Field Proven: Southeast Asia Southern Oklahoma

Field Proven: Southeast Asia Southern Oklahoma

Uploaded by

Aquiles CarreraCopyright:

Available Formats

Field Proven: Southeast Asia Southern Oklahoma

Field Proven: Southeast Asia Southern Oklahoma

Uploaded by

Aquiles CarreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Field Proven: Southeast Asia Southern Oklahoma

Field Proven: Southeast Asia Southern Oklahoma

Uploaded by

Aquiles CarreraCopyright:

Available Formats

Field Proven

SOUTHEAST ASIA SOUTHERN OKLAHOMA

FLOWING OIL WELL, 325F PUMPING WELL, 90F

50 40

35

Parts per Million Phosphonate

Parts per Million Phosphonate

40

30

30 25

20

20 15

10

10

5

0 0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Time in Days Time in Days

Calcium Carbonate Scaling Problem Calcium Sulfate Scaling Problem

Figure 3, Flowing Well in Southeast Asia. To inhibit a calcium carbonate Figure 5, Rod-Pumped Well in Southern Oklahoma. A calcium

problem, 110 gal of ScaleCaps were pumped into the well and displaced to carbonate deposition problem used 15 gal of ScaleCaps. Caps were circulated

the rathole. Average fluid production during test was 4029 BOPD and into the well and the well shut-in to allow the inhibitor to fall into the

5232 BWPD. rathole. Average production during the test was 15 BOPD and 385 BWPD.

WEST TEXAS EAST TEXAS

ROD PUMPING WELL, 170F ROD PUMPING WELL, 110F

25 50

Parts per Million Phosphonate

20 Parts per Million Phosphonate 40

15 30

10 20

5 10

0 0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 0 20 40 60 80 100 120

Time in Days Time in Days

Calcium Sulfate Scaling Problem Carbonate Scaling Problem

Figure 4, Rod Pumped Well inWest Texas. A chronic gypsum problem Figure 6, Rod Pumped Well in East Texas. Calcium carbonate scale was

was treated with 10 gal of ScaleCaps by circulating the inhibitor into the inhibited with 10 gal of ScaleCaps circulated into well. Shut-in time allowed

well and allowing it to fall into the rathole. Average production during test the inhibitor to fall into the rathole. Average production during test was

was 19 BOPD and 227 BWPD. 210 BOPD and 35 BWPD.

Disclaimer

Information contained in this brochure is representative of tests conducted on a developmental project. The information is believed to be accurate, but all recommendations are made without warranty, since the conditions of use are

beyond UNICHEMs control. UNICHEM does not warrant against infringement by reason of the use of any of its products in combination with other materials or in any process.

You might also like

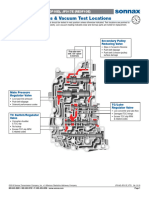

- Jf016e Jf017e PDFDocument4 pagesJf016e Jf017e PDFSAMAD90% (10)

- Jf016e Jf017e PDFDocument4 pagesJf016e Jf017e PDFanzor86% (7)

- A650e VBDocument2 pagesA650e VB陳瑞崇100% (1)

- Manual de Usuario Volkswagen Jetta (2011) (217 Páginas)Document2 pagesManual de Usuario Volkswagen Jetta (2011) (217 Páginas)ChintoNo ratings yet

- JF016E-JF017E Vacuum Manual Valve BodyDocument4 pagesJF016E-JF017E Vacuum Manual Valve Bodyak_adam100% (2)

- ReportDocument4 pagesReportAsux LinuxerNo ratings yet

- Latest Lighting Gantry Steel Structure Shopdrawing - 20231016-7Document1 pageLatest Lighting Gantry Steel Structure Shopdrawing - 20231016-7jmr76803No ratings yet

- Detail PJ1: Kusen Kayu 5/10Document1 pageDetail PJ1: Kusen Kayu 5/10musthafa achikNo ratings yet

- First FloorDocument1 pageFirst Floortadesse felekeNo ratings yet

- Grain Size Distribution: Client Mbits Project Name Po1 Project Number Po1Document1 pageGrain Size Distribution: Client Mbits Project Name Po1 Project Number Po1Dileep K NambiarNo ratings yet

- 01 ParterDocument1 page01 ParterJaravete Sebastian DamianNo ratings yet

- Super Skill Pinball - Cyberhack - FREEDocument1 pageSuper Skill Pinball - Cyberhack - FREEAlfonso CáceresNo ratings yet

- HI-Iron HI-Iron DM-1 DM-1 SA-300 SA-300 CI-400 CI-400 Liquid AGA Liquid AGADocument1 pageHI-Iron HI-Iron DM-1 DM-1 SA-300 SA-300 CI-400 CI-400 Liquid AGA Liquid AGAOleg KokorynetsNo ratings yet

- PLAN PARTER (Propus) Scara 1:100: H/L 841 / 420 (0.35m2) Allplan 2018Document1 pagePLAN PARTER (Propus) Scara 1:100: H/L 841 / 420 (0.35m2) Allplan 2018Victor RîndunicaNo ratings yet

- 06 SubpantaDocument1 page06 SubpantaCamelia RosuNo ratings yet

- ST James Infirmary-Euph2Document1 pageST James Infirmary-Euph2Philippe PoiretNo ratings yet

- ST James Infirmary-Bari - SaxDocument1 pageST James Infirmary-Bari - SaxPhilippe PoiretNo ratings yet

- Denah Me - Unit Tipe Family 1 - Hotel Royal WonderDocument4 pagesDenah Me - Unit Tipe Family 1 - Hotel Royal WonderTri Puji SantanaNo ratings yet

- In Line Control ValvesDocument1 pageIn Line Control ValvesDanielEscobarMontecinosNo ratings yet

- как жить и не работать джэф016 PDFDocument4 pagesкак жить и не работать джэф016 PDFМихаил БолотинNo ratings yet

- 464192534 вакуум тест для JF016 017 PDFDocument4 pages464192534 вакуум тест для JF016 017 PDF89539306889No ratings yet

- вакуум тест для JF016-017 PDFDocument4 pagesвакуум тест для JF016-017 PDFМихаил Болотин100% (1)

- Critical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodyDocument4 pagesCritical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodySAMADNo ratings yet

- Sdre14-19 TFS 1-2-1dec17Document3 pagesSdre14-19 TFS 1-2-1dec17lwin_oo2435No ratings yet

- Rapporte Des Problèmes Conception TESTING For OrderingDocument4 pagesRapporte Des Problèmes Conception TESTING For Orderingabdou.trafficNo ratings yet

- BL - MM2500 - 2.0l - Vs - HVFR - 1.0kg - 62C 05182020Document1 pageBL - MM2500 - 2.0l - Vs - HVFR - 1.0kg - 62C 05182020Oleg KokorynetsNo ratings yet

- Coretan Ukuran Ruang Karoke JojoDocument3 pagesCoretan Ukuran Ruang Karoke JojoariesviodwiyantoNo ratings yet

- Timarini Curva CaracteristicaDocument1 pageTimarini Curva Caracteristicapamel.rr20No ratings yet

- Grain Size Distribution: Client Mbits Project Name P05 Project Number Po5Document1 pageGrain Size Distribution: Client Mbits Project Name P05 Project Number Po5Dileep K NambiarNo ratings yet

- Interior Point HomyDocument22 pagesInterior Point HomyjimmyrikhardiNo ratings yet

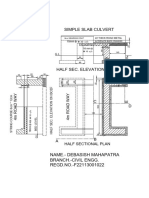

- SIMPLE SLABE CULVERT 1-ModelDocument1 pageSIMPLE SLABE CULVERT 1-ModelFree fire LoverNo ratings yet

- Diagrama de Molière R134a: RefrigerantesDocument1 pageDiagrama de Molière R134a: RefrigerantesHumnerNo ratings yet

- ST James Infirmary-Euph - 1Document1 pageST James Infirmary-Euph - 1Philippe PoiretNo ratings yet

- L I Quang MinhDocument1 pageL I Quang Minhconduongtrithuc1997No ratings yet

- La Guia MetAs 10 06 Densidad AguaDocument19 pagesLa Guia MetAs 10 06 Densidad AguaMayreneDavilaNo ratings yet

- Abba Gold BajoDocument4 pagesAbba Gold BajoPABLO GonzalezNo ratings yet

- Grain Size Distribution: Client Mbits Project Name P05 Project Number Po5Document1 pageGrain Size Distribution: Client Mbits Project Name P05 Project Number Po5Dileep K NambiarNo ratings yet

- 8.3.2.2 Fan Curve - NormalDocument1 page8.3.2.2 Fan Curve - NormalAdhi NugrohoNo ratings yet

- O.5 - Fabry Perot Resonator PDFDocument19 pagesO.5 - Fabry Perot Resonator PDFAlexeiNo ratings yet

- MTC Map 1 To 25000Document1 pageMTC Map 1 To 25000bussens2012No ratings yet

- JF016E-JF017E Vacuum Manual Valve BodyDocument4 pagesJF016E-JF017E Vacuum Manual Valve Bodychiwaramatthew30No ratings yet

- Rock Around The Clock-Trombone 3Document1 pageRock Around The Clock-Trombone 3Philippe PoiretNo ratings yet

- GEM Series - En12845 Fire Fighting Booster Sets in Egypt, Technical Catalog Part 2Document66 pagesGEM Series - En12845 Fire Fighting Booster Sets in Egypt, Technical Catalog Part 2Rheoserve Industrial SolutionsNo ratings yet

- Technical FlowpakDocument3 pagesTechnical FlowpakAmjad HussainNo ratings yet

- ST James Infirmary-BassDocument1 pageST James Infirmary-BassPhilippe PoiretNo ratings yet

- Map Pointing Europe Class 7Document2 pagesMap Pointing Europe Class 7rishabhaarush0111No ratings yet

- Improve Your Coarse Fishing TruePDF-Issue 322 2017Document132 pagesImprove Your Coarse Fishing TruePDF-Issue 322 2017Ciprian CociubaNo ratings yet

- Sugarcane IrrigationDocument36 pagesSugarcane IrrigationRahul PersandNo ratings yet

- Land Use MapDocument1 pageLand Use MapOlajide AwaiyeNo ratings yet

- 4T65 E VacTestDocument3 pages4T65 E VacTestanzorNo ratings yet

- Rekapan Januari 2020Document99 pagesRekapan Januari 2020Muhammad Zakky SeptiantNo ratings yet

- Week #38 Environmental Walkthrough Observation ReportDocument5 pagesWeek #38 Environmental Walkthrough Observation ReportQADEER SHANNo ratings yet

- Peta GH Latdas 39 New-1Document1 pagePeta GH Latdas 39 New-1Humaira BjmNo ratings yet

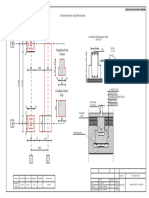

- R.01 Foundation Detail for 11 Quick RoadDocument1 pageR.01 Foundation Detail for 11 Quick RoadAlex ButnaruNo ratings yet

- PP 45 X 30Document1 pagePP 45 X 30Alex LimoNo ratings yet

- BracketDocument1 pageBracketbapernastNo ratings yet

- Manual 2016 Kaos Evo 2.5!12!15 Tamanho GrandeDocument2 pagesManual 2016 Kaos Evo 2.5!12!15 Tamanho GrandeDeivid Weber100% (1)

- Corpiño ImprimirDocument1 pageCorpiño ImprimirSebastianNo ratings yet

- Evoplus Ts EngDocument96 pagesEvoplus Ts EnggabitermoinstalNo ratings yet

- Afh-Fab-Grp-Spz-Stl-004 (00) B1Document1 pageAfh-Fab-Grp-Spz-Stl-004 (00) B1wrkrvlgNo ratings yet

- Raindrops Keep 1Document2 pagesRaindrops Keep 1Juliano SouzaNo ratings yet

- CE GilsoniteDocument2 pagesCE GilsoniteAquiles CarreraNo ratings yet

- Ce Mpa 1 Mpa 2Document1 pageCe Mpa 1 Mpa 2Aquiles CarreraNo ratings yet

- SPE/IADC 57585 Custom-Blending Foamed Cement For Multiple ChallengesDocument10 pagesSPE/IADC 57585 Custom-Blending Foamed Cement For Multiple ChallengesAquiles CarreraNo ratings yet

- Calcium Chloride/Calcium Chloride-L: CementingDocument2 pagesCalcium Chloride/Calcium Chloride-L: CementingAquiles CarreraNo ratings yet

- Chapter 03 PP Overview - SDocument16 pagesChapter 03 PP Overview - SAquiles CarreraNo ratings yet

- Cementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYDocument1 pageCementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYAquiles CarreraNo ratings yet

- RE ParavanSystems PDFDocument1 pageRE ParavanSystems PDFAquiles CarreraNo ratings yet

- Cementing: Applications Applications Applications Applications ApplicationsDocument2 pagesCementing: Applications Applications Applications Applications ApplicationsAquiles CarreraNo ratings yet

- Paravan 25X - LBDocument2 pagesParavan 25X - LBAquiles CarreraNo ratings yet

- Poly Plug 1Document5 pagesPoly Plug 1Aquiles CarreraNo ratings yet

- MCS SpacerDocument3 pagesMCS SpacerAquiles CarreraNo ratings yet

- Mpa-1 Usa PDFDocument7 pagesMpa-1 Usa PDFAquiles CarreraNo ratings yet

- A 3L PDFDocument4 pagesA 3L PDFAquiles CarreraNo ratings yet

- MCS AgDocument1 pageMCS AgAquiles CarreraNo ratings yet

- M AquatrolDocument23 pagesM AquatrolAquiles CarreraNo ratings yet

- Sand Vac OGJ-APRIL-2002 PDFDocument6 pagesSand Vac OGJ-APRIL-2002 PDFAquiles CarreraNo ratings yet

- SPE 53943 New Down-Hole External Casing Mud Removal Technology Improves Primary Cement ResultsDocument7 pagesSPE 53943 New Down-Hole External Casing Mud Removal Technology Improves Primary Cement ResultsAquiles CarreraNo ratings yet

- Cementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYDocument1 pageCementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYAquiles CarreraNo ratings yet

- ST FerrotrolDocument2 pagesST FerrotrolAquiles CarreraNo ratings yet

- Data Sheet 2BH1 100: Side Channel BlowerDocument2 pagesData Sheet 2BH1 100: Side Channel BlowerJuan MolinaNo ratings yet

- Lehe0449-00 2 PDFDocument5 pagesLehe0449-00 2 PDFjulio cesarNo ratings yet

- Armor Magazine, September-October 1987Document56 pagesArmor Magazine, September-October 1987"Rufus"100% (3)

- 24 Bit Aircraft ID ProgrammingDocument3 pages24 Bit Aircraft ID ProgrammingAidan MonaghanNo ratings yet

- Track and Trace For Pharmaceutical Serialization The Way ForwardDocument12 pagesTrack and Trace For Pharmaceutical Serialization The Way ForwardBharti Gupta100% (2)

- Banking AnalyticsDocument14 pagesBanking Analyticsgaurav1200No ratings yet

- Hasil To-2 3SMPDocument18 pagesHasil To-2 3SMPMattew SibaraniNo ratings yet

- Accord Dash Kit (Metra, 99-7864)Document8 pagesAccord Dash Kit (Metra, 99-7864)heideswNo ratings yet

- ESR Load Calculation Sheet 2011Document4 pagesESR Load Calculation Sheet 2011Betto MtNo ratings yet

- Feasibility Study ProjectDocument25 pagesFeasibility Study Projectjudytafe91% (11)

- Chassis Universal TH-2918A DiagramaDocument11 pagesChassis Universal TH-2918A DiagramaHamza Abbasi AbbasiNo ratings yet

- Abap ResumeDocument3 pagesAbap ResumeMukund Reddy BasaniNo ratings yet

- SPP 4355Document808 pagesSPP 4355Enrique RamirezNo ratings yet

- Heat Exchanger Fundamentals: Heat Exchange Concepts & Heat ExchangersDocument3 pagesHeat Exchanger Fundamentals: Heat Exchange Concepts & Heat ExchangersGustavNo ratings yet

- Predimensionamiento de Columnas Por Gravedad: ( ) Tipo de Ladrillo: SOLIDO / HUECO, Altura Mayor de TabiqueriaDocument15 pagesPredimensionamiento de Columnas Por Gravedad: ( ) Tipo de Ladrillo: SOLIDO / HUECO, Altura Mayor de TabiqueriaCharles Joseph MinardNo ratings yet

- Dattatraya Vairal (1.8 Yr Exp.) - Front End DeveloperDocument3 pagesDattatraya Vairal (1.8 Yr Exp.) - Front End DeveloperAnonymous kBI8dq2No ratings yet

- CRM - An Operational Tool For Customer Centric Actions: Case Study in Service SectorDocument19 pagesCRM - An Operational Tool For Customer Centric Actions: Case Study in Service SectorHarshal Patil100% (1)

- Programming Assignment 1 - PercolationDocument3 pagesProgramming Assignment 1 - Percolationtimtam89No ratings yet

- MEMO - Profiling of KK and Youth DatabaseDocument11 pagesMEMO - Profiling of KK and Youth DatabaseArjay DelapeñaNo ratings yet

- Narrative Report 2Document39 pagesNarrative Report 2Jericho Castillo50% (2)

- Design of Distillation Sequence From Conventional To Fully Thermally Couple Distillation SystemDocument23 pagesDesign of Distillation Sequence From Conventional To Fully Thermally Couple Distillation SystemRinda Nur HidayatiNo ratings yet

- Brosjyre Niton XL5Document2 pagesBrosjyre Niton XL5Agustin A.No ratings yet

- QHSE Inspection ReportDocument4 pagesQHSE Inspection ReportAadarshNo ratings yet

- 0 - FOX615 Overview 2014 - FinalDocument2 pages0 - FOX615 Overview 2014 - Finalbabiso33% (3)

- Valvula de Boom PlumaDocument3 pagesValvula de Boom PlumaWillian Samir Huamani VargasNo ratings yet

- Project Requirement GatheringDocument2 pagesProject Requirement GatheringmarishaNo ratings yet

- Reference Letter For ImmigrationDocument8 pagesReference Letter For Immigrationaflkubfrv100% (1)

- MM Project ProposalDocument4 pagesMM Project ProposalSikander AzamNo ratings yet