Belz

Belz

Uploaded by

rohanmanimaniCopyright:

Available Formats

Belz

Belz

Uploaded by

rohanmanimaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Belz

Belz

Uploaded by

rohanmanimaniCopyright:

Available Formats

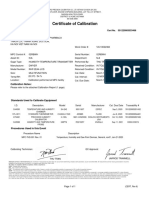

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd.

, 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 1 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

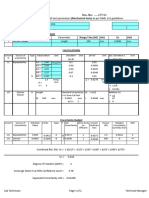

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

ELECTRO-TECHNICAL CALIBRATION

I. SOURCE

1. DC Voltage# 1mV to 300mV 0.55% to 0.01% Using Fluke 9100 MF

300mV to 300V 0.01% to 0.03% Calibrator

300V to 1000V 0.03% to 0.014%

2. DC Current# 1µA to 300mA 1.5% to 0.03% Using Fluke 9100 MF

300mA to 10A 0.03% to 0.12% Calibrator with current Coil

10A to 1000 A 0.12% to 0.70%

3. AC Voltage# 50 Hz /60 Hz Using Fluke 9100 MF

10mV to 300mV 1.15 % to 0.2% Calibrator

300mV to 100V 0.2% to 0.08%

100V to 1000V 0.08%

4. AC Current # 50 Hz /60 Hz Using Fluke 9100 MF

100µA to 300mA 0.45% to 0.13% Calibrator with current Coil

300mA to 10A 0.13% to 0.31%

10A to 1000 A 0.31% to 0.9%

5. Resistance# 50µΩ 0.3% to 0.13% Using Low Resistance box

(4 Wire) 100µΩ (Fixed Value)

0.001Ω

0.01Ω

0.1Ω

1Ω

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 2 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

6. Resistance# 1Ω to 4MΩ 1.2% to 0.07% Using Fluke 9100 MF

(2 Wire) 4MΩ to 40MΩ 0.07% to 0.18% Calibrator

40MΩ to 400MΩ 0.18% to 0.32%

High Resistance 500 MΩ, 1 GΩ, 2 2.5% Using High Resistance Box

(2 Wire) # GΩ, 10 GΩ, 20 GΩ,

100 GΩ, 200 GΩ

500 GΩ,1TΩ

7. Frequency# 10Hz to 10MHz 0.07% to 0.008% Using Fluke 9100 MF

Calibrator

8. Capacitance# 1kHz Using Fluke 9100 MF

1nF to 100µf 7.2% to 2.5% Calibrator

9. DC Power# 10W to 19 kW 0.31% Using Fluke 9100 MF

10V to 1000V Calibrator

1A to19A

10. AC Power# 10V to 640V 0.25% to 0.8% Using Fluke 9100 MF

(Active Power 1ɸ) 1A to 19A Calibrator

UPF

240 V

0.1 to 1A

0.5 Lead/Lag

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 3 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

11. Temperature Simulation#

(Indicator/controller/

Recorder)

RTD (-)200oC to 800oC 0.43oC Using Fluke 9100 MF

‘T’ Type Thermocouple (-)200oC to 400oC 0.7oC Calibrator

‘S’ Type Thermocouple (-)0oC to 1700oC 0.5oC

‘J’ Type Thermocouple (-)200oC to 1200oC 0.3oC

‘N’ Type Thermocouple (-)200oC to 1300oC 0.3oC

‘K’ Type Thermocouple (-)200oC to 1300oC 0.37oC

‘R’ Type Thermocouple (-)0oC to 1700oC 0.5oC

‘B’ Type Thermocouple 600oC to 1700oC 0.5oC

‘E’ Type Thermocouple (-)100oC to 600oC 0.5oC

12. Oscilloscope# 10 ns to 5 sec. 0.63s Using Fluke 9100 MF

Time Base Calibrator

(Marker)

Amplitude 1kHz 1.0%

(Deflection Factor) 1MΩ

5mV to 120V

Sin/Square 50kHz to 20MHz 1.0%

(DC) 50Ω

Bandwidth 20mV to 2.5V

1kHz to 250MHz 5.0%

13. Turn Ratio Meter# 1.11 0.65% Using Ratio Calibration

1.22 0.43% Standard

1.44 0.41%

1.110 0.31%

1.220 0.25%

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 4 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

II. MEASURE

1. DC Voltage# 1mV to 100mV 0.5% to 0.01% Using 6½ DMM

100mV t 10V 0.01% to 0.06%

10V to 1000V 0.06% to 0.02%

2. DC Current# 1µA to 10mA 3.0%to 0.08% Using 6½ DMM

10mA to 3A 0.08% to 0.16%

3A to 10 A 0.16% to 0.2%

3. AC Voltage# 50 Hz / 60Hz Using 6½ DMM

10mV to 10V 0.53% to 0.12%

10V to 1000V 0.12% to 0.18%

4. AC Current# 50 Hz / 60Hz Using 6½ DMM & Current

50µA to 100mA 0.9% to 0.5% Transformer

10mA to 10A 0.5% to 0.25%

5. Resistance# 100µΩ to 1Ω 0.6% to 0.06% Using Microohm meter &

(4 Wire) 1Ω to 10Ω 0.06% to 0.05% Low Resistance Standard

6. Resistance# 10Ω to 1MΩ 0.06% to 0.13% Using 6½ DMM & Micro

(2 Wire) 1MΩ to 100MΩ 0.13% to 0.9% ohm meter

100MΩ to 1GΩ 0.9%to 2.36%

7. AC Resistance# 1 kHz Using LCR Meter

1Ω to 100kΩ 0.23%

8. Frequency# 10Hz to 1MHz 0.06% Using 6½ DMM

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 5 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

9. Capacitance# 1kHz Using LCR Meter

1nF to 1µF 0.2%

10kHz

1nFto1µF 0.2%

10. Inductance# 1 kHz Using LCR meter

100µH to 1H 0.45% to 0.8%

11. Power/Energy# 50Hz 1.0% Using Power /Energy Meter

(1Ф. 3Ф.) UPF to 0.5 PF Accuchek & Power source

(Lag/Lead)

Voltage : 240V/63.5V

Current: 1A/5A

12. Timer / Stop Watch# 100 ms 0.003s Using Digital Timer

(Digital/Analog) 1s 0.003s

60s 0.03s

600 s 0.27s

1800 s 0.55s

3600 s (1 hour) 1.3s

7200 s (2 hour) 2.3s

14400 s (4 hour) 4.3s

86400 ( 24 hour) 20.5s

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 6 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

13. Temperature Simulation# Using

(Temperature source, Temperature Indicator

Indicator/Controller/

Recorder)

RTD 200oC to 800oC 0.42 oC

‘T’ Type Thermocouple (-)200oC to 400oC 0.60 oC

‘S’ Type Thermocouple 50oC to 1700oC 0.63 oC

‘J’ Type Thermocouple (-)200oC to 1200oC 0.61 oC

‘N’ Type Thermocouple (-)200oC to 1300oC 0.65 oC

‘K’ Type Thermocouple 50oC to 1300oC 0.66 oC

‘R’ Type Thermocouple 600oC to 1700oC 0.63 oC

‘B’ Type Thermocouple 600oC to 1700oC 0.62 oC

‘E’ Type Thermocouple 100oC to 600oC 0.61 oC

14. AC High Current# 50 Hz Using 6½ DMM & Current

10A to 1000A 1.3% to 0.65% Transformer

15. DC High Current# 10A to 750A 1.0% Using 6½ DMM &

900A/75mV Shunt

16. AC High Voltage# 50 kHz Using HV Probe with DMM

1kV to 28 kV 2.4%

17. DC High Voltage# 1kV to 37 kV 1.7% Using HV Probe with DMM

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 7 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MECHANICAL CALIBRATION

I. DIMENSION (BASIC MEASURING INSTRUMENT, GAUGE ETC.)

1. Vernier/Dial/ Digimatic

Caliper$

L.C.: 0.01 mm Upto 300mm 8.0 µm Using Slip Gauge Grade ‘0’,

Upto 1000mm 14.70 µm Long Gauge Block &

L.C.: 0.02 mm Upto 2000mm 49.0 µm Caliper Checker

2. External Micrometer$

L.C.: 0.001 mm Upto 100mm 1.50 µm Using Slip Gauge Grade ‘0’

100 to 150mm 2.5 µm & Long Gauge Block

150 to 300mm 3.8 µm

3. Internal Micrometer$

L.C.: 0.001 mm Upto 300mm 4 µm Using Slip Gauge Grade ‘0’

& Accessories Set

4. Depth Micrometer$

L.C.: 0.01 mm Upto 300mm 7 µm Using Slip Gauge Grade ‘0’,

Long Gauge Block &

Caliper Checker

5. Depth Caliper / Depth

Gauge$

L.C.: 0.01 mm Upto 300mm 7.5 µm Using Slip Gauge Grade ‘0’,

Long Gauge Block &

Caliper Checker

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 8 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

6. Height Gauge$

L.C.: 0.001 mm Upto 600mm 6.0 µm Using Slip Gauge Grade ‘0’

L.C.: 0.01 mm Upto 1000mm 12.8 µm & Caliper Checker

7. Dial Gauge$

L.C.: 0.001 mm Upto 100mm 3.0 µm Using Single Axis M/c

8. Dial Test Indicator$

L.C.: 0.001 mm 0 to 1.0mm 3.0 µm Using Single Axis M/c

9. Dial Bore Gauge$

L.C.: 0.001 mm Upto 1mm Travel 3.0 µm Using Single Axis M/c

10. Plain Plug Gauge$

L.C.: 0.001 mm Upto 100mm 3.0 µm Using Single Axis M/c

100 mm to 185mm 3.5 µm

11. Plain Ring Gauge$ 3mm to 100mm 1.8 µm Using Single Axis M/c

100mm to 280mm 4.6 µm

12. Scale & Tape Up to 1000mm 60 µm Using Slip & Long Gauge

Calibration Unit$ Blocks

13. Radius Gauge$ Up to 100mm 96 µm Using Profile Projector

14. Snap Gauge$ 1mm to 150mm 2.2 µm Using Slip Gauge Grade 0

15. Measuring Pin Gauge$ 0.5mm to 20mm 1.5 µm Using Single Axis M/c

16. Three Wire Unit$ 0.17mm to 4 mm 1.5 µm Using Single Axis M/c

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 9 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

17. Feeler Gauge/ Up to 1mm 1.5 µm Using Single Axis M/c

1.6 µm

Foils$ 1.5 mm

18. Dial Thickness Gauge$

L.C.: 0.001 mm Up to 50mm 1 µm Using Slip Gauge Grade 0

19. Thread Plug Gauge$ Up to 100mm 5.6 µm Using Three Wire set,

Micrometer

20. Thread Pitch Gauge$ 0.40 to 7.0 mm 7.0 µm Using Profile Projector

3.0 min. of arc

21. Length Gauge / Up to 100mm 2.0 µm Using Single Axis M/c

Setting Master$ 100 mm to 280mm 2.6 µm

22. Steel Scale$

LC: 1mm Upto 1000mm 154√L µm Using Standard Scale with

L in meter DRO

23. Measuring Tape$

LC: 1mm Up to 50 mtr. 154√L µm, Where L is in Using Standard Scale with

meter DRO

24. Bevel Protractor/ 0° - 90° - 0o 5 min. of arc Using Slip Gauge Grade 0,

Combination$ Sine Bar & Master Cylinder

25. Electronic Probe$ Up to 25 mm 0.6 µm Using Slip Gauge Grade 0

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 10 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

26. Dial Calibration Tester$

LC: 0.001 mm Up to 25mm 1.0 µm Using Slip Gauge Grade 0

& Electronic Probe

27. Coating Thickness Up to 1500 µm 5 µm Using Standard Foils

Gauge$

28. Angle Plate Up to 300mm 10 µm Using Slip Gauge Grade ‘0’,

Squarness$ Master Cylinder & Dial Test

Indicator

29. Electronic Level$ +/-2mm/mtr 3.7 µm/mtr Using Electronic Level

Spirit Level (Sensitivity 0.001 Comparison Method

mm/mtr)

+/-200mm/mtr 7.0 µm/mtr

(Sensitivity 0.01

mm/mtr)

+/-100mm/mtr 12.0 µm/mtr

(Sensitivity 0.02

mm/mtr)

30. Test Sieves$ 32 µm to 4000 µm 6.2 µm Using Profile Projector/

(Aperture Size) 4mm to 50mm 20 µm Digital Caliper

50mm to 125mm 30 µm

31. Thread Ring Gauge$ 4mm to 100mm 3.4 µm Using Single Axis M/c.

(Effective Dia Only)

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 11 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

32. Sine Bar Flatness Up to 300 mm 3.80 µm Using Elect.Probe & Slip

/ Parallelism / 3.80 µm Gauge Grade 0

Central Distance$ 4.00 µm

Setting Angle$ 6.2 sec. Using Surface Plate, Angle

Gauge, Electronic Probe &

Slip Gauge Grade 0

33. Straight Edge Up to 1000mm 3.4 µm Using Surface Plate & Slip

Straightness$ Gauge Grade 0

34. Engineering Up to 500 mm Using Dial Test Indicator &

Square/Right Angle$ Surface Plate

Flatness 5.7 µm

Perpendicularity Using Slip Gauge Grade 0

5.0 µm & Master Cylinder

35. Test Mandrel$ Up to 300 mm 2.4 µm Using Sine Centre & Dial

Variation in diameter Test Indicator

Lack of trueness of

rotation 16 µm

(between centers)

Lack of trueness of

rotation

(between centers)

36. Magnetic V Block$ Up to 150mm 5.7 µm Using Slip Gauge Set, Dial

Flatness Test Indicator & Surface

Parallelism 8.3 µm Plate

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 12 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Parallelism 5.7 µm Using Slip Gauge Set, Dial

Test Indicator, Test Mandrel

& Surface Plate

Symmetricity Error 8.3 µm Using Slip Gauge Set, Dial

Test Indicator, Test Mandrel

& Surface Plate

Perpendicularity 6.0 µm Using Slip Gauge Grade 0,

Master Cylinder & Surface

Plate

37. Standard Steel Ball$ 4 mm to 65 mm 2.6 µm Using Digital Micrometer

38. Profile Projector# 0-300mm (X,Y Axis) 3.9 µm Using Slip Gauge & Long

Gauge Block

Linear Dimension

Magnification 50 x 1.00% Using Slip Gauge Grade 0

& Digital Caliper/Glass

Scale

Angle Measurement 0-360° 75 sec of arc Using Angle Gauges

39. Universal Length Up to 100 mm 1.0 µm Using Slip Gauge Grade 0

Measuring Machine # Resolution: 0.0001

40. Surface Plate# 6000mm x 4000mm 1.3√(L+W)/125 Using Electronic Level

where L & W are in mm

41. Comparator Stand# 300 mm x 300 mm 1.2√(L+W)/150 Using Electronic Level

Where L & W are in mm

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 13 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

42. Bench Centre# Up to 300mm 10.0 µm Using Mandrel & Dial Test

Parallelism Indicator

Coaxiality 10.0 µm

43. Sine Centre# Up to 300mm Using Test Mandrel & Dial

Parallelism of working 4.0 µm Test Indicator, Electronic

surface Probe & Surface Plate,

Coaxiality of Dead 4.0 µm Electronic Probe, Slip

center Gauge Grade 0 &Angle

Central Distance 3.8 µm Gauge

II. WEIGHTS

1. Mass $ 1 mg 0.01mg Using E2 Class Weight &

(Weights) 2 mg 0.010 mg Mass Comparator

5 mg 0.010 mg (Readability 0.01 mg) As

10 mg 0.010 mg per OIML R-111 Calibration

20 mg 0.010 mg of Class F2 accuracy and

50 mg 0.010 mg coarser

100 mg 0.010 mg

200 mg 0.010 mg

500 mg 0.013mg

1g 0.015 mg

2g 0.02 mg

5g 0.02mg

10 g 0.023mg

20 g 0.042mg

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 14 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

50 g 0.10mg Using E2 Class Weight &

100 g 0.15mg Mass Comparator

200 g 0.24mg (Readability 0.01 mg) As

per OIML R-111 Calibration

of Class F2 accuracy and

coarser

500 g 2mg Using F1 Class Weight &

1 kg 10mg Mass Comparator

(Readability 0.001 g) As per

OIML R-111 Calibration of

Class F2 accuracy and

coarser

2 kg 13mg Using F1 Class Weight &

5 kg 13mg Mass Comparator

(Readability 0.01 g) As per

OIML R-111 Calibration of

Class F2 accuracy and

coarser

10 kg 89mg Using F1 Class Weight &

Mass Comparator

(Readability 0.1 g) As per

OIML R-111 Calibration of

Class M1 accuracy and

coarser

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 15 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

20 kg 1.07g Using M1 Class Weight &

50 kg 1.27g Mass Comparator

100 kg 1.27 (Readability 0.001 k g) As

per OIML R-111 Calibration

of Class M2 accuracy and

coarser

III. VOLUME

1. Micro Pipette$ 10 µl to 100 µl 0.06 µl Using E2 Class Weight &

100 µl to 1000 µl 0.10 µl Precision Weighing Balance

( Readability

0.01mg & 0.1 mg) and

Distilled Water as per ISO

8655

2. Glassware$ 1 ml to 10 ml 0.5 µl Using Standard weight &

(Measuring Cylinder / 10 ml to 100 ml 8.2 µl weighing balance

Jar, Volumetric Flask, 100 ml to 200 ml 0.04 ml (readability 0.1mg)

Beaker, Glass Pipette, 200 ml to 500 ml 0.14 ml Readability: 0.001g

Dispenser & Burette) 500 ml to 1 Ltr. 0.2 ml Readability: 0.01g

1 Ltr to 2 Ltr. 0.4 ml (Readability: 0.1g) with

2 Ltr. To 5 Ltr. 0.6 ml distilled water by

5 Ltr to 10 Ltr. 1.1 ml gravimetric method as per

ISO 4787

IV. WEIGHING SCALE AND BALANCE

1. Spring Balance$

L.C. 0.1 g Up to 100 kg 60g Using F1 & M1 Class

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 16 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

weight Comparison Method

2. Weighing Balance#

Readability 0.01 mg & Up to 30 g 0.06mg Using E 2 Class Weight As

Coarser Per OIML R76-1

Readability 0.1 mg & >30g to 220g 0.14mg

Coarser

Readability 1 mg & >220g to 1000g 0.006g Using E2 class weight &

Coarser F1 Class Weight As Per

OIML R76-1

Readability 0.01 g & >1kg to 6kg 0.01g Using F1 Class Weight As

Coarser Per OIML R76-1

Readability 0.1 g & >6kg to 12 kg 0.06g

Coarser

Readability 1 g & >12 kg to 100 kg 0.8g Using M1 Class Weight As

Coarser Per OIML R76-1

V. DENSITY AND VISCOSITY

1. Density / 0.6 g/ml to 1.8 g/ml 0.0015g/ml Using Hydrometer &

Hydrometers / Compatible Liquid

Lactometers$ Comparison Method

IS 3104-1 & 2

III. PRESSURE INDICATING DEVICES

1. Vacuum Gauge, (-)0.95 bar to 0bar 0.0036bar Using Digital Pressure

Transmitters Digital / Gauge

Analog#

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 17 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. Barometric Pressure 200 to 1050 mbar 1.32 mbar Using Pressure Calibrator

Gauge#

3. Pneumatic Pressure (-) 1300 to 0 pascal 2.0 Pa Using Pressure Calibrator &

Gauge (Digital / 0 to 2000 pascal 2.0 Pa Diff. Pressure Gauge by

Analog Manometer, 20mbar to 100 mbar 0.1 mbar comparison method

Diff. Gauge,

Transmitters,

Magnehalic Gauge#

4. Pressure Gauge , 0 to 3 bar 0.0036 bar Using Digital Pressure

Transmitters 0 to 30 bar 0.036 bar Gauge & Pressure

Digital/Analog# Comparator by comparison

Pneumatic method

5. Pressure Gauge 0 to 700 bar 1.15 bar Using Digital Pressure

(Analog/Digital)- Gauge & Pressure

Hydraulic# Comparator by comparison

method

6. Hydraulic Pressure 1 to 41.1 kg/cm2 0.052% rdg Using Dead Weight Tester

Digital / Analog 40 to 800 kg/cm2

Pressure Gauge$

IV. ACOUSTICS

1 Sound Level Meter# 94 dB 0.55dB Using Sound Calibrator

114 Db

V. DUROMETER

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 18 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

1. Rubber Hardness 0 to 100 Shore A 0.7 Shore A Using Weighing Balance,

Tester# 0 to 100 Shore D 0.7 Shore D Readability : 1g

VI. ACCELERATION AND SPEED

1. Speed 10 to 40 rpm 5% Using RPM Source by Direct

Contact Type RPM 40 to 100 rpm 0.35% Method

/Tachometer / 100 to 1000 rpm 0.25%

Stroboscope , 1000 to 9950 rpm 0.09%

Centrifuge#

2. Non-Contact Type 10 to 40 rpm 5.0 % Using Tachometer Calibrator

RPM 40 to 1000 rpm 1.7 % by Direct / Comparison

Stroboscope/Pulse 1000 to 10000 rpm 0.09 % Method

Engine Tachometer/ 10000 to 99000 rpm 0.06 %

Digital Tachometer,

Centrifuge#

VII. TORQUE GENERATING DEVICES

1. Torque Wrench# Type II 4 to 2000 Nm 1.3% Using Torque Transducer with

Type I: Class Type I 4 o 500 Nm 1.3% indicator

B,C,D,E

Type II: Class

A,B,D,E

VIII. MOBILE FORCE MEASURING SYSTEM

1. Push Pull Gauge$ 1N to 100N 0.1N Using Newtonian Weight &

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 19 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

100N to 900N 1.1N Frame Fixture & Hangers

THERMAL CALIBRATION

1. Temperature (-)196oC to -40oC 0.32oC Using RTD

Transmitter RTD’s (Pt-100) 4 wire Digital

Thermocouples with & Thermometer & Liquid

without Nitrogen Bath

(Controller/Indicator/D

ata Logger/Recorder),

Temperature Gauge,

Glass Thermometer &

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 20 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Digital Thermometer#

2. Temperature (-)40oC to 50oC 0.20°C Using RTD (Pt-100) 4 wire

Transmitter RTD’s Digital Thermometer and Low

Thermocouples with & Temp Bath

without

(Controller/Indicator/D

ata Logger/Recorder)

Temperature Gauge,

Glass Thermometer &

Digital Thermometer#

3. Temperature >50oC to 200oC 0.20°C Using RTD (Pt-100) 4 wire

Transmitter RTD’s Digital Thermometer and Oil

Thermocouples with & Temperature Bath

without

(Controller/Indicator/D

ata Logger/Recorder),

Temperature Gauge,

Glass Thermometer &

Digital Thermometer#

4. Temperature 200oC to 300oC 0.80°C Using RTD (Pt-100) 4 wire

Transmitter RTD’s Digital Thermometer and

Thermocouples with & Dry Block Bath

without

(Controller/Indicator/

Data

Logger/Recorder/),

Temperature Gauge,

Glass Thermometer &

Digital Thermometer#

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 21 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

5. Thermocouples, >300oC to 1200oC 1.83°C Using Thermocouple wire

RTD’sTemperature Digital Thermometer and

Transmitter with & Dry Block Bath

without

(Controller/Indicator/ /

Recorder), Data

Logger & Digital

Thermometer#

6. Temperature (-)196oC to -40oC 0.32°C Using RTD (Pt-100) 4 wire,

Indicators of Freezers, Digital Thermometer

Oven, Environment

Chamber, Incubator,

BOD Incubator, Liquid

Bath / Dry Block

Furnaces#

7. Temperature Indicator (-)40oC to 250oC 0.2°C Using RTD (Pt-100) 4 wire

of Freezers, Oven, Digital Thermometer and

Environment Chamber, Dry Block Bath

Incubator, BOD

Incubator, Liquid Bath /

Dry Block Furnaces#

8. Temperature Indicators 250oC to 1200oC 1.8°C Using S Type

of – (Muffle Furnace, Thermocouple & Digital

Dry Block Furnace) # Thermometer

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 22 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

9. Radiation Pyrometer 50oC to 500oC 3.3°C Using Radiation

(Non-Contact Type) # Pyrometer, Digital

Thermometer & Black Bod

Source)

10. Freezers, Oven, Cold (-)80oC to 50oC 0.5°C Using Multi-point Data

Chamber, Environment 50oC to 250oC 1.3°C Logger with RTD (Pt-100)

Chamber# Sensors

11. Digital & Analog 10% - 95% RH 0.7%RH Using Std. RH Sensor with

Hygrometer, RH @ Indicator & RH Calibrator

Sensors / Transmitters approx. 25 oC

with

controller/Indicator/Re

corder/Data Logger#

II. SPECIFIC HEAT AND HUMIDITY

1. (Humidity 10% - 95% RH 1.95%RH Using STD. RH Sensor

Calibrator /Generator with Indicator

Chamber) #

2. Freezers, Oven, Cold -80oC to 50oC 0.5°C Using Multi-point Data

Chamber, Environment 50oC to 250oC 1.3°C Logger with RTD (Pt-100)

Chamber, Centrifuged Sensors

Chamber, Incubator &

BOD Incubator♣

3. Industrial Furnaces / 4.2°C Using Multi-point Data

Spatial Thermal 200oC to 1200oC Logger with N-Type

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 23 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Mapping♣ Sensors

4. Environment Chamber 15% - 95% RH 1.95%RH Using Std RH Sensors /

/ Humidity Chamber♣ @ Transmitters with Data

approx. 25 oC Logger

FLUID FLOW CALIBRATION

1. Rotameter / Flow 1 LPM to 5 LPM 1.40% rdg Using Fluke Flow Meter

Meters (Flow >5 LPM to 50 LPM 0.58% rdg consist of Molbloc sensor

Rates) # by Comparision method

2. Volume Flow 0.8m3/hr to 80 m3/hr 1.98 % rdg Using Transducer based

Rate >80m3/hr to 200m3/hr 1.18% rdg portable Ultrasonic Flow

(Medium of >200m3/hr to 1450 m3/hr 0.41 % rdg Meter

Calibration

Liquid-Water) ♣

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

Dheeraj Chawla Avijit Das

Convenor Program Director

Laboratory Belz Calibration Laboratory, Belz Instruments Pvt. Ltd., 5L-123, NIT,

Faridabad, Haryana

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2733 (In lieu of C-0100, C-0158,C-0407, Page 24 of 24

C-1424)

Validity 28.06.2018 to 27.06.2020 Last Amended on 25.07.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

$

Only in Permanent Laboratory

♣

Only for Site Calibration

#

The laboratory is also capable for site calibration however, the uncertainty at site depends on the

prevailing actual environmental conditions and master equipment used.

Dheeraj Chawla Avijit Das

Convenor Program Director

You might also like

- The Couples Therapy Companion - A Cognitive Behavior Workbook PDFDocument203 pagesThe Couples Therapy Companion - A Cognitive Behavior Workbook PDFEdgar Suarez100% (2)

- Technical Note of Usp 41 For BalancesDocument2 pagesTechnical Note of Usp 41 For BalancesSamir BoradNo ratings yet

- Cal Cert FormatDocument6 pagesCal Cert FormatINSTRUCAL CALIBRATION SERVICESNo ratings yet

- Hyrometer Calibration Using Solid Reference StandardsDocument2 pagesHyrometer Calibration Using Solid Reference StandardsHi Tech Calibration ServicesNo ratings yet

- RDS - TTR 1887Document1 pageRDS - TTR 1887emc roorkee59100% (1)

- Certificate of Calibration: Customer InformationDocument2 pagesCertificate of Calibration: Customer InformationSazzath HossainNo ratings yet

- Weight Box (1 MG To 200g)Document1 pageWeight Box (1 MG To 200g)Amit KumarNo ratings yet

- Certificate of Calibration: CustomerDocument1 pageCertificate of Calibration: Customergaconvt92No ratings yet

- SASSCO Intermediate Check Instruction SheetDocument4 pagesSASSCO Intermediate Check Instruction SheetStudent ForeignNo ratings yet

- Standard Calibration Procedure Hydrometer Doc. No. Call/SCP/033 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Hydrometer Doc. No. Call/SCP/033 Rev. 00 May 01, 2015Ajlan Khan100% (1)

- Scales CalibrationDocument6 pagesScales Calibrationmuhammad nomanNo ratings yet

- PH Buffer Solution 4Document2 pagesPH Buffer Solution 4Anil Rawat100% (1)

- Training Plan For A Small Calibration LabDocument1 pageTraining Plan For A Small Calibration LabYog AkoNo ratings yet

- Oiml TC17 SC2 N3 2007Document25 pagesOiml TC17 SC2 N3 2007acanis1016No ratings yet

- U 897 DWM 600Document1 pageU 897 DWM 600Amit KumarNo ratings yet

- Nabl 216 PDFDocument17 pagesNabl 216 PDFmaheshNo ratings yet

- Calb 4Document1 pageCalb 4ranjt53No ratings yet

- WeightsDocument4 pagesWeightsBhavikNo ratings yet

- The Basics of Calibration Procedure and Estimation of UncertaintyDocument6 pagesThe Basics of Calibration Procedure and Estimation of UncertaintyCristiano PernichelliNo ratings yet

- U 933 Humidity ControllerDocument17 pagesU 933 Humidity ControllerAmit KumarNo ratings yet

- Kalibratiecertificaat Trescal Koffernr BF1-004Document2 pagesKalibratiecertificaat Trescal Koffernr BF1-004mega dorreNo ratings yet

- PROC-TC-012 Procedure For Calibration Flask, Cylinder SOP (PROC - C)Document19 pagesPROC-TC-012 Procedure For Calibration Flask, Cylinder SOP (PROC - C)Ban ZanganaNo ratings yet

- Digital-Universal-Calibrator - (Model BTH C9) PDFDocument1 pageDigital-Universal-Calibrator - (Model BTH C9) PDFgokulrajeNo ratings yet

- Standard Calibration Procedure Vernier Caliper Doc. No. Call/SCP/008 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Vernier Caliper Doc. No. Call/SCP/008 Rev. 00 May 01, 2015Ajlan Khan100% (1)

- CC Calibration FileDocument6 pagesCC Calibration FilesheikmoinNo ratings yet

- Calibration For The Lux MeterDocument1 pageCalibration For The Lux MeterBonifacio SautNo ratings yet

- NABL 103 Doc Chemical Testing LaboratoryDocument30 pagesNABL 103 Doc Chemical Testing LaboratoryKaushik SenguptaNo ratings yet

- Calibration of Weighing Systems PDFDocument18 pagesCalibration of Weighing Systems PDFIskanderNo ratings yet

- Uncertainty. of Mean Rib AreaDocument2 pagesUncertainty. of Mean Rib AreaSantosh KumarNo ratings yet

- Example of Measurement Uncertainty EstimationDocument7 pagesExample of Measurement Uncertainty EstimationCristiano PernichelliNo ratings yet

- Calibration Certificate: MechanicalDocument2 pagesCalibration Certificate: MechanicalAmit KumarNo ratings yet

- TSC - 22-23 - 5490-1 TachometerDocument2 pagesTSC - 22-23 - 5490-1 TachometerDebabrata MajhiNo ratings yet

- Ba Tho 5000toce Full Calibration Sop en 58130094bDocument38 pagesBa Tho 5000toce Full Calibration Sop en 58130094bعبدالعزيز بدرNo ratings yet

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Document3 pagesIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind Dhaka0% (1)

- Decision Rule Calculation FormDocument3 pagesDecision Rule Calculation FormSavira PradiatiNo ratings yet

- Antimicrobial Efficacy Study of IMAGARD ID 401 IJBARDocument3 pagesAntimicrobial Efficacy Study of IMAGARD ID 401 IJBARmktginfinitilinesNo ratings yet

- HEPA Filtration System Performance of Residential and Commercial Vacuum CleanersDocument3 pagesHEPA Filtration System Performance of Residential and Commercial Vacuum CleanersMartin TapankovNo ratings yet

- Full CMC Template CalibrationDocument31 pagesFull CMC Template CalibrationStudent ForeignNo ratings yet

- ITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometerDocument12 pagesITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometertungluongNo ratings yet

- Trs 398 FDocument124 pagesTrs 398 FvkseshadriNo ratings yet

- Vaisala Humidity Conversion Formulas-EnDocument17 pagesVaisala Humidity Conversion Formulas-Endpee27619438No ratings yet

- Kosaka Lab Scope CC 2611Document50 pagesKosaka Lab Scope CC 2611kumarNo ratings yet

- Analytical Balance SOPDocument2 pagesAnalytical Balance SOPdivine production100% (1)

- Chemical Test Report - OPC (Mar'2019)Document2 pagesChemical Test Report - OPC (Mar'2019)tuaburgmailcomNo ratings yet

- Calibration Certificate - Gas Coriolis - Unit#1Document2 pagesCalibration Certificate - Gas Coriolis - Unit#1Said100% (1)

- 7.7 F-02 Replicate en ReportDocument2 pages7.7 F-02 Replicate en ReportAshish DubeyNo ratings yet

- 0547-22.03 Grinding MachineDocument1 page0547-22.03 Grinding MachineAlvin RejisNo ratings yet

- Calibration Requirements For Determining Particle Size Distribution Using Light Interaction MethodsDocument6 pagesCalibration Requirements For Determining Particle Size Distribution Using Light Interaction Methodstuhintahmid1093No ratings yet

- Criteria For Performing Calibration and Intermediate Checks On Equipment Used in Accredited FacilitiesDocument6 pagesCriteria For Performing Calibration and Intermediate Checks On Equipment Used in Accredited FacilitiesJeji Hirbora100% (1)

- Nist Technical Note 1297 SDocument25 pagesNist Technical Note 1297 SRonny Andalas100% (1)

- Calibration Certificate M1Document1 pageCalibration Certificate M1AHmed YaSsenNo ratings yet

- NABL-124-doc Thermal Discipline NewDocument21 pagesNABL-124-doc Thermal Discipline NewUmang SOdhiNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- 26.scope Location 1 CC-2688Document14 pages26.scope Location 1 CC-2688Ravichandran DNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument19 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument11 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- Sl. Quantity Measured/ Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument16 pagesSl. Quantity Measured/ Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- 1953Document5 pages1953rohanmanimaniNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument25 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Sl. Quantity Measured/ Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument16 pagesSl. Quantity Measured/ Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- Scope 52351 CC 2622 1698453246Document51 pagesScope 52351 CC 2622 1698453246rohanmanimaniNo ratings yet

- Scope 64631 CC 3768 1709314431Document55 pagesScope 64631 CC 3768 1709314431rohanmanimaniNo ratings yet

- Hrishik CV Resume1-2-3-2-2Document2 pagesHrishik CV Resume1-2-3-2-2rohanmanimaniNo ratings yet

- Resume HseDocument1 pageResume HserohanmanimaniNo ratings yet

- Minal ResumeDocument2 pagesMinal ResumerohanmanimaniNo ratings yet

- Document No.: Rev. No.: 0 Date: Page No.: 1 of 1: TOPIC: Calibration Method of Metallurgical MicroscopeDocument2 pagesDocument No.: Rev. No.: 0 Date: Page No.: 1 of 1: TOPIC: Calibration Method of Metallurgical MicroscoperohanmanimaniNo ratings yet

- Swapnil ResumeDocument4 pagesSwapnil ResumerohanmanimaniNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument4 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- Vijay Up CVDocument2 pagesVijay Up CVrohanmanimaniNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument11 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- VijayDocument1 pageVijayrohanmanimaniNo ratings yet

- Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksDocument3 pagesQuantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksrohanmanimaniNo ratings yet

- 6501Document1 page6501rohanmanimaniNo ratings yet

- MikronixDocument3 pagesMikronixrohanmanimaniNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument2 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- CaliDocument7 pagesCaliYogesh AnapNo ratings yet

- Is 1481 1970Document15 pagesIs 1481 1970rohanmanimaniNo ratings yet

- Astm f1957 1999Document8 pagesAstm f1957 1999rohanmanimaniNo ratings yet

- 6 Ster Il CountsDocument5 pages6 Ster Il CountsrohanmanimaniNo ratings yet

- 10% HappierDocument3 pages10% Happiermasudur rahmanNo ratings yet

- Chapter 12 The Black-Scholes FormulaDocument5 pagesChapter 12 The Black-Scholes FormulaMuhammad Luthfi Al AkbarNo ratings yet

- CH00 - COURSE INTRO INTERNATIONAL ACCOUNTING 3 CreditsDocument12 pagesCH00 - COURSE INTRO INTERNATIONAL ACCOUNTING 3 CreditsTuyen PhamNo ratings yet

- The Orphan of Zhao: A Child For All AgesDocument6 pagesThe Orphan of Zhao: A Child For All AgesKeri LNo ratings yet

- The Tragedy of HamletDocument7 pagesThe Tragedy of HamletMaria ShoukatNo ratings yet

- Caliban and Ariel Are Two Contrasting CharactersDocument2 pagesCaliban and Ariel Are Two Contrasting CharactersMence Ristova100% (1)

- Political Science 1Document21 pagesPolitical Science 1Neeraj DwivediNo ratings yet

- Republic v. SantosDocument4 pagesRepublic v. SantosMaria Michelle MoracaNo ratings yet

- Lecture On ForceDocument3 pagesLecture On ForceJes Espago VillaramNo ratings yet

- Gardner - ATHENADocument90 pagesGardner - ATHENAFinn PowersNo ratings yet

- Studenta2 Unit 10 Lesson ADocument4 pagesStudenta2 Unit 10 Lesson AJennifer Itzel Pérez Rodríguez0% (1)

- Pan-Assessment Tool Grade-1 FinalDocument4 pagesPan-Assessment Tool Grade-1 FinalMaestro Varix100% (2)

- Grammar Tenses Mix PracticeDocument10 pagesGrammar Tenses Mix PracticeAlfredo ValenzuelaNo ratings yet

- Bacterial Identification ThesisDocument6 pagesBacterial Identification Thesisjenniferrobinsonjackson100% (2)

- All Too Well: Taylor SwiftDocument2 pagesAll Too Well: Taylor Swiftkarlinarahma100% (1)

- Extracted Chapter 1Document103 pagesExtracted Chapter 1PalisthaNo ratings yet

- Jehovah NissiDocument9 pagesJehovah Nissirajeshrout1No ratings yet

- QS IpcDocument7 pagesQS Ipcmohammad_mohiuddi_15No ratings yet

- Sloth Bear Habitat Akhtar Bargali 15 2Document9 pagesSloth Bear Habitat Akhtar Bargali 15 2Sabyasachi RathNo ratings yet

- Factors That Contribute To The Effectiveness of Internal Auditing in Public Sectors in Tanzania. A Case of Ubungo District CouncilDocument12 pagesFactors That Contribute To The Effectiveness of Internal Auditing in Public Sectors in Tanzania. A Case of Ubungo District CouncilgrimmNo ratings yet

- PaccarServiceManual2005 2010Document189 pagesPaccarServiceManual2005 2010Eric Porter100% (21)

- B.SC (Maths)Document32 pagesB.SC (Maths)vrsafeNo ratings yet

- Javellana V Lutero and RCA JaroDocument4 pagesJavellana V Lutero and RCA JaroYet Barreda BasbasNo ratings yet

- Group 2 Concept of ExerciseDocument3 pagesGroup 2 Concept of ExerciseJe-an CautibarNo ratings yet

- 2020 10 05 XI Physical Education 0Document5 pages2020 10 05 XI Physical Education 0Labhesh DhanmeherNo ratings yet

- Tiger Monkey Elephant: Wild AnimalsDocument17 pagesTiger Monkey Elephant: Wild AnimalsAinhoaBjNo ratings yet

- Ode To West Wind MCQsDocument6 pagesOde To West Wind MCQsMazhar Hussain100% (5)

- Foreign Words in EnglishDocument11 pagesForeign Words in EnglishSaransh MehrotraNo ratings yet

- IELTS Writing Task 2 Actual Tests 2015 - 2016 - 2017 & Sample AnswersDocument113 pagesIELTS Writing Task 2 Actual Tests 2015 - 2016 - 2017 & Sample AnswersMuzaffar Senior Imomov94% (36)