Autoclaves - Generic Assessment - L Use of Autoclaves

Autoclaves - Generic Assessment - L Use of Autoclaves

Uploaded by

aKureishiCopyright:

Available Formats

Autoclaves - Generic Assessment - L Use of Autoclaves

Autoclaves - Generic Assessment - L Use of Autoclaves

Uploaded by

aKureishiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Autoclaves - Generic Assessment - L Use of Autoclaves

Autoclaves - Generic Assessment - L Use of Autoclaves

Uploaded by

aKureishiCopyright:

Available Formats

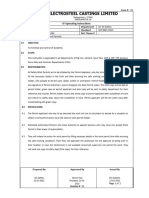

SCHOOL OF MATERIALS RISK ASSESSMENT FORM

Assessors Unit : Building & Room of Task

Task Title / Description of procedure: General use of Autoclaves

Hazards and potential harm (Risks) involved Who might be Actions to prevent or control harm (control measures) Risk assessment

in the task harmed score

(What are the dangers and likely injuries?) (including training, maintenance, servicing) (see below)

1. Electrical hazard causing electric shock User and those in 1. Ensure all electrical equipment is PAT tested, report any faults 2x4=8

close proximity

2. Explosion due to failure of pressure vessel User and those in 2. Ensure properly inspected, maintained and serviced, fitted with 2x3=6

causing impact injuries close proximity pressure release valve. Records must be kept 3x2=6

3. High pressure steam, steam, hot liquids and User 3. Training, Interlock fitted, use PPE, follow bio-hazard guidelines 3x2=6

containers

4. Chemical hazard of substances prior to User 4. See COSHH Assessments for safety control measures See COSHH

autoclaving see COSHH assessments

5. Glass sharps causing cuts to hands User 5. Use gloves, see SOM018 2x2=4

Does this procedure require an Out-of-Hours working permit? YES / NO Is this procedure authorised for Lone working? YES / NO

Reference Number: Is this procedure authorised for Out-of-Hours working? YES / NO

Assessor Print name : Signature & email Date

Supervisor Print name : Signature Date

Review 1 - Signature Date

Email : Review 2 - Signature Date

Seen also by : signature

& date

Seen by Safety Advisor Associated Safety Assessments Risk Assessment Number

(signature & date)

SEVERITY

If Probability or Severity = 4 Stop work immediately, review control measures

PROBABILITY

4.Probable / likely 4..Fatal or injury causing long term or permanent absence from work Risk Assessment Action

3..Possible 3..Major injury greater than 3 days incapacity from work Score

2..Remote possibility 2..Minor injury causing up to 3 days incapacity from work 16..Stop work immediately, review control measures, seek advice

1..Virtually impossible 1..Minor injury or illness, no absence from work 12 or above..Stop work review control measures to reduce risk, monitor regularly

8 or 9...Review control measures to try to reduce risk

Probability x Severity = Risk Assessment Score less than 8..Low priority, but still try to reduce risk

Regulations, Standards, Codes of Practice and guidance notes can be found in the School Safety Policy and on the School web site www.materials.manchester.ac.uk

ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596

You might also like

- Functional Specifications - Chromeleon 7.2.10Document364 pagesFunctional Specifications - Chromeleon 7.2.10Mondommeg SohanemNo ratings yet

- Electrical SopDocument10 pagesElectrical SopDhaneswar SwainNo ratings yet

- SOP of Media PreparationDocument8 pagesSOP of Media PreparationaKureishiNo ratings yet

- SOP of Water TestingDocument17 pagesSOP of Water TestingaKureishi71% (7)

- PPE Evaluation FormDocument2 pagesPPE Evaluation FormZao KiliNo ratings yet

- Environmental Aspect / Impact Register - Form No. 01: Engineering & Construction Co. L.L.CDocument1 pageEnvironmental Aspect / Impact Register - Form No. 01: Engineering & Construction Co. L.L.CgkNo ratings yet

- Hazard Identification & Risk Assessment RegisterDocument1 pageHazard Identification & Risk Assessment RegisterHafiz Arshad100% (1)

- Eyewash AssessmentDocument2 pagesEyewash AssessmentivelisseNo ratings yet

- Confined Space NarrativeDocument8 pagesConfined Space NarrativeKhalid MahmoudNo ratings yet

- Title SOP Incubator Operation QC 047 01Document12 pagesTitle SOP Incubator Operation QC 047 01aKureishiNo ratings yet

- SOP of Destruction of Culture MediaDocument6 pagesSOP of Destruction of Culture MediaaKureishi100% (1)

- Endotoxin CalculationsDocument5 pagesEndotoxin Calculationsjaks2771% (7)

- CABI Presentation - Yelitza Colmenarez - CPHD 2021Document30 pagesCABI Presentation - Yelitza Colmenarez - CPHD 2021CABINo ratings yet

- Lab Self Inspection Checklist PDFDocument11 pagesLab Self Inspection Checklist PDFarif_fatur324872No ratings yet

- Using A Fume Hood: RiskwareDocument7 pagesUsing A Fume Hood: RiskwaretafouzeltNo ratings yet

- 2.309-Near Miss Reporting ProcedureDocument4 pages2.309-Near Miss Reporting Procedurekirandevi1981No ratings yet

- Hazardous Substances & Dangerous Goods WHSPRO-007 CMDocument7 pagesHazardous Substances & Dangerous Goods WHSPRO-007 CMJason McIntoshNo ratings yet

- Emergency Eyewash Shower Sop FinalDocument8 pagesEmergency Eyewash Shower Sop FinalDominic EmerencianaNo ratings yet

- Equipment Risk AssessmentDocument7 pagesEquipment Risk Assessmentgullipalli srinivasa raoNo ratings yet

- Sop For GeneratorDocument5 pagesSop For Generatorponnada shanmukha pavan kumar0% (1)

- QPMO-700-00-FM-030 Incident Report Rev 0Document6 pagesQPMO-700-00-FM-030 Incident Report Rev 0IslamAl-BazNo ratings yet

- Work Permit SOPDocument2 pagesWork Permit SOPMeghanath LalemmaNo ratings yet

- Material Handeling OCPDocument1 pageMaterial Handeling OCPAshwani KumarNo ratings yet

- IMS-FR-016 High Height Work PermitDocument1 pageIMS-FR-016 High Height Work PermitSamsung NetworksNo ratings yet

- Personal Protective Equipment ProceduresDocument7 pagesPersonal Protective Equipment ProceduresIbrahim Azam IbrahimNo ratings yet

- F 05 KDI QHSE 17a Environmental Inspection ChecklistDocument4 pagesF 05 KDI QHSE 17a Environmental Inspection ChecklistArsh AlamNo ratings yet

- Fire Safety Management AuditDocument16 pagesFire Safety Management Auditoky kurniawanNo ratings yet

- HSE SOP-04 HSE Hazard Identification Risk Assessment and C.Document6 pagesHSE SOP-04 HSE Hazard Identification Risk Assessment and C.Imad ChaudharyNo ratings yet

- Dosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceDocument5 pagesDosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceMahin patelNo ratings yet

- Kharafi National: Health & Safety Safe Operating Procedure Sop 005 First AidDocument6 pagesKharafi National: Health & Safety Safe Operating Procedure Sop 005 First AidF KhanNo ratings yet

- L17 Legal Requirements in EHS Dr. AndhareDocument40 pagesL17 Legal Requirements in EHS Dr. AndhareD PandeyNo ratings yet

- HS614 Chemical Audit Checklist: Heading Requirement Check (Y/N)Document2 pagesHS614 Chemical Audit Checklist: Heading Requirement Check (Y/N)Thụy Du KhúcNo ratings yet

- Schedule For Inspection Nov 19Document1 pageSchedule For Inspection Nov 19Siddharth RanaNo ratings yet

- HIRA FormatDocument2 pagesHIRA FormatSAYED ROMARIONo ratings yet

- Behavior Based Safety (BBS) - FinalDocument4 pagesBehavior Based Safety (BBS) - FinalSurhidayat Ibn MusthafaNo ratings yet

- Incident Investigation - Tripod by Syed Naman Shah (Pakistan Refinery Limited)Document11 pagesIncident Investigation - Tripod by Syed Naman Shah (Pakistan Refinery Limited)Khuda BukshNo ratings yet

- WINEWISE-Water Management ChecklistDocument3 pagesWINEWISE-Water Management ChecklistCCR100% (1)

- Mr. Sushil Kharkwal, PI Industries - RC As A Globally Accepted StandardDocument59 pagesMr. Sushil Kharkwal, PI Industries - RC As A Globally Accepted StandardhariNo ratings yet

- SOP Compressed GasDocument4 pagesSOP Compressed GasSandeep ShettyNo ratings yet

- Site Specific Safety OrientationDocument39 pagesSite Specific Safety OrientationBernard AmooNo ratings yet

- Safe Handling of Gas Cylinders: Pocket Safety Guide No. 2Document8 pagesSafe Handling of Gas Cylinders: Pocket Safety Guide No. 2Suresh Thevanindrian100% (1)

- FORM 1.1b DAILY HOUSEKEEPING CHECKLIST SCHEDULEDocument5 pagesFORM 1.1b DAILY HOUSEKEEPING CHECKLIST SCHEDULEAnnacel CondinatoNo ratings yet

- Chapter 2 - Risk AccessmentDocument66 pagesChapter 2 - Risk AccessmentMan ManNo ratings yet

- QPT01 - Training and Personnel Competency - 15092022Document26 pagesQPT01 - Training and Personnel Competency - 15092022saidmohamadkamil100% (1)

- Compressed Air HSEDocument50 pagesCompressed Air HSEOdalis ToscanoNo ratings yet

- HSE Operational Control Procedure For Electrical WorkDocument3 pagesHSE Operational Control Procedure For Electrical Workalit2No ratings yet

- Procedure For Managing MSDS and LabelsDocument6 pagesProcedure For Managing MSDS and LabelsasikurNo ratings yet

- Exp 1 3304 Rice GrindingDocument11 pagesExp 1 3304 Rice Grindingnasonex91No ratings yet

- (Pharma-Tech Assignment) : Fire Hazards IN Pharmaceutical IndustryDocument6 pages(Pharma-Tech Assignment) : Fire Hazards IN Pharmaceutical IndustryZulqarnain AslamNo ratings yet

- 5fire Prevention Checklist, Rev.0Document3 pages5fire Prevention Checklist, Rev.0Malikrachman Alwaysthebest ThoppyNo ratings yet

- Application For Permit To Work Permit No:: (Work Shall Not Commence Until Stage 1 To Stage 3 For Contract Jobs Is DultDocument3 pagesApplication For Permit To Work Permit No:: (Work Shall Not Commence Until Stage 1 To Stage 3 For Contract Jobs Is DultReaz UddinNo ratings yet

- Tahmina-Zebin-General Risk Assessment FormDocument6 pagesTahmina-Zebin-General Risk Assessment FormTahmina L. ZebinNo ratings yet

- : ﺔﻘﻴﺛﻮﻟا ناﻮﻨﻋ: ﺔﻴﻤﻴﻈﻨﺘﻟا ةﺪﺣﻮﻟا Work Instructions title: Organization Unit: Doc Ref.: ﺔﻘﻴﺛﻮﻟا ﻢﻗرDocument1 page: ﺔﻘﻴﺛﻮﻟا ناﻮﻨﻋ: ﺔﻴﻤﻴﻈﻨﺘﻟا ةﺪﺣﻮﻟا Work Instructions title: Organization Unit: Doc Ref.: ﺔﻘﻴﺛﻮﻟا ﻢﻗرDavidNo ratings yet

- 4 Safe Practices For ElecDocument8 pages4 Safe Practices For ElecSandeep GuptaNo ratings yet

- Benzoxe N - Ghs Msds Template Safety Data SheetDocument5 pagesBenzoxe N - Ghs Msds Template Safety Data Sheetelpangjaya jayNo ratings yet

- Generic Risk Assessment - General Lathe Use v.1Document7 pagesGeneric Risk Assessment - General Lathe Use v.1Darus YasunNo ratings yet

- IMSP 19 Identification Evaluation of Env Aspects PDFDocument7 pagesIMSP 19 Identification Evaluation of Env Aspects PDFSAMEER JAVEDNo ratings yet

- Safety Audit Format Gs ManmadDocument3 pagesSafety Audit Format Gs ManmadsunilNo ratings yet

- Is 5572 - Hazardous ClassificationDocument2 pagesIs 5572 - Hazardous ClassificationMathavaraj DharmarajNo ratings yet

- 2 NP 2Document6 pages2 NP 2Melati Nurul Utami100% (1)

- SOPDocument5 pagesSOPMd Nazmus SakibNo ratings yet

- Storage TAnk Checklist PDFDocument1 pageStorage TAnk Checklist PDFJon Carlo MalecdomNo ratings yet

- SCBA Wiki PDFDocument6 pagesSCBA Wiki PDFomar benounaNo ratings yet

- Equipment Machinery Safety Checklist-Pdf-EnDocument2 pagesEquipment Machinery Safety Checklist-Pdf-EnOliver Reazon RueloNo ratings yet

- Toluene:: Standard Operating ProcedureDocument7 pagesToluene:: Standard Operating ProcedureRicardo VilchezNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- Airborne Particulate Cleanliness ClassesDocument4 pagesAirborne Particulate Cleanliness ClassesaKureishiNo ratings yet

- SOP of SamplingDocument8 pagesSOP of SamplingaKureishi100% (1)

- Services On DemandDocument13 pagesServices On DemandaKureishiNo ratings yet

- Plant Risk Assessment FormDocument7 pagesPlant Risk Assessment FormaKureishiNo ratings yet

- Task Risk Analysis FormDocument5 pagesTask Risk Analysis FormaKureishiNo ratings yet

- FP 201112123122121Document10 pagesFP 201112123122121aKureishiNo ratings yet

- Appendix-I PQ #. 1 Sampling Point: SP001 (Feed Water Inlet) : G Io N CH Lo Rid e Ni Tra TeDocument14 pagesAppendix-I PQ #. 1 Sampling Point: SP001 (Feed Water Inlet) : G Io N CH Lo Rid e Ni Tra TeaKureishiNo ratings yet

- Risk Management Laboratory Standard Operating ProceduresDocument10 pagesRisk Management Laboratory Standard Operating ProceduresaKureishi100% (1)

- General Risk Assessment FormDocument5 pagesGeneral Risk Assessment FormaKureishiNo ratings yet

- What Is An Example of An Inspection Checklist For A Manufacturing FacilityDocument7 pagesWhat Is An Example of An Inspection Checklist For A Manufacturing FacilityaKureishi100% (1)

- White Paper Tri 2008Document3 pagesWhite Paper Tri 2008aKureishiNo ratings yet

- Bugs and Drugs: A Summary of Pharmaceutical MicrobiologyDocument20 pagesBugs and Drugs: A Summary of Pharmaceutical MicrobiologyaKureishiNo ratings yet

- Bacterial en Do Toxins Test 1 Manual For PDFDocument72 pagesBacterial en Do Toxins Test 1 Manual For PDFaKureishiNo ratings yet

- WSF AQC Presentation Richard Glindon Klaus Herick Tcm18-219589Document21 pagesWSF AQC Presentation Richard Glindon Klaus Herick Tcm18-219589aKureishiNo ratings yet

- Sample Radiobroadcasting ScriptDocument3 pagesSample Radiobroadcasting ScriptMervin BauyaNo ratings yet

- De Kiem Tra 15 Phut Tieng Anh Lop 8 Unit 11 Science and TechnologyDocument3 pagesDe Kiem Tra 15 Phut Tieng Anh Lop 8 Unit 11 Science and TechnologyBùi TuấnNo ratings yet

- hw06 Solutions PDFDocument5 pageshw06 Solutions PDFRana FaizanNo ratings yet

- IB 2 SL Atoms & RadioactivityDocument12 pagesIB 2 SL Atoms & RadioactivityJessica GuyNo ratings yet

- Model S270 Intrinsically Safe Smoke Detector: Nova-5000 Detection & Control SystemDocument2 pagesModel S270 Intrinsically Safe Smoke Detector: Nova-5000 Detection & Control SystemStephanie Reyes HdezNo ratings yet

- Unit-5: The Link Layer and Local Area NetworksDocument38 pagesUnit-5: The Link Layer and Local Area NetworksJinkal DarjiNo ratings yet

- PHY 212-QuantumMechanics-I PHY 513 Quantum Theory-I-Muhammad Sabieh AnwarDocument4 pagesPHY 212-QuantumMechanics-I PHY 513 Quantum Theory-I-Muhammad Sabieh AnwarMuhammadTahaNo ratings yet

- Maximum Power Transfer Theorem Case 1 125274Document1 pageMaximum Power Transfer Theorem Case 1 125274akashdeep tickooNo ratings yet

- Istorija: Simca 1100Document24 pagesIstorija: Simca 1100Zastava 101 KlubNo ratings yet

- Labsheet Intersection Volume Studies PDFDocument17 pagesLabsheet Intersection Volume Studies PDFDdeqz Elina Bueno INo ratings yet

- Symbolism and AllegoryDocument13 pagesSymbolism and Allegory김민재No ratings yet

- Hybridization 1Document36 pagesHybridization 1Yordanos GetnetNo ratings yet

- Machine Elements Quiz 2Document15 pagesMachine Elements Quiz 2Quen CuestaNo ratings yet

- JEE Mains 2023 Shift 1 Question Paper 11 Apr With Solutions PDFDocument28 pagesJEE Mains 2023 Shift 1 Question Paper 11 Apr With Solutions PDFSAUMIL SINHANo ratings yet

- HistologyDocument65 pagesHistologyAlliana FlorenzaNo ratings yet

- Compilation of Works IN World Literature: Submitted By: Pontanar, Jiezl Faith V. English 4-ADocument18 pagesCompilation of Works IN World Literature: Submitted By: Pontanar, Jiezl Faith V. English 4-ARonald SillanaNo ratings yet

- Mixture Final 94 Math PDFDocument55 pagesMixture Final 94 Math PDFEraj MaxNo ratings yet

- 9 El-Khazali Lead Controller DesignDocument39 pages9 El-Khazali Lead Controller Designs.a.s1d3233No ratings yet

- LP Chemical ReactionDocument5 pagesLP Chemical ReactionAries Blado Pascua0% (1)

- Minor Project: Object Recognition SystemDocument20 pagesMinor Project: Object Recognition SystemAditya AnandNo ratings yet

- Journey Towards PerfectionDocument7 pagesJourney Towards Perfectionapi-3738883No ratings yet

- Ganga Basin: Presented By: Barsha Rani Das Roll. No: PE 04/16 Petroleum Engineering, 6 SemesterDocument20 pagesGanga Basin: Presented By: Barsha Rani Das Roll. No: PE 04/16 Petroleum Engineering, 6 SemesterAbu ikhtiarNo ratings yet

- Theory of FormsDocument2 pagesTheory of FormslauNo ratings yet

- Test 1, Math 211: DirectionsDocument9 pagesTest 1, Math 211: DirectionsNicole BilottoNo ratings yet

- J-Integral and VCCT (MSC Marc)Document2 pagesJ-Integral and VCCT (MSC Marc)nunchakuNo ratings yet

- Werewolf The Forsaken - Forsaken Chronicler's Guide - I - To IsolateDocument29 pagesWerewolf The Forsaken - Forsaken Chronicler's Guide - I - To IsolateMark Laurence Cruz Pascua80% (5)

- X Science SQP 2018-19Document6 pagesX Science SQP 2018-19muthu100% (1)

- Vernier Scales and Other Early Devices FDocument7 pagesVernier Scales and Other Early Devices FIbraheem TalashNo ratings yet