0 ratings0% found this document useful (0 votes)

75 viewsSEIL

SEIL

Uploaded by

Gopal RamalingamThe document reports the results of hardness and chemical tests on two samples. The hardness test found the crushing bit holder to have an average Brinell hardness of 154.33 HBW and the crushing bit to be 421 HBW. The chemical analysis found the compositions of carbon, silicon, manganese, phosphorus, sulfur, chromium and molybdenum in each sample to be within specified limits.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

SEIL

SEIL

Uploaded by

Gopal Ramalingam0 ratings0% found this document useful (0 votes)

75 views4 pagesThe document reports the results of hardness and chemical tests on two samples. The hardness test found the crushing bit holder to have an average Brinell hardness of 154.33 HBW and the crushing bit to be 421 HBW. The chemical analysis found the compositions of carbon, silicon, manganese, phosphorus, sulfur, chromium and molybdenum in each sample to be within specified limits.

Original Title

SEIL.doc.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document reports the results of hardness and chemical tests on two samples. The hardness test found the crushing bit holder to have an average Brinell hardness of 154.33 HBW and the crushing bit to be 421 HBW. The chemical analysis found the compositions of carbon, silicon, manganese, phosphorus, sulfur, chromium and molybdenum in each sample to be within specified limits.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

75 views4 pagesSEIL

SEIL

Uploaded by

Gopal RamalingamThe document reports the results of hardness and chemical tests on two samples. The hardness test found the crushing bit holder to have an average Brinell hardness of 154.33 HBW and the crushing bit to be 421 HBW. The chemical analysis found the compositions of carbon, silicon, manganese, phosphorus, sulfur, chromium and molybdenum in each sample to be within specified limits.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

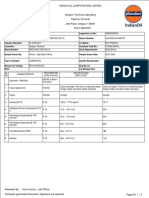

Hardness Test Report

Work order No: AIT/19/01635 Work Order Date: 08-Mar-2019

Test Report No: M-00700-H Test Report date: 12-Mar-2019

Custmer Name & Address: Sample Received Date :09.Mar.2019

SEIL Tested Date:12.Mar.2019

Ref.No: Request form Ref.Date:09/03/2019

Test Details

Machine Details: Test Procedure :IS 1500-2005

Name : Brinell Hardness Type of Hahrdness: HBW

Srl.No:2013/152 Indenter :10mm Ball

Calibration on Date:05.09.2018 Load Applied:3000Kgs

Calibration Due Date:05.09.2019

Hardness test

Material Specification: BS 970:Part 3:1991 Gr:078M40(EN-19A)

S.No Identification Location Observed Values in HBW 10mm Ball/3000

Impression Impression Impression Average

1 2 3

2 Crushing BIT On Surface 420 420 423 421

Apt Inspection Technologies

Plot No-137, Telecom Nagar, RG Residency, Gachibowli, Hyderabad, Telangana - 500 032.

Website: http//:www.aptit.co.in, Mobile: 9959011794

Hardness Test Report

Work order No: AIT/19/01635 Work Order Date: 08-Mar-2019

Test Report No: M-00700-H Test Report date: 12-Mar-2019

Custmer Name & Address: Sample Received Date :09.Mar.2019

SEIL Tested Date:12.Mar.2019

Ref.No: Request form Ref.Date:09/03/2019

Test Details

Machine Details: Test Procedure :IS 1500-2005

Name : Brinell Hardness Type of Hahrdness: HBW

Srl.No:2013/152 Indenter :10mm Ball

Calibration on Date:05.09.2018 Load Applied:3000Kgs

Calibration Due Date:05.09.2019

Hardness test

Material Specification: BS 970:Part 3:1991 Gr:070M20(EN-3A)

S.No Identification Location Observed Values in HBW 10mm Ball/3000

Impression Impression Impression Average

1 2 3

1 Crushing BIT On Surface 154 154 155 154.33

Holder

Apt Inspection Technologies

Plot No-137, Telecom Nagar, RG Residency, Gachibowli, Hyderabad, Telangana - 500 032.

Website: http//:www.aptit.co.in, Mobile: 9959011794

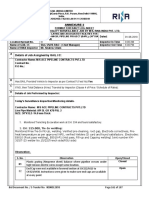

Test Report for chemical Testing

Work order No: AIT/19/01635 Work Order Date: 08-Mar-2019

Test Report No: M-00700-H Test Report date: 12-Mar-2019

Custmer Name & Address: Sample Received Date :09.Mar.2019

SEIL Tested Date:12.Mar.2019

Ref.No: Request form Ref.Date:09/03/2019

Equipment Used: Spectro Sample Received As: DIA 60MM X 50MM

Chemical Analysis (%)

Specification:BS 970:part 3 :1991 Gr:070M20(EN-3A) Test Procedure :ASTM E415,2008

S.No Material Identification C Si Mn P S

1 Crushing BIT Holder 0.13 0.26 0.50 0.015 0.023

Specified Values: Min: 0.16 0.10 0.50 - -

Max: 0.24 0.40 0.90 0.05 0.05

Result: The elements tested are within limits of the above specifications

Apt Inspection Technologies

Plot No-137, Telecom Nagar, RG Residency, Gachibowli, Hyderabad, Telangana - 500 032.

Website: http//:www.aptit.co.in, Mobile: 9959011794

Test Report for chemical Testing

Work order No: AIT/19/01635 Work Order Date: 08-Mar-2019

Test Report No: M-00700-H Test Report date: 12-Mar-2019

Custmer Name & Address: Sample Received Date :09.Mar.2019

SEIL Tested Date:12.Mar.2019

Ref.No: Request form Ref.Date:09/03/2019

Equipment Used:Spectro Sample Received As:DIA 60MM X 50MM

Chemical Analysis (%)

Specification:BS 970:part 3 :1991 Gr:708M40(EN-19A) Test Procedure :ASTM E415,2008

S.No Material Identification C Si Mn P S Cr Mo

1 Crushing Bit 0.39 0.36 0.9 0.011 0.018 0.85 0.22

Specified Values: Min: 0.36 0.10 0.70 - - 0.9 0.15

Max: 0.44 0.4 1 0.035 0.04 1.2 0.25

Result: The elements tested are within limits of the above specifications

Apt Inspection Technologies

Plot No-137, Telecom Nagar, RG Residency, Gachibowli, Hyderabad, Telangana - 500 032.

Website: http//:www.aptit.co.in, Mobile: 9959011794

You might also like

- Test Certificate 12mmDocument1 pageTest Certificate 12mmSabyasachi Bangal60% (10)

- Lytron Manual and SchematicsDocument38 pagesLytron Manual and Schematicsbruce hu100% (2)

- 12 in CL300 Alba Mill CertfDocument4 pages12 in CL300 Alba Mill CertfIrsyad RosyidiNo ratings yet

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- Eddy Current Test ProcedureDocument7 pagesEddy Current Test ProcedureGopal RamalingamNo ratings yet

- GBE-CW6 Part-1-1993Document44 pagesGBE-CW6 Part-1-1993pcmfilho100% (2)

- ScanDocument1 pageScanSamiran SarkerNo ratings yet

- Format. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Document3 pagesFormat. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Raja KrsNo ratings yet

- 412006-08-08, Supplier - Mishra Ent., Part Name - Fem NPL Rod.Document4 pages412006-08-08, Supplier - Mishra Ent., Part Name - Fem NPL Rod.phoenixenggworkNo ratings yet

- Visual / NDT Examination Certificate: Cargo Carrying Unit (Ccu)Document1 pageVisual / NDT Examination Certificate: Cargo Carrying Unit (Ccu)Princewill EmmanuelNo ratings yet

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Document3 pagesIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind Dhaka0% (1)

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- 832102496, Part Name - Sheet, Material - HR 1Document5 pages832102496, Part Name - Sheet, Material - HR 1phoenixenggworkNo ratings yet

- Artison PEBB Test ResultsDocument3 pagesArtison PEBB Test ResultsratnatejreddyNo ratings yet

- 19 Test CertificatesDocument10 pages19 Test CertificatesBernice AkotoNo ratings yet

- DCL Test Report - Size 12.7 MM - 18-2-2020Document2 pagesDCL Test Report - Size 12.7 MM - 18-2-2020docpt76No ratings yet

- Spectro Fire Test ReportDocument7 pagesSpectro Fire Test ReportKishoreNo ratings yet

- Procurement Services: Industry & Facilities DivisionDocument6 pagesProcurement Services: Industry & Facilities DivisionVikas Mani TripathiNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- TC No 1201 StudDocument2 pagesTC No 1201 StudGaurav100% (1)

- Test Report: Work Order No. JSA-19-05651Document3 pagesTest Report: Work Order No. JSA-19-05651SantoshNo ratings yet

- CLOTHDocument3 pagesCLOTHTesting LabsNo ratings yet

- Test Report: Destiny Retail Mall Developers Private LimitedDocument3 pagesTest Report: Destiny Retail Mall Developers Private LimitedAbhijit KarpeNo ratings yet

- Ir - EFFRA INDUSTRIES LLP - MEW MS PO 02 2022 23 - 462023 - 472023ICS4199Document2 pagesIr - EFFRA INDUSTRIES LLP - MEW MS PO 02 2022 23 - 462023 - 472023ICS4199Voltonix InfratechNo ratings yet

- International Limited: Certificate of Visual ExaminationDocument15 pagesInternational Limited: Certificate of Visual ExaminationMichael OkwuwaNo ratings yet

- N-2023-0470 - NataDocument8 pagesN-2023-0470 - NataphungquocdienNo ratings yet

- Brinell Hardness TestDocument1 pageBrinell Hardness TestBHUSHANNo ratings yet

- Report PT Mulia Mandiri MarineDocument9 pagesReport PT Mulia Mandiri MarineBudi Setia RahmanNo ratings yet

- Inspection Report Smls PipeDocument10 pagesInspection Report Smls PipelouaimohamedNo ratings yet

- Sup 2019 0003Document3 pagesSup 2019 0003james.anitNo ratings yet

- 190724005SHF-001 Drum Peel Strength PDFDocument5 pages190724005SHF-001 Drum Peel Strength PDFaziz hNo ratings yet

- 316L Stainless Steel Test ReportDocument2 pages316L Stainless Steel Test ReportIza Chan100% (2)

- JRF 1240Document3 pagesJRF 1240Varun S KumarNo ratings yet

- MTC'sDocument5 pagesMTC'sWalid DamiNo ratings yet

- TC SS304-16-12-19Document2 pagesTC SS304-16-12-19ashish kumarNo ratings yet

- Steel-Cecpl 06 098 24-25Document4 pagesSteel-Cecpl 06 098 24-25premchand.sconNo ratings yet

- Inspectorate Griffith India Pvt. LTD: 608, Central Plaza, 2/6, Sarat Bose Road, Kolkata - 700 020, West Bengal, IndiaDocument5 pagesInspectorate Griffith India Pvt. LTD: 608, Central Plaza, 2/6, Sarat Bose Road, Kolkata - 700 020, West Bengal, Indiaapi-3671132No ratings yet

- International Limited: Certificate of Visual ExaminationDocument24 pagesInternational Limited: Certificate of Visual ExaminationMichael OkwuwaNo ratings yet

- Test Report: Destiny Retail Mall Developers Private LimitedDocument3 pagesTest Report: Destiny Retail Mall Developers Private LimitedAbhijit KarpeNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- Test Report 2 10.2.2023Document2 pagesTest Report 2 10.2.2023prudvirajsriujjwalaNo ratings yet

- Daily Log Sheet BAPL III Dated 01-06-2019Document2 pagesDaily Log Sheet BAPL III Dated 01-06-2019shahroz alamNo ratings yet

- DCL Test Report - Size 9.53 MM - 18-2-2020Document2 pagesDCL Test Report - Size 9.53 MM - 18-2-2020docpt76No ratings yet

- Certificate of Examination Certificate Number:: MPI DetailsDocument2 pagesCertificate of Examination Certificate Number:: MPI Detailsمحمد الديبNo ratings yet

- Hertz Inspection Service PVT LTD Irc1Document18 pagesHertz Inspection Service PVT LTD Irc1Rahul N PatelNo ratings yet

- 1335 - Ec1904Document1 page1335 - Ec1904Deipak HoleNo ratings yet

- Spectro Gauze ReportDocument2 pagesSpectro Gauze ReportMANOJ GUPTA100% (1)

- 2018091981-Inspection Report-Raigarh PDFDocument13 pages2018091981-Inspection Report-Raigarh PDFiprao50% (2)

- Inspection ReportDocument1 pageInspection ReportRaja Sekar SelvamNo ratings yet

- Certificate of Visual Examination and Dpi: Description of Equipment Billy Pugh X-904-4 Personnel Transfer DeviceDocument3 pagesCertificate of Visual Examination and Dpi: Description of Equipment Billy Pugh X-904-4 Personnel Transfer DeviceMichael OkwuwaNo ratings yet

- En353 3753 5948Document1 pageEn353 3753 5948K.s. Raghavendra KumarNo ratings yet

- FIR Dt.08.06.2023Document1 pageFIR Dt.08.06.2023MallikarjunNo ratings yet

- International Limited: Certificate of Visual ExaminationDocument6 pagesInternational Limited: Certificate of Visual ExaminationMichael OkwuwaNo ratings yet

- TSC-R-120-21-1124 - Tatanagar-Shriram EPC LTD (ANAND SINGH)Document2 pagesTSC-R-120-21-1124 - Tatanagar-Shriram EPC LTD (ANAND SINGH)Tsc TechnoNo ratings yet

- All CertificatesDocument8 pagesAll CertificatesLuis BassoNo ratings yet

- Firm Profile:-: 1.Mr. Sudhakar - Managing PartnerDocument3 pagesFirm Profile:-: 1.Mr. Sudhakar - Managing PartnerCorrosion FactoryNo ratings yet

- 500097 (2)Document27 pages500097 (2)ckadam83No ratings yet

- Inv-02073Document1 pageInv-02073dnyaneshdocumentsNo ratings yet

- Electrode Qualification TestDocument5 pagesElectrode Qualification TestAbhishek Kumar Vishwakarma100% (1)

- 3165-Report LVD-e4Document15 pages3165-Report LVD-e4Ayman elsayedNo ratings yet

- IATF 16949:2016 Ester Industries Limited Engineering Plastics Test ReportDocument1 pageIATF 16949:2016 Ester Industries Limited Engineering Plastics Test ReportBLUE STAR ENGINEERSNo ratings yet

- DCL Test Report - Size 15.24 MM - 18-2-2020Document2 pagesDCL Test Report - Size 15.24 MM - 18-2-2020docpt76No ratings yet

- HFO Thick PDFDocument11 pagesHFO Thick PDFGopal RamalingamNo ratings yet

- Rules-56-Under-Sec-31-Full-Factories ActDocument6 pagesRules-56-Under-Sec-31-Full-Factories ActGopal RamalingamNo ratings yet

- MS Valve Stem Fracture PDFDocument7 pagesMS Valve Stem Fracture PDFGopal RamalingamNo ratings yet

- Hydro Test JointsDocument6 pagesHydro Test JointsGopal RamalingamNo ratings yet

- Corrosion AuditDocument4 pagesCorrosion AuditGopal RamalingamNo ratings yet

- Mill#1-Tie RodDocument2 pagesMill#1-Tie RodGopal RamalingamNo ratings yet

- SEIL Chemical RegisterDocument3 pagesSEIL Chemical RegisterGopal RamalingamNo ratings yet

- B) CW PipingDocument2 pagesB) CW PipingGopal RamalingamNo ratings yet

- TPCIL - 16-R1 - Inspection Calls, IR & RNsDocument7 pagesTPCIL - 16-R1 - Inspection Calls, IR & RNsGopal RamalingamNo ratings yet

- Emitting FrameDocument12 pagesEmitting FrameGopal RamalingamNo ratings yet

- Scotch Marine Boiler Design: Wetback Vs DrybackDocument24 pagesScotch Marine Boiler Design: Wetback Vs DrybackGopal RamalingamNo ratings yet

- RT Offer-16.10Document42 pagesRT Offer-16.10Gopal RamalingamNo ratings yet

- WellKnownList310315 LatestDocument41 pagesWellKnownList310315 LatestGopal RamalingamNo ratings yet

- Precondition For Turbine Box-UpDocument3 pagesPrecondition For Turbine Box-UpGopal RamalingamNo ratings yet

- Boiler Annual Check ListDocument4 pagesBoiler Annual Check ListGopal Ramalingam100% (2)

- Troubleshooting and Prevention of Cracking in Induction Hardening Os Steels - Part 2Document8 pagesTroubleshooting and Prevention of Cracking in Induction Hardening Os Steels - Part 2Jader PitangueiraNo ratings yet

- Applied Statistics in Business and Economics 4th Edition Doane Solutions Manual 1Document28 pagesApplied Statistics in Business and Economics 4th Edition Doane Solutions Manual 1michelle100% (55)

- Physical Chemistry Chapter Wise Previous Year QuestionDocument12 pagesPhysical Chemistry Chapter Wise Previous Year QuestionManojNo ratings yet

- Proteus: Electrohydraulic Flow Control and Monitoring SystemDocument2 pagesProteus: Electrohydraulic Flow Control and Monitoring SystemabdouNo ratings yet

- Lưu lượng kế Porter B-125-50Document12 pagesLưu lượng kế Porter B-125-50nguyenanhtuanbNo ratings yet

- Name: Grade 12 - AMETHYST Date: April 23, 2021 1 Summative Exam - Physical Science (Quarter 3)Document1 pageName: Grade 12 - AMETHYST Date: April 23, 2021 1 Summative Exam - Physical Science (Quarter 3)Jeff Tristan CaliganNo ratings yet

- Loads, Load Combinations, Calculation and ResultsDocument30 pagesLoads, Load Combinations, Calculation and ResultsBorce StoilovskiNo ratings yet

- Achievers A2 Grammar Worksheet Consolidation Unit 3Document1 pageAchievers A2 Grammar Worksheet Consolidation Unit 3Lara Vigil GonzálezNo ratings yet

- NBPhO19 EngDocument2 pagesNBPhO19 EngDino SelimovicNo ratings yet

- Influence of Motivation and Organizational Commitment On Work Satisfaction and Employee PerformanceDocument8 pagesInfluence of Motivation and Organizational Commitment On Work Satisfaction and Employee PerformanceNely Noer SofwatiNo ratings yet

- 8 Steps - Control of Heating SystemsDocument192 pages8 Steps - Control of Heating SystemsIvanNo ratings yet

- Flares For Biogas & Landfill GasDocument3 pagesFlares For Biogas & Landfill GasSachin KumarNo ratings yet

- Types of Jigs and Fixtures - Prescient TechnologiesDocument9 pagesTypes of Jigs and Fixtures - Prescient Technologiesmensahgeorge836No ratings yet

- Practice Problems: Unit 4 Our Solar System 1Document3 pagesPractice Problems: Unit 4 Our Solar System 122สุวิจักขณ์ ขจีสวัสดิการNo ratings yet

- Module 5Document72 pagesModule 5Kamalendu C MenonNo ratings yet

- Preface: by Rohan Patel X ScienceDocument108 pagesPreface: by Rohan Patel X Sciencecrazytapan07No ratings yet

- MT ProcedureDocument22 pagesMT Procedureefmartin21No ratings yet

- SOLIDWORKS Electrical Getting StartedDocument31 pagesSOLIDWORKS Electrical Getting StartedIsaias Israel HernandezNo ratings yet

- Case Study: ATM Machine II: Identifying Class AttributesDocument16 pagesCase Study: ATM Machine II: Identifying Class AttributesCharmi yantinaNo ratings yet

- Druck Dpi605 ManualDocument234 pagesDruck Dpi605 ManualFR PERANo ratings yet

- Project Report: Faculty of Electrical and Electronic EngineeringDocument16 pagesProject Report: Faculty of Electrical and Electronic Engineeringabdikadir hassanNo ratings yet

- MSAN MA5600T Basic OperationDocument110 pagesMSAN MA5600T Basic OperationIptech solutionsNo ratings yet

- Biotech ReviewerDocument5 pagesBiotech ReviewerKristine Ross PelaezNo ratings yet

- Technical Datasheet_2500kVA_ALDocument2 pagesTechnical Datasheet_2500kVA_ALthegioibaoduongNo ratings yet

- 5051 October 19Document12 pages5051 October 19Vivek VNo ratings yet

- Lab Assignment 5Document7 pagesLab Assignment 5Mohammed Al DawoodNo ratings yet

- Design of Shopping ComplexDocument100 pagesDesign of Shopping ComplexRohit Chaurasia100% (1)

- Onkyo - C 701 ADocument21 pagesOnkyo - C 701 Anyoman dundunNo ratings yet