Itp Brickwork and Blockwork

Itp Brickwork and Blockwork

Uploaded by

api-372251810Copyright:

Available Formats

Itp Brickwork and Blockwork

Itp Brickwork and Blockwork

Uploaded by

api-372251810Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Itp Brickwork and Blockwork

Itp Brickwork and Blockwork

Uploaded by

api-372251810Copyright:

Available Formats

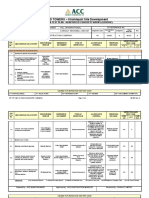

Business Unit Form Building UK - Northern Inspection and Test Plan

Staff room/ Classroom

Project Title: Sudley Infants Project No: 10000327 Work Area:

Extension

ITP Title: Blockwork/ Brickwork Work By: Stock Brickwork ITP No.: SI 004

Change Control Record document changes and update Issue No.

Issue No. Prepared By Issue Comments Date Accepted By Date

1. Keaton Martin For approval 09/08/17

Inspection Inspection

Detail Detail

Codes Codes

H Hold Point cease works until inspected and approved R Record Review review record/document to verify checks have been done

I Inspection complete inspection and record findings N/A Not Applicable not required

T Test / Measure / Sample test/measure/sample and record results

List relevant drawing numbers, specification references, British Standards, RAMS, manufacturers literature, technical

Drawing Numbers and Document References guidance, etc. Bullet points below are prompts and are to be overwritten with project specific information or deleted

where not applicable.

Kier temporary works procedure Technical Guidance Document

9999001-030-01/SUDLEY/R01- Structural Specification

Avoiding Defects Booklet

1077405/ST/03, 1077405/ST/05, 1077405/ST/04, 1077405/ST/07, 1077405/ST/01

1077405/ST/06, 1077405/ST/12

This Inspection and Test plan is to be read in conjunction with the documents referenced above

Authorised By: Nick Shepherd Page 1 of 2 KGA-FOR-BUK-N-3001

Author: Adam Davies Issue Date: July 2016 Version: 1.0

th

As part of our KGA review, the next review is due on 30 September 2017

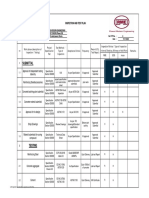

Business Unit Form Building UK - Northern Inspection and Test Plan

Controlling Pass / Fail Inspection By Verifying Document /

Op Activity Document Frequency (insert relevant inspection code)

What is to be inspected / tested / reviewed / Criteria Per element, delivery, room, Record

No monitored / sampled?

Drawings, Specs, BS, Tech Lit,

Manufacturers Guidance,

What are the specifics of what floor, phase, structure etc. Other Quality Checklist, Marked up drawing,

needs to be achieved? S/C Kier Photo, Diary entry, Test Cert., etc.

Employer Requirements, etc. State who & I.C.

Risks mitigated? Design approved? Equipment in calibration? Personnel competent? Materials approved?

Section 1 Pre-Commencement (what must be done before works commence) RAMS approved? Temporary works / preceding works handed over?

1. RAMS obtained and reviewed Kier minimum standards Meets standards Prior to commencement H I R RAMS evaluation sheet

2. Working drawings approved Specification Drawings approved Prior to commencement H H I Drawing Register

Temporary work design in place Kier minimum standards,

3. DCC in place Prior to commencement H H KPS I Design check certs

and approved if necessary temporary works criteria,

Competency check for Certs, induction kept in

4. CSCS, NVQ Respective certificates Prior to commencement H R N/ A

workmanship induction folder

Ensure that work area has suitable

5. Kier minimum standards Meets standards Prior to commencement H H I Photographs

access and egress

Common defects associated with this activity considered? Materials checked before use? Setting out checked?

Section 2 Installation (what must be done to quality assure the works) Checklists developed and implemented? Testing carried out as specified? Final inspections complete?

Check list in line with

Check list completed and signed off Meets drawings and During installation

1. drawings and I I N/ A Signed checklist QA file

upon each item close out. specification 100%

specification

Meets drawings and During installation

2. Close supervision of workmanship Specification, Drawings I I N/ A Photographs QA file

specification 100%

Ensure sign off procedure is completed

3. prior to scaffold being erected for the Checklist In line with checklist Upon completion I I N/ A Sign off sheet QA file

next lift

Handover plan and activities agreed? Works adequately protected? Certification and

Section 3 Post Installation (what must be done to maintain the work before handover to others / Client) Warranties available? Health and Safety information submitted for O&Ms?

Ensure brickwork is set before next Until Brickwork is set

1. N/ A N/ A I I N/ A Photographs QA file

scaffold lift if tying into the structure (3days)

Ensure brickwork is set before brick Until Brickwork is set

2. N/ A N/ A I I N/ A Photographs QA file

clean (3days)

ITP Close Out Declaration Final sign-off of the ITP once works are completed and all relevant assurance documentation is in place

This work package / element has been undertaken and completed in accordance with this ITP and associated documentation, e.g. procedures, specifications, drawings, design changes, and instructions

Subcontractor Supvr / Mngr Kier Mngr

Sign Date Sign Date

H Hold Point cease works until inspected and approved I Inspection - complete inspection and record findings R Record Review review record/document to verify checks have been made

T Test / Measure / Sample complete and record results N/A Not required

Authorised By: Nick Shepherd Page 2 of 2 KGA-FOR-BUK-NOR-3400

Author: Adam Davies Issue Date: September 2016 Version: 1.0

As part of our KGA review the next review date is due on 30th September 2017

You might also like

- National Cranberry CooperativeDocument11 pagesNational Cranberry CooperativeFabiola SE100% (2)

- ITP - Concrete Works PDFDocument2 pagesITP - Concrete Works PDFntah8484% (38)

- ITP - Fencing and Gates Installation Works - MAB1Document24 pagesITP - Fencing and Gates Installation Works - MAB1Vasilica Barbarasa100% (2)

- Drainage Work - Inspection Test Plan - ITPDocument4 pagesDrainage Work - Inspection Test Plan - ITPAlaa Ali67% (3)

- ITP - Blockwork R0 - HKHDocument2 pagesITP - Blockwork R0 - HKHabdou90% (10)

- ITP For Brick Masonry WorkDocument8 pagesITP For Brick Masonry WorkVipin Kumar ParasharNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Ceramic Tiles (For Walls)Document4 pagesEtihad Towers Project: Inspection & Test Plan - Ceramic Tiles (For Walls)jini100% (2)

- Itp For For Excavation, Backfilling & Compaction For Building WorksDocument4 pagesItp For For Excavation, Backfilling & Compaction For Building WorksBleep NewsNo ratings yet

- ITP For Earthworks of Onshore HighwayDocument6 pagesITP For Earthworks of Onshore HighwayYay B. Gico100% (2)

- Itp - Rebar & ConcreteDocument4 pagesItp - Rebar & ConcreteMohammad Arif RasheedNo ratings yet

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- Sample - ITP For Architectural WorksDocument3 pagesSample - ITP For Architectural Worksiman arief100% (5)

- Inspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CDocument1 pageInspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Material Inspection Request FormDocument1 pageMaterial Inspection Request FormEnvicon Projects100% (3)

- Inspection and Test Plan: DESCRIPTION: Manhole ConstructionDocument4 pagesInspection and Test Plan: DESCRIPTION: Manhole ConstructionDelta akathehusky67% (3)

- Method Statement For Block Works PDFDocument9 pagesMethod Statement For Block Works PDFrayNo ratings yet

- Rectification of Existing Slab ITPDocument2 pagesRectification of Existing Slab ITPrayNo ratings yet

- ITP PLUMBING WORKS SampleDocument1 pageITP PLUMBING WORKS SampleJay Chris L. Beron80% (5)

- INSPECTION & TEST PLAN (ITP) : Anti Termite TreatmentDocument1 pageINSPECTION & TEST PLAN (ITP) : Anti Termite TreatmentLOPA THANDAR100% (2)

- Inspection and Test Plan - Plumbing Works (Qcitp) : Material InspectionsDocument28 pagesInspection and Test Plan - Plumbing Works (Qcitp) : Material InspectionsJay Chris L. Beron100% (1)

- ITP For Caprentry & Joinery WorksDocument2 pagesITP For Caprentry & Joinery Worksexia19920% (2)

- Inspection & Test Plan For Floor ScreedDocument2 pagesInspection & Test Plan For Floor Screedexia199250% (2)

- PD-CL-021 - 1 Precast Panel InstallationDocument1 pagePD-CL-021 - 1 Precast Panel Installationkimura takuyaNo ratings yet

- Inspection & Test Plan For Concrete Protective CoatingDocument6 pagesInspection & Test Plan For Concrete Protective CoatingQaisar KhaiyamNo ratings yet

- Method Statement & Itp For Waterproofing WorkDocument7 pagesMethod Statement & Itp For Waterproofing WorkRumi ZamNo ratings yet

- ITP For Block WorkDocument9 pagesITP For Block WorkMohammed Ghareib Nasr50% (2)

- 6.ITP For RebarDocument1 page6.ITP For RebarDaniel Sinaga100% (1)

- AlumDoor-Inspection & Testing Plan (ITP)Document1 pageAlumDoor-Inspection & Testing Plan (ITP)Yash Sharma67% (3)

- Itp PlasteringDocument7 pagesItp PlasteringJervino RuahNo ratings yet

- Method Statement For PCC Pouring, Waterproofing & ScreedDocument9 pagesMethod Statement For PCC Pouring, Waterproofing & ScreedJoe PsNo ratings yet

- Check List For Rebar & FormworkDocument1 pageCheck List For Rebar & FormworkEbrahimAbuZaid0% (1)

- C8516-CLT-QMT-0032 - Rev-00 Inspection Checklist For Kerbstone Installation WorksDocument1 pageC8516-CLT-QMT-0032 - Rev-00 Inspection Checklist For Kerbstone Installation WorksJabin100% (3)

- Excavation ChecklistDocument1 pageExcavation ChecklistBudoy SmithNo ratings yet

- Checklist For Pre-Pour ConcretingDocument1 pageChecklist For Pre-Pour ConcretingDanish mallick100% (1)

- Itp For Installation of FormworksDocument1 pageItp For Installation of FormworksImho TepNo ratings yet

- ITP For CivilDocument85 pagesITP For CivilBilibili weekly TOP 10 videos100% (7)

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Inspection-Test-plan For Block WorkDocument3 pagesInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- ITP For RC RC Slab, Beams WorkDocument3 pagesITP For RC RC Slab, Beams WorkMohammed Ghareib NasrNo ratings yet

- Check List For CONCRETE Block WorksDocument1 pageCheck List For CONCRETE Block WorksYash Sharma100% (1)

- Inspection Checklist Format - Excavation, Stone Dust Filling & PCCDocument2 pagesInspection Checklist Format - Excavation, Stone Dust Filling & PCCgalfar7100% (2)

- Inspection and Testing Plan (Itp) : Backfilling WorksDocument2 pagesInspection and Testing Plan (Itp) : Backfilling WorksYash Sharma100% (1)

- Reference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawDocument3 pagesReference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawPresanna Rajasekaran100% (2)

- ITP For BLOCKWORKDocument4 pagesITP For BLOCKWORKimkashifsaleemNo ratings yet

- ITP For Blinding Concrete WorksDocument3 pagesITP For Blinding Concrete WorksMohammed Ghareib NasrNo ratings yet

- Checklist For Tiling Wall Dadoing FlooringDocument4 pagesChecklist For Tiling Wall Dadoing FlooringickoNo ratings yet

- Inspection and Test Plan (Reinforced Concrete Slab Construction)Document2 pagesInspection and Test Plan (Reinforced Concrete Slab Construction)ray100% (2)

- ITP CIVIL WORK-Rev-1Document6 pagesITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- Checklist For Window M.S GrillDocument2 pagesChecklist For Window M.S GrillAh RashedNo ratings yet

- Inspection & Test Plan For Cmu WorkDocument14 pagesInspection & Test Plan For Cmu WorkQaisar KhaiyamNo ratings yet

- Curing Compound ChecklistDocument1 pageCuring Compound ChecklistMohammed ArishNo ratings yet

- ITP For Concrete Paving WorkDocument15 pagesITP For Concrete Paving WorkShewale Pravin100% (3)

- 030 - CHECKLIST FOR Enamel PainitngDocument1 page030 - CHECKLIST FOR Enamel PainitngR HarshavardhanaNo ratings yet

- Checklist For Tiles FlooringDocument2 pagesChecklist For Tiles FlooringKishoreNo ratings yet

- Check List For Backfilling WorksDocument1 pageCheck List For Backfilling WorksYash Sharma100% (3)

- Plastering CHK ListDocument2 pagesPlastering CHK Listhafis0% (1)

- ITP Fencing Rev - 00 PDFDocument3 pagesITP Fencing Rev - 00 PDFanon_987276020No ratings yet

- Concrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17Document1 pageConcrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17mahesh naikNo ratings yet

- Inspection and Test Plan (ITP) - Civil WorksDocument1 pageInspection and Test Plan (ITP) - Civil WorksNaveen GladsonNo ratings yet

- Checklist PlasteringDocument1 pageChecklist Plasteringrodindavid1618No ratings yet

- Checklist For Shuttering WorkDocument6 pagesChecklist For Shuttering WorkfbellimamNo ratings yet

- It and CommunicationDocument7 pagesIt and CommunicationMohamad AdiputraNo ratings yet

- Complete Contents of The Collected Words of D. W. WinnicottDocument54 pagesComplete Contents of The Collected Words of D. W. WinnicottGabriel Serra ManhaesNo ratings yet

- Indian Law Report - Allahabad Series - Sep-Oct2003Document168 pagesIndian Law Report - Allahabad Series - Sep-Oct2003PrasadNo ratings yet

- How To Have A Quiet Time With GodDocument5 pagesHow To Have A Quiet Time With Godgladilyn100% (1)

- At.2503 Audit Evidence and Documentation The FrameworkDocument43 pagesAt.2503 Audit Evidence and Documentation The Frameworkawesome bloggersNo ratings yet

- Kastelic Karmen GOOGLEDocument2 pagesKastelic Karmen GOOGLEkarmen kastelicNo ratings yet

- TQ Contemporary PrelimDocument2 pagesTQ Contemporary PrelimBernard Baruiz100% (1)

- ACE PALAWAN MGAS-SECOND FLOOR-ModelDocument1 pageACE PALAWAN MGAS-SECOND FLOOR-ModelBerlin Andrew SionNo ratings yet

- Dare Adventure Farm Corporation v. Spouses Felix and Nenita NG, Et Al DigestDocument2 pagesDare Adventure Farm Corporation v. Spouses Felix and Nenita NG, Et Al DigestNic OngNo ratings yet

- IcdsDocument3 pagesIcdsArchana SahuNo ratings yet

- SUN2000-100KTL-H1 Datasheet 20180729 PDFDocument2 pagesSUN2000-100KTL-H1 Datasheet 20180729 PDFLaddy Vivivana Parra EcheverryNo ratings yet

- N.C. A&T Magazine Fall-Winter 2022-2023Document39 pagesN.C. A&T Magazine Fall-Winter 2022-2023ДмитрийNo ratings yet

- Facts:: Case # 003. Cabansag v. FernandezDocument2 pagesFacts:: Case # 003. Cabansag v. FernandezMaria Jennifer Yumul Borbon100% (3)

- GVI Fiji Achievement Report July - The Silana ProjectDocument3 pagesGVI Fiji Achievement Report July - The Silana ProjectGlobal Vision International FijiNo ratings yet

- Generally Accepted Accounting Principles (GAAP)Document4 pagesGenerally Accepted Accounting Principles (GAAP)Sakata369100% (1)

- Me and My Social MapDocument1 pageMe and My Social MapsinemaNo ratings yet

- Review The Trellis and The VineDocument4 pagesReview The Trellis and The Vinedrisdale75% (4)

- Mycobacterium TuberculosisDocument54 pagesMycobacterium TuberculosisDaniel WaweruNo ratings yet

- FM 3-04.240 (FM 1-240) Instrument Flight For Army Aviators-April 2007Document362 pagesFM 3-04.240 (FM 1-240) Instrument Flight For Army Aviators-April 2007wawalandNo ratings yet

- KRNL Download - KRNLDocument1 pageKRNL Download - KRNLRit RuechaNo ratings yet

- Jasmen Basambekyan, A075 665 907 (BIA Nov. 28, 2017)Document9 pagesJasmen Basambekyan, A075 665 907 (BIA Nov. 28, 2017)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Health Education: (GRADE 10)Document37 pagesHealth Education: (GRADE 10)paratosayoNo ratings yet

- Procredit Alb 2018Document64 pagesProcredit Alb 2018Thomas SzutsNo ratings yet

- Mod de Calcul Rata AbsorbtieDocument18 pagesMod de Calcul Rata AbsorbtieCristina RusNo ratings yet

- Kevin Martinez, 10sep 1725 MiamiDocument2 pagesKevin Martinez, 10sep 1725 MiamiLoggui BooguiNo ratings yet

- Exam Capsule LED Property LawDocument37 pagesExam Capsule LED Property Lawaryamaan.bhardwajNo ratings yet

- Onlyfans Agency by Tony Miller - Ecorp - 2022Document100 pagesOnlyfans Agency by Tony Miller - Ecorp - 20222g967dcq24No ratings yet

- Weiqi Vs Chess - The Thin Red Line Between Smart and Subtle Power - Gian Luca Atzori-LibreDocument3 pagesWeiqi Vs Chess - The Thin Red Line Between Smart and Subtle Power - Gian Luca Atzori-LibrevonquixoteNo ratings yet

- BHPDocument20 pagesBHPAnonymous 0bkfMCBPaCNo ratings yet