0 ratings0% found this document useful (0 votes)

27 viewsFpe Winter 2017

Fpe Winter 2017

Uploaded by

Rushabh PatelThis document is an exam for a fluid power engineering course, consisting of 5 questions with 3 parts each. It covers topics like jet propulsion, hydraulic turbines, pumps, compressors, accumulators, and fluid couplings. The questions involve calculations related to forces on vanes, turbine dimensions, pump power requirements, compressor performance, and more. Diagrams may be required to explain operating principles. Formulas need to be derived or applied for questions involving hydraulic or mechanical efficiencies.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Fpe Winter 2017

Fpe Winter 2017

Uploaded by

Rushabh Patel0 ratings0% found this document useful (0 votes)

27 views2 pagesThis document is an exam for a fluid power engineering course, consisting of 5 questions with 3 parts each. It covers topics like jet propulsion, hydraulic turbines, pumps, compressors, accumulators, and fluid couplings. The questions involve calculations related to forces on vanes, turbine dimensions, pump power requirements, compressor performance, and more. Diagrams may be required to explain operating principles. Formulas need to be derived or applied for questions involving hydraulic or mechanical efficiencies.

Original Description:

vgbj

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document is an exam for a fluid power engineering course, consisting of 5 questions with 3 parts each. It covers topics like jet propulsion, hydraulic turbines, pumps, compressors, accumulators, and fluid couplings. The questions involve calculations related to forces on vanes, turbine dimensions, pump power requirements, compressor performance, and more. Diagrams may be required to explain operating principles. Formulas need to be derived or applied for questions involving hydraulic or mechanical efficiencies.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

27 views2 pagesFpe Winter 2017

Fpe Winter 2017

Uploaded by

Rushabh PatelThis document is an exam for a fluid power engineering course, consisting of 5 questions with 3 parts each. It covers topics like jet propulsion, hydraulic turbines, pumps, compressors, accumulators, and fluid couplings. The questions involve calculations related to forces on vanes, turbine dimensions, pump power requirements, compressor performance, and more. Diagrams may be required to explain operating principles. Formulas need to be derived or applied for questions involving hydraulic or mechanical efficiencies.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

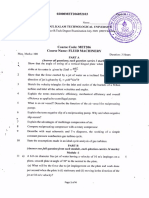

Seat No.: ________ Enrolment No.

___________

GUJARAT TECHNOLOGICAL UNIVERSITY

BE - SEMESTER–V (NEW) EXAMINATION – WINTER 2017

Subject Code: 2151903 Date: 08/11/2017

Subject Name: Fluid Power Engineering

Time: 10:30 AM TO 01:00 PM Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

Q.1 (a) Jet Propulsion. 3

(b) Prove that Force Exerted by the series of flat plate is 50% 4

(c) A jet of water impinges on a symmetrically curved vane at the center. The velocity of 7

the jet is 60 m/sec and the diameter 120 mm. The jet is deflected through an angle of

1200 . Calculate the force on the vane if the vane is fixed. Also determine the force if

the vane moves with a velocity of 25 m/sec in the direction of jet. What will be the

power and efficiency?

Q.2 (a) Explain: Hydraulic efficiency, Mechanical Efficiency. 3

(b) Write the Impulse Momentum equation. What is NPSH? 4

(c) Sketch Hydro Electric Power Plant and Explain its different element. 7

OR

(c) A jet of water moving with the velocity 12 m/sec impinges on a concave shaped vane 7

to deflect the jet through 1200 when stationary. If the vane moves at 5 m/sec,

determine the angle of jet so that there is no shock at the inlet. What is absolute velocity

of water at the exit in magnitude and direction? Also find the work done per unit mass

of water. Assume that the vane is smooth.

Q.3 (a) Draw and explain main characteristic curves of Francis turbine 3

(b) Explain governing of Francis turbine with neat sketch. 4

(c) Determine the main dimensions for a Francis turbine for the following conditions: 7

Head 100m, Power 3000 kW, Speed 400 rpm, ηh= 0.89, ηo= 0.86,B1=0.1D1, flow

ratio 0.2, D1=2D2, velocity of flow is constant.

OR

Q.3 (a) Explain with neat sketch the functions of three main components of Pelton turbine. 3

(b) Derive the equation of hydraulic efficiency of a Pelton turbine. Obtain condition for 4

maximum hydraulic efficiency.

(c) A Pelton wheel is required to develop 4000 kW at 400 rev/min, operating under net 7

head of 350m. There are two jets and the bucket deflection angle is 1650 . Calculate

the bucket pitch circle diameter, the cross sectional area of each jet and the hydraulic

efficiency of the turbine. Make the following assumptions (i) overall efficiency is 85%

when the water is discharged from the wheel in a direction parallel to the axis of

rotation(ii) Co-efficient of velocity of nozzle Kv=0.97 and the blade speed ratio

Ku=0.46(iii) relative velocity of water at exit from the bucket is 0.86 times the relative

velocity at inlet.

Q.4 (a) What are the functions of air vessels in Reciprocating pump? Where are they located? 3

(b) Explain working principle of centrifugal compressor with pressure and velocity 4

diagram.

(c) Explain the effect of blade shape of impellers on performance of Centrifugal 7

compressor. Also classify the blades based on curvature.

OR

Q.4 (a) Explain slip factor and power input factor for centrifugal compressor. 3

(b) Explain with the help of neat sketch the principle and operation of Fluid torque 4

converter.

(c) A Centrifugal pump impeller has diameter of 600mm and width of 60mm at the outlet. 7

The pump runs at 1450 rpm and delivers 0.8 m3 /sec against a head of 80m.The

leakage loss after the impeller is 4% of discharge, the mechanical loss is 10kW and

the hydraulic efficiency is 80%.Determine the blade angle at the outlet, the power

required and the overall efficiency of the pump.

Q.5 (a) Draw a neat sketch, and explain the operation of Hydraulic Accumulator 3

(b) Compare Reciprocating pump with Centrifugal pump 4

(c) For 50% degree reaction of axial flow compressor prove 𝛼1 =𝛽2 and 𝛼2 = 𝛽1 , notations 7

carry usual meaning.

OR

Q.5 (a) Write a short on Hydraulic Ram. 3

(b) Draw a neat sketch, and explain the operation of Hydraulic Crane. 4

(c) Explain Fluid Coupling with neat sketch. 7

************

You might also like

- Dynamics of Flight-Bernard EtkinDocument395 pagesDynamics of Flight-Bernard EtkinDann MoralesNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVraj ShahNo ratings yet

- 151411-151903-Fluid Power EngineeringDocument2 pages151411-151903-Fluid Power EngineeringHerat HirparaNo ratings yet

- Me 4 Sem Hydraulics Machines Summer 2018 PDFDocument4 pagesMe 4 Sem Hydraulics Machines Summer 2018 PDFPranitNo ratings yet

- 151406-151903-Fluid Power EngineeringDocument2 pages151406-151903-Fluid Power EngineeringHerat HirparaNo ratings yet

- 08 May 2019Document2 pages08 May 2019Ramesh SagapariyaNo ratings yet

- Met206 Fluid Machinery, July 2021Document4 pagesMet206 Fluid Machinery, July 2021AkashNo ratings yet

- FMHM Pepars OnlyDocument10 pagesFMHM Pepars Onlysp2532658.1970No ratings yet

- (Time: 3 Hours) (Total Marks: 70) : Printed Pages: 3Document3 pages(Time: 3 Hours) (Total Marks: 70) : Printed Pages: 3Awanish SinghNo ratings yet

- BME05104 Hydraulic Machine and Hydroelectric Power Plant Unit-IDocument2 pagesBME05104 Hydraulic Machine and Hydroelectric Power Plant Unit-IGautam GunjanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityrahul35.rbkNo ratings yet

- Hydraulic Paper SetDocument30 pagesHydraulic Paper SetBablu ShaikhNo ratings yet

- Me206 QPDocument2 pagesMe206 QPMohammed Jihad PmNo ratings yet

- Hydrolic, Hydrology QuizDocument8 pagesHydrolic, Hydrology Quizmuratogluinsaat1701No ratings yet

- WWW - Manaresults.Co - In: (Common To CE, CEE)Document2 pagesWWW - Manaresults.Co - In: (Common To CE, CEE)Balja NitinNo ratings yet

- Assignment Fluid Power Engineering 1ET1010504 CompressedDocument7 pagesAssignment Fluid Power Engineering 1ET1010504 CompressedPatel SarkarNo ratings yet

- 2024 Jan. MET206-GDocument3 pages2024 Jan. MET206-Gadharshmm210No ratings yet

- Fluid Mechanics & MachineryDocument1 pageFluid Mechanics & MachineryPranav SuryavanshiNo ratings yet

- Ahe ModelDocument2 pagesAhe Modelkarthick VijayanNo ratings yet

- Ajay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringDocument3 pagesAjay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringMradul GuptaNo ratings yet

- HM&S - Me16323Document2 pagesHM&S - Me16323Chary100% (1)

- FMHM Regular Jntu Question Papers 2008Document8 pagesFMHM Regular Jntu Question Papers 2008anjaneyulud100% (1)

- Fluid Machinery Eme011 PDFDocument2 pagesFluid Machinery Eme011 PDFgaurav pandey1212No ratings yet

- R05220104-Hydraulics and Hydraulic MachineryDocument8 pagesR05220104-Hydraulics and Hydraulic MachinerySRINIVASA RAO GANTANo ratings yet

- FLUID MECHANICS & HYDRAULIC MACHINERY - PDF SyllabusDocument4 pagesFLUID MECHANICS & HYDRAULIC MACHINERY - PDF SyllabusShareef KhanNo ratings yet

- Fluid MachineryDocument4 pagesFluid MachineryFaraz MehdiNo ratings yet

- Set No. 1Document9 pagesSet No. 1himabindugvsd71No ratings yet

- Set No. 1Document8 pagesSet No. 129viswa12No ratings yet

- Fpe DBC 5th Sem AssignmentDocument10 pagesFpe DBC 5th Sem AssignmentJain shahilkumarNo ratings yet

- Course Code: ME 2416Document2 pagesCourse Code: ME 2416Ramakrishna KocherlaNo ratings yet

- 22445-2023-Winter-Question-Paper (Msbte Study Resources)Document4 pages22445-2023-Winter-Question-Paper (Msbte Study Resources)Pratham DalviNo ratings yet

- FebruaryMarch 2022Document1 pageFebruaryMarch 2022rohitchanakya76No ratings yet

- QP FMM 22445 ME4I Summer 2022Document5 pagesQP FMM 22445 ME4I Summer 2022Shantanu WaghmareNo ratings yet

- Fluid MachinesDocument14 pagesFluid MachinesNishankzattNo ratings yet

- 9a01404-Fluid Mechanics & Hydraulic MachineryDocument4 pages9a01404-Fluid Mechanics & Hydraulic MachineryK. Pavan Kumar ReddyNo ratings yet

- Rr310302 Hydraulic Machinery and SystemsDocument8 pagesRr310302 Hydraulic Machinery and SystemsSrinivasa Rao GNo ratings yet

- Fluid Machinery Question BankDocument2 pagesFluid Machinery Question BanksandeeposNo ratings yet

- 2023 Summer Question Paper (Msbte Study Resources)Document4 pages2023 Summer Question Paper (Msbte Study Resources)Pratham DalviNo ratings yet

- KOM PapersDocument30 pagesKOM PapersjrravikirankopelliNo ratings yet

- Fluid Machinery: Roll No. Total No. of Pages: 02 Total No. of Questions: 09 B.Tech. (ME) (2011 Onwards) (Sem. - 6)Document2 pagesFluid Machinery: Roll No. Total No. of Pages: 02 Total No. of Questions: 09 B.Tech. (ME) (2011 Onwards) (Sem. - 6)himanshuNo ratings yet

- Propulsion - I: B.E. (Aeronautical Engineering) Fifth Semester (C.B.S.)Document2 pagesPropulsion - I: B.E. (Aeronautical Engineering) Fifth Semester (C.B.S.)fashion storeNo ratings yet

- Question Paper Code: X: (10×2 20 Marks)Document3 pagesQuestion Paper Code: X: (10×2 20 Marks)annamalai_s873323No ratings yet

- A-PDF Merger DEMO: Purchase FromDocument66 pagesA-PDF Merger DEMO: Purchase Frommanju0806No ratings yet

- AQ Fluid Machinery-1Document3 pagesAQ Fluid Machinery-1Sourabh BelladNo ratings yet

- r05222202 Prime Movers and Mechanical ComponentsDocument9 pagesr05222202 Prime Movers and Mechanical ComponentsSRINIVASA RAO GANTANo ratings yet

- Fluid Mechanics Q4Document2 pagesFluid Mechanics Q4Shiva GlennNo ratings yet

- Propulsion - I: B.E. (Aeronautical Engineering) Semester Fifth (C.B.S.)Document2 pagesPropulsion - I: B.E. (Aeronautical Engineering) Semester Fifth (C.B.S.)Preshit SamNo ratings yet

- Images - MEQP - 08 - R05310302 HYDRAULIC MACHINERY AND SYSTEMS PDFDocument8 pagesImages - MEQP - 08 - R05310302 HYDRAULIC MACHINERY AND SYSTEMS PDFvishnu chaudharyNo ratings yet

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.annamalai_s873323No ratings yet

- Ptce7401 Applied Hydraulic EngineeringDocument2 pagesPtce7401 Applied Hydraulic EngineeringSaranyaNo ratings yet

- FMHM 2022 Summer and Winter Combined PapersDocument4 pagesFMHM 2022 Summer and Winter Combined PapersparantapNo ratings yet

- Fluid Flow Operation GtuDocument2 pagesFluid Flow Operation GtuRohan MalhotraNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityrahul35.rbkNo ratings yet

- Kec FLUID MACHINERYDocument3 pagesKec FLUID MACHINERYanadinath sharmaNo ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsMital PatelNo ratings yet

- Tula's Institute, Dhoolkot, DehradunDocument2 pagesTula's Institute, Dhoolkot, Dehradunanadinath sharmaNo ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Power System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)From EverandPower System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)No ratings yet

- Resistivity Modeling: Propagation, Laterolog and Micro-Pad AnalysisFrom EverandResistivity Modeling: Propagation, Laterolog and Micro-Pad AnalysisNo ratings yet

- Electricity in Fish Research and Management: Theory and PracticeFrom EverandElectricity in Fish Research and Management: Theory and PracticeNo ratings yet

- Guidelines of Textile MarketDocument4 pagesGuidelines of Textile MarketRushabh PatelNo ratings yet

- Shoulder Stretching and Strengthening: IMG Physical TherapyDocument8 pagesShoulder Stretching and Strengthening: IMG Physical TherapyRushabh PatelNo ratings yet

- ) ZT Dcfguz5Fl, SF: Smjl0V!) V/Tu"T LCZF Ahfzg (RF,) ZFBJF V/U (GL Dfu"Nlx"Sf Q LgidmDocument5 pages) ZT Dcfguz5Fl, SF: Smjl0V!) V/Tu"T LCZF Ahfzg (RF,) ZFBJF V/U (GL Dfu"Nlx"Sf Q LgidmRushabh PatelNo ratings yet

- Experiment - 5: AIM: Study and Calculate The Efficiency of Fin in Natural and Forced ConvectionDocument17 pagesExperiment - 5: AIM: Study and Calculate The Efficiency of Fin in Natural and Forced ConvectionRushabh PatelNo ratings yet

- GuidelinesOfDiamondFactory PDFDocument5 pagesGuidelinesOfDiamondFactory PDFRushabh PatelNo ratings yet

- Post-Graduate Research Centre For Industrial Design: B.E. Semester IV: Design Engineering - 1BDocument12 pagesPost-Graduate Research Centre For Industrial Design: B.E. Semester IV: Design Engineering - 1BRushabh PatelNo ratings yet

- Academic Calender 16-17 EvenDocument2 pagesAcademic Calender 16-17 EvenRushabh PatelNo ratings yet

- Ebaco Indoor Rubber FlooringDocument3 pagesEbaco Indoor Rubber FlooringRushabh PatelNo ratings yet

- Composite WallDocument6 pagesComposite WallRushabh PatelNo ratings yet

- Experiment - 4: AIM: To Measure The Emissivity of Test PlateDocument8 pagesExperiment - 4: AIM: To Measure The Emissivity of Test PlateRushabh PatelNo ratings yet

- Experiment - 2: Heat Loss by Natural Convection From Ice PlateDocument7 pagesExperiment - 2: Heat Loss by Natural Convection From Ice PlateRushabh PatelNo ratings yet

- Prof. Tejaskumar C. Patel Assitant Professor, Mechanical Engineering Department, SSASITDocument1 pageProf. Tejaskumar C. Patel Assitant Professor, Mechanical Engineering Department, SSASITRushabh PatelNo ratings yet

- Student Upload Sample 1yDocument65 pagesStudent Upload Sample 1yRushabh PatelNo ratings yet

- Heat Transfer: Lab ManualDocument3 pagesHeat Transfer: Lab ManualRushabh PatelNo ratings yet

- Schedule For School Visit at SSASIT: Date-30-11-2017Document1 pageSchedule For School Visit at SSASIT: Date-30-11-2017Rushabh PatelNo ratings yet

- Lab 217 A: Subject:Regarding Maintenance of ComputerDocument2 pagesLab 217 A: Subject:Regarding Maintenance of ComputerRushabh PatelNo ratings yet

- 02-08-2018Document121 pages02-08-2018Rushabh PatelNo ratings yet

- Analog Electronics LabDocument3 pagesAnalog Electronics LabRushabh PatelNo ratings yet

- Dead Stock Verification ofDocument5 pagesDead Stock Verification ofRushabh PatelNo ratings yet

- Viva EntryDocument3 pagesViva EntryRushabh PatelNo ratings yet

- SR No. Name of Faculty Qualification 1 2 3 4 5 6 7 8 9 10 11 12 13 14Document2 pagesSR No. Name of Faculty Qualification 1 2 3 4 5 6 7 8 9 10 11 12 13 14Rushabh PatelNo ratings yet

- Gradually Varied Flow PDFDocument34 pagesGradually Varied Flow PDFRobert BuiNo ratings yet

- Current ElectricityDocument126 pagesCurrent ElectricityAvishkar Jaiswal100% (1)

- Aerodynamics and Structural Analysis of Wind Turbine Blade Aerodynamics and Structural Analysis of Wind Turbine BladeDocument10 pagesAerodynamics and Structural Analysis of Wind Turbine Blade Aerodynamics and Structural Analysis of Wind Turbine BladeM IssaNo ratings yet

- Assignment 5-MTF-Fall 2019Document2 pagesAssignment 5-MTF-Fall 2019Junaid JohnsonNo ratings yet

- DARK MATTER TigershroffDocument10 pagesDARK MATTER TigershroffVandana GowdaNo ratings yet

- Tifr Physics 2018 QuestionsDocument10 pagesTifr Physics 2018 QuestionsAaloka GautamaNo ratings yet

- LND, Inc.: General SpecificationsDocument5 pagesLND, Inc.: General SpecificationsValentina ManniNo ratings yet

- Shear Connectors DesignDocument8 pagesShear Connectors Designriaz16shaikNo ratings yet

- ProceedingsDocument680 pagesProceedingsrajeevraniNo ratings yet

- Propossed EMW SYLLABUSDocument2 pagesPropossed EMW SYLLABUSAkram MohdNo ratings yet

- Fresnel DiffractionDocument32 pagesFresnel DiffractionaishatoonyNo ratings yet

- D0597186 CHEM12 C1300 SWBT Mig PDFDocument15 pagesD0597186 CHEM12 C1300 SWBT Mig PDFDianaGarnicaNo ratings yet

- Turbo MachineryDocument132 pagesTurbo Machinerysridevi73No ratings yet

- Mathematical Model of A Direct Methanol Fuel Cell: DMFC023Document6 pagesMathematical Model of A Direct Methanol Fuel Cell: DMFC023KaustubhNo ratings yet

- Breviar de Calcul - Cos C.R.Document63 pagesBreviar de Calcul - Cos C.R.tulvyNo ratings yet

- Remember The Three-Step Process:: ExampleDocument1 pageRemember The Three-Step Process:: ExampleMăndița BaiasNo ratings yet

- FatigueTest and Wave Propagtion Sum20Document18 pagesFatigueTest and Wave Propagtion Sum20Everlasting MemoriesNo ratings yet

- Voltage Dip Calculations Using SpreadsheetsDocument6 pagesVoltage Dip Calculations Using SpreadsheetsRudanekNo ratings yet

- Laminar and Turbulent Flows in Bounded SystemsDocument11 pagesLaminar and Turbulent Flows in Bounded SystemsRamy Abd Elkhalek Shahin100% (1)

- Mechanics Lab Manual PDFDocument33 pagesMechanics Lab Manual PDFSohaib ZaibNo ratings yet

- 2306 8MA0-22 ExemplarDocument35 pages2306 8MA0-22 ExemplarYasmeen HallakNo ratings yet

- KTG ThermodynamicDocument7 pagesKTG Thermodynamicdevshrivastava630No ratings yet

- Summer 2020 EEE 3107 / EEE 301 Electrical Properties of Materials Dr. Sadid MuneerDocument8 pagesSummer 2020 EEE 3107 / EEE 301 Electrical Properties of Materials Dr. Sadid MuneerUmmu Abiha AssociatesNo ratings yet

- Xi Neet WT - 25 PhysicsDocument6 pagesXi Neet WT - 25 PhysicsspvsathyabamaNo ratings yet

- Midterm Examination in Physical ScienceDocument4 pagesMidterm Examination in Physical ScienceTristan PereyNo ratings yet

- Electricity Lesson PlanDocument2 pagesElectricity Lesson PlanSuta PinatihNo ratings yet

- 4 Flexural Members PDFDocument9 pages4 Flexural Members PDFCristan RetuermaNo ratings yet

- Experiments: Adsorption From Solution (AS) ObjectiveDocument10 pagesExperiments: Adsorption From Solution (AS) ObjectiveAIYODOT DOTNo ratings yet

- Constitutive Relations and Conditions For Reciprocity in Bianisotropic Media (Macroscopic Approach)Document5 pagesConstitutive Relations and Conditions For Reciprocity in Bianisotropic Media (Macroscopic Approach)aldoNo ratings yet