Xuper 2240

Xuper 2240

Uploaded by

Ashis Kumar MohantyCopyright:

Available Formats

Xuper 2240

Xuper 2240

Uploaded by

Ashis Kumar MohantyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Xuper 2240

Xuper 2240

Uploaded by

Ashis Kumar MohantyCopyright:

Available Formats

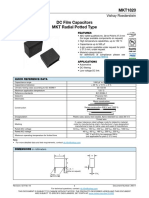

Versatile Electrode for All Weldable Cast Irons

Xuper 2240

WELDING

Excellent tie-in and fluidity characteristics in all-positions

Excellent welding wash and fluidity with little or no spatter

Unique chemistry for in-process weld cleaning and little to

no spatter

Ductile matrix imparts high crack resistance

PRODUCT INFORMATION

DESCRIPTION WELDING PROCEDURE & TECHNIQUE

Preparation: Prepare casting defect by chamfering with

Xuper 2240 is an extremely versatile joining and re-build

either Eutectic ChamferTrode or ExoTrode. Cracks should

electrode specially formulated for gray, ductile, nodular and

PRODUCT INFORMATION

be prepared with drilled holes to prevent growth and either

alloyed cast irons. This all-position electrode possesses a

a single-V or double-V depending on casting thickness and

unique arc, which aids in removing harmful contaminants.

accessibility. Allow a 1/8" root opening for full-penetration

Xuper 2240 deposits weld metal having a crack-resistant

welds. Preheat large castings to 400F (pre-heat tempera-

structure. It is easily handled, produces little to no spatter

ture will vary with casting size, type and condition).

and it welds with excellent fluidity and wash. Weld deposits

are machinable.

Technique: Deposit short runs no longer than 2" and mod-

erately peen the 2nd and subsequent passes. Use either a

cascade or block deposition sequence (see figures below)

TYPICAL APPLICATIONS

for large sectional thickness castings.

Pump Casings p q

Bell Housings

High-Strength Alloyed Cast Iron Gear Boxes

Machine Bases

Repairing Foundry Defects

Motor Casings

Cascade Sequence: Weld metal is deposited in overlapping layers.

TECHNICAL DATA

Typical Tensile Strength: 55,000 psi (380 N/mm2)

Typical Yield Strength: 38,000 psi (262 N/mm2)

Typical Hardness : HRB: 75

Current: AC or DCEN (-)

Block Sequence: Weld metal is deposited in intervening increments.

Post-Welding: Slow cool after welding using insulating

material such as vermiculite or heat-retardant blankets.

WELDING PARAMETERS

Diameter 3/32" (2.4mm) 1/8" (3.2) 5/32" (4.0mm)

Amperage 80-90 105-115 130-145

YOUR RESOURCE FOR PROTECTION, REPAIR AND JOINING SOLUTIONS

Eutectic Corporation Eutectic Canada Eutectic Mexico

N94 W14355 Garwin Mace Drive 52 Hymus Blvd. Suite 220 KM 36.5 Autopista

Menomonee Falls, WI 53051 USA Pointe-Claire, Quebec Mexico-Quertaro

P 800-558-8524 F 262-255-5542 H9R 1C9 54730 Cautitlan-Izcalli

www.eutecticusa.com Phone: (800) 361-9439 Estado de Mexico, Mexico

Fax: (514) 695-8793 Phone: 011 (52) 55-5872-1111

www.eutectic-na.com e-mail: eutectic@eutectic.com.mx

Statement of Liability: Due to variations inherent in specific applications, the technical information contained herein, including any information as to suggested product applications or results, is presented without

representation or warranty, expressed or implied. Without limitation, there are no warranties of merchantability or of fitness for a particular purpose. Each process and application must be fully evaluated by the user

in all respects, including suitability, compliance with applicable law and non-infringement of the rights of others, and Eutectic Corporation and its affiliates shall have no liability in respect thereof.

2240 DS-05-09-12

You might also like

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Revitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsDocument2 pagesRevitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsJesus VerduzcoNo ratings yet

- Bottle Manufacturing ProcessDocument17 pagesBottle Manufacturing ProcessAshis Kumar Mohanty67% (3)

- EutecTrode 4002Document2 pagesEutecTrode 4002bassemahmedmeNo ratings yet

- Nucleotec 2222Document2 pagesNucleotec 2222Marco MorenoNo ratings yet

- EutecTrode 3055Document2 pagesEutecTrode 3055asmaa aliNo ratings yet

- Abratec 6715: WeldingDocument2 pagesAbratec 6715: Weldingmohamed AdelNo ratings yet

- EnDOtec 358Document2 pagesEnDOtec 358Luis NarvaezNo ratings yet

- EnDOtec 310Document2 pagesEnDOtec 310EdwinNo ratings yet

- EWACDocument2 pagesEWACsandeepNo ratings yet

- Abratec 6710 XHD: WeldingDocument2 pagesAbratec 6710 XHD: WeldingAravind rajNo ratings yet

- An 4633Document2 pagesAn 4633erikaNo ratings yet

- Thomas Betts Thobetc00020 19Document1 pageThomas Betts Thobetc00020 19AF VMNo ratings yet

- Eutronic Arc Spray 4Document2 pagesEutronic Arc Spray 4Simelemon TolomeoNo ratings yet

- 2209 EutecTrodeDocument1 page2209 EutecTrodeSimelemon TolomeoNo ratings yet

- Xuper 680 CGS: WeldingDocument2 pagesXuper 680 CGS: WeldingSharad ShahNo ratings yet

- Receptaculo Con Tapa y Caja Mod. ARE-6424Document7 pagesReceptaculo Con Tapa y Caja Mod. ARE-6424Rolando GilNo ratings yet

- Hazardous Heavy DutyDocument5 pagesHazardous Heavy DutyNisarg BavishiNo ratings yet

- Eutalloy 10224Document2 pagesEutalloy 10224folkenralkfanelNo ratings yet

- Siemens Energy Micalastic® Global Vacuum Pressure Impregnation (GVPI)Document4 pagesSiemens Energy Micalastic® Global Vacuum Pressure Impregnation (GVPI)Mantenimiento GEINo ratings yet

- EutecDur N 6070Document2 pagesEutecDur N 6070shadabkhan5557No ratings yet

- CapacitorDocument17 pagesCapacitorjuliolocNo ratings yet

- Ve 24 Vacuum Circuit BreakersDocument9 pagesVe 24 Vacuum Circuit Breakersharihoed.s7201801No ratings yet

- Extreme Cat 6 Component-Rated Utp Quickport Jack: Product Specifications 61110-Xx6Document2 pagesExtreme Cat 6 Component-Rated Utp Quickport Jack: Product Specifications 61110-Xx6Adi PurnomoNo ratings yet

- Extreme Cat 6 Component-Rated Utp Quickport Jack: Product Specifications 61110-Xx6Document2 pagesExtreme Cat 6 Component-Rated Utp Quickport Jack: Product Specifications 61110-Xx6Adde JonNo ratings yet

- Xuper 646 XHDDocument2 pagesXuper 646 XHDJuan LondonoNo ratings yet

- Teromatec An 4617Document2 pagesTeromatec An 4617erikaNo ratings yet

- Vishay Roederstein: FeaturesDocument17 pagesVishay Roederstein: FeaturesAdiyatma DjatnikaNo ratings yet

- WaboCrete Membrane 1206Document4 pagesWaboCrete Membrane 1206MARCO ANTONIO AYALA MARTINEZNo ratings yet

- WEG Weg Insulation System Micatherm 50105432 Brochure EnglishDocument8 pagesWEG Weg Insulation System Micatherm 50105432 Brochure Englishhsu cuterNo ratings yet

- AbraTec 6715Document2 pagesAbraTec 6715Luis MoriNo ratings yet

- Bushing Connection Animal Cover: Energy DivisionDocument2 pagesBushing Connection Animal Cover: Energy Divisionjorge_moralesmNo ratings yet

- Xuper 1665 XFCDocument2 pagesXuper 1665 XFCAntonio CardosoNo ratings yet

- Datasheet - CoronaShield C - 215.55 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.55 - EN - GLLECTORNo ratings yet

- Corona Station AV 300/400Document4 pagesCorona Station AV 300/400vladimirNo ratings yet

- Xuper 6804 XHD: WeldingDocument2 pagesXuper 6804 XHD: WeldingAravind rajNo ratings yet

- Xuper 2109Document2 pagesXuper 2109Brian HernandezNo ratings yet

- 1STC Molds 2013mayDocument93 pages1STC Molds 2013mayreginaldo joseNo ratings yet

- Datasheet - CoronaShield C - 215.51 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.51 - EN - GLLECTORNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- Vishay Roederstein: FeaturesDocument15 pagesVishay Roederstein: Featuresiman wahyudinNo ratings yet

- Ujc-S Underground Junction Chamber: Catalogue 2018Document6 pagesUjc-S Underground Junction Chamber: Catalogue 2018Anonymous tCb9gF0No ratings yet

- C&D Flooded Batteries-KCR-KARDocument4 pagesC&D Flooded Batteries-KCR-KARvikasmikkuNo ratings yet

- Cavi RychemDocument4 pagesCavi RychemmammolloNo ratings yet

- High Alloyed Flux Core Wire For Welding Dissimilar Steels and Unknown SteelsDocument1 pageHigh Alloyed Flux Core Wire For Welding Dissimilar Steels and Unknown SteelsNapoleon DasNo ratings yet

- 224 XyronDocument1 page224 Xyrontabrizee nurNo ratings yet

- Generator in Situ Inspection Fact Sheet PDFDocument2 pagesGenerator in Situ Inspection Fact Sheet PDFShanjiNo ratings yet

- 2-Ewac o 521Document1 page2-Ewac o 521Napoleon DasNo ratings yet

- Epp 2154Document4 pagesEpp 2154RazkulNo ratings yet

- 10224Document2 pages10224yeison piedrahitaNo ratings yet

- Solar Panel Zone 1 and 2Document2 pagesSolar Panel Zone 1 and 2Fermín FigueroaNo ratings yet

- Nkt-06086 Katalog HochspannungsgarniturenDocument20 pagesNkt-06086 Katalog Hochspannungsgarniturenrjk941-1No ratings yet

- Datasheet: Model 230 Brushless Slip RingDocument7 pagesDatasheet: Model 230 Brushless Slip Ringedwintrujillo.gecNo ratings yet

- WKO Series: AC ACDocument4 pagesWKO Series: AC ACGeorge GryphoneNo ratings yet

- 2-3 Protecting and Switching Power Equipment. Metering, Control and Measurement Devices, Power Supply EquipmentDocument88 pages2-3 Protecting and Switching Power Equipment. Metering, Control and Measurement Devices, Power Supply EquipmentBold ByambaaNo ratings yet

- Catalogueelectrical Power Connectors12062023ldDocument56 pagesCatalogueelectrical Power Connectors12062023ldiemch2908100% (1)

- StrutTech FRP Strut Catalog - 2.0 AsdfDocument52 pagesStrutTech FRP Strut Catalog - 2.0 AsdfD100% (1)

- Form C 1608 AnchorLoc3 Install GuideDocument4 pagesForm C 1608 AnchorLoc3 Install GuideKelvin JinNo ratings yet

- DBTS Megatron Catalogue-1Document40 pagesDBTS Megatron Catalogue-1KNS CSBNo ratings yet

- India's Foreign Policy: Changing Dynamics: ContextDocument4 pagesIndia's Foreign Policy: Changing Dynamics: ContextAshis Kumar MohantyNo ratings yet

- Sl. No. Decision of The Group of Ministers (Gom) : (A) To (C) : Accepted The Recommendations of TheDocument7 pagesSl. No. Decision of The Group of Ministers (Gom) : (A) To (C) : Accepted The Recommendations of TheAshis Kumar MohantyNo ratings yet

- Mock Test 1 (IAS Prelims Paper-I) : This Section Is Taken From The BookDocument17 pagesMock Test 1 (IAS Prelims Paper-I) : This Section Is Taken From The BookAshis Kumar MohantyNo ratings yet

- Design Procedure For A Water Pumping SystemDocument55 pagesDesign Procedure For A Water Pumping SystemAshis Kumar MohantyNo ratings yet

- Air Compressor ChecklistDocument1 pageAir Compressor ChecklistAshis Kumar MohantyNo ratings yet

- Erection Protocol Sheet: Bangalore Water Supply & Sewerage Board S1A2, 5 MLD STP, ChikkabanavaraDocument2 pagesErection Protocol Sheet: Bangalore Water Supply & Sewerage Board S1A2, 5 MLD STP, ChikkabanavaraAshis Kumar MohantyNo ratings yet

- Load CombDocument49 pagesLoad CombNeeraj DubeyNo ratings yet

- Vince Hagan Concrete Batching Plants Parts CatalogDocument1 pageVince Hagan Concrete Batching Plants Parts CatalogSubrata KarmakarNo ratings yet

- VISI Machining-2016-LOW PDFDocument8 pagesVISI Machining-2016-LOW PDFBenedict JoNo ratings yet

- WESTERMAN, Jonah. Between Action and Image - Performance As Inframedium' (2015)Document4 pagesWESTERMAN, Jonah. Between Action and Image - Performance As Inframedium' (2015)BIAGIOPECORELLINo ratings yet

- Limit and Fit - ISO Hole Chart - ToleranceDocument2 pagesLimit and Fit - ISO Hole Chart - Toleranceagniva datta100% (2)

- Study of Major Fires at Storage Tanks - Lesson Learnt and ImplementationDocument113 pagesStudy of Major Fires at Storage Tanks - Lesson Learnt and ImplementationShashank AB Jain100% (2)

- Sop Prepare To The Guest Room VD and OdDocument2 pagesSop Prepare To The Guest Room VD and Odjasonfernandes10000No ratings yet

- Methods of Presentation of SubjectDocument40 pagesMethods of Presentation of SubjectMarineth MonsantoNo ratings yet

- Hi Crush FB Silo To Blender Conveyor TechSheetDocument2 pagesHi Crush FB Silo To Blender Conveyor TechSheetsmithyry2014No ratings yet

- HPCL VRMP Engg PresentationDocument18 pagesHPCL VRMP Engg PresentationgssmilesNo ratings yet

- Commercial Law Seminar Two QuestionsDocument3 pagesCommercial Law Seminar Two QuestionsIsmail PatelNo ratings yet

- Top 10 Architectural Wonders of The WorldDocument13 pagesTop 10 Architectural Wonders of The WorldRein Michael MendozaNo ratings yet

- WKS 4 Excavations Excavation Safety Guide PDFDocument84 pagesWKS 4 Excavations Excavation Safety Guide PDFAbinesh AB100% (1)

- 01 Technical Dossier On GRP Pipes PDFDocument23 pages01 Technical Dossier On GRP Pipes PDFSuhail PashaNo ratings yet

- Whirlpool 7MWED1600BM0Document15 pagesWhirlpool 7MWED1600BM0omar leonNo ratings yet

- IKEA Home PlannerDocument18 pagesIKEA Home PlannerM Alim Ur RahmanNo ratings yet

- 4AT Gears PDFDocument8 pages4AT Gears PDFNoah IstreNo ratings yet

- Triple Roll MillDocument2 pagesTriple Roll MillAshish Mishra100% (1)

- Skua 10,10ST1&10ST2 PDFDocument1,291 pagesSkua 10,10ST1&10ST2 PDFNoraza HanafiahNo ratings yet

- 750NevadaClub 1998-2001 PL (GB) PDFDocument56 pages750NevadaClub 1998-2001 PL (GB) PDFTrakadasGeorgesNo ratings yet

- Reheat Cycle: Steam Turbines ForDocument4 pagesReheat Cycle: Steam Turbines Forruben colqueNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedurefizulislamNo ratings yet

- Rt0700c ManualDocument108 pagesRt0700c ManualsamserbanexNo ratings yet

- Asado PDFDocument89 pagesAsado PDFheningputriNo ratings yet

- Type 28 Gas Seals System Presentation PDFDocument108 pagesType 28 Gas Seals System Presentation PDFlogicloverNo ratings yet

- Armaturenbau SF6 Density MeterDocument16 pagesArmaturenbau SF6 Density MeterRichard SyNo ratings yet

- Diagrama SA AK300Document14 pagesDiagrama SA AK300Jaciel Fielder Jimenez100% (1)

- Boiler and Aux Maintenance ManualDocument248 pagesBoiler and Aux Maintenance Manualkeerthi dayarathnaNo ratings yet

- A1.45 Dock Leveler DetailDocument1 pageA1.45 Dock Leveler DetailHendri Pecinta KedamaiAnNo ratings yet

- MODEL: 3203 Owners Manual: WarningDocument21 pagesMODEL: 3203 Owners Manual: WarningdlmamrNo ratings yet