247 - AM5K Manual Standard 2016-12-08

247 - AM5K Manual Standard 2016-12-08

Uploaded by

EbukaCopyright:

Available Formats

247 - AM5K Manual Standard 2016-12-08

247 - AM5K Manual Standard 2016-12-08

Uploaded by

EbukaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

247 - AM5K Manual Standard 2016-12-08

247 - AM5K Manual Standard 2016-12-08

Uploaded by

EbukaCopyright:

Available Formats

AM5K COMBINED DEPTH/TENSION

MEASUREMENT DEVICE

Zone 2 - Class 1 Div 2

For Open & Cased Hole or

Cased Hole E-Line Logging

STANDARD CONFIGURATIONS

AM5K STANDARD DEC 2016 Page 1 of 129

CONTENTS

SAFETY WARNINGS

QUICK START GUIDE

1.0 GENERAL

2.0 SYSTEM DESCRIPTION

3.0 OPERATION

4.0 MAINTENANCE AND REPAIR

4.5.5 Encoder Mount & Top Guide Wheel Removal

4.5.6 Replace Load Axle

5.0 OPTIONS AND ACCESSORIES

6.0 CERTIFICATION DOCUMENTS

6.1 6.6 Certificates

6.7 Safety labels

7.0 SPARE PARTS LISTS

8.0 DRAWINGS & SPECIFICATIONS

8.1 Measuring head assembly

8.2 Magnetic mark detector

8.3 Load pin

8.4 Encoder

8.5 Backup odometer

AM5K STANDARD DEC 2016 Page 2 of 129

SAFETY WARNINGS

This apparatus is suitable for use in ATEX Zone 2 Locations.

This apparatus is suitable for use in Class I, Division 2, Groups A, B, C, & D

Hazardous (Classified) or Unclassified Locations.

WARNING EXPLOSION HAZARD SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR ATEX Zone 2 LOCATIONS.

AVERTISSEMENT RISQUE DEXPLOSION LA SUBSTITUTION DE

COMPOSANT PEUT RENDRE CE MATERIEL INACCEPTABLE POUR LES ATEX

Zone 2 LOCALES.

WARNING - EXPLOSION HAZARD SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR CLASS I, DIVISION 2;

AVERTISSEMENT - RISQUE D'EXPLOSION LA SUBSTITUTION DE

COMPOSANTS PEUT RENDRE CE MATERIEL INACCEPTABLE POUR LES

EMPLACEMENTS DE CLASSE I, DIVISION 2

WARNING EXPLOSION HAZARD DO NOT DISCONNECT EQUIPMENT

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOW TO BE

NON-HAZAROUS;

AVERTISSEMENT RISQUE DEXPLOSION AVANT DE DECONNECTER

LEQUIPMENT, COUPER LE COURANT OU SASSURER QUE LEMPLACEMENT

EST DESIGNE NON DANGEREUX.

WARNING - PROTECTION MAY BE IMPAIRED IF THIS DEVICE IS USED IN AN

APPLICATION OR MANNER NOT SPECIFIED IN THE MANUAL

NOTE The safe ambient temperature operating range for this equipment is -20 to

40C or -4 to 104F.

___________________________________________________

BenchMark measuring equipment will frequently be operated in hazardous

environments. Appropriate safety precautions need to be taken.

Training - Operators shall be trained in the proper and safe use of the device.

Do not exceed the tension limit specified for this device in this manual.

AM5K STANDARD DEC 2016 Page 3 of 129

SAFETY WARNINGS continued

Flammable Substances - Flammable and explosive substances are often found in the

proximity of the equipment operations. Proper venting should take place where

practicable. Avoid open flames, sparks and other ignition sources.

Electric Shock Depending on the equipment being used, both AC and DC current

may be present. Frequently in wellsite operations conductive fluids and chemicals are

used. Use extra caution when working with BenchMark equipment and follow

manufacturer warnings to avoid electric shock.

Do not separate any electrical connector, while powered, in a hazardous area.

Separate only when power is removed, and/or in a safe area.

Safe Operating Temperatures BenchMark Wireline equipment is designed to

operate safely within these temperature ranges. Do not try to operate this equipment

in conditions that outside these temperature limits.

The safe ambient temperature operating range for this equipment is -20 to 40C or -4 to

104F.

Hazardous Equipment Marking - See General Assembly drawings for hazardous

equipment marking.

ALL WARNING LABELS ON THE EQUIPMENT MUST BE OBSERVED AND FOLLOWED.

Installation Instructions - Install measuring device onto the spooling mechanism per

the unit manufacturer instructions. Take care to avoid pinching or cutting of electrical

cables when the measuring device moves during the spooling operation.

Take care to thread the wire through the device properly to prevent the wire from

rubbing the frame during operation. The Table of Contents of this manual will list

where the threading procedure is located.

Rotating Equipment BenchMark Wireline measuring equipment is often attached to

rotating industrial machinery. This may include winches, pulleys, rigging, rotating

drums plus moving cable and wire. Though BenchMarks measuring equipment does

not normally present a safety hazard when in operation provided it is used within the

design parameters of the equipment, the heavy equipment used in this type of work in

proximity to BenchMarks equipment may. Never attempt to use BenchMark

equipment in any way or for any other purpose than for which it was designed.

Use every precaution to keep a safe distance from dangerous equipment when it is in

operation. Never approach the measuring device while the cable drum is turning.

AM5K STANDARD DEC 2016 Page 4 of 129

QUICK START PROCEDURES

1.1 Install the measuring head on to the spooling arm.

1.2 Open the measuring head.

1.3 Position the measuring head below the wire.

1.4 Clamp the head over the wire, close it and insert the locking pin.

1.5 Connect encoder and load pin cables to measuring head and panel.

1.6 Begin operations

AM5K STANDARD DEC 2016 Page 5 of 129

RECOMMENDED SPARE PARTS

It is recommended that the following parts be kept on hand in the indicated quantities

QTY.

ITEM P/N DESCRIPTION QTY

RECOMMENDED SPARE PARTS FOR ALL LOCATIONS

14 AM5KA058 ASSY BACKUP MAGNETIC EEx Na 1

22 AM5KM001 WHEEL MEASURING 2FT 5 SPOKE 2

31 AM5KA247 ASSY WHEEL GUIDE PLAS 35MM BRG 4

33 AM5KA063 ASSY WHEEL TENSN SHALLOW GROOVE 1

33 AM5KA073 ASSY WHEEL TENSN DEEP GROOVE 1

34 AM5KA364 ASSY WHEEL TENSN FIXD 35MM BRG 2

36 AM5KM073 COUPLING MOD ENCDR 0.250/0.375 2

51 AMS1P009 RETAINING PIN (T HANDLE) 1

ITEM P/N DESCRIPTION QTY

ADDITIONAL RECOMMENDED SPARE PARTS FOR REMOTE LOCATIONS

10 ASSY LOAD AXLE / PIN 1

12 AM5KA066 ASSY MAG MARK DETECTOR EEx nA 1

13 ENCODER 1

35 AM5KA065 ASSY ROLLER SPOOLNG 2.75" PLAS 4

54 AM5KM157 BEARING BALL 35MM ID MOD 6

55 AM5KP088 BEARING LINEAR 30MMID X 40MMOD 8

56 AM3KP204 BEARING BALL 20MM FAFNIR 204PP 4

58 AM5KM134 BEARING BALL 40MM ID MOD 1

59 AM5KP229 CLAMP TOGGLE PUSH/PULL SST 1

101 AM5KP130 NOZZLE GREASE FITTNG FLUSH 1

NOTE - ONLY STOCK THE LOAD AXLE AND ENCODER USED IN YOUR

MEASURING HEAD. A COMPLETE LIST IS FOUND IN THE BILL OF MATERIALS

AM5K STANDARD DEC 2016 Page 6 of 129

NOTE 1:

Heads manufactured before Sep 2013 did not have bearing seal retainers. We have

since installed retainers on the bearings installed in the AM5KA137 and AM5KA164.

The part numbers for these wheels have been changed to AM5KA247 and AM5KA364.

Visit 7.3 to see pictures of the new wheels.

AM5K STANDARD DEC 2016 Page 7 of 129

OBTAINING TECHNICAL ASSISTANCE

Call BenchMark Wireline Products Inc. at +1 281 346 4300

Or contact by email mail@benchmarkwireline.com

Or fax in request at +1 281 346 4301

Information in the form of user manuals and instructional videos are also

available on our website www.benchmarkwireline.com

Parts can be ordered by email, phone, or fax

Equipment can be returned for repair and maintenance. Please notify us by

Phone, email, or fax before sending any equipment.

To return equipment to BenchMark, ship it to:

BenchMark Wireline Products

36220 FM 1093

Simonton, Texas 77476

U.S.A.

AM5K STANDARD DEC 2016 Page 8 of 129

Manual Revision Log

Revision R - Jun 2010

Page 12 Added contact information for customer support

Pages 24-27 Added Options and Accessories section

Pages 43-48 Added new ATEX Zone 2 Certificates

Updated parts lists and numbers

Revision S - Jan 2016

Quick Start Revised parts list

3.7 K Factors

5.0 Additional options

7.0 Revised parts list

AM5K STANDARD DEC 2016 Page 9 of 129

1.0 GENERAL

The AM5K Wireline Measuring Device is a compact and lightweight device for

measuring both wireline depth and tension. The device is designed to be mounted to

the spooling arm of a wireline unit. It is unique to other measuring devices in that it

measures both depth and tension on wireline cables from .190 to .494. This device

will work on both open and cased hole wireline units which allows standardization on

a measuring head for all types of operations.

FEATURES AND BENEFITS:

Straight-line measurement - (cable sizes can be changed without affecting

depth measurement)

Dual Tangential Measuring Wheels - made from specially hardened steel

Accepts cable sizes - from .190 to .875 diameter (4.8 mm to 22 mm)

Optional guide wheels - available for wirelines up to .650 diameter

Lightweight design with integral tension - makes for easier high angle rigup

Device opens up - to provide easy cable installation and removal, by removing

a single pin

Includes both horizontal and vertical guide rollers - to minimize measuring

wheel loading

Rollers are oversized - to increase reliability and reduce maintenance

Guide rollers are made from composite material - to reduce weight and cable

wear

Rear or Center spooling arm mount - to minimize head jerking

Tension Load Axle and amplifier - can be configured for different outputs.

Digital Magnetic Mark Detector

Accepts single or dual encoders

Supports fully independent backup depth measuring system - using a

magnetic pickup

Backup depth system - reduces drag on measuring wheel by eliminating

mechanical drive cable

Encoder, Mark Detector, and Tension amplifier - certified for Zone II area use

Anodized aluminum frame - All steel parts are plated or SST

All bearings are SST

AM5K STANDARD DEC 2016 Page 10 of 129

2.0 SYSTEM DESCRIPTION

DEPTH MEASUREMENT:

The AM5K Measuring Head uses dual spring-loaded measuring wheels to measure

the amount of wireline moving to and from the borehole. The measuring wheels are

coupled to one or two optical encoders that transmit electrical signals via a cable to

the hoistmans panel and/or logging computer. An independently powered magnetic

encoder is used for back up depth indication.

The hardened measuring wheels are 2.0000 ft. (.609600 m) in circumference.

Springs are used to hold the measuring wheels in contact with the wireline. The

springs are sized to provide the appropriate friction between the wheels and wireline.

The frame members are anodized 6061-T6 aluminum.

Under ideal conditions, without magnetic marks, the measuring heads have an

accuracy of +/- 3 m in 3000 m (10 ft in 10,000 ft.). With magnetic marks and

accurate line stretch calculations, an accuracy of .3 m in 3000 m (1 ft in 10,000 ft) can

be achieved. The Hoistman's panel is required to fully utilize the mark detection and

stretch correction algorithms.

AM5K STANDARD DEC 2016 Page 11 of 129

TENSION MEASUREMENT:

The AM5K uses an electronic load axle to measure line tension. Three wheels are

used to create a force on the load axle. To generate this force the wheel mounted on

the load axle is offset from the other two slightly. This offset creates a slight bend in

the cable.

As wireline tension increases the small offset creates a corresponding bending force

on the strain-gauged load axle. An electronic signal is transmitted via cable to the

hoistmans panel and/or logging computer representing wireline tension. A calibrate

resistor is included in the load pin to send out a signal to calibrate the computer

system.

GENERAL SPECIFICATIONS:

WEIGHT: 58 lbs 26.3 kg

LENGTH: 26.5 673 mm

HEIGHT: 10.8 274 mm

WIDTH: 15.3 389 mm

MAXIMUM TENSION: 20,000 lbs 9072 kg

MEASURING WHEEL SIZE: 24.000 609.60 mm

CABLE SIZES: .190 to .875 diameter (4.8 mm to 22 mm)

CABLE BEND OVER TENSION WHEEL: 2.5 7.5 degrees (depends on cable)

Minimal or no affects on magnetic marks

AM5K STANDARD DEC 2016 Page 12 of 129

3.0 OPERATION

3.1 SPOOLING ARM INSTALLATION OVERHEAD SPOOLING ARM

Take Adequate Precautions when installing the Measuring Head to Avoid

the Risk of Mechanical Damage

Install the measuring head on to the spooling arm by using the top adapter

mount assembly to mount to an overhead spooling arm. The mount is

designed to mount with a standard U-joint yoke.

AM5K STANDARD DEC 2016 Page 13 of 129

3.1 SPOOLING ARM INSTALLATION continued

MOUNTING YOKE

AM5K STANDARD DEC 2016 Page 14 of 129

3.2 HEAD-ON CABLE INSTALL

Make sure that the head can freely sit on the wireline. If the mounting

arrangement will not let the head travel up and down freely and if the cable puts

a upward or downward force on the measuring head, this force will cause an

offset to the tension measurement which will result in an incorrect tension

reading.

AM5K STANDARD DEC 2016 Page 15 of 129

3.3 CABLE INSTALLATION

To install cable, first open the wheels by shifting the red release handles.

Next, remove the push pin, and hinge the head open.

Lifting up on the wireline cable makes it easier to remove the push pin.

The cable can now be inserted or removed.

Close the red release handles to tighten the wheels against the wireline.

Swing the head closed and reinsert the pin.

AM5K STANDARD DEC 2016 Page 16 of 129

3.4 CABLE REMOVAL UNDER LOAD

3.4.1 If under load, the load will need to be removed from the device

prior to removing the retaining pin. A C-clamp" or a nylon "ratchet strap"

can be used to remove the load.

3.4.2 Install a C-Clamp across the top and bottom frames as shown in

the drawing below. The ratchet strap can be installed in a similar way.

3.4.3 Tighten the C Clamp until the load is removed from the retaining

pin. Remove the retaining pin then loosen and remove the C Clamp.

AM5K STANDARD DEC 2016 Page 17 of 129

3.5 CHANGING BENCHMARK LOAD PIN WHILE DOWNHOLE

1. Stop Cable drum and Set Brake

2. Hold Safety Meeting with crew, ensure all persons are aware of roles and

responsibilities

3. Place cable clamp on cable approximately 1ft away from the front of the

lower sheave (side facing winch drum) and tighten onto cable, ensuring bolts

are made up crosswise

4. Spray a mark on the cable at the front of the clamp using spray paint

5. Attach chain and binder to cable clamp shackles and bind to a secure point

removing the slack from the chain to ensure when the cable is slacked, the

clamp does move forward too far and jam onto the lower sheave wheel.

6. Slack cable on the drum 5ft and monitor mark at the cable clamp for 1

minute to ensure no slippage of cable through the clamp

7. Perform load pin change-out as per below procedure:

a. Electronic load pin is held in place by one retaining ring on the outer

end of its shaft. Remove the retaining ring by using a small screw

driver to lift one end of the ring out of the groove then walk the ring

off of the pin.

b. The load pin can then be removed from the mounting frame.

c. Install the new load pin, replacing the retaining ring

d. Reattach data cable and ensure stable and correct readings are being

seen on the benchmark system

8. Pick up 5ft of cable slack, set drum brake.

9. Slacken and remove chain and binder

10. Slacken and remove cable clamp

11. Ensure tension values on benchmark system are reading correctly

12. Continue operation.

AM5K STANDARD DEC 2016 Page 18 of 129

3.6 CHANGING CONFIGURATION BETWEEN OPEN HOLE AND CASED

HOLE

A measuring head configured for open hole will typically contain a magnetic

mark detector and a 2nd encoder. Cased hole operations rarely require a

magnetic mark detector and typically use only one encoder.

If the head is configured for open hole, no changes are required to run it on a

cased hole unit. You may elect to remove the magnetic mark detector if you

have no plans to use the head on an open hole unit any time in the near future.

The cased hole head can be configured with a different wear plate. The cased

hole wear plate is thicker and stepped on one end to the keep the line

from riding near the top of the wheels. This can occur when going in the hole

with a small cable (7/32") with a very light load. The open hole wear plate is flat.

Both plates are made from hardened tool steel. The wear plate is mounted on

the upper frame above the measure wheels.

Part number for the open hole wear plate is: AM5KM034

Part number for the cased hole wear plate is: AM5KM074

3.6.1 To remove the magnetic mark detector, refer to item 12 on the

parts list. Remove the four screws holding the detector in place then

remove the detector. To install a magnetic mark detector, reverse this

procedure.

3.6.2 To remove an encoder, remove the four screws securing the

encoder adapter to the head. Remove the encoder and adapter. Remove

the coupling from the measuring wheel shaft.

AM5K STANDARD DEC 2016 Page 19 of 129

3.7 INSTALLING THE DEEP GROOVED TENSION WHEEL

3.7.1 A deep grooved "High Tension" wheel is available for use when

line tension greater than 10,000 lbs is commonly encountered. This

wheel is grooved to better support the wireline at high tensions. The

groove also reduces the radius of the wheel which lowers the bend angle

of the wireline. This wheel is only for use with 15/32 or larger cables and

cannot be used with smaller cable sizes. We recommend using this

wheel for lines 7/16 or larger.

The normal shallow grooved wheel can be used at high loads for short

pull durations but should not be used when loads exceed 10,000 lbs for

an extended period of time.

3.7.2 To install the deep grooved tension wheel, replace the standard

shallow grooved tension wheel with the deep grooved tension wheel.

The load pin does not need to be changed. To account for the decreased

bend angle of the cable, the Load Cell Angle value will need to be

changed when using this wheel.

Ensure that the slot in the bushing of the tension wheel is aligned with the

roll pin on the side of the frame. The roll pin is only installed on one side

of the frame and it needs to be inserted in the slot.

Also ensure that the grease hole in the tension wheel is installed on the

opposite side as the load pin amplifier.

3.7.3 The deep grooved wheel assembly can be ordered by part number

AM5KA073. The shallow grooved tension wheel assembly can be order

by part number AM5KA063.

AM5K STANDARD DEC 2016 Page 20 of 129

3.7.4 INSTALLING THE DEEP GROOVED TENSION WHEEL

continued

STANDARD SHALLOW GROOVED TENSION WHEEL

DEEP GROOVED TENSION WHEEL

AM5K STANDARD DEC 2016 Page 21 of 129

3.8 SYSTEM OPERATION

3.8.1 Determine cable size to be used .490" to .190. Since the

wireline cable actually bends over the tension wheel, the bend radius of

the wireline cable will affect the tension measurement.

3.8.2 Enter tension calibrate factor. These corrections are automatically

made in the Benchmark Hoistman's panel by selecting the proper cable

size from the menu. If a different panel is used, enter the tension factor

at this time.

Value for shallow grooved tension wheel with standard load pin

VALUES CABLE SIZE

.9 .484

1 .472

1.1 7/16

1.2 3/8

1.4 5/16

1.5 9/32

1.8 7/32

Value for deep grooved tension wheel with standard load pin

VALUES CABLE SIZE

2.15 .490

2.30 .484

2.40 .472

Note A special set of wheels is required for line sizes greater than .490.

550 WHEEL SET

VALUES CABLE SIZE

2.33 .500

2.16 .520 High Strength

2.05 17/32

650 WHEEL SET

VALUES CABLE SIZE

2.10 9/16

AM5K STANDARD DEC 2016 Page 22 of 129

3.8 SYSTEM OPERATION continued

3.8.3 Install line in measuring head (refer to section 3.2).

3.8.4 Make sure line is lying slack and head is free to move. Press the

Ten Zero Cal button and tension value should read 0.

3.8.5 Press the Ten Cal button and tension should read the value

indicated in paragraph 3.6.2.

3.8.6 At this point, the system is ready to log. Watch for visual

indications of problems such as excessive vibration, wheel or roller

slippage or lockups that signify bearing or shaft failures, or cable tracking

problems.

AM5K STANDARD DEC 2016 Page 23 of 129

3.9 BEARING SEAL RETAINERS

AM5K STANDARD DEC 2016 Page 24 of 129

3.9 BEARING SEAL RETAINERS continued

NOTE 1:

Heads manufactured before Sep 2013 did not have bearing seal retainers. We have

since installed retainers on the bearings installed in the AM5KA137 and AM5KA164.

The part numbers for these wheels have been changed to AM5KA247 and AM5KA364.

AM5K STANDARD DEC 2016 Page 25 of 129

4.0 MAINTENANCE AND REPAIR

4.1 OBTAINING TECHNICAL ASSISTANCE

Call BenchMark Wireline Products Inc. at +1 281 346 4300

Or contact by email mail@benchmarkwireline.com

Or fax in request at +1 281 346 4301

Information in the form of user manuals and instructional videos are also

available on our website www.benchmarkwireline.com

Parts can be ordered by email, phone, or fax

Equipment can be returned for repair and maintenance. Please notify us

by Phone, email, or fax before sending any equipment.

To return equipment to BenchMark, ship it to:

BenchMark Wireline Products

36220 FM 1093

Simonton, Texas 77476

U.S.A.

AM5K STANDARD DEC 2016 Page 26 of 129

4.2 PRE-JOB CHECK

Each time the system is used perform the following steps:

Verify that the AM5K is properly and securely attached to the spooling arm.

Several different mounting kits are available for different types of spooling arms.

Verify that the depth measuring wheels are clean and that no groove has been

worn into the measuring wheel surface. Check the measuring and guide wheels

for looseness, play, out-of-roundness, worn or rough sounding bearings, or

other mechanical conditions that could affect measurement accuracy. Ensure

that the wheel bearings inner race is not spinning on the shaft and that the shaft

is not spinning in the bushings.

Verify that all fasteners are tight and that the ball lock pushpin is secure. Verify

that the encoder, electronic load pin, and backup counter cable are installed and

properly routed. Verify that the depth system is working by turning the wheel

and observing the hoistmans panel and backup display unit to indicate cable

movement. The hoistman's panel and backup display should measure 2' for

each rotation of the wheel. If more than one encoder is installed check both

encoders by turning each wheel and verifying that the hoistman's panel will read

2' for each rotation of either wheel.

AM5K STANDARD DEC 2016 Page 27 of 129

4.3 POST-JOB MAINTENANCE

At the completion of each job, thoroughly clean and dry the device as soon as

possible. This avoids problems caused from borehole residues transferred from

the wireline onto the measuring device. Borehole residues should be washed

from the device with a cleaning solvent such as Varsol or an equivalent type.

Rinse the device with water, dry, and wipe down with an oily rag.

Do not pressure wash

AM5K STANDARD DEC 2016 Page 28 of 129

4.4 MONTHLY MAINTENANCE

Visually inspect the interiors of the electrical connectors for the encoders and

electronic load axle for dirt and evidence of insulation breakdown. Clean or

replace as necessary. Install dust caps on the connectors if the cables are

removed.

Manually rotate each wheel by hand to verify its condition. Inspect the depth

measuring wheels for signs of abnormal wear, diameter changes, or

shaft/bearing play that can affect measurement accuracy. The wheel should be

replaced if it is grooved more than .005". The wheel should be 7.639 / 7.640"

(194 mm) in diameter with a 24" circumference (609.6 mm).

Inspect the tension wheel for signs of abnormal wear, diameter changes, or

shaft and bearing play that could affect tension measurement accuracy. The

shallow groove tension wheel (item 33 in section 7.0 of this manual) should be

5" in diameter at the bottom of the groove. It should be replaced if it is worn

more than .010".

The deep grooved tension wheel (item 33 in section 7.0 of this manual) should

be 4.375" in diameter at the bottom of groove. It should be replaced if it is worn

more than .010".

Inspect the two grooved guide wheels on either side of the tension wheel (items

34 in section 7.0 of this manual). They should be 4" (101.6 mm) in diameter

(bottom of groove). They should be replaced if they are worn more than .010".

NOTE: If the tension wheels or guide wheels mentioned above are worn

more than .010 then the tension reading will be less than the actual line

tension. The amount of error is relative to the amount of wear.

Grease all the wheels and bearings that are fitted with a flush mount grease

fitting (see following diagram). Use a water-proof, marine grade grease. An

inverted grease nozzle (p/n AM5KP130) is supplied with each head. This

nozzle will fit any standard grease gun.

AM5K STANDARD DEC 2016 Page 29 of 129

AM5K STANDARD DEC 2016 Page 30 of 129

4.5 ASSEMBLY / DISASSEMBLY PROCEDURES

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

4.5.1 MEASURING WHEEL, SHAFT, AND BEARING REMOVAL

Either measuring wheel can be removed from the measuring head. First

shift the red release handle to move the wheel away from the frame.

Next remove the encoder with its adapter.

On the later model heads, the wheels are keyed onto the shaft and can

be removed simply by removing the screw holding the wheel to the shaft.

On earlier model heads, the wheels are pressed on to the shaft. The

lower snap ring between the wheel and the bearing must first be

removed. Pull the wheel and shaft from the mount. Reassemble in the

opposite order. The bearing should also be replaced at this time.

4.5.2 ELECTRONIC LOAD PIN REMOVAL

The electronic load pin is held in place by one retaining ring on the outer

end of its shaft. Remove the retaining ring by using a small screw driver

to lift one end of the ring out of the groove then walk the ring off of the

pin. The load pin can then be removed from the mounting frame.

4.5.3 BACKUP DEPTH MAGNETIC PICKUP REMOVAL AND

INSTALLATION

The backup depth magnetic pickup is mounted to the encoder adapter. It

is held in place by four screws. Remove the screws and the pickup can

then be removed. The pickup must be properly oriented to work

correctly. The slot should be oriented to the top. The top side is the

encoder side. Ensure that an o-ring is inserted between the plastic

housing and the mount. An additional o-ring is used between the

connector and the housing to keep moisture out.

If the backup display is counting backward (i.e. counting negative when

going down hole), simply rotate the pickup 180 degrees to change the

direction.

AM5K STANDARD DEC 2016 Page 31 of 129

4.5.4 ENCODER COUPLING INSTALLATION

To install the encoder coupling, first remove the plug in the encoder

adapter. Install one of the metal parts of the three piece coupling (item

36) to the wheel shaft and tighten it using a hex wrench. Next, install the

center plastic piece of the coupling onto the wheel shaft coupling. Place

the other metal coupling on the encoder shaft and set the encoder on the

mount. Snug up the encoder coupling then remove the encoder and

tighten the coupling.

Reinstall the encoder with o-rings (item 98) and tighten it to the encoder

mount (item 6). Next tighten the plug.

See Parts List in Section 8.1

AM5K STANDARD DEC 2016 Page 32 of 129

4.5.5 ENCODER MOUNT AND TOP GUIDE WHEEL REMOVAL

Follow these steps to remove the encoder mounts.

1. Using a pair of vice grips, grab the end of the pin and pull on it.

AM5K STANDARD DEC 2016 Page 33 of 129

2. Use a screw driver to capture the end of the spring.

AM5K STANDARD DEC 2016 Page 34 of 129

3. The end cap and the pin can now be removed.

AM5K STANDARD DEC 2016 Page 35 of 129

4 Use a hook to pull the spring out far enough to remove the screwdriver

(Careful not to bend the spring).

AM5K STANDARD DEC 2016 Page 36 of 129

5. Simply slide the floating encoder assembly off the 2 shafts.

6. Repeat for the other side.

AM5K STANDARD DEC 2016 Page 37 of 129

7. Remove anti-rotation screw (if equipped) and snap ring.

AM5K STANDARD DEC 2016 Page 38 of 129

8. Slide the shaft out of the frame.

AM5K STANDARD DEC 2016 Page 39 of 129

9. Remove the wheel assembly.

10. Re-assemble in reverse order making sure that slot in the bearing lines

up with the anti-rotation screw hole (if equipped). Note wheels come in

a variety of colors and materials.

AM5K STANDARD DEC 2016 Page 40 of 129

4.5.6 INSTALLING THE LOAD AXLE WHEEL

1. Insert the tension wheel into the frame. Make sure the slotted hole in the

tension wheel bushing is on the same side as the roll pin hole in the frame

and the grease hole is on the opposite side.

AM5K STANDARD DEC 2016 Page 41 of 129

2. Use a bolt in place of the load pin to hold the wheel in place. Install an

Allen wrench or other long tool to align the hole in the bearing with the

slotted hole in the frame.

AM5K STANDARD DEC 2016 Page 42 of 129

3. Insert a 3/16 x 1/2 long roll pin into the hole. Do not use a longer roll pin

as it will bind the wheel.

AM5K STANDARD DEC 2016 Page 43 of 129

4. Drive in the roll pin flush with the frame. Make sure that the wheel can

freely slide up and down in the frame.

AM5K STANDARD DEC 2016 Page 44 of 129

5. Remove the bolt and install the load pin. Align the notch in the load pin

with the flat side on the frame.

AM5K STANDARD DEC 2016 Page 45 of 129

AFTER ASSEMBLY IS COMPLETE THE LOAD PIN SHOULD BE

CONFIGURED AS SHOWN BELOW

AM5K STANDARD DEC 2016 Page 46 of 129

5.0 OPTIONS AND ACCESSORIES

5.1 SHIPPING CASE AM5KM198

This case is designed to help easily transport the measuring head.

CUSTOM FOAM LINED FOR AM5K

RETRACTABLE HANDLE

ROLLER WHEELS

OUTSIDE DIMENSIONS: 31.5L X 22.88W X 18.88

AM5K STANDARD DEC 2016 Page 47 of 129

5.1 SHIPPING CASE continued - AM5KM198

AM5K SHIPPING CASE

AM5K STANDARD DEC 2016 Page 48 of 129

5.2 AM5KA090 DRIP PAN KIT

This drip pan will mount to the bottom of the AM5K measuring head. It is

designed to capture fluids and debris that drip or fall from the measuring head.

A hose is provided as a means to drain the pan into an external container.

P/N DESCRIPTION QTY UNIT

AM5KM090 PAN DRIP ALUMINUM AM5K 1 EA

AM5KM092 PIN CLEVIS 13/16 X 2-3/4 SST 2 EA

AM5KP205 PIN HAIR 0.125 X 5/8-7/8 SST 4 EA

AM5KP209 TEE 3/4 MALE PUSH-ON NYLON 1 EA

AM5KP208 CLAMP HOSE 0.56-1.06 SST 5 EA

AM5KP207 TBG PVC .75ID X 1.00OD CLEAR 12 EA

AM5K STANDARD DEC 2016 Page 49 of 129

5.2 AM5KA090 DRIP PAN KIT continued

AM5K STANDARD DEC 2016 Page 50 of 129

5.2 AM5KA090 DRIP PAN KIT continued

AM5K STANDARD DEC 2016 Page 51 of 129

5.3 AM5KA239 ADJUSTABLE GUIDE ROLLER KIT

This kit is designed to force smaller sizes of wireline to run straight across the

measuring wheels. Large wirelines (7/16 or larger) are stiff enough so they will

run straight but smaller lines such as 7/32 can walk up/down the measuring

wheel if they are not under much tension. This can occur when running into the

well with pressure through grease tubes. This will cause a depth error (less

depth measured then actual) because any vertical movement of the wireline will

not turn the measuring wheel as far as it should.

This roller is mounted on an adjustable cam shaft. The shaft can be turned to

raise or lower the roller to press the wireline against the bottom of the groove in

the upper guide roller. This assures that the wireline will run straight across the

measuring wheels.

AM5K STANDARD DEC 2016 Page 52 of 129

5.3 AM5KA239 ADJUSTABLE GUIDE ROLLER KIT continued

AM5KA239 ADJUSTABLE GUIDE WHEEL PARTS LIST

ITEM P/N DESCRIPTION QTY UNIT

1 AM5KM231 SHAFT KEYED 3/4 ADJ RLR SST 1 EA

2 AM5KM232 BOLT MOD SHOULDER 5/16 X 1 SST 1 EA

3 AM5KA144 ASSY WHEEL GUIDE 4.266 SST 1 EA

4 AM5KP234 SPRING COMP 7/8 OAL 0.42 OD 1 EA

5 AM5KP235 KEY 3/16 SQUARE SST 2 EA

6 AM5KM146 BUSHING INDEXED KEYED 30MM 1 EA

7 AM5KM147 BUSHING 30MM KEYED 3/4 SHAFT 1 EA

8 AM5KM148 COLLAR LATCH ADJ ROLLER SST 1 EA

9 AM5KP236 BEARING BRZ .314 ID X .378 OD 1 EA

10 AM5KP181 SCREW 3/8-16 X 3/4 BUTTON HD 2 EA

11 AMS1P058 WASHER 3/8 LOCK SS 2 EA

12 C276P513 WASHER 3/8 FLAT SST 2 EA

AM5K STANDARD DEC 2016 Page 53 of 129

5.4 550 WHEELS AM5KK550

This kit includes guide wheels and tension wheel that are grooved to fit wirelines

from .500 up to .550 diameter.

The kit includes 6 steel guide wheels. It replaces the two steel guide wheels

and four plastic guide wheels on the standard head. A new tension wheel is

also included.

The tension K factor is different with this wheel.

P/N DESCRIPTION QTY UNIT

AM5KA391 ASSY WHEEL TENSN FIXD 35MM BRG 6 EA

AM5KA095 ASSY WHEEL TENS 0.550 LOAD AXL 1 EA

AM5K STANDARD DEC 2016 Page 54 of 129

5.4 550 WHEELS AM5KK550 continued

AM5K STANDARD DEC 2016 Page 55 of 129

5.5 650 WHEELS AM5KK650

This kit includes guide wheels and tension wheel that are grooved to fit wirelines

from .550 up to .650 diameter.

The kit includes 6 steel guide wheels. It replaces the two steel guide wheels

and four plastic guide wheels on the standard head. A new tension wheel is

also included.

The tension K factor is different with this wheel.

P/N DESCRIPTION QTY UNIT

AM5KA392 ASSY WHEEL TENSN FIXD 35MM BRG 6 EA

AM5KA096 ASSY WHEEL TENS 0.650 LOAD AXL 1 EA

AM5K STANDARD DEC 2016 Page 56 of 129

5.5 650 WHEELS AM5KK650 continued

AM5K STANDARD DEC 2016 Page 57 of 129

5.6 AM5KA140 - LOWER ARM MOUNT

AM5K STANDARD DEC 2016 Page 58 of 129

5.6 AM5KA140 - LOWER ARM MOUNT

ITEM P/N DESCRIPTION QTY

1 AM5KM131-1 PLATE SIDE PIVOT BTM 30MM 5K 1.0000 EA Nor 1

2 AM5KM131-2 PLATE SIDE PIVOT BTM 30MM 5K 1

3 AM5KM133 PLATE SIDE DAMPER BTM PIVOT 5K 2

4 AM5KM139 CLEVIS DAMPER BOTTOM MT AM5K 2

7 AM3KM041 SPACER SST 3/4 OH ARM 3 WHEEL 4

8 AM5KM052 SHAFT TENSION ROLLER 30MM OH 1

9 AM5KM008 BEARING BRZ FLANGE 30MM ID MOD 2

11 AM5KM142 BUSHING SIDE PLT BOTTOM PIVOT 2

12 AM5KM143 SPACER PLT DAMPER BTM PIVOT 2

15 AM5KP171 DAMPER HYD 4IN DBL ACTING ADJ 1

16 AM5KP172 2 PIN CLEVIS 1/4 X 1-3/8 SST 2

17 230949000 PIN COTTER SST .093 X .750 IN 2

18 AM3KP076 PIN QUICK REL 3/8 OD X 2-1/2 1

24 AM5KP140 SCREW 1/2-13 X 3.50 SOC HD SST 5

25 C276P037 WASHER 1/2 FLAT SST 10

26 AMS1P066 WASHER 1/2 LOCK SS 5

27 AMS1P065 NUT 1/2-13 HEX SST 5

28 AM5KP173 SCREW 1/4-20 X 3 SOC HD SS 3

29 C276P036 WASHER 1/4 LOCK SS 2

30 AM5KP174 SCREW 1/4-20 X 3-1/4 SOC HD SS 3

31 AM5KP048 NUT 1/4-20 ELASTIC STOP SST 6

32 ACMU2P31 WASHER 1/4 FLAT 5/8OD SST 14

33 AM5KP117 SCREW 1/4-20 X 5/8 BTN HD SST 2

39 AM5KP075 CHAIN SASH #35 SST 6 INCH

AM5K STANDARD DEC 2016 Page 59 of 129

5.7 AM5KA243B - OVERHEAD ARM MOUNT ASEP AUTOSPOOLER

AM5K STANDARD DEC 2016 Page 60 of 129

5.7 AM5KA243B - OVERHEAD ARM MOUNT ASEP AUTOSPOOLER

ITEM P/N DESCRIPTION QTY

1 AM3KM124 HOUSING BRG FLANGE 40MM ASEP 2

2 AM3KM138 HUB GUIDE ASEP OH ARM 1

3 AM3KM139 HUB GUIDE INNER ASEP OH ARM 2

4 AM3KM140 SPACER GUIDE ASEP OH ARM 1

6 AM3KM141 PLATE CHAIN GUIDE ASEP OH ARM 1

10 AM3KM144 BEARING FLANGE 2 IN ID MOD 2

BEARING LINEAR 40MMID X

12 AMSLP088 2

50MMOD

14 AMS1P045 SCREW 5/16-18 X 3/4 SHCS SST 1

15 AM5KP117 SCREW 1/4-20 X 5/8 BTN HD SST 2

16 AM5KP042 SCREW 1/2-13 X 3/4 SOC HD SST 2

18 AM3KP057 SCREW 5/16-18 X 1-1/4 SOC HD 8

19 AM5KP183 SCREW 3/8-16 X 2 SOC HD SST 1

20 AMS1P049 SCREW 1/4-20 X 2-1/4 SOC HD SS 2

21 AM3KP058 SCREW 10-24 X 1-1/4 SHCS SST 3

22 AM5KP040 SCREW 10-24 X 3/8 SOC HD SST 4

23 AMS1P065 NUT 1/2-13 HEX SST 2

24 AM3KP059 NUT 10-24 ELASTIC STOP SST 3

26 AMS1P047 WASHER 5/16 LOCK SS 9

28 C276P036 WASHER 1/4 LOCK SS 4

29 ACMU2P31 WASHER 1/4 FLAT 5/8OD SST 4

30 AMS1P054 WASHER #10 FLAT SS 6

31 C276P035 WASHER #10 LOCK SS 4

33 C276P513 WASHER 3/8 FLAT SST 0

34 AMS1P058 WASHER 3/8 LOCK SS 0

35 AMS1P059 NUT 3/8-16 SST 0

36 AMS1P009 PIN QUICK REL 1/2 OD X 2-1/2 3

37 AM3KP073 PIN QUICK REL 3/8 OD X 5 GRIP 1

50 C276P003 BEARING BRZ .375 ID X .500 OD 4

51 AM5KP022 BEARING BRZ FLANGED 3/4" ID 4

52 AM5KP011 WASHER M20 FLAT SST 3

53 AMSLP060 SCREW 3/8-16 X 2-3/4 SOC HD SS 9

54 AM5KP075 CHAIN SASH #35 SST 6 INCH

55 AM5KP075 CHAIN SASH #35 SST 8 INCH

56 AM5KP075 CHAIN SASH #35 SST 6 INCH

57 AM5KP075 CHAIN SASH #35 SST 8 INCH

AM5K STANDARD DEC 2016 Page 61 of 129

5.7 AM5KA243B - OVERHEAD ARM MOUNT ASEP AUTOSPOOLER

ITEM P/N DESCRIPTION QTY

69 AM5KM069 SHAFT PIVOT HORIZ ASEP AUTOSPL 1

70 AM3KM070 PIVOT TIE-DN HORZ ASEP AUTOSPL 2

71 AM5KM076 PLATE PIVOT MOUNT ASEP AUTOSPL 2

72 AM5KM068 BEAM SUPPORT ASEP AUTOSPL AM5K 1

73 AM3KM073 ADAPTER HORZ PIVT ASEP AUTOSPL 1

74 AM3KM074 MOUNT SHAFT HORZ PIVT ASEP AS 1

76 AM3KM076 BRACKET TIE-DN QUIK PIN HORIZ 1

77 AM5KM077 KNUCKLE REAR ASEP AUTOSPL 5K 1

78 AM5KM078 YOKE STUB CENTER MT SST 1

79 AM5KM079 SPACER PLATE ASEP AUTOSPL 1

80 AM5KM080 PLATE TIE-DN MT ASEP AUTOSPL 2

81 AM5KM081 BUSHING FLANGE QUIK PIN SS 2

82 AM5KP023 BOLT SHOULDER 3/4 X 3 SST 0

83 AM5KM082 PIN HINGE 3/8 SST ASEP ASPOOL 1

AM5K STANDARD DEC 2016 Page 62 of 129

6.0 CERTIFICATION DOCUMENTATION

6.1 MEASURING HEAD ATEX Conformity Certificate

AM5K STANDARD DEC 2016 Page 63 of 129

6.2 MEASURING HEAD ATEX Conformity Certificate Sheet 1

AM5K STANDARD DEC 2016 Page 64 of 129

MEASURING HEAD ATEX Conformity Certificate Sheet 2

AM5K STANDARD DEC 2016 Page 65 of 129

6.3 ENCODER ATEX Conformity Certificates

AM5K STANDARD DEC 2016 Page 66 of 129

AM5K STANDARD DEC 2016 Page 67 of 129

AM5K STANDARD DEC 2016 Page 68 of 129

6.4 LOAD PIN ATEX Conformity Certificates

AM5K STANDARD DEC 2016 Page 69 of 129

AM5K STANDARD DEC 2016 Page 70 of 129

AM5K STANDARD DEC 2016 Page 71 of 129

6.5 MARK DETECTOR ATEX Conformity Certificates

AM5K STANDARD DEC 2016 Page 72 of 129

AM5K STANDARD DEC 2016 Page 73 of 129

6.6 CLASS 1 DIVISION 2 CERTIFICATES

AM5K STANDARD DEC 2016 Page 74 of 129

AM5K STANDARD DEC 2016 Page 75 of 129

6.7 SAFETY LABELS

AM5K STANDARD DEC 2016 Page 76 of 129

7.0 SPARE PARTS LISTS

7.1 RECOMMENDED SPARE PARTS

It is recommended that the following parts be kept on hand in the indicated

quantities QTY.

ITEM P/N DESCRIPTION QTY

RECOMMENDED SPARE PARTS FOR ALL LOCATIONS

14 AM5KA058 ASSY BACKUP MAGNETIC EEx Na 1

22 AM5KM001 WHEEL MEASURING 2FT 5 SPOKE 2

31 AM5KA247 ASSY WHEEL GUIDE PLAS 35MM BRG 4

33 AM5KA063 ASSY WHEEL TENSN SHALLOW GROOVE 1

33 AM5KA073 ASSY WHEEL TENSN DEEP GROOVE 1

34 AM5KA364 ASSY WHEEL TENSN FIXD 35MM BRG 2

36 AM5KM073 COUPLING MOD ENCDR 0.250/0.375 2

51 AMS1P009 RETAINING PIN (T HANDLE) 1

ITEM P/N DESCRIPTION QTY

ADDITIONAL RECOMMENDED SPARE PARTS FOR REMOTE LOCATIONS

10 ASSY LOAD AXLE / PIN 1

12 AM5KA066 ASSY MAG MARK DETECTOR EEx nA 1

13 ENCODER 1

35 AM5KA065 ASSY ROLLER SPOOLNG 2.75" PLAS 4

54 AM5KM157 BEARING BALL 35MM ID MOD 6

55 AM5KP088 BEARING LINEAR 30MMID X 40MMOD 8

56 AM3KP204 BEARING BALL 20MM FAFNIR 204PP 4

58 AM5KM134 BEARING BALL 40MM ID MOD 1

59 AM5KP229 CLAMP TOGGLE PUSH/PULL SST 1

101 AM5KP130 NOZZLE GREASE FITTNG FLUSH 1

NOTE - ONLY STOCK THE LOAD AXLE AND ENCODER USED IN YOUR MEASURING

HEAD. A COMPLETE LIST IS FOUND IN THE BILL OF MATERIALS

AM5K STANDARD DEC 2016 Page 77 of 129

NOTE 1:

Heads manufactured before Sep 2013 did not have bearing seal retainers. We have

since installed retainers on the bearings installed in the AM5KA137 and AM5KA164.

The part numbers for these wheels have been changed to AM5KA247 and AM5KA364.

Visit 7.3 to see pictures of the new wheels.

AM5K STANDARD DEC 2016 Page 78 of 129

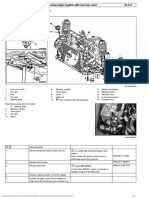

7.2 AM5K MEASURING HEAD STANDARD CONFIG BILL OF MATERIALS

ITEM P/N DESCRIPTION QTY REF

1 AM5KA131 ASSY FRAME BACKBONE UPPER W/BUSHINGS 1

ASSY LOWER FRAME W/BUSHINGS AND WEAR

2 AM5KA332 1

BLOCKS

3 AM5KA052-1 ASSY MOUNT FLTNG ENCDR WHL W/ 1 OPTION

4 AM5KA052-2 ASSY MOUNT FLTNG ENCDR WHL W/0 1

5 AM5KA053 ASSY BLOCK PIVOT HORIZ/VERT 1

6 AM5KM057 ADAPTER ENCODER H37C/H25D 2 OPTION

6 AM5KM058 COVER ENCODER ADAPTER 1 OPTION

7 AM5KM020 ENDCAP FLOATING ENCODER MOUNT 4

8 AM5KA057 ASSY MOUNT SPOOLNG ROLLR FRNT 1

9 AM5KM026 MOUNT SPOOLING ROLLER REAR 1

10 MANY ASSY LOAD AXLE / PIN 1 SEE CHART 8.3

11 AM5KA040 ASSY MOUNT CENTER YOKE 5 WHEEL 1 OPTION

12 AM5KA066 ASSY MAG MARK DETECTOR EEx Na 1

13 MANY ENCODER 1 SEE CHART 8.3

14 AM5KA058 ASSY BACKUP MAGNETIC EEx Na 1

15 AM5KM024 SHAFT PIVOT VERTICAL 20MM SST 1

16 AM5KM011 SHAFT TENSION ROLLER 30MM SST 5

17 AM5KA059 ASSY SHAFT ENCODER SLIDE 30MM 2

18 AM5KM023 SHAFT PIVOT HORIZONTAL 1/2 SST 1

19 AM5KM013 SHAFT SPOOLING ROLLER 20MM 3

20 AM5KP023 BOLT SHOULDER 3/4 X 3 SST 1

21 AM5KP002 SPRING EXT 4" OAL 47/64 DIA SST 4

22 AM5KM001 WHEEL MEASURING 2FT 5 SPOKE 2

23 AM5KM141 ANCHOR SPRING 1/2" FLOATING 4

24 AM5KM034 PLATE WEAR 1/16 X 1.5 X 3.5 1

25 AM5KM049 BLOCK WEAR 1.50 X 1.50 X 0.56 STL 2 LARGE LINES

25 AM5KM074 BLOCK WEAR UPPER TOOL STL CH 1 SMALL LINES ONLY

26 AM3KM134 BLOCK WEAR 0.75 X 2.50 TOOLSTL 2

27 AM5KM159 BLOCK GUIDE TENSION WHEEL PLAS 2

28 AM5KM084 SCREW ANTI-ROTATION TENS WHEEL 6

29 AM5KM010 SHAFT WHEEL CANTILEVERED 5 WHL 1

30 AM5KM060 SHAFT WHEEL CANTLVRD MAG 5 WHL 1 OPTION

31 AM5KA247 ASSY WHEEL GUIDE PLAS 35MM BRG 4

OPTION (HI

TENSION) USE with

33 AM5KA073 ASSY WHEEL TENSN DEEP GROOVE 1 line tensions > 10,000

pounds or cables >

7/16

AM5K STANDARD DEC 2016 Page 79 of 129

7.2 AM5K MEASURING HEAD STANDARD CONFIG BILL OF MATERIALS

continued

ITEM P/N DESCRIPTION QTY REF

ASSY WHEEL TENSN FIXD 35MM BRG

34 AM5KA164 0

OBSOLETE REPLACED WITH AM5KA364

35 AM5KA065 ASSY ROLLER SPOOLNG 2.75" PLAS 4

36 AM5KM073 COUPLING MOD ENCDR 0.250/0.375 2 OPTION

37 AM5KP124 PIN COILED SPRING 1/4 X 1-1/8 2 ENCODER SLIDE

TENSION WHEEL

38 AM5KP125 PIN COILED SPRING 3/16 X 1/2 1

PIN

42 AM5KM138 YOKE PIVOT CENTER MOUNT SST 1

43 AM5KM040 PUSHROD TOGGLE CLAMP PLASTIC 2

51 AMS1P009 RETAINING PIN (T HANDLE) 1

52 AMS1P072 PLUG 3/8 NPT SS 2

53 AM5KP075 CHAIN SASH #35 SST 6

54 AM5KM157 BEARING BALL 35MM ID MOD 6

55 AM5KP088 BEARING LINEAR 30MMID X 40MMOD 8

56 AM3KP204 BEARING BALL 20MM FAFNIR 204PP 4

58 AM5KM134 BEARING BALL 40MM ID MOD 1

59 AM5KP229 CLAMP TOGGLE PUSH/PULL SST 2

60 AM5KM055 KEY 1/8 X 1/8 X 0.625L SST 2

61 AM5KP144 WASHER 1/4 LOCK SS HIGH COLLAR 4

62 ACMU2P31 WASHER 1/4 FLAT SS 8

63 AMS1P058 WASHER 3/8 LOCK SS 3

64 C276P513 WASHER 3/8 FLAT SST 2

65 C276P036 WASHER 1/4 LOCK SS 4

66 AM5KP011 WASHER 20MM FLAT SST 12

67 C276P039 WASHER 5/16 FLAT SST 2

68 AMS1P066 WASHER 1/2 LOCK SS 2

69 AMS1P047 WASHER 5/16 LOCK SS 4

70 C276P037 WASHER 1/2 FLAT SST 2

71 C276P046 WASHER #6 LOCK SS 4

72 C276P035 WASHER #10 LOCK SS 7

73 AMS1P052 SCREW 10-24 X 5/8 SOC HD SST 4

74 C276P331 SCREW 6-32 X 1/2 PHIL PAN SST 4

75 AM5KP117 SCREW 1/4-20 X 5/8 BTN HD SST 4

76 AM5KP038 SCREW 5/16-18 X 7/8 FH SOC SS 8

77 AM5KP039 SCREW 10-24 X 7/8 FH SOC SST 2

AM5K STANDARD DEC 2016 Page 80 of 129

7.2 AM5K MEASURING HEAD STANDARD CONFIG BILL OF MATERIALS

continued

ITEM P/N DESCRIPTION QTY REF

78 AM5KP040 SCREW 10-24 X 3/8 SOC HD SST 5

79 AM5KP042 SCREW 1/2-13 X 3/4 SOC HD SST 2

80 AMS1P048 SCREW 1/4-20 X 3/4 SOC HD SST 4 OPTION W/COVER

80 C276P031 SCREW 1/4-20 X 1-1/4 SOC HD SS 8

82 AM5KP037 SCREW 5/16-18 X 4-1/2 SOC HD 2

83 AM3KP028 SCREW 5/16-18 X 1/2 SHCS SST 2

84 AMS1P052 SCREW 10-24 X 5/8 SOC HD SST 8 OPTION

OPTION W/HD

84 AMS1P053 SCREW 10-24 X 2 SHCS SST 8

ENCDR

85 AM5KP043 SCREW 3/8-16 X 1/2 BUTTON HD 3

86 AMS1P006 RING RETNG INT UR187S 4

87 AM5KP033 RING RETNG EXT 0.500 SHAFT SST 1

89 AM3KP018 RING RETNG EXT 1.188 SHAFT SST 14

90 AM5KP168 RING RETNG INT 2.875 LT DUTY 12

91 C276P041 O-RING 2-017 BUNA N 1 BACKUP HSG

92 AM5KP072 O-RING 2-046 BUNA N MMD COVER 1

93 C276P040 O-RING 2-235 BUNA N L/P LID 1

94 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1

95 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1

96 AM5KP020 O-RING 2-030 BUNA N ENDCAP 4

97 AMS1P014 O-RING 2-152 BUNA N ENC ADPTR 2

98 AM5KP071 O-RING 2-141 BUNA N H25 ENCDR 2

99 AM5KP119 O-RING 2-026 BUNA N MMD CONN 1

100 C276P042 O-RING 2-016 BUNA N 1 BACKUP CONN

101 AM5KP130 NOZZLE GREASE FITTNG FLUSH 1 NOT SHOWN

AM5K STANDARD DEC 2016 Page 81 of 129

8.0 DRAWINGS & SPECIFICATIONS

8.1 MEASURE HEAD ASSEMBLY

AM5K - SIDE VIEW

AM5K STANDARD DEC 2016 Page 82 of 129

AM5K - SIDE VIEW

AM5K STANDARD DEC 2016 Page 83 of 129

AM5K - TOP VIEW

AM5K STANDARD DEC 2016 Page 84 of 129

AM5K - FRONT VIEW

AM5K STANDARD DEC 2016 Page 85 of 129

AM5K - REAR VIEW

AM5K STANDARD DEC 2016 Page 86 of 129

8.2 MMD - MAGNETIC MARK DETECTOR SPECIFICATION

1. General

This specification describes the latest magnetic mark detector. It replaces the

original AMS100 detector, p/n AMS1A003. The performance characteristics

emulate the original unit.

2. Mechanical

The mark detector will work in both the original housing p/n AMS1M022 and the

AM5K versions using p/n AM5KM029. The pc board is potted to prevent

damage from shock, vibration, or humidity.

3. Power

Input power is 9 - 30vdc at 100ma max.

4. Outputs

Digital line driver out for strong & strong\ and also weak & weak\ where a weak

mark is 4 gauss or less and a strong mark is greater than 4.1 gauss measured

0.10 inch from cable surface. The signals are a +5vdc digital pulse. A digitized

0-5vdc representation of the analog signal is provided.

5. Performance

a) Operating temperature -40 to +120 f. compensated and stable. Storage

temperature -60 to +180 f.

b) Magnetic mark detection at cable line speeds of 1 to 1000 feet per

minute.

c) Auto cal feature removes offset of the electronics and any constant

magnetic field less than 1 gauss every 100ms. If in a greater field, it will auto

calibrate every 11 seconds.

d) Detection of apparent zero gauss (at high/low crossing) is within 0.1 inch

and repeatable so as any error is not accumulative.

e) Will survive a gauss level exposure of 60 gauss.

AM5K STANDARD DEC 2016 Page 87 of 129

8.2 MMD continued

AM5KA066 ASSY MMD EEx nA

ITEM P/N DESCRIPTION QTY UNIT

1 AM5KM029 ENCLSR MAGNETIC MARK DETECTOR 1 EA

2 AM5KM035 COVER MAGNETIC MARK DETECTOR 1 EA

5 ACMU1P21 CONN MS3102E-20-27P 14 PIN RECEPT 1 EA

6 AM5KP119 O-RING 2-026 BUNA N MMD CONN 1-1/4 X 1-3/8 X 1/16 1 EA

7 ACMU1P22 DUST CAP MS25D43-20DA 1 EA

O-RING 2-046 BUNA N MMD COVER 4.239ID X 4.3790D X

8 AM5KP072 1 EA

0.070

10 AM5KA035 PCB MMD POTTED, AM5K OR AMS100 1 EA

23 C276P035 WASHER #10 LOCK SS 5 EA

24 AMS8P029 SCREW 10-24 X 1/2 SOC HD SST 5 EA

26 AMS1P040 SCREW 6-32 X 3/8 PAN HD SST 4 EA

AM5K STANDARD DEC 2016 Page 88 of 129

8.3 MEASURING HEAD PART NUMBERS, LOAD PINS AND ENCODERS

The Selection Matrix shows AM5K measuring heads sorted in three

different ways.

- Measuring head part number

- Load pin part number

- Encoder part number

Using the matrix you can either identify your measuring head part

number or by the proper encoder/load pin combination for your

measuring head.

Also, with the correct measuring head part number, you can see the

load pin and encoder options available to you.

AM5K STANDARD DEC 2016 Page 89 of 129

AM5K STANDARD DEC 2016 Page 90 of 129

AM5K STANDARD DEC 2016 Page 91 of 129

AM5K STANDARD DEC 2016 Page 92 of 129

AM5K STANDARD DEC 2016 Page 93 of 129

AM5K STANDARD DEC 2016 Page 94 of 129

AM5K STANDARD DEC 2016 Page 95 of 129

8.4.1 LOAD PIN - AM5KA067

TENSION SPECIFICATIONS:

Power Requirements: 12 vdc excitation

Proprietary circuit board which buffers the load pin signals and provides a

3mv/v output

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 96 of 129

8.4.1 LOAD PIN - AM5KA067 continued

AM5KA067 ASSY LOAD AXLE 3MV/V

ITEM P/N DESCRIPTION QTY UNIT

45 AM5KP068 CONN 10-107218-1P BENDIX QWL COURSE THD 10 PIN 1 EA

46 AM5KP067 DUST CAP CW49N16C CANNON CWL COURSE THREAD 1 EA

93 C276P040 O-RING 2-235 BUNA N L/P LID 3-1/8 X 3-3/8 X 1/8 1 EA

94 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1.98ID X 2.19OD X 0.103W 1 EA

95 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1-1/16 X 1-3/16 X 1/16 1 EA

AM5K STANDARD DEC 2016 Page 97 of 129

8.4.2 LOAD PIN - AM5KA069 OR AM5KA010

TENSION SPECIFICATIONS:

Power Requirements: +/-15 vdc power

Proprietary circuit board which amplifies the load pin signals and provides

a 1.5v differential output.

0vdc = 0lbs, 1.5vdc = 20,000 lbs.

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 98 of 129

8.4.2 LOAD PIN - AM5KA069 OR AM5KA010 continued

AM5KA069 ASSY LOAD AXLE 1.5 V DIFFERENTIAL Ex

ITEM P/N DESCRIPTION QTY REF

45 AMS8P055 CONN KPT 02A16-8P 1 EA

46 AMS8P056 DUST CAP KPT81-16C 1 EA

10 AMTKA014B PCB ASSY 0-1.5V DIFF LP EX 1 EA

93 C276P040 O-RING 2-235 BUNA N L/P LID 3-1/8 X 3-3/8 X 1/8 1 EA

94 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1.98ID X 2.19OD X 0.103W 1 EA

95 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1-1/16 X 1-3/16 X 1/16 1 EA

AM5K STANDARD DEC 2016 Page 99 of 129

8.4.3 LOAD PIN - AM5KA071

TENSION SPECIFICATIONS:

Power Requirements: 12 vdc excitation

Proprietary circuit board which buffers the load pin signals and provides a

3mv/v output

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 100 of 129

8.4.3 LOAD PIN - AM5KA071 continued

AM5K STANDARD DEC 2016 Page 101 of 129

8.4.3 LOAD PIN - AM5KA071 continued

ITEM P/N DESCRIPTION QTY UNIT

1 AMS8M010 HOUSING LOAD PIN AMS80 1 EA

2 AMTKA013 ASSY PCB LOW LEVEL TENSION 1 EA

3 AM5KM262 LID LOAD PIN HSG BLACK WARNING 1 EA

4 AM5KP104 PIN LOAD 3000# 1/2 OD 2.0 MV/V 1 EA

5 AMS8P055 CONN KPT02A16-8P 1 EA

6 AMS8P056 DUST CAP KPT8116C RECEPT 1 EA

7 C276P040 O-RING 2-235 BUNA N L/P LID 1 EA

8 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1 EA

9 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1 EA

10 AM5KP041 SCREW 10-24 X 1-1/4 PHIL PAN 4 EA

11 AMS8P034 SCREW 4-40 X 3/8 SOC HD SST 6 EA

12 AM5KP228 STANDOFF 4-40 X 1/2 M/F HEX 2 EA

13 C276P035 WASHER #10 LOCK SS 4 EA

15 C276P035 WASHER #10 LOCK SS 4 EA

16 AMS8P036 WASHER #4 LOCK SST 6 EA

17 AMS8P090 WASHER #4 FLAT SST 6 EA

AM5K STANDARD DEC 2016 Page 102 of 129

8.4.4 LOAD PIN - AM5KA078

TENSION SPECIFICATIONS:

Power Requirements: 12 vdc excitation

Proprietary circuit board which buffers the load pin signals and provides a

3mv/v output

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 103 of 129

8.4.4 LOAD PIN - AM5KA078 continued

AM5KA078 ASSY LOAD AXLE 3MV/V

ITEM P/N DESCRIPTION QTY UNIT

1 AMS8M010 HOUSING LOAD PIN AMS80 1 EA

2 AMTKA013 ASSY PCB LOW LEVEL TENSION 1 EA

4 AM5KP104 PIN LOAD 3000# 1/2 OD 2.0 MV/V 1 EA

5 AMS8P055 CONN KPT02A16-8P 1 EA

6 AMS8P056 DUST CAP KPT8116C RECEPT 1 EA

7 C276P040 O-RING 2-235 BUNA N L/P LID 1 EA

8 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1 EA

9 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1 EA

10 AM5KP041 SCREW 10-24 X 1-1/4 PHIL PAN 4 EA

11 AMS8P034 SCREW 4-40 X 3/8 SOC HD SST 6 EA

15 C276P035 WASHER #10 LOCK SS 4 EA

16 AMS8P036 WASHER #4 LOCK SST 6 EA

AM5K STANDARD DEC 2016 Page 104 of 129

8.4.5 LOAD PIN - AM5KA087

TENSION SPECIFICATIONS:

Power Requirements: 12 vdc excitation

Proprietary circuit board which buffers the load pin signals and provides a

3mv/v output

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 105 of 129

8.4.5 LOAD PIN - AM5KA087 continued

AM5KA087 ASSY LOAD AXLE 3MV/V

ITEM P/N DESCRIPTION QTY UNIT

45 AM5KP068 CONN 10-107218-1P BENDIX QWL COURSE THD 10 PIN 1 EA

46 AM5KP067 DUST CAP CW49N16C CANNON CWL COURSE THREAD 1 EA

93 C276P040 O-RING 2-235 BUNA N L/P LID 3-1/8 X 3-3/8 X 1/8 1 EA

94 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1.98ID X 2.19OD X 0.103W 1 EA

95 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1-1/16 X 1-3/16 X 1/16 1 EA

AM5K STANDARD DEC 2016 Page 106 of 129

8.4.6 LOAD PIN - AM5KA313

TENSION SPECIFICATIONS:

Power Requirements: 12 vdc excitation

Proprietary circuit board which buffers the load pin signals and provides a

3mv/v output

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 107 of 129

8.4.6 LOAD PIN - AM5KA313 continued

ITEM P/N DESCRIPTION QTY UNIT

1 AMS8M010 HOUSING LOAD PIN AMS80 1 EA

2 AMTKA013 ASSY PCB LOW LEVEL TENSION 1 EA

3 AM5KM262 LID LOAD PIN HSG BLACK WARNING 1 EA

4 AM5KP104 PIN LOAD 3000# 1/2 OD 2.0 MV/V 1 EA

5 AMS8P055 CONN KPT02A16-8P 1 EA

6 AMS8P056 DUST CAP KPT8116C RECEPT 1 EA

7 C276P040 O-RING 2-235 BUNA N L/P LID 1 EA

8 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1 EA

9 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1 EA

10 AM5KP041 SCREW 10-24 X 1-1/4 PHIL PAN 4 EA

11 AMS8P034 SCREW 4-40 X 3/8 SOC HD SST 6 EA

12 AM5KP228 STANDOFF 4-40 X 1/2 M/F HEX 2 EA

13 C276P035 WASHER #10 LOCK SS 4 EA

16 AMS8P036 WASHER #4 LOCK SST 6 EA

17 AMS8P090 WASHER #4 FLAT SST 6 EA

AM5K STANDARD DEC 2016 Page 108 of 129

8.4.7 LOAD PIN - AM5KA420

TENSION SPECIFICATIONS:

Power Requirements: +24 vdc input power

BenchMark proprietary circuit board which amplifies the strain gauge

signal and

provides a 4-20ma current loop output.

4 ma = 0 lbs (0kg)

12 ma = 10,000 lbs (4,536 kg) shunt cal

20 ma = 20,000 lbs (9,072 kg)

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 109 of 129

8.4.7 LOAD PIN - AM5KA420 continued

AM5KA420 ASSY LOAD AXLE 3MV/V

ITEM P/N DESCRIPTION QTY UNIT

45 AM5KP068 CONN MS3102E-18-9P 1 EA

46 AM5KP067 DUST CAP MS25042-18DA 1 EA

93 C276P040 O-RING 2-235 BUNA N L/P LID 3-1/8 X 3-3/8 X 1/8 1 EA

94 AMS8P066 O-RING 2-136 BUNA N L/P HSG 1.98ID X 2.19OD X 0.103W 1 EA

95 AM5KP118 O-RING 2-023 BUNA N L/P CONN 1-1/16 X 1-3/16 X 1/16 1 EA

AM5K STANDARD DEC 2016 Page 110 of 129

8.4.8 LOAD PIN - AM5KA573 OR AM5KF103

TENSION SPECIFICATIONS:

Power Requirements: 12 vdc excitation

Temperature stability: <= .015% full scale / deg F on zero

<= .02% full scale / deg F on output

Accuracy: Within 150 lbs or 3% of actual, whichever is greater

Maximum load (tested): 25,000 lbs 11,340 kg

(with deep grooved tension wheel)

Take Adequate Precautions when Installing the Load Pin to Avoid the Risk

of Mechanical Damage

WARNING DO NOT SEPARATE CONNECTORS WHEN ENERGIZED

AM5K STANDARD DEC 2016 Page 111 of 129

8.4.8 LOAD PIN - AM5KA573 OR AM5KP103 continued

AM5K STANDARD DEC 2016 Page 112 of 129

8.5.1 ENCODER - AM3KP161

P/N DESCRIPTION QTY UNIT

AM3KP161 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

120 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

C - A\

B - B

E - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 113 of 129

8.5.2 ENCODER - AM5KA068

P/N DESCRIPTION QTY UNIT

AM5KP161 ENCODER H25D-SS-1200-ABC-4469 EEx nA 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

E - A

C - A\

G - B

D - B\

A - +5 to +15 vdc

B - Gnd

F - Case

AM5K STANDARD DEC 2016 Page 114 of 129

8.5.3 ENCODER - AM5KA070

ITEM P/N DESCRIPTION QTY UNIT

13 AM5KP163 ENCODER H25D-SS-1200-ABC-4469 EEx nA 2 EA

36 AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

44 AMS1P071 DUST CAP MS25043-16DA (HES) 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

C - A\

B - B

E - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 115 of 129

8.5.4 ENCODER - AM5KA074

P/N DESCRIPTION QTY UNIT

AMSLP061 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

H - A\

B - B

I - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 116 of 129

8.5.5 ENCODER - AM5KA079

P/N DESCRIPTION QTY UNIT

AM5KP188 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

E - A

C - A\

G - B

D - B\

A - +5 to +15 vdc

B - Gnd

F - Case

AM5K STANDARD DEC 2016 Page 117 of 129

8.5.6 ENCODER - AM5KA080

P/N DESCRIPTION QTY UNIT

AM5KP192 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

C - A\

B - B

E - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 118 of 129

8.5.7 ENCODER - AM5KP161

P/N DESCRIPTION QTY UNIT

AM5KP161 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

E - A

C - A\

G - B

D - B\

A - +5 to +15 vdc

B - Gnd

F - Case

AM5K STANDARD DEC 2016 Page 119 of 129

8.5.8 ENCODER - AM5KP163

P/N DESCRIPTION QTY UNIT

AM5KP163 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

ACMU2P09 DUST CAP MS25043-18DA 2 EA

AMS1P053 10-24 X 2" SOCKET HEAD CAP SCREWS SST ENCODER MOUNTING 4 EA

Specifications

512-780 Pulses per revolution Dual Resolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

C - A\

B - B

E - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 120 of 129

8.5.9 ENCODER - AM5KP164

P/N DESCRIPTION QTY UNIT

AM5KP164 ENCODER IS25-HA-37F-1200-ABC-69-S-16-15 ATEX EEx ia IIB T4 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

ACMU2P09 DUST CAP MS25043-18DA 2 EA

AMS1P053 10-24 X 2" SOCKET HEAD CAP SCREWS SST ENCODER MOUNTING 4 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

H - A\

B - B

I - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 121 of 129

8.5.10 ENCODER - AM5KP188

P/N DESCRIPTION QTY UNIT

AM5KP188 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

C - A\

B - B

E - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 122 of 129

8.5.11 ENCODER - AM5KP189

P/N DESCRIPTION QTY UNIT

AM5IP189 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

C - A\

B - B

E - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 123 of 129

8.5.12 ENCODER - AM5KP192

P/N DESCRIPTION QTY UNIT

AM5KP192 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

C - A\

B - B

E - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 124 of 129

8.5.13 ENCODER AMS7P131

P/N DESCRIPTION QTY UNIT

AM5KP131 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

ACMU2P09 DUST CAP MS25043-18DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

H - A\

B - B

I - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 125 of 129

8.5.14 ENCODER AMS7P191

P/N DESCRIPTION QTY UNIT

AM5KP191 ENCODER H25D-SS-1200-ABC-4469 ATEX EEx ia IIB T4 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

AMS1P071 DUST CAP MS25043-16DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

E - A

C - A\

G - B

D - B\

A - +5 to +15 vdc

B - Gnd

F - Case

AM5K STANDARD DEC 2016 Page 126 of 129

8.5.15 ENCODER AMSLP061

P/N DESCRIPTION QTY UNIT

AM5KP061 ENCODER H25D-SS-1200-ABC-4469 2 EA

AM5KM073 COUPLING MOD ENCDR 0.250/0.375 BORE 2 EA

ACMU2P09 DUST CAP MS25043-18DA 2 EA

Specifications

1200 Pulses per revolution

+5 to +15 vdc power

Differential Quadrature output (A A not, B B not)

Pin Out

A - A

H - A\

B - B

I - B\

D - +5 to +15 vdc

F - Gnd

G - Case

AM5K STANDARD DEC 2016 Page 127 of 129

8.6 BACKUP ODOMETER - CABLE AND WIRING

ITEM P/N DESCRIPTION QTY UNIT

14 AM5KA058 ASSY ENCODER BACKUP MAGNETIC 1 EA

49 AM5KP027 CONN KPT02E10-6P RECEPTACLE MS3112 1 EA

50 AM5KP034 DUST CAP KPT8110C CANNON SHELL SIZE 10 1 EA

51 C276P041 O-RING 2-017 2 EA

74 AMS1P040 SCREW 6-32 X 3/8 PAN HD SST 4 EA

AM5K STANDARD DEC 2016 Page 128 of 129

8.6 BACKUP ODOMETER continued

AM5KA024-20 BACKUP ODOMETER CABLE 101343792

ITEM P/N DESCRIPTION QTY UNIT

CABLE 24/2P STNDED TC PE/PVC AL/MY SHLD W/DW NEC

1 AMS7P062 20 FT

CMUL2919

2 AM5KP057 CONN KPT06F10-6P STR PLUG 1 EA

3 AM5KP058 CONN KPT08F10-6S RT ANGLE PLUG 1 EA

4 AM5KP059 DUST CAP KPT8010C CANNON 2 EA

5 AM5KA034 BUSHING #9779-513-4 AMPHENOL 2 EA

AM5K STANDARD DEC 2016 Page 129 of 129

You might also like

- JCB 331HST and 335 HST Service ManualDocument352 pagesJCB 331HST and 335 HST Service ManualVlado KuzmanNo ratings yet

- Manual Oil India LTD Truck PDFDocument421 pagesManual Oil India LTD Truck PDFJuan Mejia OspinaNo ratings yet

- Casing Collar LocatorsDocument13 pagesCasing Collar LocatorshaudvNo ratings yet

- 9 Power TrainDocument146 pages9 Power TraineduamaNo ratings yet

- Simon Boxer 170 Parts ManualDocument105 pagesSimon Boxer 170 Parts ManualРоманNo ratings yet

- E-Line and Braided LineDocument40 pagesE-Line and Braided LineLherrera07No ratings yet

- MPR Users Guide 7505043Document321 pagesMPR Users Guide 7505043MaximNo ratings yet

- Cerberus WirelineDocument6 pagesCerberus Wirelinejavier100% (2)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Terex AC-140 - 170TDocument18 pagesTerex AC-140 - 170TBronwynne October100% (2)

- ServiceDocument1,146 pagesServiceEmanuel Nicolas Villarruel100% (1)

- Minetruck MT436B: Atlas Copco Underground TrucksDocument3 pagesMinetruck MT436B: Atlas Copco Underground TrucksjoaquimNo ratings yet

- Manual SpoolerDocument118 pagesManual Spooleryubelly gómezNo ratings yet

- Probe 1-11-16 RADII DualReceiverCementBondLog - SFLBDocument1 pageProbe 1-11-16 RADII DualReceiverCementBondLog - SFLBu2006262918No ratings yet

- ,DanaInfo WWW - Hub.slb - Com+s03 WC Ver1 19 4137706 01Document37 pages,DanaInfo WWW - Hub.slb - Com+s03 WC Ver1 19 4137706 01wahyupurwatmo100% (1)

- Peak Product Catalogue December 2016-SmallDocument115 pagesPeak Product Catalogue December 2016-SmallRoy SihalohoNo ratings yet

- Winch Operators Slickline Cased Hole Analog PanelDocument2 pagesWinch Operators Slickline Cased Hole Analog PanelHenry FuentesNo ratings yet

- Equipo para Correr Registros Electricos-Clase Unacar Ing Petrolera PDFDocument14 pagesEquipo para Correr Registros Electricos-Clase Unacar Ing Petrolera PDFYuriko LagunaNo ratings yet

- Gtops CMTD 5669583 02Document10 pagesGtops CMTD 5669583 02Wualdir Martin Vivas ChungaNo ratings yet

- K10 Software Manual ENDocument12 pagesK10 Software Manual ENfarhad2004No ratings yet

- Sec 1 L&PBasicsDocument36 pagesSec 1 L&PBasicsAnshul JhaNo ratings yet

- Assistant Slickline Operator 001Document3 pagesAssistant Slickline Operator 001Muhammad shehryar KhanNo ratings yet

- Catalogs - SchlumbergerDocument2 pagesCatalogs - SchlumbergerchengcaiwangNo ratings yet

- Wireline Combi Unit PPDocument141 pagesWireline Combi Unit PPЕТМNo ratings yet

- Wireline Operations - 231001 - 011117Document31 pagesWireline Operations - 231001 - 011117rezaNo ratings yet

- Rotary Cutters PDFDocument3 pagesRotary Cutters PDFAlleyson AkinNo ratings yet

- Schlumberger Wireline Tool RatingsDocument4 pagesSchlumberger Wireline Tool RatingsWaleed Barakat MariaNo ratings yet

- CH 5 PDFDocument45 pagesCH 5 PDFAbderrazak BerrahalNo ratings yet

- Wireline Tools CodeDocument19 pagesWireline Tools Coded30kaNo ratings yet

- AdaptersDocument69 pagesAdaptersPrakhar SarkarNo ratings yet

- Ops-Wl-Pr-012 Wireline Depth Control ProcedureDocument11 pagesOps-Wl-Pr-012 Wireline Depth Control ProcedureLuisNo ratings yet

- Ws Wireline UnitDocument1 pageWs Wireline Unithesam abbaszadehNo ratings yet

- Slickline TenderDocument10 pagesSlickline Tender李四江No ratings yet

- Well Intervention Operation FlyerDocument21 pagesWell Intervention Operation Flyerfakhrurrozi arbian100% (1)

- Wireline Equipment Checks: - 2. Wire HistoryDocument10 pagesWireline Equipment Checks: - 2. Wire HistoryRio de MarioNo ratings yet

- Upstroke JarDocument2 pagesUpstroke JarJai DubeyNo ratings yet

- Elmar Enviro SBLWDocument48 pagesElmar Enviro SBLWKASHIF KHANNo ratings yet

- Eline Tool ComparisonDocument16 pagesEline Tool ComparisonMoustafa Ashraf100% (1)

- SS2800 Side Pocket Mandrel GaugesDocument2 pagesSS2800 Side Pocket Mandrel GaugesGonza PfNo ratings yet

- Elmar Wireline Tools CatalogDocument147 pagesElmar Wireline Tools CatalogDragonNo ratings yet

- Oh - DSLT, DSST, Mast CH - DSLT, Mast, SCMT: Sonic ToolsDocument18 pagesOh - DSLT, DSST, Mast CH - DSLT, Mast, SCMT: Sonic ToolsWualdir Martin Vivas ChungaNo ratings yet

- Nov Asep Elmar Ict WL Tools Poster v3Document95 pagesNov Asep Elmar Ict WL Tools Poster v3Victor Martinez100% (2)

- WPCE Venting-Glycol Injection ValveDocument1 pageWPCE Venting-Glycol Injection ValveMARIONo ratings yet

- 59 PSL Wireline Basic Manual Rev2Document128 pages59 PSL Wireline Basic Manual Rev2Tebengz ShakespearNo ratings yet

- 4 Depth Control - Dec2016 - NoMM - JFEDocument103 pages4 Depth Control - Dec2016 - NoMM - JFEmortizNo ratings yet

- A1 001 Wireline Unit PTO SwapBody 24ftDocument2 pagesA1 001 Wireline Unit PTO SwapBody 24ftRio de MarioNo ratings yet

- Sperry Sun - Motor BookletDocument40 pagesSperry Sun - Motor BookletAnonymous pMAZFE41Tt100% (1)

- Wireline Jars PDFDocument12 pagesWireline Jars PDFfelipeNo ratings yet

- 3 Ok-6 PDFDocument16 pages3 Ok-6 PDFYovaraj Karunakaran100% (1)

- Hunting007 Thru Tubing Cat Rev6 WebDocument72 pagesHunting007 Thru Tubing Cat Rev6 Webchubby_hippoNo ratings yet

- Prakarsa-Iliadi - Slickline - Rigless Application 20180307Document90 pagesPrakarsa-Iliadi - Slickline - Rigless Application 20180307Asfan100% (1)

- Camco KBMM, KBMG, KBUG Side Pocket MandrelDocument4 pagesCamco KBMM, KBMG, KBUG Side Pocket MandrelYovaraj KarunakaranNo ratings yet

- Schlumberger AR 1984Document52 pagesSchlumberger AR 1984Cesar Mora100% (1)

- Unloading Job With CTU LBD-04 PDFDocument5 pagesUnloading Job With CTU LBD-04 PDFBayu Priyogo100% (2)

- Well InterventionsDocument124 pagesWell InterventionsAntonio BevilacquaNo ratings yet

- Schlumberger Production Logging Tool ProgramDocument3 pagesSchlumberger Production Logging Tool ProgramdoombuggyNo ratings yet

- Kickover Tools KOT SeriesDocument6 pagesKickover Tools KOT SeriesfelipeNo ratings yet

- Wireline Field EngineeriDocument3 pagesWireline Field EngineeriTeguh BudiartoNo ratings yet

- B-Positioning XA RA XO XDDocument2 pagesB-Positioning XA RA XO XDSorin100% (1)

- Off-Factory Test Procedure For X-Mas TreesDocument11 pagesOff-Factory Test Procedure For X-Mas Treesomar shady100% (1)

- Normal - Slickline ManualDocument3 pagesNormal - Slickline ManualKaystain Chris IhemeNo ratings yet

- Kea Oilfield Engineering Pte LTDDocument9 pagesKea Oilfield Engineering Pte LTDFabio ParceroNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Ficha Tecnica de AutomotrizDocument242 pagesFicha Tecnica de AutomotrizIvonne Dayanna Ortiz RangelNo ratings yet

- iAutoConnect Sellers 2022Document135 pagesiAutoConnect Sellers 2022Arun KumarNo ratings yet

- YCN - Fiat Tractor Parts 2Document432 pagesYCN - Fiat Tractor Parts 2deisy ortega100% (4)

- Cartoon Car PDFDocument3 pagesCartoon Car PDFShridhar ZambareNo ratings yet

- Meritor Parts Failure AnalysisDocument115 pagesMeritor Parts Failure Analysiskkmech100% (1)

- SEM 919&921 Motor Grader OMMDocument10 pagesSEM 919&921 Motor Grader OMMJosé Diaz100% (2)

- Atlas Copco Wagner Scooptram ST-3.5Document20 pagesAtlas Copco Wagner Scooptram ST-3.5ait mimoune100% (1)

- Folleto T-5Document5 pagesFolleto T-5giulianogjNo ratings yet

- Link Belt HTC 8675Document28 pagesLink Belt HTC 8675Sergio ZuritaNo ratings yet

- Optimum: Ersatzteile - Spare Parts - D660Document19 pagesOptimum: Ersatzteile - Spare Parts - D660Silva JoãoNo ratings yet

- Machine Component Index: Manitowoc Crane GroupDocument1,682 pagesMachine Component Index: Manitowoc Crane GroupAlberto QuispeNo ratings yet