Ibr Calculations

Ibr Calculations

Uploaded by

Gopal RamalingamCopyright:

Available Formats

Ibr Calculations

Ibr Calculations

Uploaded by

Gopal RamalingamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ibr Calculations

Ibr Calculations

Uploaded by

Gopal RamalingamCopyright:

Available Formats

IBR

CALCULATIONS

PROJECT : RANBAXY LABORATORIES LIMITED P-101 MPFB (API BLOCK)

CLIENT : NNE PHARMAPLAN INDIA LIMITED

CONSULTANT : PURNA DESIGN ENGINEERS PVT LTD., BANGALORE

REV : 0

ISSUE DATE : 07.08.2009

PPD CHK APP

GKG RS BVR

Page 1 of 12

A CONTENTS

SL.NO DRAWING NO DRAWING TITLE PAGE

1.0 NPI/090513/PIP(GEN)-B1/01 HP STEAM LINE 4-8

PPD CHK APP

GKG RS BVR

Page 2 of 12

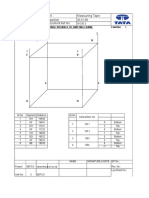

B - DESIGN DATA

Code for Design, Fabrication and inspection: IBR 1950

(With Amendments upto 01-07-1998)

SL.NO DESIGN DATA

REFERENCE DRG.

.

1.0 HP STEAM LINE

(i) 150

Design Pressure [Kg/cm2] : 17.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 26.4

(ii) A) 125

Design Pressure [Kg/cm2] : 17.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 26.4

B) 125

Design Pressure [Kg/cm2] : 6.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 9.9

(iii) 100

Design Pressure [Kg/cm2] : 17.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 26.4

(iv) A) 80 NPI/090513/PIP(GEN)-B1/01

Design Pressure [Kg/cm2] : 17.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 26.4

B) 80

Design Pressure [Kg/cm2] : 6.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 9.9

(v) A) 50

Design Pressure [Kg/cm2] : 17.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 26.4

B) 50

Design Pressure [Kg/cm2] : 6.6

Design Temperature [Deg.C] : 201.4

Hydro Test Pressure [Kg/cm2] : 9.9

PPD CHK APP

GKG RS BVR

Page 3 of 12

1.0 HP STEAM

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

(i) Size OD 168.28x7.11

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 168.28

2 Provided Nominal Thickness mm : 7.11

3 Negative Tolerance mm : 0.89

4 Minimum Thickness t mm : 6.22

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 : 1054.85

(As per ASME Sec-II Part D)

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

70.90

11 Max. Working Pressure Kg/cm2 : 17.6

12 Remarks :

SAFE

(ii) A) Size OD 141.3x6.55

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 141.3

2 Provided Nominal Thickness mm : 6.55

3 Negative Tolerance mm : 0.82

4 Minimum Thickness t mm : 5.73

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 :

(As per ASME Sec-II Part D) 1054.85

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

77.09

PPD CHK APP

GKG RS BVR

Page 4 of 12

11 Max. Working Pressure Kg/cm2 : 17.6

12 Remarks :

SAFE

B) Size OD 141.3x6.55

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 141.3

2 Provided Nominal Thickness mm : 6.55

3 Negative Tolerance mm : 0.82

4 Minimum Thickness t mm : 5.73

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 :

(As per ASME Sec-II Part D) 1054.85

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

77.09

11 Max. Working Pressure Kg/cm2 : 6.6

12 Remarks :

SAFE

(iii) Size OD 114.3x6.02

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 114.3

2 Provided Nominal Thickness mm : 6.02

3 Negative Tolerance mm : 0.75

4 Minimum Thickness t mm : 5.27

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 :

(As per ASME Sec-II Part D) 1054.85

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

86.81

PPD CHK APP

GKG RS BVR

Page 5 of 12

11 Max. Working Pressure Kg/cm2 : 17.6

12 Remarks :

SAFE

(iv) A) Size OD 88.9x5.49

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 88.9

2 Provided Nominal Thickness mm : 5.49

3 Negative Tolerance mm : 0.69

4 Minimum Thickness t mm : 4.80

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 :

(As per ASME Sec-II Part D) 1054.85

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

100.80

PPD CHK APP

GKG RS BVR

Page 6 of 12

11 Max. Working Pressure Kg/cm2 : 17.6

12 Remarks :

SAFE

B) Size OD 88.9x5.49

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 88.9

2 Provided Nominal Thickness mm : 5.49

3 Negative Tolerance mm : 0.69

4 Minimum Thickness t mm : 4.80

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 :

(As per ASME Sec-II Part D) 1054.85

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

100.80

11 Max. Working Pressure Kg/cm2 : 6.6

12 Remarks :

SAFE

(v) A) Size OD 60.33x3.91

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 60.33

2 Provided Nominal Thickness mm : 3.91

3 Negative Tolerance mm : 0.49

4 Minimum Thickness t mm : 3.42

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 :

(As per ASME Sec-II Part D) 1054.85

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

97.74

PPD CHK APP

GKG RS BVR

Page 7 of 12

11 Max. Working Pressure Kg/cm2 : 17.6

12 Remarks :

SAFE

B) Size OD 60.33x3.91

(Drg. No. NPI/090513/PIP(GEN)-B1/01)

Calculation for Max. Allowable Working Pressure as per IBR Reg. 350

1 External Dia of Pipe D mm : 60.33

2 Provided Nominal Thickness mm : 3.91

3 Negative Tolerance mm : 0.49

4 Minimum Thickness t mm : 3.42

5 Max. Working Metal Temperature Deg C : 201.4

6 Material Specification : A106Gr.B

7 Max. Permissible Stress. f Kg/cm2 :

(As per ASME Sec-II Part D) 1054.85

8 C' Value mm : 0.75

9 Efficiency Factor E E : 1

10 Max. Allowable Working Pressure W.P W.P. Kg/cm2 :

2fE (t C)

Dt+C

97.74

11 Max. Working Pressure Kg/cm2 : 6.6

12 Remarks :

SAFE

PPD CHK APP

GKG RS BVR

Page 8 of 12

PPD CHK APP

GKG RS BVR

Page 9 of 12

PPD CHK APP

GKG RS BVR

Page 10 of 12

PPD CHK APP

GKG RS BVR

Page 11 of 12

PPD CHK APP

GKG RS BVR

Page 12 of 12

You might also like

- Ael-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating CoilDocument3 pagesAel-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating Coilpavan0% (1)

- Social CircleDocument33 pagesSocial Circlejames_kearns_3100% (3)

- Policy NestleDocument12 pagesPolicy NestleShaeann Yee Loy100% (1)

- Compensation To Opening Sums NptelDocument9 pagesCompensation To Opening Sums NptelRADHE GRAPHICSNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Eddy Current Test ProcedureDocument7 pagesEddy Current Test ProcedureGopal RamalingamNo ratings yet

- Ibr CalculationsDocument9 pagesIbr CalculationsoperationmanagerNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- 400 KPH Boiler IBR Design Calculations - R1-6-2-13Document8 pages400 KPH Boiler IBR Design Calculations - R1-6-2-13Vishal KandNo ratings yet

- FD Aerofoil 1590x2640Document4 pagesFD Aerofoil 1590x2640Prakash WarrierNo ratings yet

- IBR Quiz 1Document6 pagesIBR Quiz 1RAJKUMARNo ratings yet

- Amendments To The Indian Boiler RegulationsDocument42 pagesAmendments To The Indian Boiler RegulationsAayush LawrenceNo ratings yet

- Glaxo Vol IDocument164 pagesGlaxo Vol IPrakash WarrierNo ratings yet

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Document9 pagesStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002mohan babuNo ratings yet

- Ibr RegulationsDocument9 pagesIbr RegulationsAJITSPATILNo ratings yet

- Analysis of Air Water Cooled Condenser in Vapour Compression System IJERTV10IS050132Document6 pagesAnalysis of Air Water Cooled Condenser in Vapour Compression System IJERTV10IS050132Abdulrahman AlnasharNo ratings yet

- Development of AerofoilDocument6 pagesDevelopment of Aerofoilvaisakp777No ratings yet

- Contact Us Search Our Services: Click To Enable Adobe Flash PlayerDocument2 pagesContact Us Search Our Services: Click To Enable Adobe Flash Playert githenderNo ratings yet

- CDQ ProcessDocument2 pagesCDQ ProcessVirendra PatilNo ratings yet

- 045 - Tech. Dairy of Shree PowerDocument81 pages045 - Tech. Dairy of Shree PowerAamirMalikNo ratings yet

- DraughtDocument33 pagesDraughtNipun SabharwalNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- The Indian Boilers Act 1923Document16 pagesThe Indian Boilers Act 1923Anand Swami100% (1)

- Steam Drum (Single) : Drum Thickness Calculation - Sa 516 Gr. 70 (As Per Ibr)Document3 pagesSteam Drum (Single) : Drum Thickness Calculation - Sa 516 Gr. 70 (As Per Ibr)neelNo ratings yet

- Cross Sectional Area of WeldsDocument4 pagesCross Sectional Area of WeldsJuan RodriguezNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- Matl Specn.: Matl Temp - in Deg.fDocument15 pagesMatl Specn.: Matl Temp - in Deg.fpandiangvNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33No ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- Stresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFDocument8 pagesStresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFanishNo ratings yet

- Water Circulation SystemDocument31 pagesWater Circulation SystemSaurav Kumar0% (1)

- Boiler Circulation SystemDocument32 pagesBoiler Circulation SystemRitik Dewangan100% (2)

- Tech Spec Bhel PheDocument55 pagesTech Spec Bhel PheYasmin 2021No ratings yet

- IbrDocument5 pagesIbrSuresh Ram RNo ratings yet

- Boiler I.B.R. CalculationDocument10 pagesBoiler I.B.R. CalculationGurinder Jit Singh100% (1)

- Pipe Weight CalculationDocument1 pagePipe Weight Calculationtnasrevid100% (1)

- Air Cooled COndenser PDFDocument7 pagesAir Cooled COndenser PDFRajAnandNo ratings yet

- Inspecton ProcedureDocument3 pagesInspecton ProcedureSanthosh ReddyNo ratings yet

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyNo ratings yet

- 1 TPH 10.54 KG, Vapi Care PharmaDocument16 pages1 TPH 10.54 KG, Vapi Care PharmashastrysnNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Pressure Testing Request FormDocument1 pagePressure Testing Request FormSyed Mahmud Habibur RahmanNo ratings yet

- Technical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Document12 pagesTechnical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Bijaya Kumar MohantyNo ratings yet

- IBR Thickness CalculationDocument17 pagesIBR Thickness CalculationArindom100% (1)

- STRAINERDocument25 pagesSTRAINERcadhoaNo ratings yet

- Ibr CalculationsDocument9 pagesIbr Calculationsaroonchelikani67% (3)

- Boiler 2 Furnace Tube Thickness and LifeDocument1 pageBoiler 2 Furnace Tube Thickness and LifegandungwNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan Panchal100% (1)

- Data Sheet For MercuryDocument5 pagesData Sheet For MercuryMohamed hamza souissiNo ratings yet

- Mech. Cal. Pig Receiver (KPT-201) - Rev.ADocument9 pagesMech. Cal. Pig Receiver (KPT-201) - Rev.AMahfudin NurNo ratings yet

- Nuberg Technical Specification SheetDocument5 pagesNuberg Technical Specification SheetSmart ChannelNo ratings yet

- Air-Cooled Heat Exchanger - Specification Sheet: Tube BundleDocument2 pagesAir-Cooled Heat Exchanger - Specification Sheet: Tube BundlebondsivamaniNo ratings yet

- RF Pad Calculation-1Document2 pagesRF Pad Calculation-1gauravvats14_4304308No ratings yet

- Final Electric RoomDocument7 pagesFinal Electric Roomawad91005No ratings yet

- Static Calculation 10 - X - 15 - R0-1 PDFDocument17 pagesStatic Calculation 10 - X - 15 - R0-1 PDFsriramNo ratings yet

- 8103 M-42 6u2816013 Plate Type CoolersDocument60 pages8103 M-42 6u2816013 Plate Type CoolersABDULLAHNo ratings yet

- Best Tank Calculation SheetDocument88 pagesBest Tank Calculation Sheetchriscivil12100% (1)

- Storage Tank Design Calculation - Api 650Document92 pagesStorage Tank Design Calculation - Api 650Abelardo ContrerasNo ratings yet

- RD Pad-24x20 Inch-A1aDocument2 pagesRD Pad-24x20 Inch-A1agauravvats14_4304308No ratings yet

- 174-Fisa TehnicaDocument1 page174-Fisa TehnicaCosma loredanaNo ratings yet

- Bang Head Here PDFDocument12 pagesBang Head Here PDFhalackNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- HFO Thick PDFDocument11 pagesHFO Thick PDFGopal RamalingamNo ratings yet

- MS Valve Stem Fracture PDFDocument7 pagesMS Valve Stem Fracture PDFGopal RamalingamNo ratings yet

- Hydro Test JointsDocument6 pagesHydro Test JointsGopal RamalingamNo ratings yet

- Corrosion AuditDocument4 pagesCorrosion AuditGopal RamalingamNo ratings yet

- Rules-56-Under-Sec-31-Full-Factories ActDocument6 pagesRules-56-Under-Sec-31-Full-Factories ActGopal RamalingamNo ratings yet

- SEILDocument4 pagesSEILGopal RamalingamNo ratings yet

- SEIL Chemical RegisterDocument3 pagesSEIL Chemical RegisterGopal RamalingamNo ratings yet

- B) CW PipingDocument2 pagesB) CW PipingGopal RamalingamNo ratings yet

- RT Offer-16.10Document42 pagesRT Offer-16.10Gopal RamalingamNo ratings yet

- Mill#1-Tie RodDocument2 pagesMill#1-Tie RodGopal RamalingamNo ratings yet

- Boiler Annual Check ListDocument4 pagesBoiler Annual Check ListGopal Ramalingam100% (2)

- Emitting FrameDocument12 pagesEmitting FrameGopal RamalingamNo ratings yet

- Precondition For Turbine Box-UpDocument3 pagesPrecondition For Turbine Box-UpGopal RamalingamNo ratings yet

- TPCIL - 16-R1 - Inspection Calls, IR & RNsDocument7 pagesTPCIL - 16-R1 - Inspection Calls, IR & RNsGopal RamalingamNo ratings yet

- WellKnownList310315 LatestDocument41 pagesWellKnownList310315 LatestGopal RamalingamNo ratings yet

- Scotch Marine Boiler Design: Wetback Vs DrybackDocument24 pagesScotch Marine Boiler Design: Wetback Vs DrybackGopal RamalingamNo ratings yet

- ANA101 Lab Activity Endocrine SystemDocument3 pagesANA101 Lab Activity Endocrine SystemCarina DioblesNo ratings yet

- Sdo250 50hz Doosan GeneratorDocument4 pagesSdo250 50hz Doosan GeneratorsunshinemachineryNo ratings yet

- 11.10.21 State Wise Sheep & Goat BreedsDocument1 page11.10.21 State Wise Sheep & Goat BreedsVishnu PrabhuNo ratings yet

- Dental and Oral Health Education For Elementary School Students Through Patient Hygiene Performance Index IndicatorDocument5 pagesDental and Oral Health Education For Elementary School Students Through Patient Hygiene Performance Index IndicatorSamehada SamaNo ratings yet

- Daya Hambat Ekstrak Bunga Ruku-Ruku (Ocimum Sanctum L.) TERHADAP PERTUMBUHAN Streptococcus MutansDocument8 pagesDaya Hambat Ekstrak Bunga Ruku-Ruku (Ocimum Sanctum L.) TERHADAP PERTUMBUHAN Streptococcus Mutanssyarifa husniNo ratings yet

- Captains Dine@ ShamimDocument9 pagesCaptains Dine@ ShamimJahidul karimNo ratings yet

- LRN Level B1 January 2016 Exam PaperDocument14 pagesLRN Level B1 January 2016 Exam PaperMarina Penelope100% (1)

- 5G60ME-C10.5-HPSCR - LS - 103.0 - RPM - 14200 - KW DataDocument9 pages5G60ME-C10.5-HPSCR - LS - 103.0 - RPM - 14200 - KW DatawalacrNo ratings yet

- Replacementt of Palm Kernel Shell As Course Aggregate in Concrete.Document61 pagesReplacementt of Palm Kernel Shell As Course Aggregate in Concrete.Abdullahi MuhammadNo ratings yet

- Tienari Et. Al 1985, Finnish Adoptive 1984Document11 pagesTienari Et. Al 1985, Finnish Adoptive 1984DestriNo ratings yet

- Constant-Composition Expansion Test (CCE) : Tập Đoàn Dầu Khí Việt NamDocument19 pagesConstant-Composition Expansion Test (CCE) : Tập Đoàn Dầu Khí Việt NamTruong1102100% (1)

- Ecl 041a 2Document1 pageEcl 041a 2AdrianNo ratings yet

- WR Led Specs 2016Document10 pagesWR Led Specs 2016Sr. DEENo ratings yet

- China HandbookDocument210 pagesChina HandbookPMNo ratings yet

- Basic Introduction To Gas-Condensate ReservoirDocument27 pagesBasic Introduction To Gas-Condensate ReservoirMyatNo ratings yet

- Contributions of Insurance in The Management of Risk in Nigeria Oil Industry (A Study of Shell Petroleum PLC)Document72 pagesContributions of Insurance in The Management of Risk in Nigeria Oil Industry (A Study of Shell Petroleum PLC)Nwigwe Promise ChukwuebukaNo ratings yet

- Diamond ChipDocument4 pagesDiamond ChipNaveen EggadiNo ratings yet

- Mabini Colleges Daet, Camarines Norte MAPE 114 Prelim Examination 1 SemesterDocument3 pagesMabini Colleges Daet, Camarines Norte MAPE 114 Prelim Examination 1 SemesterJessel ReyesNo ratings yet

- Which 802-FinalDocument6 pagesWhich 802-FinalWawire WycliffeNo ratings yet

- Sahara 120 FVO OvenDocument3 pagesSahara 120 FVO Ovenjmathew_984887No ratings yet

- 2024 - CS - BSCATPH - 1st Year - PE1 - (PATHFIT1) Movement Competency Training (MCT)Document8 pages2024 - CS - BSCATPH - 1st Year - PE1 - (PATHFIT1) Movement Competency Training (MCT)Rannie Rodriguez EspantoNo ratings yet

- GNWC1723 UnvDocument1 pageGNWC1723 UnvdreamerchantNo ratings yet

- Presentation ECONDocument20 pagesPresentation ECONAntonis ThemistokleousNo ratings yet

- Asexual ReproductionDocument21 pagesAsexual ReproductionMakanaka SambureniNo ratings yet

- Polyol 700 (Voranol CP755) Dow TDSDocument2 pagesPolyol 700 (Voranol CP755) Dow TDSOrlando FloresNo ratings yet

- 1 - Kunci Jawaban PS Medical Terminology 1 vg2ZY JQZDocument7 pages1 - Kunci Jawaban PS Medical Terminology 1 vg2ZY JQZrhn 5b1coolNo ratings yet

- Prevalence of Eating Disorders in A Pediatric Population in The Eastern Region of MoroccoDocument6 pagesPrevalence of Eating Disorders in A Pediatric Population in The Eastern Region of MoroccoIJAR JOURNALNo ratings yet

- Sampling MethodsDocument3 pagesSampling MethodsShantiram DahalNo ratings yet