0 ratings0% found this document useful (0 votes)

58 viewsData Sheet Potable Sampling Pump

Data Sheet Potable Sampling Pump

Uploaded by

Hendri HermawanThis document provides specifications for installing a sampling point on incinerator, boiler, and furnace stacks at Petronas Gas Bhd Units 03 and 06. It outlines requirements for a portable low-pressure flue gas sampling pump, including operating conditions, site conditions, design details, materials of construction, piping, accessories, and inspection/testing requirements. The pump will be used to take intermittent samples from the stacks at flow rates up to 13.5 CFM and temperatures up to 100°C.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Data Sheet Potable Sampling Pump

Data Sheet Potable Sampling Pump

Uploaded by

Hendri Hermawan0 ratings0% found this document useful (0 votes)

58 views2 pagesThis document provides specifications for installing a sampling point on incinerator, boiler, and furnace stacks at Petronas Gas Bhd Units 03 and 06. It outlines requirements for a portable low-pressure flue gas sampling pump, including operating conditions, site conditions, design details, materials of construction, piping, accessories, and inspection/testing requirements. The pump will be used to take intermittent samples from the stacks at flow rates up to 13.5 CFM and temperatures up to 100°C.

Original Description:

sgsfg

Original Title

070111 Data Sheet Potable Sampling Pump

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides specifications for installing a sampling point on incinerator, boiler, and furnace stacks at Petronas Gas Bhd Units 03 and 06. It outlines requirements for a portable low-pressure flue gas sampling pump, including operating conditions, site conditions, design details, materials of construction, piping, accessories, and inspection/testing requirements. The pump will be used to take intermittent samples from the stacks at flow rates up to 13.5 CFM and temperatures up to 100°C.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

58 views2 pagesData Sheet Potable Sampling Pump

Data Sheet Potable Sampling Pump

Uploaded by

Hendri HermawanThis document provides specifications for installing a sampling point on incinerator, boiler, and furnace stacks at Petronas Gas Bhd Units 03 and 06. It outlines requirements for a portable low-pressure flue gas sampling pump, including operating conditions, site conditions, design details, materials of construction, piping, accessories, and inspection/testing requirements. The pump will be used to take intermittent samples from the stacks at flow rates up to 13.5 CFM and temperatures up to 100°C.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 2

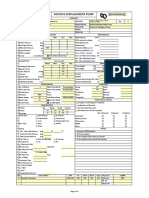

PROJECT : INSTALLATION OF SAMPLING POINT TO ALL

INCINERATIORS, BOILER AND FURNACE STACKS - ( COMMON )

APPLICABLE TO : PURCHASE PROPOSAL AS BUILT

FOR PETRONAS GAS BHD UNIT 03 AND 06

SITE GPP - 5 / 6 NO OF PUMPS REQUIRED ONE (1)

SERVICE LOW PRESSURE FLUE GAS SAMPLING SIZE AND TYPE PORTABLE

MANUFACTURER SERIAL NO

OPERATING DATA PUMPING DATA

Fluid FLUE GAS Head in suction vessel m liq abs

H2S Content N/A mg/kg Head in discharge vessel m liq abs

Hazardous Service ZONE 1 DIV 2 Highest Of liqiud level insuction vessel

Corrosive/Erosive YES (INTERNALLY) above/below pump center line (min) m

Operation : continuous/intermittent INTERMITTENT Height of liqiud level in discharge vessel

Capacity 13.5 CFM above/below pump center line (max) m

Min process flow N/A m3/hr Total head loss in suction line

Specific process condition during start-up/stop/transient between suction vessel and pump m liq

Pumping Temprature 100 m3/hr Total head loss in discharge line

Minimum design temperature deg C between pump and discharge vessel m liq

Max design temperature deg C Total minimum suction head

Specific Gravity / Density 1.34 kg/m3 Total maximum discharge head

Viscosity at P.T. 0.024 cP Head of vapour pressure m liq abs

Vapour pressure at P.T Differential head at rated capacity m liq.

Design Pressure FULL VACUUM bara Minimum available NPSH m liq.

Operating Pressure upto 29 Hg VAC bara Estimated efficiency %

Brake power at estimated efficiency 0.746 kW

SITE CONDITION PUMP DRIVE

Ambient Temperature 32 - 38 deg C Type Electric Motor

Area Classification Zone 1 Div 2 Speed 1450rpm

Electrical Supply 240 V 50 Hz 1 phase Transmission Direct Coupled

Estimated Installed Power (*) kW

DESIGN OPERATION CONDITION MECHANICAL SEAL

Pump speed (single/ double suc impeller) 1450 rpm Make/ type (*)

Capacity Rated 13.4 m3/ hr API Classification (*)

Efficiency at Rated (*) % API seal pipng plan (*)

Power absorbed at duty (*) kW Static? Rotating bellow/ Pusher type

Power absorbed t 120% BHP (*) kW Flushing/ barrier/ quench fluid

Recommended Drive Power (*) kW Cartrige mounted

Viscous Correction Factor (*) Allowable reverse pressure (*) barg

NPSH available at rated capacity m liqs Flush quantity required (*) m3/hr

NPSH Required for Water at rated capacity m liqs Barrier quantity required m3/hr

Pressure rating static/ dynamic/ reverse nra

PUMP DESIGN Seal chamber pressure (*) barg

Pump Type Maximum temperature rating (*) deg C

- horizontal/ Vertical horizontal

- axial/ radial spit (*) MATERIAL OF CONSTRUCTION

- overhung/ between bearings (*) Casing or outer barrel SS316

- single/ double volute/ diff (*) Inner casing (*)

- center line / foot mounted (*) Casing stud (*)

- single/ double suction (*) Min wall thickness (*) mm

Direction of Rotation (*) Cover (*)

Number of stage (*) Casing gasket (*)

Max/ Actual/ Min Impeller Diameter (*) mm Impeller (*)

Max allowable casing working pressure (*) barg Impeller waering hardness (*) H.B

max allowable jacket/ C.W. piping pressure (*) barg Casing earing hardness (*) H.B

Suction pressure speed with max impeller (*) Wear Ring coating (*)

Minimum continuos stable/ thermal flow (*) m3/hr Shaft (*)

Capacity at BHP (actual impeller diam.) (*) m3/hr Shaft sleeve for seal (*)

Interstage shaft sleeve (*)

MATERIAL OF CONSTRUCTION (Cont) Interstage bushing (*)

Throttle Bushing (*)

Thoat Bushing (*) BEARING AND LUBRICATION

Seal End Plate (*) Type of Bearing Lubrication (*)

Stationary Seal Face(s) (*) Radial Bearing : Type/ Make (*)

Rotating Seal Face(s) Thrust Bearing : Type/ Make (*)

Seal Spring(s)/ Bellow(s) Forced feed lubrication acc API614 : yes/no (*)

Lubricator : Type/ Make (*)

PIPING Lube Oil Healing : electirc/ steam (*)

Discharge size/ ANS flange class 3/4" / QUICK COUPLER (FEMALE)

possition (facing drive end) side COOLING

Suction size/ ANS flange class 1" /QUICK COUPLER (FEMALE) Medium / temp (deg C) / max inlet pressure (barg)

possition (facing drive end) side Cooling Water piping API plan/ material (*)

Connection on seal end plate : sreawed/ welde (*) Flow to stuffing box/ bearings (*)

Flow to gland / pedestal(s) (*)

ACCESSOREIES AND MATERIALS

Base plate : combined/ separate Combined INSPECTION AND TESTS

Foundation bolts : yes/ no N Hydrostatic Test : yes/ no Y

Coupling : make/ type (*) Performance Test : yes/ no Y

Coupl;ing Guard - non-sparking : yes/ no Y NPSHR test : yes/ no (*)

Vibration Equipment / connections : yes/no N Sound Level test : yes/no Y

Manufacturer/ type (*) Auxilliary Equipment Test : yes/ no Y

Pump speed during performance test (rpm) Y

WEIGHTS (kgs) DIMENSIONS Performnce Test on water : capacity/ head/ power Y

Pump (*) kgs Length 600 mm Hydrostatic Test Pressure casing/ jacket/ pipng Y

Driver & acc. (*) kgs Width 600 mm

Baseplate (*) kgs Heigh 600 mm

Total (note 8)

REMARK

1) (*) - Vendor to indicate & complete the data sheet

2) The shall be supplioed complteet with SS316 surge bottle

3) All pipng within the skid limit shall be inaccordance with ASME B31.3

4) All connections to the client facillities shall be locted at the skid edge

5) All package shall be supplied with pressure gauge on the suction line to monitor the suction pressure

6) The skid shall be supplied on steel base plate complete with teflon wheel and steel handle for easy mobilisation and dimension

7) The package shall be supplied with a minimum weight and minimum dimension for only single operator handling

8) The skid total weight shall be limited to single operator comfort lifting. The maximum total weight shall be less than 20kgs.

You might also like

- XE690DK参数 清晰版 海外Document2 pagesXE690DK参数 清晰版 海外Anangtri WahyudiNo ratings yet

- Specification For Hyundai Synchronous GeneratorDocument27 pagesSpecification For Hyundai Synchronous Generatorwin htike100% (1)

- Bil-Jax 3522A Operator Manual PDFDocument54 pagesBil-Jax 3522A Operator Manual PDFLynn WardleNo ratings yet

- Webasto Heater Thermo Top C E & Z Installation ManualDocument30 pagesWebasto Heater Thermo Top C E & Z Installation Manualopenid_KAPpxWagNo ratings yet

- DP Pumps for RTN Project_DW15420Document6 pagesDP Pumps for RTN Project_DW15420Chaiwat PrssatpornNo ratings yet

- DP Pumps for RTN Project_DW15419Document6 pagesDP Pumps for RTN Project_DW15419Chaiwat PrssatpornNo ratings yet

- Pump Data SheetDocument4 pagesPump Data Sheetgaolebe lucasNo ratings yet

- Especificaciones Mist Cannon CompletasDocument9 pagesEspecificaciones Mist Cannon CompletasIvan VascoNo ratings yet

- GFL-N2-12-R.0-Data Sheet of HCL Feed Pump (P-164 DE) 24.10.17 PDFDocument1 pageGFL-N2-12-R.0-Data Sheet of HCL Feed Pump (P-164 DE) 24.10.17 PDFSavit KulshreshthaNo ratings yet

- Technical Data PM50-6ADocument3 pagesTechnical Data PM50-6ADodi HermawanNo ratings yet

- 2 ST Pump Data Sheet - 1-ADocument1 page2 ST Pump Data Sheet - 1-Acruz romeroNo ratings yet

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- NT6222GK (MBP) - DatasheetDocument5 pagesNT6222GK (MBP) - Datasheetdesenvolvimento appNo ratings yet

- Hitachi - Suez Project - 20-0712Document18 pagesHitachi - Suez Project - 20-0712Kelly PolemiNo ratings yet

- Ebara 50 DS 1.5kWDocument4 pagesEbara 50 DS 1.5kWrizki.fajarlrbNo ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- 200WQ400-24-37 (Origin WQ2290-4173-200)Document5 pages200WQ400-24-37 (Origin WQ2290-4173-200)Candi BaroajiNo ratings yet

- Technical Data Sheet: Customer: Ref.Document1 pageTechnical Data Sheet: Customer: Ref.Mohamad ItaniNo ratings yet

- Wilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetDocument3 pagesWilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetViral ParmarNo ratings yet

- Data Sheet: Rated ParametersDocument4 pagesData Sheet: Rated ParametersCandi BaroajiNo ratings yet

- Turbine Field Operator Log BookDocument23 pagesTurbine Field Operator Log Bookmkoelreal100% (1)

- Data Sheet 100 DLB 57.5Document4 pagesData Sheet 100 DLB 57.5absshopofficialNo ratings yet

- Sundyne Pump Specification Sheet: Applicable To Proposal Metric With BarDocument4 pagesSundyne Pump Specification Sheet: Applicable To Proposal Metric With Barvarun.sunderNo ratings yet

- Pump Tag - 2Document3 pagesPump Tag - 2Subani ShanmugamNo ratings yet

- Technical Data: 1710F-150-125-250G15kW4P/A3FAAARR4NDocument3 pagesTechnical Data: 1710F-150-125-250G15kW4P/A3FAAARR4NAji BagusNo ratings yet

- VT 10466-40Document5 pagesVT 10466-40Technical SupportNo ratings yet

- PDS Centrifugal PumpsDocument3 pagesPDS Centrifugal Pumpsrupawer56No ratings yet

- Rotary Valve()Document4 pagesRotary Valve()Dahll EnggNo ratings yet

- Specification Synchronous Generator: For FinalDocument32 pagesSpecification Synchronous Generator: For Final1121986jedNo ratings yet

- 043 17 GP DS 003 IS00 Pre Coat - PumpDocument6 pages043 17 GP DS 003 IS00 Pre Coat - PumpWLDT WLDTNo ratings yet

- NS2-YT01-P0LD-120002-AB (Condensate Polishing Plant) - MOTOR DATA SHEETDocument61 pagesNS2-YT01-P0LD-120002-AB (Condensate Polishing Plant) - MOTOR DATA SHEETtrong ngoc PhanNo ratings yet

- Data Sheet 80 DML 53.7Document4 pagesData Sheet 80 DML 53.7rijadhNo ratings yet

- MGS1700R-50Hz-380V-CGT-7PD (G3 Class)Document5 pagesMGS1700R-50Hz-380V-CGT-7PD (G3 Class)bmemileniumNo ratings yet

- 200KQW400-20-30_4Document5 pages200KQW400-20-30_4singgihNo ratings yet

- VT 10466-30Document5 pagesVT 10466-30Technical SupportNo ratings yet

- Pi 269PDocument3 pagesPi 269PMohamed TahaNo ratings yet

- Pi 17.4PDocument3 pagesPi 17.4PMohamed TahaNo ratings yet

- Submersible - Semi-Vortex - Pump (Sewage Pump) 100 LPM 10 MeterDocument4 pagesSubmersible - Semi-Vortex - Pump (Sewage Pump) 100 LPM 10 MeterHandrawan Han-han SugiantoNo ratings yet

- Pi400c QSGDocument3 pagesPi400c QSGURG OfficialNo ratings yet

- CSY-TAM-0096-12E Data Sheet & Curve Rev01 Efecto Placo OrificioDocument3 pagesCSY-TAM-0096-12E Data Sheet & Curve Rev01 Efecto Placo Orificioaldoacss_148400122No ratings yet

- Hoja Tecnica Cabillero Srp302Document2 pagesHoja Tecnica Cabillero Srp302gustavo rivasNo ratings yet

- Datasheet Pompa PDFDocument2 pagesDatasheet Pompa PDFadrian bargasNo ratings yet

- Diaphragm - Pumps - 7011 Thomas PDFDocument2 pagesDiaphragm - Pumps - 7011 Thomas PDFcalejandrotgNo ratings yet

- PDS - Centrifugal - PumpsDocument3 pagesPDS - Centrifugal - Pumpsrupawer56No ratings yet

- Pump CurvesDocument20 pagesPump CurvesThe old man's theoryNo ratings yet

- Positive Displacement PumpDocument2 pagesPositive Displacement Pumpanon_884425478No ratings yet

- Himsen H17-28 - Synchronus GeneratorDocument15 pagesHimsen H17-28 - Synchronus Generatorswiatekpiotrwp.plNo ratings yet

- Data Sheet 80 DML 515Document4 pagesData Sheet 80 DML 515Jover GencianosNo ratings yet

- P 100 Annex - A1Document44 pagesP 100 Annex - A1vasuNo ratings yet

- Planta CumminsDocument8 pagesPlanta CumminsHAROLD DAMIAN PEREA GUERRANo ratings yet

- MMF Feed PumpDocument7 pagesMMF Feed PumpWidhiAhmadNo ratings yet

- Chicago Pneumatic CPS 250 Diesel Air Compressor FlyerDocument2 pagesChicago Pneumatic CPS 250 Diesel Air Compressor FlyerProveedora de servicios y suministros PSSNo ratings yet

- Pump Data Sheet - 3-ADocument1 pagePump Data Sheet - 3-Acruz romeroNo ratings yet

- Data Sheet 65 DS 51.5Document4 pagesData Sheet 65 DS 51.5Gokula Krishnan CNo ratings yet

- Submittal-279873-4 Ton - 5 Ton RTU's 208V - 3Ph + ECONO + CURBDocument13 pagesSubmittal-279873-4 Ton - 5 Ton RTU's 208V - 3Ph + ECONO + CURBMcr KumaraNo ratings yet

- Data Sheet Sanicubic 2 ProDocument3 pagesData Sheet Sanicubic 2 ProSebastian RaduNo ratings yet

- Part - C Technical SchedulesDocument63 pagesPart - C Technical SchedulesMridulHasanNo ratings yet

- Compressor - NT6217Z (HBP) - DatasheetDocument5 pagesCompressor - NT6217Z (HBP) - DatasheetSamuel OsmagNo ratings yet

- Catalogue Generator AC-550 QSZ13-G10Document7 pagesCatalogue Generator AC-550 QSZ13-G10MinhThanh AdminNo ratings yet

- Impact Blow Gun: Air SavingDocument2 pagesImpact Blow Gun: Air SavingAvinash MishraNo ratings yet

- Submittal AM072BXVGJHAADocument2 pagesSubmittal AM072BXVGJHAASaul AguilarNo ratings yet

- Standby Rate Man Power SupplyDocument5 pagesStandby Rate Man Power SupplyHendri HermawanNo ratings yet

- Apron Calc HB200 To HB250Document7 pagesApron Calc HB200 To HB250Hendri HermawanNo ratings yet

- Title Epc Tuban Jetty Permanent RecoveryDocument1 pageTitle Epc Tuban Jetty Permanent RecoveryHendri HermawanNo ratings yet

- Orthotropic Material Properties Used To Model The Behavior of Pin-Joint ConnectionDocument4 pagesOrthotropic Material Properties Used To Model The Behavior of Pin-Joint ConnectionHendri HermawanNo ratings yet

- Apron - HB 250 To HB 250Document17 pagesApron - HB 250 To HB 250Hendri HermawanNo ratings yet

- Annisa Putri E.: 01311840000034 Kekas A: Cteria Phyllum: Proteobacteria Classis: Ordo: RhodobacteralesDocument1 pageAnnisa Putri E.: 01311840000034 Kekas A: Cteria Phyllum: Proteobacteria Classis: Ordo: RhodobacteralesHendri HermawanNo ratings yet

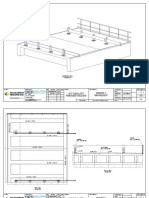

- Epc Tuban Jetty Permanent Recovery Segment A Arrangement: Isometric ViewDocument2 pagesEpc Tuban Jetty Permanent Recovery Segment A Arrangement: Isometric ViewHendri HermawanNo ratings yet

- Surveying ProcedureDocument7 pagesSurveying ProcedureHendri HermawanNo ratings yet

- Fluid-Soil-Structure Interaction Phenomena On Vibration Case at Pump Station BuildingDocument8 pagesFluid-Soil-Structure Interaction Phenomena On Vibration Case at Pump Station BuildingHendri HermawanNo ratings yet

- Pgas C024 3172 DG STR SP 004Document1 pagePgas C024 3172 DG STR SP 004Hendri HermawanNo ratings yet

- Dak TailDocument6 pagesDak TailHendri HermawanNo ratings yet

- 303 Chapter2 1Document11 pages303 Chapter2 1Hendri HermawanNo ratings yet

- 3.1 Research Flow ChartDocument23 pages3.1 Research Flow ChartHendri HermawanNo ratings yet

- 4.2.6 Non-Linear TH Analysis Output: Fig 4.10: Force Wave (Y-Dir) - KDocument8 pages4.2.6 Non-Linear TH Analysis Output: Fig 4.10: Force Wave (Y-Dir) - KHendri HermawanNo ratings yet

- Elastic Behaviour Phase: TotalDocument4 pagesElastic Behaviour Phase: TotalHendri HermawanNo ratings yet

- JPC C DWG TT 01 Rev1Document2 pagesJPC C DWG TT 01 Rev1Hendri HermawanNo ratings yet

- Pt. Asia Berdikari Cemerlang: JPC-S-DWG-TC-02Document1 pagePt. Asia Berdikari Cemerlang: JPC-S-DWG-TC-02Hendri HermawanNo ratings yet

- JPC C DWG Rs 01 Rev2Document2 pagesJPC C DWG Rs 01 Rev2Hendri HermawanNo ratings yet

- Surat - Pernyataan - Tidak Palsu DataDocument2 pagesSurat - Pernyataan - Tidak Palsu DataHendri HermawanNo ratings yet

- See Drawing: Sheet 2: Pt. Asia Berdikari CemerlangDocument2 pagesSee Drawing: Sheet 2: Pt. Asia Berdikari CemerlangHendri HermawanNo ratings yet

- JPC C DWG BF 01 PDFDocument3 pagesJPC C DWG BF 01 PDFHendri HermawanNo ratings yet

- Story StiffnesDocument66 pagesStory StiffnesHendri HermawanNo ratings yet

- Sakai SV544-parts-catalogDocument230 pagesSakai SV544-parts-catalogSamuelBartoMunthe100% (2)

- Vilter VSS Screw Compressor - 13668843-MANUAL-VILTER PDFDocument244 pagesVilter VSS Screw Compressor - 13668843-MANUAL-VILTER PDFPaul Maragoni100% (1)

- LB HS NK LSC LSP Family Ib101-F PDFDocument11 pagesLB HS NK LSC LSP Family Ib101-F PDFjambrong88No ratings yet

- Experiment No. 2 Analysis of Pressure Drop and Coefficient of Discharge in A Piping SystemDocument10 pagesExperiment No. 2 Analysis of Pressure Drop and Coefficient of Discharge in A Piping SystemPietro Ian AbdonNo ratings yet

- Pcm-Lagoa Series Brochure - English2Document6 pagesPcm-Lagoa Series Brochure - English2Hafid NaufalNo ratings yet

- GRUNDFOS All Product BrochureDocument24 pagesGRUNDFOS All Product BrochureAhmed MagdiNo ratings yet

- Oil PumpsDocument5 pagesOil PumpsArch OutNo ratings yet

- Vacuum PumpDocument2 pagesVacuum PumpGonzhalo Ramireç ChaveçNo ratings yet

- K GBDocument18 pagesK GBLuis Fernando Juchani MoralesNo ratings yet

- S5000 Sandfilter ManualDocument20 pagesS5000 Sandfilter ManualAdam MesserNo ratings yet

- Yz106867 19Document8 pagesYz106867 19Eduardo ServínNo ratings yet

- Zx490,530,690,890-5a Sales 1Document189 pagesZx490,530,690,890-5a Sales 1Halil Kara50% (2)

- Hydrotest Procedure For PipelineDocument12 pagesHydrotest Procedure For PipelineCarlos Luis Esquerdo Marcano100% (3)

- Catalogo Valvulas Cartucho Oil ControlDocument127 pagesCatalogo Valvulas Cartucho Oil ControlAnonymous nPK85ZFzNo ratings yet

- Mech 3Document10 pagesMech 3Harshal PatilNo ratings yet

- Exhibit 6 Appendix 12 Supplier Document Requirements Listing SDRLDocument42 pagesExhibit 6 Appendix 12 Supplier Document Requirements Listing SDRLPrathmesh Gujarati100% (1)

- Ia123-B Om (A) PDFDocument2 pagesIa123-B Om (A) PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- Icool LITE Owners ManualDocument18 pagesIcool LITE Owners ManualrenzoNo ratings yet

- Industry Study - Pom AravinthDocument17 pagesIndustry Study - Pom AravinthAravinth SNo ratings yet

- PFD P&id PDFDocument431 pagesPFD P&id PDFA.R.100% (1)

- Hydraulic SteeringDocument15 pagesHydraulic SteeringAkejelu GeorgeNo ratings yet

- 2019 Fuel Pump PDFDocument158 pages2019 Fuel Pump PDFDiego Villa LuzuriagaNo ratings yet

- Valvel Reset Relief OS-131380 Rev.ADocument26 pagesValvel Reset Relief OS-131380 Rev.APiter GonzalezNo ratings yet

- Polish Abs Translation Teves MkiiDocument69 pagesPolish Abs Translation Teves MkiiJim AllenNo ratings yet

- FW Pump Suction & Discharge Cal PDFDocument2 pagesFW Pump Suction & Discharge Cal PDFkisan singh100% (1)

- Access Truck Parts Solutions CatalogDocument40 pagesAccess Truck Parts Solutions CatalogHS TECHNOLOGIESNo ratings yet

- 6850HYDRDocument4 pages6850HYDRAhmed HakamNo ratings yet

- Sulphur Remelters PDFDocument4 pagesSulphur Remelters PDFNenadNo ratings yet