Element List

Element List

Uploaded by

rgrao85Copyright:

Available Formats

Element List

Element List

Uploaded by

rgrao85Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Element List

Element List

Uploaded by

rgrao85Copyright:

Available Formats

APQP Element Evidence Documentation Abreviations

1.Confidentiality Agreement (FAU-F-SP-4004/en) 1. CA

2. Quality Assurance Agreement (FAU-F-SP-3124/en) 2. QAA

2 Confidentiality Agreement / QAA/ Certificate of Conformity 3. Certificate of Conformity (FIS-F-DS2-0411) 3. C of C

5 Technical Review 1. Technical Review Meeting Minutes 1. Minutes

7 Master Schedule 1. Program Timing or Master Schedule from Suppliers (FAU-F-SP-2407) 1. Timing

1. Team Feasibility Commitment letter (FAU-F-SPG-2408) 1. Feas.

8 Feasibility Commitment 2. Capacity Plan 2. Capacity

1. Supplier Kick Off Presentation 1. KO Pres.

2. Supplier Kick Off Sign in sheet 2. KO Att.

3. Program Review #2- Product Design & Development 3. PR#2

11 Program Review Kick-Off 4. Program Review #3- Production Set-Up/ Pre-Series 4. PR#3

13 Design Review 1. Design Review Meeting Minutes (if applicable) 1. Minutes

1. Prototype Documentation (PPSR or GP-11) 1. Proto Doc.

2. Prototype Dimensionals 2. Proto Dim

14 Prototype Builds 3. Open Issues Lists 3. OI List

15 Design Verification Plan 1. DVPR (if applicable) 1. DVPR

1. Process Flow Diagram. (FAU-S-SPG-2417) - not a specific form. 1. PFLOW

2. Plant Layout. 2. Layout

3. A-5 Floor Plan Check List 3. A-5

17 Process Flow Chart & Manufacturing Floor Plan 4. A-6 Process Flow Chart Checklist 4. A-6

1 Preliminary PFMEA. 1. PFMEA

2. A-7 Process FMEA Checklist 2. A-7

18 Process FMEA 3. PFMEA Audit 3. Audit

1. Tooling & equipment list identified. 1. Tool List

2. Gauge+Build & Design Approval Checklist (FAU-F-SPG-2419) 2. Check

3. A-3 New Equipment, Tooling & Test Equipment checklist. 3. A-3

4. GR&R Forms (FAU-F-PSG-0301 or FAU-F-PSG-0303) 4. GR&R

19 Facilities, Tools, Gaging 5. Faciities, Tool & Gaging Check list (FAU-F-SP 5. Check

1. Pre Production Control Plan (FAU-S-PSG-9012) 1. CP

2. A-8 Production Control Plan Checklist 2. A-8

20 Control Plan and Testing 3. Control Plan Process Audit 3. Audit

1. Packaging Proposal Form 1. Pack Prop

2. Packaging Concept & sign off 2. Concept SO

3. Testing Plan, Approval & sign off 3. App SO

21 Packaging & Shipping Specifications 4. Overall Timing 4. Timing

22 Training Plan 1. Training plan doc. 1. Training

1. Appearance Approval Report. (if applicable) 1. AAP

2. Tool Graining kick-off & timing 2. Grain KO

3. Graining Approval 3. Grain App.

23 Appearance Approval Reports 4. Pre-Grain approval part dimensionals 4. PG Dim.

1. Standard Operator Work Instructions, Process Sheeets, etc. 1. WI

24 Product and Process Quality File (Proc. Monitoring - WI's) 2. A-4 Product / Process quality checklist 2. A-4

1.FIS MPT report (FAU-F-SPG-2425) & checklists (FIS PSO Checklist). 1. MPT

25 Trial Run at Rate / Line Speed Demonstration 2. Specific OEM form (PDR or R@R) 2. OEM Doc.

1. Proc. Audit

1. Process Audit (FAU-F-SPG-2426) 2. CP Audit

26 Process Audit 2. Special Audit of Key Charact. in Ctrol Plan (FAU-F-PSG-0800)

27 Process Capability Study 1. Process Capability Calculation Form (FAU-F-SPG-3504) 1. Cap.

1. Approved DVP&R. 1. DVP&R

28 Production Validation Plan (Test Sample Sizes & Freq.) 2. IMDS Submission 2. IMDS

1. Final Inspection Validation form (FAU-F-PSG-0661) 1. Insp. Val

2. I-charts. 2. I-charts

29 Early Production Containment 3. Convergence plan. 3. Conv. Pl

1. 18 elements PPAP 4th edition 1. PPAP

30 Production Part Approval 2. PPAP checklist (FAU-F-SPG-2430) 2. Check

31 Transition to Series and Lessons Learned 1. APQP Lessons Learned Transition to Series (FAU-S-SPG-2431) 1. Lessons

You might also like

- Helios 3D Reference-DocumentationDocument223 pagesHelios 3D Reference-DocumentationSimon Aguilera100% (3)

- Grupo AntolinDocument41 pagesGrupo AntolinRavi Gowda50% (2)

- CARA NC Management Tool Instructions For Client: IATF OversightDocument8 pagesCARA NC Management Tool Instructions For Client: IATF OversightOBSC PerfectionNo ratings yet

- SINOPEC Lubricants For Off Highway EquipmentsDocument24 pagesSINOPEC Lubricants For Off Highway EquipmentsSumaya AkterNo ratings yet

- Procurement & LogisticDocument1 pageProcurement & Logisticrgrao85No ratings yet

- SAP R - 3 Guide To EDI, IDocs and Interfaces 3rd EditionDocument155 pagesSAP R - 3 Guide To EDI, IDocs and Interfaces 3rd EditionJose Carlos Ortiz RojasNo ratings yet

- Yanfeng Gage Fixture Stardards Rev006Document85 pagesYanfeng Gage Fixture Stardards Rev006eazaNo ratings yet

- Pfmea - Yxa Aac PanelDocument26 pagesPfmea - Yxa Aac Panelakash.vd.1603No ratings yet

- PSWDocument2 pagesPSWLinda G. CordovaNo ratings yet

- Plato Scio Fmea Presentation 01Document22 pagesPlato Scio Fmea Presentation 01Shree BiradarNo ratings yet

- Quality Assurance Matrix in Automotive Industry: ArticleDocument6 pagesQuality Assurance Matrix in Automotive Industry: ArticleAbdullah BalouchNo ratings yet

- 6110 Aluminum Composition SpecDocument1 page6110 Aluminum Composition SpecSung-Sil, JungNo ratings yet

- Moudling Operation GSIC Process: MouldingDocument13 pagesMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNo ratings yet

- Standard For Process Flow DiagramDocument6 pagesStandard For Process Flow Diagrammahesh100% (1)

- Volvo Rts Form MasterDocument9 pagesVolvo Rts Form MasterclintNo ratings yet

- PFC, CP, Pfmea 165Document6 pagesPFC, CP, Pfmea 165Mahesh SharmaNo ratings yet

- Injection Muolding MachineDocument26 pagesInjection Muolding MachineSidharth Shankar singhNo ratings yet

- 01 - Layered Process Audit Example B 2011Document7 pages01 - Layered Process Audit Example B 2011RN XaverNo ratings yet

- Rmi CMRT 6.31Document188 pagesRmi CMRT 6.31Anjali DeshpandeNo ratings yet

- Bare PCB Manufacturing Process, Defects, and TestingDocument6 pagesBare PCB Manufacturing Process, Defects, and TestingjackNo ratings yet

- Process Audit: VDA 6.3 Process Audit: Assessment Matrix With Product Group CalculationDocument1 pageProcess Audit: VDA 6.3 Process Audit: Assessment Matrix With Product Group CalculationjohnNo ratings yet

- Dead Endclamp Failure AnalysisDocument26 pagesDead Endclamp Failure AnalysisRK KumarNo ratings yet

- Automotive Zero Defects Framework: February 26, 2020Document55 pagesAutomotive Zero Defects Framework: February 26, 2020isolongNo ratings yet

- Supplier Manual-7th Revision - April 23 FinalDocument35 pagesSupplier Manual-7th Revision - April 23 FinalvishnuNo ratings yet

- Iatf Cara ToolDocument10 pagesIatf Cara ToolJohn OoNo ratings yet

- Iatf & IsoDocument8 pagesIatf & IsoStu PididiotNo ratings yet

- Lear-70-SSD Spec Characteristics GdlnesDocument10 pagesLear-70-SSD Spec Characteristics Gdlnesrpagarwal2No ratings yet

- IATF TRAINING MATERIAL - PowerpointDocument6 pagesIATF TRAINING MATERIAL - Powerpointshalinmishra0% (1)

- CastingDocument19 pagesCastingMohd SyafiqNo ratings yet

- Process Capability LV - (EDW) 2016-2017Document65 pagesProcess Capability LV - (EDW) 2016-2017Muhammad Daud Abu BakarNo ratings yet

- Apqp FormsDocument32 pagesApqp FormsVenuNo ratings yet

- Revised SOP For TinningDocument2 pagesRevised SOP For TinningAnkit GalaniNo ratings yet

- Kaizen Suggestion FormDocument4 pagesKaizen Suggestion FormambicaNo ratings yet

- Nox-Rust 311 HMDocument1 pageNox-Rust 311 HMNavin JoshiNo ratings yet

- 08 FmeaDocument27 pages08 FmeanormalNo ratings yet

- Autocar Ppap Requirements Rev 5Document17 pagesAutocar Ppap Requirements Rev 5man hoNo ratings yet

- BAJAJDocument6 pagesBAJAJSubrat barikNo ratings yet

- Ferry Passenger Seat Catalog Pacific MarineDocument28 pagesFerry Passenger Seat Catalog Pacific Marinealim.46632119No ratings yet

- Fmea History Record: SR - No Fmea No. Description Complaint Received Date Fmea Rev. No Process IdentifiedDocument2 pagesFmea History Record: SR - No Fmea No. Description Complaint Received Date Fmea Rev. No Process IdentifiedshalinmishraNo ratings yet

- F-PD-05 Feasibility StudyDocument1 pageF-PD-05 Feasibility Studya9808755315No ratings yet

- Die Fitter Job DescriptionDocument1 pageDie Fitter Job Descriptionpankaj singhNo ratings yet

- 3-Format III CSR VeDocument1 page3-Format III CSR VeAyush GautamNo ratings yet

- Histogram Data Distribusi FrekuensiDocument13 pagesHistogram Data Distribusi FrekuensiAgung Firdaus100% (1)

- FMEA Base Roof 7779-617Document19 pagesFMEA Base Roof 7779-617RidwanNo ratings yet

- Potential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Document4 pagesPotential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Mukesh YadavNo ratings yet

- Volume 8D Report-EnDocument1 pageVolume 8D Report-EnHang NguyenNo ratings yet

- Bonding In-Process Inspection ChecklistDocument1 pageBonding In-Process Inspection ChecklistRonnel LeanoNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Delphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Document15 pagesDelphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Ram100% (1)

- Variation and DefectsDocument16 pagesVariation and DefectssushmaxNo ratings yet

- Process Capability Analysis OverviewDocument46 pagesProcess Capability Analysis Overviewpaneer selvamNo ratings yet

- Control of Design MTD-QSP-08 REV 1.0 - 27-08-06Document9 pagesControl of Design MTD-QSP-08 REV 1.0 - 27-08-06vinothNo ratings yet

- Supplier-QUAL TM 0027-01 PPAP PackageDocument67 pagesSupplier-QUAL TM 0027-01 PPAP PackageMahe RonaldoNo ratings yet

- Hadees e DilDocument131 pagesHadees e Dilnadeem5476100% (1)

- Defects, Root Causes in Casting Process and Their Remedies: ReviewDocument9 pagesDefects, Root Causes in Casting Process and Their Remedies: ReviewPrabagarane RamachandranNo ratings yet

- Case Study - PPAPDocument45 pagesCase Study - PPAPrc2834338No ratings yet

- Check List - Product Realisation ProcessDocument4 pagesCheck List - Product Realisation ProcessDisha ShahNo ratings yet

- Mahindra & Mahindra - CSRDocument19 pagesMahindra & Mahindra - CSRAnkit Bavishi100% (1)

- Xfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument8 pagesXfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following Formssenzo scholar100% (1)

- APQP Phase 1: Feasible Product Can Be Produced As Specified With No RevisionsDocument1 pageAPQP Phase 1: Feasible Product Can Be Produced As Specified With No RevisionsPatryk PyrchlaNo ratings yet

- APQPStatus Reporting GuidelinesDocument19 pagesAPQPStatus Reporting GuidelinesskluxNo ratings yet

- WDK Table April 22Document1 pageWDK Table April 22Jagdish PatelNo ratings yet

- Supplier Capability Self Assessment Form 2015 PROTECTEDDocument24 pagesSupplier Capability Self Assessment Form 2015 PROTECTEDrgrao85No ratings yet

- Instructions: 'No' Answers Are To Be Resolved Immediately and DocumentedDocument1 pageInstructions: 'No' Answers Are To Be Resolved Immediately and Documentedrgrao85No ratings yet

- Supplier Capability Self Assessment Form 2015 PROTECTEDDocument24 pagesSupplier Capability Self Assessment Form 2015 PROTECTEDrgrao85No ratings yet

- Company Namebuhler: Deputy Manager - ProjectsDocument1 pageCompany Namebuhler: Deputy Manager - Projectsrgrao85No ratings yet

- Starter Product RevenueDocument5 pagesStarter Product Revenuergrao85No ratings yet

- Green Belt Project Storyboard v2.0 TemplateDocument27 pagesGreen Belt Project Storyboard v2.0 Templatergrao85100% (1)

- AVP Performance Head Stud Kit For 6.0L Power Stroke: Parts Included: Tools NeededDocument2 pagesAVP Performance Head Stud Kit For 6.0L Power Stroke: Parts Included: Tools Neededrgrao85No ratings yet

- Elements of Forecasting: LN Yr Logyr Actual Sales Estd - Sales-1 Est - Logsales Est - Lnsales LN Sales Log Sales Time PeriodDocument10 pagesElements of Forecasting: LN Yr Logyr Actual Sales Estd - Sales-1 Est - Logsales Est - Lnsales LN Sales Log Sales Time Periodrgrao85No ratings yet

- S20157enDocument137 pagesS20157enrgrao85No ratings yet

- Auto and Auto Ancillaries Sector in IndiaDocument13 pagesAuto and Auto Ancillaries Sector in Indiargrao85No ratings yet

- Apparel Pattern DesigningDocument17 pagesApparel Pattern Designingrgrao85No ratings yet

- ENG FRM 001 Ve 1Document535 pagesENG FRM 001 Ve 1rgrao85No ratings yet

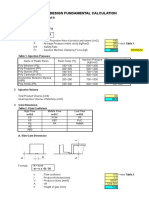

- Mold Design Fundamental Calculation BATTERY COVERDocument7 pagesMold Design Fundamental Calculation BATTERY COVERrgrao85No ratings yet

- LME Steel Rebar FactsheetDocument2 pagesLME Steel Rebar Factsheetrgrao85No ratings yet

- New Production Dev TimelineDocument2 pagesNew Production Dev Timelinergrao85No ratings yet

- Flexman QuestionDocument2 pagesFlexman Questionrgrao85No ratings yet

- RTyler Croy Gerrit-JenkinsDocument94 pagesRTyler Croy Gerrit-JenkinsionizareNo ratings yet

- DissertationDocument6 pagesDissertationVAMSHI KRISHNANo ratings yet

- Optimization For Engineering Systems1Document290 pagesOptimization For Engineering Systems1Tarun SisodiaNo ratings yet

- Dhemaji: Dhemaji District (Assam E-District Project)Document1 pageDhemaji: Dhemaji District (Assam E-District Project)Boishal Bikash BaruahNo ratings yet

- Black Viper's Windows 7 Service Pack 1 Service ConfigurationsDocument22 pagesBlack Viper's Windows 7 Service Pack 1 Service ConfigurationsStephanyNo ratings yet

- 01 What Is OOPDocument19 pages01 What Is OOPFarid KhanNo ratings yet

- Project #2 - B+Tree - CMU 15-445 - 645 - Intro To Database Systems (Fall 2017)Document1 pageProject #2 - B+Tree - CMU 15-445 - 645 - Intro To Database Systems (Fall 2017)alucardchaNo ratings yet

- Zbrajanje I Oduzimanje Do 20 BingoDocument10 pagesZbrajanje I Oduzimanje Do 20 BingoKristina BarićNo ratings yet

- CHAPTER FIVE: Sources and Methods of Data Collections 1.1 Data CollectionDocument14 pagesCHAPTER FIVE: Sources and Methods of Data Collections 1.1 Data CollectionHayelom Tadesse GebreNo ratings yet

- Safelite Auto GlassDocument4 pagesSafelite Auto GlassJosefina VicuñaNo ratings yet

- Hints To Counting GUIDocument14 pagesHints To Counting GUIdfieNo ratings yet

- MOP For NLZ U900 F2 Activation - Non-NCR Project Latitude (May 31)Document6 pagesMOP For NLZ U900 F2 Activation - Non-NCR Project Latitude (May 31)Randy Alonzo BondocNo ratings yet

- File Processing System and Its DisadvantagesDocument6 pagesFile Processing System and Its DisadvantagesKamalakar SreevatasalaNo ratings yet

- 21-22 18CS62 Kjrpia1Document5 pages21-22 18CS62 Kjrpia1rajeswari reddypatilNo ratings yet

- Comprog ReviewerDocument14 pagesComprog ReviewerFides MagistradoNo ratings yet

- Kubernetes DevOps ExpertDocument2 pagesKubernetes DevOps ExpertGautam PopliNo ratings yet

- AMV Download 178449 - AvayaMobileVideo3.4.1ReleaseNotes.0.1Document10 pagesAMV Download 178449 - AvayaMobileVideo3.4.1ReleaseNotes.0.1rndmyteam alphaNo ratings yet

- KE30Document18 pagesKE30Rajesh Nair67% (3)

- Oliver & Walker (2006) Reporting On Software Development Projects To Senior Managers and The BoardDocument23 pagesOliver & Walker (2006) Reporting On Software Development Projects To Senior Managers and The BoardgaryoliverNo ratings yet

- A 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsDocument4 pagesA 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsRamanathanNo ratings yet

- TensorFlow 1.x Deep Learning CookbookDocument823 pagesTensorFlow 1.x Deep Learning CookbookApoorv TiwariNo ratings yet

- Logarithmic FunctionsDocument20 pagesLogarithmic FunctionsDondon TayabanNo ratings yet

- Visual SUNT Pro DataDocument4 pagesVisual SUNT Pro DatabullichowNo ratings yet

- Montaj Gravity & Terrain Correction: Tutorial and User GuideDocument56 pagesMontaj Gravity & Terrain Correction: Tutorial and User GuideAndres Alejandro Maureira VillegaNo ratings yet

- Practica 4 y 5Document12 pagesPractica 4 y 5drockVolta0% (1)

- DR Lee Peng Hin: EE6203 Computer Control Systems 231 DR Lee Peng Hin: EE6203 Computer Control Systems 232Document21 pagesDR Lee Peng Hin: EE6203 Computer Control Systems 231 DR Lee Peng Hin: EE6203 Computer Control Systems 232phatctNo ratings yet

- USB Firmware ToolDocument16 pagesUSB Firmware ToolJerome PrefotNo ratings yet

- Book Chapter - Vaisman and Zimányi, 2014 - Database ConceptsDocument40 pagesBook Chapter - Vaisman and Zimányi, 2014 - Database ConceptsBenard MapakoNo ratings yet