNECTION ............................................................................................................. 5

4. SCHEMATIC................................................................................................................................................ 7

5. BILL OF MATERIALS ................................................................................................................................. 8

6. POWER SUPPLY CONNECTIONS ............................................................................................................ 8

7. MPU-6000 EVB CONNECTOR SIGNALS DESCRIPTION ........................................................................ 9

7.1 CONNECTING THE FSYNC LINE ......................................................................................................... 11

7.2 SERIAL BUS LEVELS, SPEEDS AND TERMINATIONS .............................................................................. 11

8. DATA GATHERING OPTIONS ................................................................................................................. 11

8.1 CONNECTION TO ARM EVB............................................................................................................... 11

8.2 USE OF MPU-6000 WITHOUT ARM EVB BOARD ................................................................................ 12

9. SPECIAL INSTRUCTIONS ....................................................................................................................... 12

9.1 ELECTROSTATIC DISCHARGE SENSITIVITY .......................................................................................... 12

9.2 BOARD LAYOUT................................................................................................................................. 12

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 2 AN-MPU-6000EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Document Number: AN-MPU-6000EVB-00

MPU-6000/MPU-6050 EV Board User Guide Revision: 01

Release Date: 1/12/2011

1. Revision History

Date Revision Description

1/12/2011 01 Initial release

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 3 AN-MPU-6000EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Document Number: AN-MPU-6000EVB-00

MPU-6000/MPU-6050 EV Board User Guide Revision: 01

Release Date: 1/12/2011

2. Purpose

This document describes the hardware and circuitry on the MPU-6000 and MPU-6050 (collectively

called the MPU-60X0) 9-Axis Evaluation (EV) Board. This EVB is used for evaluating the MPU-6000

and MPU-6050. It covers applying the EV board to a larger system, understanding key signals and

circuit functions, hardware jumper settings, and port connectors.

2.1 Usage

This evaluation board provides nine axes of motion sensing, comprised of:

Digital-output X-, Y-, and Z-Axis angular rate sensors (gyroscopes) with a user-

programmable full-scale range of 250, 500, 1000, and 2000/sec

Digital-output tri-axis accelerometer with a programmable full scale range of 2g, 4g,

8g and 16g

Digital-output tri-axis compass with a full scale range of 1200T

Data is measured using on-chip ADCs and is transmitted over IC or SPI interfaces.

The Evaluation board may be used by itself using SPI or IC serial communications interfaces.

Alternatively, it may be connected to InvenSenses ARM Evaluation Board (INVARMEVB) for

connectivity to a host computer using a USB interface.

2.2 Related Documents

The following documents are recommended for more fully understanding the products and

systems described in this documents.

MPU-6000 Product Specification

AK8975/AK8975C Datasheet

3. MPU-6000 9-Axis EV Board Overview

The MPU-6000 9-Axis EV Board contains the MPU-6000 digital Motion Processing Unit and the AKM

compass. Additionally, it contains a number of solder-across jumper points that permit several circuit

configurations.

Please refer to Figures 1 & 5. The EV Board is populated on its top side only for ease of measurement

access. The 10x2 customer header connector (JP14) is designed to connect with the InvenSense ARM

Evaluation Board (INVARMEVB), which is a host microcontroller board useful for adapting the MPU-

6000 9-Axis EV Board to a personal computer via its USB port.

The 5x2 extension factory header (JP13) is intended for connecting additional devices to the EV Board,

such as a camera image stabilization processor, or a digital-output compass, etc. The 3-pin power

selection header (JP12) is used to select which voltage supply is fed to the MPU-6000. The 3-pin

VLOGIC selection header (JP6) is used to select between 3 V and VDD as the logic supply voltage.

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 4 AN-MPU-6000EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Document Number: AN-MPU-6000EVB-00

MPU-6000/MPU-6050 EV Board User Guide Revision: 01

Release Date: 1/12/2011

3.1 MPU-6000 Key Function and Pin-outs

The MPU-60X0 EVB is a fully-tested evaluation board, providing for quick evaluation of the MPU-

60X0s X- , Y- , and Z- axis angular rate gyroscope + X- , Y- , and Z- axis accelerometer . MPU-

60X0 has a primary interface to talk to the application processor and a secondary interface to

communicate to an external sensor. MPU-60X0 EVB comes preloaded with a AKM 3-axis

compass to let the user experience a 9-axis sensor fusion output from MPU-60X0s Motion

Processing Unit. The MPU-60X0 uses InvenSenses proprietary MEMS technology with driven

vibrating masses to produce a functionally complete, low-cost motion sensor. All required

conditioning electronics are integrated into a single chip measuring 4 x 4 x 0.9mm. It

incorporates X- , Y- and Z-axis low-pass filters and an EEPROM for on-chip factory calibration of

the sensor. Factory trimmed scale factors eliminate the need for external active components and

end-user calibration. A built-in Proportional-To-Absolute-Temperature (PTAT) sensor provides

temperature compensation information. The product is lead-free and Green Compliant.

3.2 MPU-6000 vs. MPU-6050

2

The MPU-6000 and MPU-6050 are identical, except that the MPU-6050 supports the I C serial

2

interface only, and has a separate VLOGIC reference pin. The MPU-6000 supports both I C and

SPI interfaces and has a single supply pin, VDD, which is both the devices logic reference supply

and the analog supply for the part. The table below outlines these differences:

Table 1. Primary Differences between MPU-6000 and MPU-6050

Part / Item MPU-6000 MPU-6050

VDD 2.5V5%, 3.0V5%, or 2.5V5%, 3.0V5%, or

3.3V5%. 3.3V5%.

VLOGIC n/a 1.71V to VDD

2 2

Serial Interfaces Supported I C, SPI IC

Pin 8 /CS VLOGIC

Pin 9 AD0/SDO AD0

Pin 23 SCL/SCLK SCL

Pin 24 SDA/SDI SDA

3.3 MPU-6000 Bus Connection

The MPU-60X0 EVB communicates to a system processor through the customer header using

2

the I C serial interface. The device always acts as a slave when communicating to the system

processor.

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 5 AN-MPU-6000EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Document Number: AN-MPU-6000EVB-00

MPU-6000/MPU-6050 EV Board User Guide Revision: 01

Release Date: 1/12/2011

Figure 1. Top side of the MPU-60X0 9-Axis EV Board

Top View Top View

SCL/SCLK

CLKOUT

SDA/SDI

CLKOUT

CPOUT

CPOUT

RESV

RESV

RESV

RESV

SDA

SCL

24 23 22 21 20 19 24 23 22 21 20 19 +Z

CLKIN 1 18 GND CLKIN 1 18 GND

+Z +Y

NC 2 17 NC NC 2 17 NC

M

NC 3 16 NC NC 3 16 NC MP PU- +Y

MPU-6000 U - 600

MPU-6050 60

50 0

NC 4 15 NC NC 4 15 NC

NC 5 14 NC NC 5 14 NC

+X +X

AUX_DA 6 13 VDD AUX_DA 6 13 VDD

7 8 9 10 11 12 7 8 9 10 11 12

AUX_CL

/CS

AD0/SDO

REGOUT

FSYNC

INT

AUX_CL

VLOGIC

AD0

REGOUT

FSYNC

INT

QFN Package QFN Package Orientation of Axes of Sensitivity and

24-pin, 4mm x 4mm x 0.9mm 24-pin, 4mm x 4mm x 0.9mm Polarity of Rotation

Figure 2. MPU-6000 QFN Package (Top View) 24-pin 4mm x 4mm x 0.9mm & Axis Orientation

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 6 AN-MPU-6000EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Document Number: AN-MPU-6000EVB-00

MPU-6000/MPU-6050 EV Board User Guide Revision: 01

Release Date: 1/12/2011

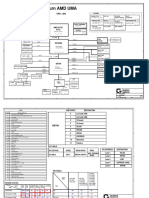

4. Schematic

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 7 AN-MPU-6000EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Document Number: AN-MPU6000EVB-01

MPU-6000 EV Board Application Note

Revision: 01

Release Date: 12/17/10

5. Bill of Materials

Table 2. Bill of Material

Item Quantity Reference Part PCB Footprint

BP13,BP14,BP15,BP16,BP17,

1 7 BP18,BP19 0.1uF C0402

2 1 C11 2200pF/50V/0402 C0402

3 2 C13,C12 0.47uF/0603 C0603

4 1 C14 0.033uF/0402 C0402

7 2 JP6,JP12 HEADER 3, 80mil, 180D, Male J79\3S

HEADER 5X2, Male, 180D,

8 1 JP13 2.0mmx2.0mm SIP2X5N2

HEADER 14X2, Male, 90D,

9 1 JP14 2.54mmx2.54mm HDB2X14NRA

10 1 R28 1K/0402 R0402

11 2 R30,R29 2K/0402 R0402

12 3 R31,R32,R40 0/0402 R0402

14 4 R34,R35,R37,R38 0R R0402

15 1 R36 100K/0402 R0402

16 1 R39 1M R0402

18 2 R44,R42 10K/0402 R0402

19 1 R43 2R2/0603 R0603

MPU, 24-Lead QFN (4mm x 4mm qfn24_4x4(0.5pitch

22 1 U5 x 0.9mm) )

QFN16_4X4(0.65PI

23 1 U6 AK8975 TCH)

24 1 U7 YB1210ST25R300 SOT235

6. Power Supply Connections

JP6 and JP12 are 3 header-pin plug-in jumpers which allow users to select between on-board

LDO and external DC supply for powering the MPU-60X0. For details, please refer Table 3.

Power Selection Jumpers.

The on-board 3.0V LDO (Low-dropout voltage regulator) is a low-noise version. Its output is

called 3V0 on the schematic, and using it will assure that the gyroscope and accelerometer

performance will meet intended specifications.

InvenSense, Inc., 1197 Borregas, Ave. Sunnyvale, CA 94089, USA 8 AN-MPU6000EVB-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

MPU-6000/MPU-6050 EV Board User Guide Document Number: AN-MPU-6000EVB-00

Revision: 01

Release Date: 1/12/2011

Selecting the raw Vcc line to power the chip is generally done while designing and evaluating

an embedded platform, where the host processor and related electronics needs full control

over the motion processing chipsets power supply.

When the user intends to use the on board LDO 3V0 power, external Vcc must be provided

with atleast 3.7V to ensure the LDO works properly.

If the user provides Vcc with 5V, JP6 and JP12 must be set as 1-2 short since the MPU-

60X0 VDD and VLOGIC operation range is 2.1V to 3.6V.

7. MPU-60X0 EVB connector signals description

Table 3. Power Selection Jumpers

JP6 Pin Number Signal description

1-2 short MPU-6050 VLOGIC = 3V (from LDO, Vcc>3.7 V)

2-3 short MPU-6050 VLOGIC = Vcc (from external source)

JP12 Pin Number Signal description

1-2 short MPU-60X0 VDD = 3V (from LDO, Vcc>3.7V)

2-3 short MPU-60X0 VDD = Vcc (from external source)

Table 4. User Interface Connector Signals

JP14 Pin Number Signal description

1 Reserved

3 Reserved

5 Reserved

7 INT, MPU-60X0 INTERRUPT output to controller

9 Reserved

11 MPU-60X0 CLK_I, External Clock Input

13 MPU-60X0 CPOUT, Charge pump Output

15 GND

17 GND

19 3V

21 MPU-60X0 FSYNC

Receive power from ARM-7 Controller Board or external. It should be 5V,

23 with >200mA

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 9 AN-MPU6000-EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

MPU-6000/MPU-6050 EV Board User Guide Document Number: AN-MPU-6000EVB-00

Revision: 01

Release Date: 1/12/2011

JP14 Pin Number Signal description

27 NC

2 NC

4 NC

6 NC

8 MPU-60X0 SPI CS

10 Reserved

12 NC

14 MPU-60X0 EVB on board LDO enable

16 NC

18 MPU-60X0 REGOUT

20 MPU-60X0 IC SCL or MPU-6000 SPI SCLK

22 MPU-60X0 IC SDA or MPU-6000 SPI SDI

24 MPU-60X0 IC Addr or MPU-6000 SPI SDO

26 NC

28 NC

25 NC

Table 5. Extended Factory Connector

JP13 Pin Number Signal description

VCC, power from ARM-7 controller board or external power. It should be

1 5V, with >200mA

3 GND

5 NC

7 NC

9 NC

2 3V

4 MPU-60X0 IC SCL or MPU-6000 SPI SCLK

6 MPU-60X0 IC SDA or MPU-6000 SPI SDI

8 MPU-60X0 IC Addr or MPU-6000 SPI SDO

10 MPU-60X0 FSYNC

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 10 AN-MPU6000-EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

MPU-6000/MPU-6050 EV Board User Guide Document Number: AN-MPU-6000EVB-00

Revision: 01

Release Date: 1/12/2011

7.1 Connecting the FSYNC Line

The FSYNC line is intended for use in a cameras image-stabilization system. It is an input

from the camera platform to the EV Board, and is intended to synchronize the MPU-60X0

serial bus transfer with the master timing set by the camera system. FSYNC can originate

from the host processor via JP14 pin-21, or from JP13 pin-10. There is no external pull-up

termination for the FSYNC line.

7.2 Serial bus Levels, Speeds and Terminations

The MPU-60X0 supports IC up to 400kHz, and MPU-6000 supports SPI up to 1MHz serial

clock rates. The IC bus open drain pull up resistors are connected to either 3.0V or an

external provided Vcc (3V or 5V depends on user). The pull up level is selected by JP6.

Please refer to Table 3. Power Selection Jumpers.

8. Data Gathering Options

The MPU-60X0 Digital Sensor Data is available at the User Header. Alternatively, for connectivity

with a host PC, an InvenSense ARM Processor Board may be used.

8.1 Connection to ARM EVB

For communications via USB to a host computer, the MPU-60X0 EVB can be connected to

InvenSenses ARM processor board, the INV-ARMEVB.

The photo below shows the connection of MPU-60X0 to INV-ARMEVB. Connection between

the two boards is made via the user header.

Figure 4. MPU-60X0 EVB connected to ARM Board

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 11 AN-MPU6000-EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

MPU-6000/MPU-6050 EV Board User Guide Document Number: AN-MPU-6000EVB-00

Revision: 01

Release Date: 1/12/2011

8.2 Use of MPU-60X0 without ARM EVB board

IC and SPI signals are available on JP13 and JP14. User can develop tools to communicate

with MPU-60X0. There is no bus mode selection setting needed.

9. Special Instructions

9.1 Electrostatic Discharge Sensitivity

The MPU-6050 gyro+accel can be permanently damaged by an electrostatic discharge. ESD

precautions for handling and storage are recommended.

9.2 Board Layout

The MPU-60X0 EV board is a 4 layer PCB with 38mm x 32mm dimension.

Figure 5. MPU-60X0 Board Layout: Top View & Bottom View

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 12 AN-MPU6000-EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

MPU-6000/MPU-6050 EV Board User Guide Document Number: AN-MPU-6000EVB-00

Revision: 01

Release Date: 1/12/2011

This information furnished by InvenSense is believed to be accurate and reliable. However, no responsibility is assumed by InvenSense

for its use, or for any infringements of patents or other rights of third parties that may result from its use. Specifications are subject to

change without notice. InvenSense reserves the right to make changes to this product, including its circuits and software, in order to

improve its design and/or performance, without prior notice. InvenSense makes no warranties, neither expressed nor implied, regarding

the information and specifications contained in this document. InvenSense assumes no responsibility for any claims or damages arising

from information contained in this document, or from the use of products and services detailed therein. This includes, but is not limited

to, claims or damages based on the infringement of patents, copyrights, mask work and/or other intellectual property rights.

Certain intellectual property owned by InvenSense and described in this document is patent protected. No license is granted by

implication or otherwise under any patent or patent rights of InvenSense. This publication supersedes and replaces all information

previously supplied. Trademarks that are registered trademarks are the property of their respective companies. InvenSense sensors

should not be used or sold in the development, storage, production or utilization of any conventional or mass-destructive weapons or for

any other weapons or life threatening applications, as well as in any other life critical applications such as medical equipment,

transportation, aerospace and nuclear instruments, undersea equipment, power plant equipment, disaster prevention and crime

prevention equipment.

InvenSenseTM is a registered trademark of InvenSense, Inc.; MPU-60X0TM, MPU-6000 TM

, and MPU-6050 TM

are trademarks of

InvenSense, Inc.

2010 InvenSense, Inc. All rights reserved.

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, Ca 94089, USA 13 AN-MPU6000-EVB-00

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 2011 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

You might also like

- Paccar Multi-Plex 2010Document195 pagesPaccar Multi-Plex 2010Luis Tepezano100% (6)

- Comfortpoint Open: Cpo-Pc200 Plant ControllerDocument10 pagesComfortpoint Open: Cpo-Pc200 Plant Controllerstefanus valorantNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- C-Arm HF 49R Instt - ServiceDocument55 pagesC-Arm HF 49R Instt - ServiceAHMED AWAD ALI100% (1)

- Chloride 70-NetDocument54 pagesChloride 70-NetMarín Ramírez García0% (1)

- Paccar 2010 Multiplexed Electrical System Sevice Manual P30 1011 PDFDocument104 pagesPaccar 2010 Multiplexed Electrical System Sevice Manual P30 1011 PDFJohanny Barrera Hurtado100% (2)

- Jenway 6310 Service Manual PDFDocument84 pagesJenway 6310 Service Manual PDFArdo IsküllNo ratings yet

- Oec 9600imaging Workstation Illustrated Parts ManualDocument95 pagesOec 9600imaging Workstation Illustrated Parts ManualJoe B Bestial100% (1)

- PaccarServiceManual2005 2010Document189 pagesPaccarServiceManual2005 2010Eric Porter100% (21)

- ServiceManualNamux4English PDFDocument112 pagesServiceManualNamux4English PDFFernando Marin100% (8)

- EE008 Load Flow Analysis of IEEE-14 Bus Using E-TAP SoftwareDocument9 pagesEE008 Load Flow Analysis of IEEE-14 Bus Using E-TAP SoftwareJULFANRI SIRAITNo ratings yet

- MT7621 Datasheet v0 3Document44 pagesMT7621 Datasheet v0 3Forrest MengNo ratings yet

- Operating Instructions Control Panels: CP620-x, CP620-WEB-x CP630-x, CP630-WEB-x CP635-x, CP635-WEB-xDocument25 pagesOperating Instructions Control Panels: CP620-x, CP620-WEB-x CP630-x, CP630-WEB-x CP635-x, CP635-WEB-xFabio Passos GuimaraesNo ratings yet

- A06B 6093 H101 β SERIES SERVO AMPLIFIER UNIT FANUC MANUAL PDFDocument74 pagesA06B 6093 H101 β SERIES SERVO AMPLIFIER UNIT FANUC MANUAL PDFNiteshNo ratings yet

- Installation and Operation Manual: ACU-1000 Intelligent Interconnect SystemDocument224 pagesInstallation and Operation Manual: ACU-1000 Intelligent Interconnect SystemMarco PoloNo ratings yet

- PB-002141-00 - E Spectra Service ManualDocument174 pagesPB-002141-00 - E Spectra Service Manualtecvision.assistenciaNo ratings yet

- Operators Manual CE S8Document71 pagesOperators Manual CE S8Nicolae ArpentiiNo ratings yet

- Jenway 6310 Service ManualDocument84 pagesJenway 6310 Service ManualJorge OliveiraNo ratings yet

- Crankshaft Position Sensor (Inductive - Floating) - RunningDocument4 pagesCrankshaft Position Sensor (Inductive - Floating) - Runningopenjavier5208No ratings yet

- Intek M-495 Power ManualDocument40 pagesIntek M-495 Power ManualSteve FahrniNo ratings yet

- HTTPSWWW - Estuneurope.euwp ContentuploadsdownloadManualiAzionamentiETS Series AC Servo User Manual PDFDocument144 pagesHTTPSWWW - Estuneurope.euwp ContentuploadsdownloadManualiAzionamentiETS Series AC Servo User Manual PDFRuanzinn FFNo ratings yet

- Infineon EVAL ICE2QR0680Z RD v01 - 01 EN 1488413Document17 pagesInfineon EVAL ICE2QR0680Z RD v01 - 01 EN 1488413Sutirtha MaitiNo ratings yet

- SPL PortatilDocument295 pagesSPL PortatilInfo e TecNo ratings yet

- VanJee ETC SolutionDocument15 pagesVanJee ETC SolutionAndy Mauricio Gonzalez HerreraNo ratings yet

- Installation / User Manual: Apsystems Yc600 MicroinverterDocument24 pagesInstallation / User Manual: Apsystems Yc600 MicroinverterCarlos BrancoNo ratings yet

- i-VIZION MANUALEDocument124 pagesi-VIZION MANUALEpierresamuel394No ratings yet

- EVK-M8CAM UserGuide (UBX-14002462)Document24 pagesEVK-M8CAM UserGuide (UBX-14002462)bruno magalhãesNo ratings yet

- Dash-2000 V3 ServiceDocument228 pagesDash-2000 V3 ServiceRaimundo JeanNo ratings yet

- Serv7106 V09N02 TXTDocument44 pagesServ7106 V09N02 TXTmario saavedra tarazonaNo ratings yet

- UHF Integrated Long-Range Reader: Installation and User ManualDocument24 pagesUHF Integrated Long-Range Reader: Installation and User ManualARMAND WALDONo ratings yet

- EVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)Document27 pagesEVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)jaychenonlyNo ratings yet

- MCU ManualDocument20 pagesMCU ManualJoaquínNo ratings yet

- Yaskawa P1000 EIP Install ManualDocument62 pagesYaskawa P1000 EIP Install Manualsrizk1_392564367No ratings yet

- AMC HWManual DigiFlex Panel CANopenDocument74 pagesAMC HWManual DigiFlex Panel CANopenebrazolinNo ratings yet

- Eb Imu 3000 00 01Document14 pagesEb Imu 3000 00 01Giuseppe OnorevoliNo ratings yet

- EVK-M8U UserGuide (UBX-15023994)Document26 pagesEVK-M8U UserGuide (UBX-15023994)bruno magalhãesNo ratings yet

- Multicube ManualDocument39 pagesMulticube ManualArturo DifuntorumNo ratings yet

- Affordable 9 DoF Sensor Fusion kriswiner-MPU6050 Wiki GitHubDocument18 pagesAffordable 9 DoF Sensor Fusion kriswiner-MPU6050 Wiki GitHubkonyeinNo ratings yet

- Antena Gps Hemisphere A101Document34 pagesAntena Gps Hemisphere A101aminatrixNo ratings yet

- ST680 User ManualDocument8 pagesST680 User ManualDaipi DebnathNo ratings yet

- Isolated Amplifier MIU 10: Instruction ManualDocument10 pagesIsolated Amplifier MIU 10: Instruction ManualRobbie Thompson100% (1)

- Isolated Amplifier MIU 10: Instruction ManualDocument10 pagesIsolated Amplifier MIU 10: Instruction ManualRobbie ThompsonNo ratings yet

- 5000 RTDocument44 pages5000 RTJeffeers PrietoNo ratings yet

- Riello TechsdlDocument32 pagesRiello TechsdldkelicNo ratings yet

- Uanalyst 2200 Interactive Timing Analyzer Users Manual Jan85Document230 pagesUanalyst 2200 Interactive Timing Analyzer Users Manual Jan85marcin.miskiewicz.tmeNo ratings yet

- Samsung HT A100t Xef HT Xa100t XefDocument122 pagesSamsung HT A100t Xef HT Xa100t XefJose Perez100% (3)

- 00.040.601 SonixMDP-SP-OP Extended User Manual C 131219Document484 pages00.040.601 SonixMDP-SP-OP Extended User Manual C 131219ROMAN88% (8)

- Seven Service ManualDocument84 pagesSeven Service ManualDavid EguezNo ratings yet

- Anritsu MS462XX VECTOR NETWORK MEASUREMENT SYSTEM 10410-00205Document205 pagesAnritsu MS462XX VECTOR NETWORK MEASUREMENT SYSTEM 10410-00205box4x4No ratings yet

- Invensense Arm Reference Board: Application NoteDocument11 pagesInvensense Arm Reference Board: Application NoteBrajesh ChandraNo ratings yet

- Tmo 963 PDFDocument112 pagesTmo 963 PDFAlex Parra100% (3)

- LCI-80x - User Manual - Rev. DDocument97 pagesLCI-80x - User Manual - Rev. DMike ClancyNo ratings yet

- Uanalyst 2100 Interactive State Analyzer Users Manual Jan85Document258 pagesUanalyst 2100 Interactive State Analyzer Users Manual Jan85marcin.miskiewicz.tmeNo ratings yet

- Mitsubishi UPS - Owners Manual 98AB SMS V20Document67 pagesMitsubishi UPS - Owners Manual 98AB SMS V20Marcelo BenacchioNo ratings yet

- Pact Series: Service Interface For Masterpact NT/NW, Compact NS, and Powerpact P-, R-Frame Circuit BreakersDocument10 pagesPact Series: Service Interface For Masterpact NT/NW, Compact NS, and Powerpact P-, R-Frame Circuit BreakersMohamad MakramNo ratings yet

- Magnum Version 8 Manual Rev1.7Document172 pagesMagnum Version 8 Manual Rev1.7shahzad32552372100% (1)

- App Note 3 - Motion Driver 6.12 Porting GuideDocument14 pagesApp Note 3 - Motion Driver 6.12 Porting GuideDamianNo ratings yet

- X-Ray System TroubleshootingDocument46 pagesX-Ray System TroubleshootingCompuWan PolancoNo ratings yet

- 9700 Owners ManualDocument65 pages9700 Owners ManualEleusis MarquezNo ratings yet

- Guide To Installation & Operations: Swivel Mount Personal Viewing Monitor Model #: Ai-56X-Swx (-Map)Document15 pagesGuide To Installation & Operations: Swivel Mount Personal Viewing Monitor Model #: Ai-56X-Swx (-Map)Jaime ArroyoNo ratings yet

- Infineon IGBT POWER SUPPLYDocument22 pagesInfineon IGBT POWER SUPPLYorkun burkayNo ratings yet

- EnergyPak Plus User Manual - ENDocument8 pagesEnergyPak Plus User Manual - ENAnand sNo ratings yet

- Unit Peperiksaan Fakulti Sains Sosial - Kertas Soalan Peperiksaan Akhir Semester 1 Sesi 2005-2006 PDFDocument169 pagesUnit Peperiksaan Fakulti Sains Sosial - Kertas Soalan Peperiksaan Akhir Semester 1 Sesi 2005-2006 PDFDzulizah Bte SantaNo ratings yet

- Aldi MD8083-2Document1 pageAldi MD8083-2ashesasksNo ratings yet

- Multi-Biometric T&A and Access Control Terminal: FeaturesDocument2 pagesMulti-Biometric T&A and Access Control Terminal: FeaturesMohammad Javad MousaviNo ratings yet

- E Catalog sk8550 1Document2 pagesE Catalog sk8550 1sgwestdepotNo ratings yet

- E7A71v1 0Document87 pagesE7A71v1 0p56jvgqcpnNo ratings yet

- 3 Transistor Headphone Amplifier - Class ABDocument3 pages3 Transistor Headphone Amplifier - Class ABszolid79No ratings yet

- Hepburn AMD UMA: VER: A00Document70 pagesHepburn AMD UMA: VER: A00avensyeNo ratings yet

- 7" HMI PI3070i-N: SpecificationsDocument1 page7" HMI PI3070i-N: SpecificationsJennifer NúñezNo ratings yet

- Safety and Reference: Owner'S ManualDocument46 pagesSafety and Reference: Owner'S ManualKushal BnNo ratings yet

- Technical Specifications: SUA3000RMI2UDocument2 pagesTechnical Specifications: SUA3000RMI2UDodai アルド SaputraNo ratings yet

- Nu Horizons Electronics - Portal February 2009Document10 pagesNu Horizons Electronics - Portal February 2009Nu HorizonsNo ratings yet

- Dia Del PadreDocument24 pagesDia Del Padrepssef.marketinglpNo ratings yet

- Group 8 - Boarding House Management System - OOPDocument21 pagesGroup 8 - Boarding House Management System - OOPkrzyxynn0916No ratings yet

- Catalogo General FRIMED Refrigeracion 2019Document22 pagesCatalogo General FRIMED Refrigeracion 2019Mauren Lopez100% (1)

- Circuit 1 Lesson LESSONDocument351 pagesCircuit 1 Lesson LESSONRoscarl Gorospe100% (1)

- DH61CR ProductGuide03 EnglishDocument78 pagesDH61CR ProductGuide03 EnglishCarlos Miguel RamirezNo ratings yet

- CANcaseXL Log Config User ManualDocument82 pagesCANcaseXL Log Config User Manualad.hjzhuNo ratings yet

- POLAR Compucut ProductsheetDocument2 pagesPOLAR Compucut ProductsheetKanniyappan GounderNo ratings yet

- Manual Service 50UHDDocument54 pagesManual Service 50UHDoscar herediaNo ratings yet

- Biometric Electronic Wallet For DigitalDocument8 pagesBiometric Electronic Wallet For DigitalHemanth PNo ratings yet

- Nexio Amp 3601 Hdi User Guide 20140408Document149 pagesNexio Amp 3601 Hdi User Guide 20140408Jose Luis Herrera ManriqueNo ratings yet

- OS Update Application: User's GuideDocument9 pagesOS Update Application: User's GuideNirut KaewketNo ratings yet

- Hioki - Electrical Measuring Instruments - 2005Document64 pagesHioki - Electrical Measuring Instruments - 2005Vajda JánosNo ratings yet

- ThinkPad T490s Datasheet ENDocument2 pagesThinkPad T490s Datasheet ENmh.moutaouakilNo ratings yet

- SBC GX533 Datashee-1019413955tDocument2 pagesSBC GX533 Datashee-1019413955tamanagofficialNo ratings yet

- An4938 Getting Started With Stm32h74xig and Stm32h75xig Hardware Development Stmicroelectronics PDFDocument47 pagesAn4938 Getting Started With Stm32h74xig and Stm32h75xig Hardware Development Stmicroelectronics PDFMax INo ratings yet

- 5V 1A Mini/Micro USB 18650 Lithium Battery Charger Board Module TP4056Document5 pages5V 1A Mini/Micro USB 18650 Lithium Battery Charger Board Module TP4056francesco marincolaNo ratings yet