Recycling of FRP Boats

Recycling of FRP Boats

Uploaded by

jayaramsomarajan1975Copyright:

Available Formats

Recycling of FRP Boats

Recycling of FRP Boats

Uploaded by

jayaramsomarajan1975Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Recycling of FRP Boats

Recycling of FRP Boats

Uploaded by

jayaramsomarajan1975Copyright:

Available Formats

International Journal of Advanced Research in Engineering and Technology (IJARET)

Volume 9, Issue 3, May - June 2018, pp. 244–252, Article ID: IJARET_09_03_030

Available online at http://www.iaeme.com/IJARET/issues.asp?JType=IJARET&VType=9&IType=3

ISSN Print: 0976-6480 and ISSN Online: 0976-6499

© IAEME Publication

RECYCLING OF FRP BOATS

Jayaram S., Sivaprasad K. and Nandakumar C. G

Department of Ship Technology,

Cochin University of Science and Technology, Kochi, Kerala, India

ABSTRACT

Application of Fibre Reinforced Plastic (FRP) for marine structures range from

small boats to ships. Their scope also extends to underwater vehicles and the deck

structures of offshore platforms. Use of composites in boat building can be traced back

to nineteen fifties. Sea going boats are subjected to considerable wave forces besides

cargo loads. With the latest developments in material science, it is possible to engineer

the composite materials with necessary strength and durability in the marine

environment. Recycling of obsolete boats is a growing issue in the marine industry

especially with the interference of various environmental monitoring agencies and

maritime organisations. Recycling of the existing boats is complex and costly since the

existing boats are not ‘built to be recycled’. Besides reporting the application of non-

metallic composite in the marine environment, this paper addresses the issue of

recycling of FRP boats. A guidance plan for the recycling of FRP boats is presented in

the paper. The paper also describes the application of design for ship recycling concept

in the context of FRP boats and presents a recyclability analysis of the FRP materials

that are dismantled from the boats. Safe recycling of FRP and other materials from

boats from a sustainable development perspective has been addressed.

Key words: FRP boats, FRP Boat Recycling, Boat Recycling Plan, Design for Ship

Recycling, Recyclability.

Cite this Article: Recycling of FRP Boats, Jayaram S, Sivaprasad K. and Nandakumar

C. G. International Journal of Advanced Research in Engineering and Technology,

9(3), 2018, pp 244–252.

http://www.iaeme.com/IJARET/issues.asp?JType=IJARET&VType=9&IType=3

1. INTRODUCTION

Naval architects and boat designers have been focussing on optimisation of scantlings of hull

structure and other components in order to make boatbuilding more economical. Research

investigations to formulate boat design solutions characterised by weight reduction have not

only fetched light scantling based structural design but also robust boatbuilding materials with

high strength to weight ratio. Finite Element Analysis based structural analysis is in the former

category of the design solutions whereas the use of composite materials, such as fibre reinforced

plastic (FRP), constitutes the latter solution part.

FRP is a composite material that is composed of reinforcing fibres and a polymer matrix to

bind together the fibres. The polymer matrix is applied as a liquid resin and is chemically cured

http://www.iaeme.com/IJARET/index.asp 244 editor@iaeme.com

Jayaram S, Sivaprasad K. and Nandakumar C. G

to form a solid. Constituent materials which are commonly used as reinforcements and matrix

in FRP products used for marine structures [1] are presented in Table 1.

Table 1 Constituents of FRP used for marine structures

Reinforcing fibre Polymer matrix

Glass fibre Polyester resin

Carbon fibre Vinyl ester resin

Aramid fibre Epoxy resin

FRP is the main type of composite material which is extensively used in boat building.

Apart from the main structural advantage of high strength to weight ratio of the composite

material, some physical and manufacturing characteristics make application of FRP in ship and

boat building more suitable. These characteristics are given in Table 2.

Application of FRP in ship and boat building will become more wide spread as the identified

marine fields are being developed in a faster rate in the recent years. More number of boats

fully fitted with FRP hull and boats with extensive FRP outfits will be introduced as a result of

these developmental activities in the maritime field.

Fibre reinforced composite materials are relatively younger member in the group of

boatbuilding materials. Considering a life expectancy of about 50 years [2] for the FRP boats,

a large number of such boats that were built in 1960s and 1970s have reached the end of their

useful lives. In addition, there can be extra ordinary situations like heavy damage to boat

demanding dismantling of the hull. These situations call for efficient methodologies of

recycling of these boats in an environmentally friendly fashion and at the same time in an

economic way. However, the existing boats were designed without considerable thoughts on

their end of life in mind. In addition, the boat recycling is yet to be developed into a full-fledged

and regulated industry like the boatbuilding or boat repair. ‘Hong Kong International

Convention for the Safe and Environmentally Sound Recycling of Ships, 2009,’ which is yet to

enter into force, has laid down the regulations applicable to recycling of ships and ship recycling

facilities [3]. Hong Kong Convention is not applicable to ships of less than 500 gross tonnage.

Since a large number of FRP boats will have a gross tonnage of less than 500, the Convention

is not going not be applicable to them. Regulations governing recycling of such boats are yet to

be formulated in most of the countries.

http://www.iaeme.com/IJARET/index.asp 245 editor@iaeme.com

Recycling of FRP Boats

Table 2 Areas of application of FRP for marine structures

Material/Manufacturing Area of

Type of marine structure

Features Application

Easy manufacturing techniques, Passenger Passenger ferries

flexibility of geometry & shape, transport Country boats in inland waterways

durability, and corrosion

Luxury cruisers

resistance Recreational/ Speed launches

Tourism

House boats/Floating hotels/Cottages

Pedal boats

Deck structures of platforms

Submersibles

Offshore

Drilling and production risers

Submarine pipelines

Fishing Fishing vessels

Components of submarines and

Defence

warships

Safety

Rescue boats and life boats

equipment

General Pontoons/ Buoys/ Buoyancy drums

service Dredging pipe lines

High strength to weight ratio Superstructure & other structures

Commercial above deck

ships

Foundations and outfitting

Defence Foundations and outfitting

Non-magnetic Defence Mine sweepers

International Council of Marine Industry Associations (ICOMIA) has reported on the

history and the present situation of decommissioning of end of life boats and has summarised

on the outcome of four projects on recycling of boats [2]. In the case of recycling of naval

vessels, some research studies have already been carried out and the recycling plans have been

published [4]. The research paper has described the practical ways of recycling of glass

reinforced polyester (GRP) hull waste that is obtained from dismantling of naval vessels owned

by the Polish navy. Hedlund-Astrom et al. [5] in their paper have given the systematic and

scientific methods to recycle waste from FRP sandwich composite ship following the principle

of waste management hierarchy in recycling. Kostopoulos et al. [6] have dealt in detail with

chemical processes employed to convert waste FRP products from the dismantling yard to

useful recycled products. Hedlund-Astrom et al. [7] have proposed an efficient information

system for identification of various recycling approaches for recycling of ships having FRP hull

and usual outfitting elements consisting of different metallic parts.

Monso [8] has made an analysis of the life cycle of boats, the impact on marine environment

when they reach their end of life, and the economic aspects of boat recycling and has made

recommendations on the administrative measures necessary for managing out-of-use boats and

on the functioning of boat recycling centres. Monso [9] has presented good practices for

scrapping and management of out of use boats and their waste. Eklund et al. have described the

challenges of disposal of obsolete boats in Denmark, Norway, Finland, and Sweden, its

environmental impacts, and the present practices of reuse and recycling of materials from end

of life boats [10].

http://www.iaeme.com/IJARET/index.asp 246 editor@iaeme.com

Jayaram S, Sivaprasad K. and Nandakumar C. G

The objectives of this paper are to examine the issues in recycling of FRP boats, to propose

a general recycling plan for FRP boats, to describe the application of ‘design for ship recycling’

concept to FRP boats, and to conduct a recyclability analysis for the FRP content of the boats.

2. RECYCLING OF BOATS MADE OF FRP

2.1. Recycling of Metallic Hull versus Recycling of FRP Hull

One of the main advantages of recycling of metallic hull is that almost all metallic materials

used on ship hull can be effectively recycled by melting and re-rolling. Re-rolling of hull steel

obtained from dismantling of obsolete vessels opens up various options as far as recyclability

of dismantled products are concerned. At present, there exists no economic option like this in

the case of recycling of FRP materials, made using thermoset resins, which are used for hull of

ships and boats. Such composite hull parts cannot be converted into other useful physical forms

either by melting, rolling or thermal forming, and moulding.

2.2. Recycling Options for FRP Boats

Recycling or reuse options are generally the requirements for an effective waste management

planning in recycling of boats. The economic factors such as cost of dismantling or recycling

and the regulatory requirements influence the decision on the recyclability options. The

hierarchy for waste management plans in the boat recycling industry are well defined [2] and

have the following four major options:

• Reuse: Extending the life of a boat or its components by putting them back to use.

• Recycling: Separating components and products from the dismantled lot, reprocessing or

refurbishing the selected group of products, and then putting to use.

• Energy Recovery: Incinerating the waste material obtained from dismantling a boat to

generate energy.

• Disposal: Disposal of waste items which cannot be subjected to any of the three options

mentioned above, to a disposal or landfill site.

Unlike metallic hull structures, which have a limited span of operational life even with

application of effective hull protection mechanisms, composite hull survive much longer period

at sea. In this context it may be noted that in many occasions it will be the equipment, outfit

items, and other metallic structural components that may become obsolete much earlier than

the composite hull structure because of the exposure to marine environment and the extent of

usage. Extension of life of the main hull structure may be possible with a bit of conversion and

repair operations. This possibility gives rise to scope for direct reuse of end of life of the boat

for the function for which the hull had been designed and developed. If the quality of composite

hull is beyond scope of repair and conversion, and of reuse in the ‘as is’ condition, the hull may

be recycled and put into some other forms.

2.3. Recycling guidance plan for FRP Boats

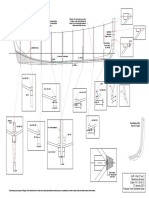

A flow chart representing the recycling guidance plan for FRP boats has been developed and is

presented in Fig.1. The recycling of boats has been divided into four phases as shown in the

flow chart. Preparation of the boat and the dismantling of easily removable items are covered

in the first phase. It is recommended to generate a boat recycling plan, which specifies the

processes and sub-processes to be carried out along with the sequence, prior to commencement

of the recycling operations. Dismantling of main machinery, other equipment, appendages, and

outfitting items are included in Phase-2. Phase-3 consists of disassembling of hull into smaller

elements called as disassemblies in two stages such as primary disassembling and secondary

http://www.iaeme.com/IJARET/index.asp 247 editor@iaeme.com

Recycling of FRP Boats

disassembling. Primary disassembling of the boat hull will result in larger blocks and secondary

disassembling in further smaller units. Disassembling of obsolete FRP boats is complex due to

the heavy fixtures on the hull for attaching the various structural, machinery, and outfit items.

Recycling of FRP material from both the hull and other components of the boat, sale of valuable

components to the second-hand market, and treatment of waste resulting from the recycling

process are to be carried during the last phase.

2.4. Recycling methods of FRP Materials from Boats

One of the main problems associated with recycling of FRP is the use of thermoset resins, which

results in a non-reversible curing action. Unlike thermoplastics, FRP products with thermoset

resins cannot be melted down and remoulded. The techniques which can be applied for

recycling of FRP materials on the hull and other components of the boats include [11]:

• Mechanical recycling

• Thermal recycling

• Chemical recycling

• Incineration

• Landfilling

Mechanical recycling consists of shredding of FRP material followed by mixing the

resulting material with virgin material for new construction or repair. This is a simple and

technically proven method. Thermal recycling or pyrolysis involves heating up the FRP

material in an inert atmosphere in order to recover the polymer material as oil. In chemical

recycling method, chemicals are used to dissolve the resin content of the FRP. Incineration

involves combustion of FRP for energy recovery [11-12].

Co-incineration of FRP in cement kilns is considered to be a better option than incineration

since it involves both material recovery and energy recovery and, therefore, facilitates more

effective utilisation of the FRP material. In this case, burning the resin results in energy

recovery whereas the glass fibres together with the fillers become a constituent of cement,

thereby resulting in material recovery [13]. Landfilling is the last option to be considered, if

permitted by the regulatory authorities, and shall be resorted to only when it is highly

unavoidable.

http://www.iaeme.com/IJARET/index.asp 248 editor@iaeme.com

Jayaram S, Sivaprasad K. and Nandakumar C. G

Figure 1. Recycling guidance plan for FRP boats

2.5. Environmental Impacts and Safety Risks with Recycling of FRP

Fibreglass is not a naturally degrading material and, therefore, its recycling requires special

consideration and sustainable working practices. The negative environmental impacts of

recycling of FRP boats involve those resulting from handling and transport; from pollution by

dust, gases, and noise generation; and those from various processes consuming energy.

Hazardous dust and fibres that are generated during shredding and grinding processes as well

as the toxic gases produced during the burning processes make the sustainable disposal of

fibreglass difficult.

http://www.iaeme.com/IJARET/index.asp 249 editor@iaeme.com

Recycling of FRP Boats

Mechanical recycling involves safety hazards and results in an end product of low value.

Grinding of FRP materials causes fire hazards since it becomes flammable when ground. Even

though air pollution is less in thermal recycling or pyrolysis method because of the absence of

combustion in an inert atmosphere, the surface defects which may be caused by the thermal

stresses can affect the strength of the recovered fibres. In chemical recycling method,

potentially hazardous solvents are utilised to carry out this process and the FRP materials need

to be granulated resulting in a reduction of the fibre length. The draw backs of incineration are

the resulting air pollution and the requirement for further disposal of the ash, containing fibre

content of the material, which may be a hazardous waste depending on its chemical composition

[11-12].

Recycling method to be opted for recycling of FRP boats shall be both sustainable and

economically viable. These options can be analysed by applying the design for ship recycling

[14] methodology to FRP boats.

3. APPLICATION OF DESIGN FOR SHIP RECYCLING FOR FRP

BOATS

Design for ship recycling can be considered as a set of engineering guidelines to be followed

during the entire lifecycle of a vessel in order to facilitate minimum negative impact on major

environmental and safety issues identified in marine industrial sector, especially during the end

of life recycling of the obsolete vessels [14].

Recyclability of a product or a component is its ability to be altered or adapted for reuse or

to be recycled. Most of the existing boats today are not ‘built to be recycled.’ While carrying

out the design of new boats and the selection of their construction materials, designers must

consider the present technologies of recycling of such materials as well as their recyclability

options, and must incorporate the recycling related aspects into the design. This will provide

opportunities to improve the recycling potential of the boat and reduce the costs for its

recycling. Conducting a recyclability analysis in the design stage can help the boat designer to

identify the components that can be reused or recycled at the end of life of the boat and to

eliminate potentially hazardous materials to the maximum possible extent. Recyclability

analysis consisting of various direct reuses of the obsolete FRP boats and use of the dismantled

products from the boats after effective recycling processes is given in Table 2.

Majority of the small boats are made in series as compared to ships, which are one of a kind

design. So for the smaller boats, it is proposed that the designer or builder must generate a

recycling manual, which specifies the disassembling procedures for the hull as well as other

components, design for ship recycling aspects that were considered during the design stage, and

the recyclability options of the materials or components of the hull and other parts. An efficient

knowledgebase is essential for, implementing design for ship recycling and subsequently its

application, like recyclability analysis of obsolete boats and their dismantled products. This

knowledgebase on boat recycling can be used to develop an expert system [14] which will

deliver some important end of life and partial boat recycling in terms of set of recommendations

of best practices in boat recycling. If a comprehensive knowledgebase of FRP boats can be

generated, it can be further used to develop an expert system for recycling of boats built using

FRP.

http://www.iaeme.com/IJARET/index.asp 250 editor@iaeme.com

Jayaram S, Sivaprasad K. and Nandakumar C. G

Table 2 Recyclability analysis of FRP boats

Recyclability

Type of Vessel Use

Option

Reuse existing hull , but replace or upgrade the equipment

and systems

Direct reuse Floating museums

Artificial reefs

Floating shopping complex/stores

Dismantled and cut to flat panels/flat bar stiffeners

Walls in composite boat moulds

Use pyrolysis method to extract the resin from the

composite

Ocean going vessels Grinding fibreglass into loose fibres and powdered resin

and use them to replace fibreglass in new products

Co-incineration in cement kilns for energy recovery and

Recycle to form as a constituent of cement

For noise absorption in wall panels

To manufacture artificial wood [13] or wood substitute

planks

Use along with other materials for road construction [13]

Use for fence posts, manhole covers, steps, pots for plants

Incineration for energy recovery

Reuse existing hull , but replace or upgrade the equipment

and systems

Direct reuse Floating shops

Passenger ferries Floating jetties

Floating stores

Recycle Same as that for oceangoing vessels mentioned above

Reuse existing hull , but replace or upgrade the equipment

Recreational speed boats Direct reuse

Paddle boats in lakes/ponds

Paddle boats Direct reuse Waste bins

4. DISCUSSION AND CONCLUSIONS

The necessity to carry out recycling of FRP boats that have reached the end of their useful lives

is a growing issue being faced by the global maritime community. Being a complex activity,

recycling of FRP boats are to be carried out in a systematic manner. This requires a guidance

plan that enables monitoring of the sequential processes involved in the recycling activities.

Generation of knowledgebase in the recycling of FRP boats is an important aspect to be

addressed by the maritime engineering community, especially by a group of experts consisting

of material scientists, chemical engineers, naval architects, pollution control scientists and the

maritime administrators. Application of ‘design for ship recycling’ philosophy will enable to

formulate a frame work for feasible solutions in this area. Application of expert system for

recycling of boats built using fibre reinforced composite materials can help the stake holders

http://www.iaeme.com/IJARET/index.asp 251 editor@iaeme.com

Recycling of FRP Boats

in the boat recycling industry to ensure safe and environmentally friendly recycling leading to

sustainable development in the maritime industrial domain.

Various issues related to recycling of obsolete FRP boats have been addressed in this paper.

A recycling guidance plan, which indicates various processes to done in sequential order, has

been developed and presented in the form of a flow chart. Application of the ‘design for ship

recycling’ concept to FRP boats has been described and a recyclability analysis has been

conducted for the FRP materials that form part of the hull and the other components of boats.

REFERENCES

[1] Eric Greene Associates. Marine Composites, 2nd Edition. Maryland, US: Eric Greene

Associates, 1999.

[2] ICOMIA (International Council of Marine Industry Associations). Decommissioning of End-

of-Life Boats- A Status Report, 2nd edition. London: International Council of Marine Industry

Associations, 2007.

[3] IMO (International Maritime Organisation). Hong Kong International Convention for the Safe

and Environmentally Sound Recycling of Ships, SR/CONF/45. Hong Kong: International

Maritime Organisation, 2009.

[4] Jastrzebska, M., Rutkowska, M. and Jurczak, W. Recycling of Ships Made of Glass Reinforced

Polyester. Proceedings of the International Conference on Recycling of Ships and Other Marine

Structures, London, 2005 pp. 115-119.

[5] Hedlund-Astrom, A., Luttropp, C. and Reinholdsson, P. Environmental Friendly Recycling of

FRP-Sandwich Ship Hulls. Proceedings of the International Conference Recycling of Ships and

Other Marine Structures, London, 2005 pp. 119-127.

[6] Kostopoulos, V., Fotiou, I. and Loutas, T. Review of Recycling Processes on Composite

Materials. Proceedings of the First International Conference on Dismantling of Obsolete

Vessels, Glasgow, 2006 pp. 79-85.

[7] Hedlund-Astrom, A. and Luttropp, C. Access of Hazardous and Metallic Integrated Objects at

Dismantling of Sandwich Ship Structures through Effective Information Handling. Proceedings

of the First International Conference on Dismantling of Obsolete Vessels, Glasgow, 2006 pp.

59-65.

[8] Monso, M.V. Diagnosis of the Current Situation of Out-of-Use Nautical Boats in Europe-

Exploration of Scrapping Process, Economic Study of Recovery and Proposals for Future.

[9] Monso, M.V. Guide on Good Scrapping and Waste Management Practices for Out-of-Use

Boats. 2012.

[10] Eklund, B., Haaksi, H., Syversen, F. and Eisted, R. Disposal of Plastic End-of-Life-Boats.

Copenhagen: Nordic Council of Ministers, 2013.

[11] Bartholomew, K. Fibreglass Reinforced Plastics Recycling. Minnesota Technical Assistance

Program, 2004.

[12] Fibreline Composites. Breakthrough: Recycling of Fibreglass is now a Reality, 2010.

https://fiberline.com/news/miljoe/breakthrough-recycling-fibreglass-now-reality

[13] Halliwell, S. Best Practice Guide- End of Life Options for Composite Waste. Cambridge, UK:

TWI Ltd, 2006.

[14] Sivaprasad, K. Development of Best Practices for Ship Recycling Processes. Ph.D. Dissertation,

Kochi: Cochin University of Science and Technology, 2010.

http://www.iaeme.com/IJARET/index.asp 252 editor@iaeme.com

You might also like

- RAC Questions AnswersDocument5 pagesRAC Questions AnswersJasper0% (1)

- Hydrofoil Ship Design - W NeillDocument46 pagesHydrofoil Ship Design - W NeillGölfried GeorgeNo ratings yet

- How To Dimension Sailing CatamaranDocument10 pagesHow To Dimension Sailing CatamaranFiqhy DianNo ratings yet

- Ship and Boat Building and Repair-5Document5 pagesShip and Boat Building and Repair-5navalmamunNo ratings yet

- Applications & Mechanical Properties of FRPDocument34 pagesApplications & Mechanical Properties of FRPAhmedHassen7No ratings yet

- BV Rules For The Classification and The Certification of Yachts Feb 08 Edition v1Document65 pagesBV Rules For The Classification and The Certification of Yachts Feb 08 Edition v1فضيلة عبدالرحمنNo ratings yet

- School of Maritime Studies Vels University Thalambur: Life Boat AIMDocument2 pagesSchool of Maritime Studies Vels University Thalambur: Life Boat AIMAayush AgrawalNo ratings yet

- ILUR - Plan 05 Stations Dimensions (Strip Planking Version) Scale 1/10 23 January 2004 François Vivier Architecte NavalDocument1 pageILUR - Plan 05 Stations Dimensions (Strip Planking Version) Scale 1/10 23 January 2004 François Vivier Architecte NavalGEORGE KARYDISNo ratings yet

- GRP Boat Building InstructionsDocument27 pagesGRP Boat Building InstructionsMiguel MendezNo ratings yet

- Soel YacthsDocument24 pagesSoel YacthsMaricar C. CamarilloNo ratings yet

- Roll Motion of Trimaran ShipsDocument273 pagesRoll Motion of Trimaran ShipsPhilSelborNo ratings yet

- Arrow 1500 DC Study PlansDocument20 pagesArrow 1500 DC Study PlansVitBar100% (1)

- Whisstock: Design 165 Doghouse Version Laminated Frames Longitudinal Structures Profile ViewDocument1 pageWhisstock: Design 165 Doghouse Version Laminated Frames Longitudinal Structures Profile ViewhjukNo ratings yet

- The Design RatiosDocument55 pagesThe Design RatiosAmit SharmaNo ratings yet

- Foot CatamaranDocument2 pagesFoot CatamaranАндрей КовальчукNo ratings yet

- Review of Ship Structural DetailDocument330 pagesReview of Ship Structural Detailreza84No ratings yet

- Rules Wooden Vessel PDFDocument66 pagesRules Wooden Vessel PDFLucas GuesseNo ratings yet

- Design of High Speed Planing Hulls For TDocument17 pagesDesign of High Speed Planing Hulls For TTihomir MarkovicNo ratings yet

- Hydrofoil CraftDocument9 pagesHydrofoil CraftAnonymous e3ceN15100% (1)

- ILUR - Plan 21 Rev 2 Backbone Structure Scale 1/15, 1/5 Et 1/2 27 January 2013 François Vivier Architecte NavalDocument1 pageILUR - Plan 21 Rev 2 Backbone Structure Scale 1/15, 1/5 Et 1/2 27 January 2013 François Vivier Architecte NavalGEORGE KARYDISNo ratings yet

- Ferro Cement 2Document22 pagesFerro Cement 2Abhishek DorugadeNo ratings yet

- Laminate GuideDocument3 pagesLaminate GuideYeni AgustiningsihNo ratings yet

- DNV Rules For Woodenships 1970Document146 pagesDNV Rules For Woodenships 1970Manuel Cares FuentesNo ratings yet

- Press R. Zefira: Yacht DesignDocument5 pagesPress R. Zefira: Yacht DesignZefiraNo ratings yet

- Introduction To Boat Building in CompositesDocument4 pagesIntroduction To Boat Building in CompositesMax BeeksNo ratings yet

- Stability of MultihullsDocument11 pagesStability of MultihullsnecatiygtNo ratings yet

- Intro To GRP and Hand Laid-Up GRP Moulding-PNS JAUHARDocument187 pagesIntro To GRP and Hand Laid-Up GRP Moulding-PNS JAUHARImran AhmedNo ratings yet

- Delta Anchor SizingDocument1 pageDelta Anchor SizingPhilSelborNo ratings yet

- (Catamaran) Effects of Shallow Water On Catamaran Interference CFD - Delft 372Document6 pages(Catamaran) Effects of Shallow Water On Catamaran Interference CFD - Delft 372Wm Erick CrNo ratings yet

- NirvanaDocument8 pagesNirvanaAndrei IulianNo ratings yet

- Engines For Planing BoatsDocument16 pagesEngines For Planing BoatsAlex MarcusNo ratings yet

- 07 - DNVs Hull STR For WW - Hull STR - Cargo Area - BottomDocument30 pages07 - DNVs Hull STR For WW - Hull STR - Cargo Area - BottomArpit Goyal100% (1)

- Concrete ShipsDocument112 pagesConcrete ShipsDábilla Adriana BehrendNo ratings yet

- The Development of A Hydrofoil-Supported-Rigid-Inflatable BoatDocument15 pagesThe Development of A Hydrofoil-Supported-Rigid-Inflatable BoatBoby48007No ratings yet

- Presentation On Hovercraft: Presented byDocument21 pagesPresentation On Hovercraft: Presented byNehaNo ratings yet

- A Runabout Reborn - Fast Modern Schooner - Lapstrake Primer: The Magazine For Wooden Boat Owners, Builders, and DesignersDocument152 pagesA Runabout Reborn - Fast Modern Schooner - Lapstrake Primer: The Magazine For Wooden Boat Owners, Builders, and DesignersPablo Besser100% (1)

- Choosing HullDocument16 pagesChoosing Hullnyaungzin100% (1)

- How To Fiberglass BoatsDocument123 pagesHow To Fiberglass BoatsMaxi Sie100% (1)

- Devlopment of The Rêvo Wasp 743 PDFDocument14 pagesDevlopment of The Rêvo Wasp 743 PDFrobertoNo ratings yet

- Sailing Hydrofoils - A.Y.R.S. Publication No.74, 1970Document292 pagesSailing Hydrofoils - A.Y.R.S. Publication No.74, 1970VitBarNo ratings yet

- Sea HawkDocument19 pagesSea HawkAlphamatrix01100% (2)

- Ship BuildingDocument29 pagesShip Buildingtmtt44No ratings yet

- DuFlex, Lightweight Composite PanelsDocument16 pagesDuFlex, Lightweight Composite PanelsDennys RamirezNo ratings yet

- Resistance Components of A CatamaranDocument13 pagesResistance Components of A CatamaranSciencezNo ratings yet

- BG Yacht Design - Pantanal 25Document6 pagesBG Yacht Design - Pantanal 25Lord AlmightyNo ratings yet

- Rhino 590 Specifications Jan 06-1Document6 pagesRhino 590 Specifications Jan 06-1MohdFarid100% (1)

- Yacht Design ENGDocument4 pagesYacht Design ENGArchin TactNo ratings yet

- Tore Holm - Bronze Fastenings - Butterfly Skylight: The Magazine For Wooden Boat Owners, Builders, and DesignersDocument140 pagesTore Holm - Bronze Fastenings - Butterfly Skylight: The Magazine For Wooden Boat Owners, Builders, and DesignersPablo BesserNo ratings yet

- GroupD ManualDocument24 pagesGroupD ManualTerminal VelocityNo ratings yet

- WBTA - Tunnel SternsDocument4 pagesWBTA - Tunnel SternsGermán Cristian Camacho SilvaNo ratings yet

- EN ISO 12215-1 - Small Craft - Hull Construction and ScantlingsDocument17 pagesEN ISO 12215-1 - Small Craft - Hull Construction and Scantlingsalessandro cabrasNo ratings yet

- 60M Mondo Marine 2014Document4 pages60M Mondo Marine 2014Denison Yacht SalesNo ratings yet

- Boat Design GlossaryDocument10 pagesBoat Design GlossaryTarek MohamedNo ratings yet

- Design 2005Document21 pagesDesign 2005bugsy77No ratings yet

- Applications of Composites in Marine Industry: Dr. S. Selvaraju, S.IlaiyavelDocument3 pagesApplications of Composites in Marine Industry: Dr. S. Selvaraju, S.IlaiyavelabhiNo ratings yet

- Sample Paper 3 PDFDocument28 pagesSample Paper 3 PDFAnni MataqeiNo ratings yet

- ClassNotes MC&W 1Document53 pagesClassNotes MC&W 1Soorsri T SNo ratings yet

- Composite in Marine ApplicationsDocument12 pagesComposite in Marine ApplicationsJithin Devan PadincharayilNo ratings yet

- 15 A Application of Composite MaterialsDocument3 pages15 A Application of Composite MaterialsKazi Tour DépenseNo ratings yet

- 2020.05 JKOSOMES TestandEvaluationProcedureofFoamCoreMaterialsforCompositeShipsDocument12 pages2020.05 JKOSOMES TestandEvaluationProcedureofFoamCoreMaterialsforCompositeShipsPrudhvi GogineniNo ratings yet

- CaseDocument2 pagesCasegkrehman0% (1)

- Ovwmp IGC0 LXF SVYubzo EDocument6 pagesOvwmp IGC0 LXF SVYubzo ESamarth KhatorNo ratings yet

- SSRN Id2395277Document3 pagesSSRN Id2395277ken nguyenNo ratings yet

- Aakash Vishwakarma (PG Thesis)Document75 pagesAakash Vishwakarma (PG Thesis)Akrity ParasharNo ratings yet

- Programmers GuideDocument76 pagesProgrammers GuideLy TheDanNo ratings yet

- Virtual and Augmented Reality ECC4351Document63 pagesVirtual and Augmented Reality ECC4351KeertanaNo ratings yet

- BMXNOM0200-Serial Link Module With 2 RS-485232 Ports inDocument3 pagesBMXNOM0200-Serial Link Module With 2 RS-485232 Ports ingrtabhilkwNo ratings yet

- Zimbabwe Energy PolicyDocument70 pagesZimbabwe Energy PolicyEd Chikuni50% (2)

- Mozilla Public License 2.0Document15 pagesMozilla Public License 2.0Sydney D. BajentingNo ratings yet

- Late in The Day at An Antique Rug Auction ThereDocument1 pageLate in The Day at An Antique Rug Auction Theretrilocksp SinghNo ratings yet

- Revalidation FormatDocument2 pagesRevalidation FormatVipin KumarNo ratings yet

- Maersk - New BOQDocument22 pagesMaersk - New BOQMT JasonNo ratings yet

- Mathematics Paper 2 Q CEKENAS Mocks 2023Document21 pagesMathematics Paper 2 Q CEKENAS Mocks 2023kongoemmanuel2006No ratings yet

- 18 Supreme Court Reports Annotated: Cabigas Us. PeopleDocument10 pages18 Supreme Court Reports Annotated: Cabigas Us. PeopledelayinggratificationNo ratings yet

- Circulation PatternDocument7 pagesCirculation PatternPrince PhilipNo ratings yet

- COPPUS Steam Turbines PRODUCT GUIDEDocument6 pagesCOPPUS Steam Turbines PRODUCT GUIDEaminardakaniNo ratings yet

- Edited Flipped ClassroomDocument58 pagesEdited Flipped ClassroomJonathan Agcaoili KupahuNo ratings yet

- Agile in Enterprise Resource Planning A Myth No MoreDocument8 pagesAgile in Enterprise Resource Planning A Myth No Moreprbansal100% (1)

- Catalogue of Fog Misting SystemDocument18 pagesCatalogue of Fog Misting SystemwapanchoNo ratings yet

- Application Eori Headquartered Inside Netherlands Do4391z9folengDocument2 pagesApplication Eori Headquartered Inside Netherlands Do4391z9folengIvan Da Silva BrazNo ratings yet

- Cost Accounting Worksheet Chap 3Document5 pagesCost Accounting Worksheet Chap 3Muhammad UsmanNo ratings yet

- Wopq Format Asme Qw-360Document1 pageWopq Format Asme Qw-360Anonymous S33n8gNo ratings yet

- SIMATICPCS7 STPCS7AO Complete English 2013 WebDocument180 pagesSIMATICPCS7 STPCS7AO Complete English 2013 WebDiana ArredondoNo ratings yet

- Roots BlowerDocument7 pagesRoots BlowerRyad GuiraNo ratings yet

- WCT-06 FeeSched Rev18Document1 pageWCT-06 FeeSched Rev18sami NaNo ratings yet

- Full Paper No 43 M 2Document9 pagesFull Paper No 43 M 2Anonymous 8qUHG4SlNo ratings yet

- Krohne Marshall Product OverviewDocument56 pagesKrohne Marshall Product Overviewzakir84md3639No ratings yet

- Perancangan Kapal Bulk Carrier 9.000 DWT Kecepatan 12 Knot Dengan Rute Pelabuhan Yos Sudarso - Pelabuhan Soekarno-HattaDocument21 pagesPerancangan Kapal Bulk Carrier 9.000 DWT Kecepatan 12 Knot Dengan Rute Pelabuhan Yos Sudarso - Pelabuhan Soekarno-HattaasrunNo ratings yet

- Traversing (NICE)Document33 pagesTraversing (NICE)prasitagnihotriNo ratings yet