Ars CX DX User Manual V11en

Ars CX DX User Manual V11en

Uploaded by

younesCopyright:

Available Formats

Ars CX DX User Manual V11en

Ars CX DX User Manual V11en

Uploaded by

younesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ars CX DX User Manual V11en

Ars CX DX User Manual V11en

Uploaded by

younesCopyright:

Available Formats

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.

tr

ARS C1/C2/C3

ARS D1/D2/D3

Gearless Synchronous Lift Machine

USER MANUAL

EN

ARKEL 1 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

Publisher ARKEL Elektrik Elektronik San. ve Tic. A.Ş.

Eyüp Sultan Mah. Şah Cihan Cad. No:69 Sancaktepe/Istanbul 34885 TURKIYE

TEL : (+90 216) 540 67 24 - 25

Fax : (+90 216) 540 67 26

E-mail: info@arkel.com.tr

www.arkel.com.tr

Date of issue 10.07.2018

Document version V1.1

This document has been created to be a guide for Arkel customers. Reproduction, transfer, distribution or storage of part or

all of the contents in this document in any form without the prior written permission of Arkel is prohibited. Arkel reserves

the right to make changes and improvements to any of the products described in this document without prior notice.

Arkel is not responsible for those mistakes that may be found in this manual and for the damages that they may cause.

ARKEL 2 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

CONTENTS

1. SAFETY RULES .......................................................................................................................................................... 4

1.1 GENERAL SAFETY INSTRUCTIONS ............................................................................................................................... 4

1.2 SAFETY PRECAUTIONS ................................................................................................................................................ 5

1.3 INTENDED USE ........................................................................................................................................................... 6

1.4 PACKING AND HANDLING........................................................................................................................................... 6

1.5 STORAGE .................................................................................................................................................................... 7

2. PRODUCT DESCRIPTION ........................................................................................................................................... 7

2.1 MAIN FEATURES ......................................................................................................................................................... 7

2.2 MACHINE NAME DETAILS ........................................................................................................................................... 8

2.3 TECHNICAL DATA........................................................................................................................................................ 8

2.4 ENCODER.................................................................................................................................................................... 9

2.5 BRAKE ......................................................................................................................................................................... 9

2.6 NAMEPLATE DATA...................................................................................................................................................... 9

3. INSTALLATION ....................................................................................................................................................... 10

3.1 SAFETY PRECAUTIONS .............................................................................................................................................. 10

3.2 FASTENING THE TRACTION MACHINE ...................................................................................................................... 10

4. ELECTRICAL CONNECTIONS .................................................................................................................................... 11

4.1 GENERAL .................................................................................................................................................................. 11

4.2 CONNECTING THE MOTOR ....................................................................................................................................... 13

4.3 CONNECTING THE BRAKE ......................................................................................................................................... 14

4.4 CONNECTING THE ENCODER .................................................................................................................................... 15

4.4.1 ENCODER CONNECTION TABLE ...................................................................................................................... 15

4.4.2 REPLACING THE ENCODER .............................................................................................................................. 16

5. TESTING THE BRAKE SYSTEM (IN ACCORDANCE WITH EN 81-20/50) ...................................................................... 17

5.1 DOUBLE BRAKE TEST (OVERLOAD TEST) ................................................................................................................... 17

5.2 SINGLE BRAKE TEST (BRAKE FAILURE TEST) .............................................................................................................. 17

5.3 BRAKE MICRO-SWITCH/MONITORING TEST ............................................................................................................ 17

6. MAINTENANCE ...................................................................................................................................................... 18

6.1 MAINTENANCE PROGRAM ....................................................................................................................................... 18

6.2 SAFETY PRECAUTIONS DURING MAINTENANCE....................................................................................................... 18

6.3 TROUBLESHOOTING ................................................................................................................................................. 19

ARKEL 3 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

1. SAFETY RULES

1.1 GENERAL SAFETY INSTRUCTIONS

This section explains the symbols used in this manual to describe the possible consequences of failure

to observe the safety rules.

Symbols used in this manual;

This symbol means that failure to follow the relative instructions or to take the necessary

precautions may lead to death or serious injuries to persons and irreversible damage to

property.

This symbol means that failure to follow the relative instructions or to take the necessary

precautions may lead to death or serious injuries to persons and irreversible damage to

property.

This symbol means that failure to follow the relative instructions or to take the necessary

precautions may lead to damage to property.

This symbol means that the relative instructions are important for the correct use of the

product and that failure to follow them may lead to serious damage.

ARKEL 4 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

1.2 SAFETY PRECAUTIONS

ARKEL ARS Cx/Dx traction machines have been designed and manufactured to be used as lifting

means for lifts in compliance with the relative standards (EN 81-20/50 and subsequent). Any other use

should be considered improper and not authorized by ARKEL. Additionally, these traction machines

should never be used to lift persons or objects on lifting systems that are not built in accordance with

the relevant regulations and that failed to pass the required tests.

These traction machines are not delivered ready for use. They may be used only after being installed

on the relevant machines or systems and after ensuring their safety by means of safety grids, barriers,

construction features or other devices, depending on the application.

Scheduled and/or special maintenance may be carried out only by qualified and authorized

personnel. Maintenance should be performed following the instructions given in this manual

or provided in any other supporting documentation supplied by ARKEL.

The personnel should be adequately instructed on the product's installation, assembly and

commissioning.

These gearless traction machines are designed to work inside close spaces, such as lift wells,

where access is allowed only to qualified and authorized personnel.

The instructions contained in this manual or in any other documentation supplied should be

followed at all times in order to avoid injuries or damage to persons and/or to the installation.

These gearless traction machines are not delivered ready for use. They may be used only

after being correctly installed and connected to an operating panel.

Before putting the machine into service, make sure that all the conditions for the proper

operation of the motor and the brake have been applied.

IT IS EXTREMELY DANGEROUS TO PUT YOUR HANDS near the traction sheave or

the lifting ropes.

Some parts of the machine can become very hot during operation (70/80°C). Therefore, it is

MANDATORY to ensure that nobody can accidentally touch these parts for maintenance or

repairs before a period of time sufficient for the parts to cool down to temperatures suitable

for direct contact.

During installation, inspection or maintenance work, DO NOT WEAR necklaces, bracelets

or loose items of clothing, such as scarves or wide-sleeved shirts, that might get caught in

moving parts.

Repairs may only be carried out by ARKEL personnel.

Unauthorized opening or tampering may result in serious damage to persons and/or to the

machine itself.

These gearless traction machines are not designed to be powered directly from the mains.

They must be connected to a frequency regulator. Connecting the traction machine directly to

the power mains may destroy the machine.

High voltages are present on the connection terminals when the motor is running.

ARKEL 5 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

1.3 INTENDED USE

The ARKEL ARS Cx/Dx is a state-of-the-art traction machine developed in compliance with the latest

technical standards and safety regulations. It may be used only in accordance to the instructions in this

manual and with all the relevant safety devices described. ARKEL shall not accept any warranty or

liability claims for personal injury or property damage resulting from the following causes:

• Improper use of the traction machine

• Improper installation, operation and/or maintenance of the traction machine

• Operation of the traction machine without the relative protection and safety devices

• Using the product not in accordance with the instructions given in this manual

• Unauthorized changes made to the traction machine

• Insufficient monitoring of parts subject to wear or failure to perform scheduled maintenance

• Emergencies or situations caused by external forces or force majeure

1.4 PACKING AND HANDLING

When handling the traction machine, only the methods described below may be used. Always make

sure that the rated capacity of the transport and lifting apparatus is sufficient to carry the weight of the

machine and its packing.

• Transport on pallet.

• Transport without pallet, lifting by hook.

The personnel in charge of handling the machine must wear

safety gloves and shoes. Clear the operating area before lifting

or moving the machine or any part of it. Also, provide an

adequate safety margin around the working area to prevent

damages to nearby persons or property. The machine is

delivered packed in a wooden box or crate for protection

against bumps or external agents. Use a forklift to lift the

machine (see figure).

• Follow the instructions printed on the packing before moving or opening the crate.

• To lift the machine use the eyebolts provided. Their location is indicated on the machine.

• Do not attach anything to the motor.

• Observe all the precautions that apply to “suspended loads”.

When moving the machine, follow all the relevant safety rules and regulations, taking into

account the load’s weight and its proper balancing.

Four eyebolts are provided to facilitate handling. The eyebolts are designed to carry the

weight of the traction machine itself only. Additional loads are not allowed.

ARKEL 6 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

1.5 STORAGE

Store the machine in a closed, dry, dust-free, well-ventilated place free from vibrations.

The storage temperature should be between -20°C and 60°C.

Do not store the traction machine in the open and/or in places exposed to the elements.

Avoid excessive storage periods (recommended: max. 1 year).

After prolonged periods of storage (more than 3 months), make the motor run at low speed

(less than 20 rpm) to redistribute the lubricating grease inside the bearings.

Measure the windings’ insulation resistance before starting the machine after a prolonged

period of storage. If the resistance has dropped below 1MΩ, the windings will have to be

dried or placing the motor in a warm dry atmosphere for a few hours or until the insulation

value rises > 1MΩ (Insulation meter voltage: 500V DC).

2. PRODUCT DESCRIPTION

2.1 MAIN FEATURES

The ARKEL ARS Cx/Dx units are gearless traction machines designed for operating lifts (elevators).

They can be installed directly inside the lift well and do not require a dedicated machine room. Thanks

to their compact dimensions and design concept - based on the projection of the traction sheave - they

allow very good size-to-power ratios. These machines are mainly designed to be installed at the top of

the lift well, where their small size makes it easy to arrange the various machine parts.

These traction machines are equipped with permanent-magnet synchronous motors, allowing excellent

performances in terms of:

• Low noise levels

• High energy efficiency

• High dynamic performance and optimal control of motion profiles

• High power-to-weight and torque-to-weight ratios

Being equipped with high-quality shielded bearings with life lubrication and having no parts that work

by friction, these machines require very little maintenance.

Feedback for the traction machine is provided by a high-quality encoder which, used in combination

with a frequency regulator, allows sophisticated motion control and accurate management of the car’s

position within the entire speed range.

Special attention was given to sizing the electromagnetic section, which was optimized by finite-

element analyses to achieve excellent performance in terms of torque and low-speed ripple reduction.

Their advanced design and the quality of the construction materials contribute to place ARS Cx/Dx

units among the sturdiest and most reliable traction machines.

ARKEL 7 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

2.2 MACHINE NAME DETAILS

This section explains the meaning of the designation given to the traction machine (shown as “Type”

in the nameplate). This designation always appears on the nameplate of the machine (see section 2.6).

ARS D1 240 800 10B 5,5kW 13A

ARKEL MACHINE TRACTION MAX CAR SPEED RATED RATED

SYNCHRONOUS SIZE SHEAVE PAYLOAD ROPING POWER CURRENT

MACHINE DIAMETER [kg] 10 = 1.0m/s [kW] [A]

[mm] B = 2:1

2.3 TECHNICAL DATA

All ARS Cx/Dx traction machines are equipped with 24 or 30 poles permanent-magnet motors. The

main technical details of the traction machines are summarized in the table below:

Max. Roping Rated Speed Traction Max. ropes x Max.

Type of machine payload torque [m/s] sheave diameter static

#

[kg] [Nm] [Ø, mm] [n° x Ø mm] load

[kN]

ARS-C1-240-320-16B-

1 320 2:1 140 1,6 240 4x6,5 20

3.7KW-8.1A

ARS-C2-210-630-16B-

2 630 2:1 200 1,6 210 6x6,5 20

6.6KW-14A

ARS-C3-210-800-10B-

3 800 2:1 250 1,0 210 7x6,5 20

4.8KW-11.5A

ARS-C3-210-800-16B-

4 800 2:1 250 1,6 210 7x6,5 20

8.2KW-17A

ARS-D1-240-800-10B-

5 800 2:1 330 1,0 240 7x6,5 26

5.5KW-13A

ARS-D1-240-800-20B-

6 800 2:1 330 2,0 240 7x6,5 26

11KW-24.6A

ARS-D2-240-1000-10B-

7 1000 2:1 480 1,0 240 7x6,5 26

8KW-18.1A

ARS-D2-240-1000-20B-

8 1000 2:1 480 2,0 240 8x6,5 26

16.1KW-34.9A

ARS-D3-320-1250-20B-

9 1250 2:1 660 2,0 320 8x8 32

16.6KW-37.8A

ARS-D3-320-1250-25B-

10 1250 2:1 660 2,5 320 8x8 32

20.7KW-45.7A

ARS-D1-240-800-16B-

11 800 2:1 330 1,6 240 7x6,5 26

8.8KW-20.7A

ARS-D2-240-1000-16B-

12 1000 2:1 480 1,6 240 8x6,5 26

12.8KW-29.2A

ARS-D3-320-1250-16B-

13 1250 2:1 660 1,6 320 8x8 32

13.2KW-31.4A

ARKEL 8 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

2.4 ENCODER

All ARS Cx/Dx traction machines are equipped with an encoder having the following features:

Supply voltage

Type of encoder Interface

[Vdc]

HOHNER SMRS64-12102312-13 SSI + 2048 Sin/Cos 5

See section 4.4 for electrical connection of the encoder.

2.5 BRAKE

All ARS Cx/Dx traction machines are equipped with a brake having the following features:

Type of brake Max. braking torque Coil Power Micro-switch

[Nm] voltage consumption [n°]

[Vdc] [W]

ALZOLA EVO-01FRLF140 2x140 2x62

ALZOLA EVO-01FRLF200 2x200 2x62

ALZOLA EVO-01FRLF250 2x250 2x62

ALZOLA EVO-02FRLF330 2x330 207 2x85 2

ALZOLA EVO-02FRLF480 2x480 2x85

ALZOLA EVO-03FRLF660 2x660 2x140

ALZOLA EVO-04FRLF900 2x900 2x185

See section 4.3 for electrical connection of the brake.

2.6 NAMEPLATE DATA

In compliance with the Machinery Directive, ARS Cx/Dx traction machines are provided with a

nameplate with details of the basic information required for the use of the machine. The following is

an example of the details of a machine nameplate:

Type of machine

Serial no.

Number of phase

Connection type Rated torque

Traction sheave

Rated power

diameter (Ø)

Rated voltage

Number of poles

Rated current

Insulation class

Rated frequency

Duty

Rated speed Degree of Weight Month/year

protection of production

ARKEL 9 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

3. INSTALLATION

3.1 SAFETY PRECAUTIONS

Make sure that all the prescribed safety measures have been applied before installing the

traction machine.

Before proceeding to install the machine, check the installation base and make sure it is

adequately sized. If it is not, do not install the machine.

The traction machine may be installed and electrically connected only by qualified and

trained technical personnel.

Bear in mind that ARS Cx/Dx traction machines are designed to be installed at the top of the

lift well, where the space is restricted and working conditions are not comfortable.

The encoder is located at the back of the machine; leave enough working space between the

machine and the wall to replace the encoder.

3.2 FASTENING THE TRACTION MACHINE

Fasten the ARS Cx series machine to the base using 4 pcs M16 bolts having strength class

12.9. The tightening torque for this class is 300Nm.

Fasten the ARS Dx series machine to the base using 4 pcs M20 bolts having strength class

12.9. The tightening torque for this class is 600Nm.

In order to reduce vibrations, place a rubber mat between the machine and the base.

The maximum allowed deviation from planarity for the supporting surface is 0.2mm.

Make sure the base is solid and adequately sized. If it is not, do not install the traction

machine.

The load applied by the ropes on the traction machine should have no lateral components in

order not to apply a shearing stress on the fastening bolts. The maximum allowed deviation

from verticality is 10°.

Place the ropes on the traction sheave only after fastening the machine and engaging the

brake.

The traction machine is equipped with 2 pieces rope slip-off guard. After placing the ropes,

set the guard at a distance from the rope of no more than 1.5mm.

ARKEL 10 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

4. ELECTRICAL CONNECTIONS

4.1 GENERAL

The traction machine may be electrically connected only by qualified personnel.

After connecting the machine and before using it in any way, check the electrical insulation

of the terminal box and the operating panel.

Before making any connections, make sure that:

• The connection cables are suitable for their specific application in terms of voltages

and currents.

• The cables are correctly installed and not susceptible to twisting, tensile or shearing

strains that might affect their characteristics.

• The protective conductor has Protection Class 1 and is properly connected to the

earthing system.

• There is no foreign matter or dirt inside the terminal box.

• The terminal box is properly sealed and the cable passages prevent the entry of dirt or

dust.

• The motor insulation system is adequately sized for connection to frequency

regulators by DC bus having a maximum voltage of 800V.

• The maximum acceptable rate of voltage rise (dU/dt) for the motor is 4kV/us. In case

that value is exceeded, suitable reactors should be introduced in the inverter-motor

connection.

• The maximum acceptable overvoltage at the machine’s terminals is 1.3kV.

ARKEL 11 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

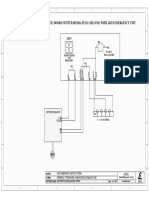

The figure below shows the general wiring diagram of the motor, the PTC thermal circuit-breaker and

the brake. These connections are made in the terminal box after removing the terminal box cover.

Inside the terminal box cover there is a figure of the connection diagram shown below.

Motor Connections Brake Connections

Colors of cables used inside

the machine:

U Red

V Blue

W Black

PE Yellow-Green

840A/B Brown

2000A/B Blue

100 Red

BRC/BRC2 Black

T1 Blue

T2 White

ARKEL 12 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

4.2 CONNECTING THE MOTOR

The electrical connections to the motor phases and the connection to the winding temperature

sensor (PTC 140°C) are shown inside the terminal box.

The connection cable for the phases and the protective conductor must have a cross-section

suitable for the rated current of the machine as outlined in the table below.

Cross-section Max. rated current S3-40%

[mm2] [A]

1 20

1,5 24

2,5 35

4 42

DATA REFERRED TO PVC SHIELDED CABLES AT MAX. AMBIENT TEMPERATURE

OF 40°C.

We recommend using oil-resistant, flame-resistant, shielded power cables for brushless

motors, with PVC sheathing and designed for fixed laying.

The motor cable must be a shielded cable with 3 poles + earth + shielding.

Make sure the cable terminations are fitted with the right terminals for connecting to the

terminal box.

Make sure the U, V, W connection order on the motor is the same as on the inverter output. If

this order is not respected the traction machine will not operate correctly, causing inverter

failure.

For safety reasons it is very important to properly connect the earth cable.

Connect the shield properly to the earth terminal located in the terminal box.

When connecting the temperature sensors (PTC) to the control panels, make sure that no more

than 2.5V voltage is applied to the PTC terminals.

ARKEL 13 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

4.3 CONNECTING THE BRAKE

The traction machine is delivered without a separate power supply for the brake. The power

supply for the brake must be provided by the user/installer.

The electrical connections for the brake’s power supply and the two microswitches are shown

inside the terminal box.

The brake voltage is 207V DC.

To reduce noises and electric arcs during brake release, the brakes should be switched-off from

the AC side during normal operation. In this way the brakes are switched-off slower and thus

quieter. To ensure instantaneous and faster brake engagement in emergencies, inspection,

recall and manual rescue operations, the brakes should be switched-off from the DC side.

A suitable varistors must be used to filter the instantaneous high-voltage peaks on the brake

coils.

Do not apply a voltage higher than 30V DC, 100mA to the brake microswitches.

The microswitches which are monitoring correct operation of the brakes should be connected

properly and should not be disabled.

Connection of the brake microswitches is made through normally closed (NC) contacts inside

the terminal box.

Make sure the cable terminations are fitted with the right terminals for connecting to the

terminal box.

See the relative section in the brake manual for further details.

ARKEL 14 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

4.4 CONNECTING THE ENCODER

ARS Cx/Dx traction machines are equipped with the following encoder:

HOHNER SSI + 2048 Sin/Cos

The encoder connection cable is located at the back of the traction machine.

The encoder connection cable is supplied without a connector.

Make sure that the encoder cable does not pass close to the motor and brake connection

cable, in order to avoid disturbances that would interfere with the position measuring system.

Due to the nature of permanent-magnet synchronous machines, the absolute position of the

encoder relative to the pulley shaft must be individually determined on each traction

machine. For further details please refer to the commissioning manual of the drive system

installed.

The encoder is the most delicate part of the traction machine. Be careful not to bump the

encoder against hard objects during handling, fastening or commissioning.

When positioning the traction machine, bear in mind that the encoder can be accessed only

from the back of the machine. Be sure to leave enough space to service or replace the

encoder.

The encoder connections are shown below.

4.4.1 ENCODER CONNECTION TABLE

Encoder cable signal-color and connection to ARKEL ADrive / ARCODE devices are as shown in the

following table.

ADrive ARCODE

Cable signal Cable color

(ENCABIT-Plus) (ENCA)

VCC Brown 5V 5V

GND White 0V 0V

A+ Red A+ A

A- Blue A- A

B+ Black B+ B

B- Violet B- B

CLOCK+ Yellow CL+ CL

CLOCK- Green CL- CL

DATA+ Pink DA+ DA

DATA- Gray DA- DA

DIR/RESET Red-Blue

Shielding Shielding

ARKEL 15 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

4.4.2 REPLACING THE ENCODER

Replace the encoder only if absolutely necessary due to an encoder fault or malfunction.

Before installing the replacement encoder make sure it is entirely interchangeable with the previous

one.

When installing a new encoder, the offset value needs to be adjusted with a specific procedure that

depends on the type of inverter (auto-tuning).

DISMOUNTING THE ENCODER

The encoder can be accessed only from the back of the machine. The encoder cable is fixed to the

encoder. To dismount the encoder, follow the steps below:

1) Remove the screw cap that functions as a protection.

2) Unscrew the M5x60 screw from machine shaft.

3) Loosen the encoder shaft coupling screw.

4) Thread the M6x55 screw and dismount the encoder.

Encoder Encoder

M5 x 60

screw M6 x 55

screw

M2,5

MOUNTING THE ENCODER

To ensure the encoder’s proper installation and operation, it is essential to apply the tightening torques

shown in the figure below (use a torque wrench).

1) Remove the screw cap that functions as a protection.

2) Place the encoder on the motor shaft.

3) Fix the encoder to motor shaft with M5x60 screw (5-5,5Nm).

4) Check the linearity with a dial indicator (<=0.2mm).

5) Tighten the encoder shaft coupling screw (0,7-0,8Nm).

6) Put back the screw cap.

Dial

indicator

M5 x 60

screw

Encoder

Encoder 6)

M2,5

ARKEL 16 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

5. TESTING THE BRAKE SYSTEM (in accordance with EN 81-20/50)

When testing the brake the car should be placed at approximately half the height of the lift

well.

Before testing the brake, the elements that short-circuit the motor windings (e.g. contactor

contacts) can be deactivated. So the effect of the brake will only be tested.

This test may be performed only by qualified specialist personnel and in strict accordance with

EU directives, national regulations and with particular reference to standard EN 81-20/50 and

any other relevant regulation.

5.1 DOUBLE BRAKE TEST (OVERLOAD TEST)

EN 81-20: “This brake on its own shall be capable of stopping the machine when the car is travelling

downward at rated speed and with the rated load plus 25%.”

Test the brake in the following conditions:

1) Car is loaded equal to 125% the rated load,

2) Downward travel,

3) Travelling at rated speed,

4) Power supply of the motor and both brake coils are switched-off at the same time.

In these conditions, the retardation of the car shall not exceed that resulting from operation of the

safety gear or stopping on the buffer.

5.2 SINGLE BRAKE TEST (BRAKE FAILURE TEST)

EN 81-20: “It shall be verified by practical tests that where one brake set is not working a sufficient

braking effort is exerted to decelerate the car, travelling downwards at rated speed and with rated

load.”

Test the brake in the following conditions:

1) Car is loaded equal to rated load,

2) Downward travel,

3) Travelling at rated speed,

4) Power supply of the motor and the single brake coil that is to be tested are switched-off at the

same time (the other brake set which is not tested must be kept open).

The test shall be performed separately for both brake sets.

For the test operation, the control panels must have suitable switch/button circuits.

It shall be possible to test each brake set independently from outside of the well.

During the test, the lift should continuously be monitored and if no deceleration is observed

the single brake set which is kept open must be closed immediately!

5.3 BRAKE MICRO-SWITCH/MONITORING TEST

Check the brake monitoring switches individually. No car travel must be permitted if a micro-switch

signal is missing or a wrong signal operates.

ARKEL 17 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

6. MAINTENANCE

The rules concerning safety, inspections and maintenance in accordance with EU directives and

national regulations, with particular reference to standard EN 81-20/50, EN 13015 and other relevant

regulations must be strictly followed.

The operator is responsible for the proper installation of the traction machine and for the full

application of the rules concerning safety, inspections and maintenance.

In particular, inspections and maintenance must be carried out only by qualified, specialist personnel

trained on working with this kind of traction machine, especially considering its intended use.

Any replacement on the traction machine must be done following the instructions and making sure that

any nuts and bolts are replaced with parts belonging to the same strength class.

6.1 MAINTENANCE PROGRAM

Description and frequency of operations to perform in order to maintain the traction machine at full

efficiency:

MAINTENANCE OPERATION INTERVAL

Check the brake air gap Every 6 months

Check the functioning of the brake and of the brake monitoring switches Every 6 months

Check the bearing noise Every 6 months

Check the conditions of the grooves on the sheave Every 6 months

Check the strength class and conditions of the screws and bolts on the

Every 6 months

sheave and the base

Check the conditions of the electric cables and wires Every 6 months

Check the rope slip-off guard Every 6 months

Check the general safety devices installed Every 6 months

Clean the outer surface of the machine and the brake As necessary

6.2 SAFETY PRECAUTIONS DURING MAINTENANCE

The following are the main precautions to take when carrying out maintenance on the machine:

Disconnect the power supply before removing any protective panel or replacing any component.

Do not wear rings, watches, chains, bracelets, etc., when performing maintenance.

Always wear personal protective equipment (gloves and shoes).

Do not use open flames, pins or sharp objects for cleaning.

Do not smoke.

Some parts of the machine can become very hot during operation (70/80°C). Therefore, it is

MANDATORY to ensure that nobody can accidentally touch these parts for maintenance or

repairs before a period of time sufficient for the parts to cool down to temperatures suitable for

direct contact.

IT IS EXTREMELY DANGEROUS TO PUT YOUR HANDS near the traction sheave or the

car lifting ropes when unprotected.

ARKEL 18 ARS Cx/Dx

ARKEL Elektrik Elektronik San. ve Tic. A.Ş. www.arkel.com.tr

6.3 TROUBLESHOOTING

FAULT/

POSSIBLE CAUSE POSSIBLE REMEDY

MALFUNCTION

Motor does not 1) Incorrect phase connection order 1) Connect motor correctly.

start, does not (U, V, W) between motor and drive. 2) Connect encoder correctly.

respond or develops 2) Encoder not properly connected. 3) Check inverter parameterization.

4) Check connection of cable shielding and earth

no torque. 3) Incorrect inverter

terminal as required by inverter manual. Avoid running

parameterization (e.g., number of power cables next to encoder cable for long tracts.

poles, etc.). 5) Check offset angle set on the inverter; if necessary,

4) Electromagnetic interferences readjust offset value following the required procedure

with encoder cables. (this operation depends on the type of inverter installed,

5) Incorrect encoder offset angle setand should be carried out with no ropes on the sheave

on inverter. and the brake released).

6) Replace encoder, readjust offset on machine and

6) Faulty encoder.

update offset value on machine.

Motor noise. 1) Faulty or worn bearings. 1) Contact customer service.

2) Incorrect inverter 2) Check inverter parameterization.

parameterization. 3) Replace encoder after checking conditions of

3) Faulty encoder. connection cable.

Brake makes loud 1) DC side switching of the brake in 1) Change over to brake control by AC side switching

noise during normal operation. in normal operation

switching. 2) Brake air gap too large. 2) Can be caused to abnormal wear of brake lining due

to non-coordination between brake dropping time and

torque release time. Check air gap, adjust brake

operating times.

Braking torque too 1) Dirt, grease or oil on friction 1) Clean and dry friction surfaces.

low. surfaces. 2) Remove foreign bodies.

2) Foreign bodies inside the brake. 3) Restore system unbalance and torque to allowable

3) Load torque too high. values.

4) Brake non completely de- 4) Check zero voltage on brake terminals; check

energized. electrical connection.

Brake does not 1) Brake is not powered. 1) Check electrical connection.

release. 2) Brake magnet voltage too low. 2) Check brake supply voltage

3) Brake rectifier defective. 3) Check brake supply voltage. If necessary replace

4) Brake is mechanically blocked. brake rectifier.

4) Contact customer service.

Delay in brake Brake rectifier defective. Replace brake rectifier.

release.

Brake does not Brake mechanically blocked. Contact customer service.

engage.

Delay in brake Brake closing time is too long due to Ensure that brake is switched-off from the AC side in

engage. Switching-off only from the AC normal operation and from the DC side in

side. emergency/manual operation.

ARKEL 19 ARS Cx/Dx

You might also like

- John Deere 1640, 1840, 2040, 2040s Tractors Service Technical ManualDocument22 pagesJohn Deere 1640, 1840, 2040, 2040s Tractors Service Technical Manualkabalkabal56% (9)

- Manual Troubleshotting Hitachi ZW 310Document506 pagesManual Troubleshotting Hitachi ZW 310Tomas HP67% (3)

- FSI King Air C90GTi Pilot Training Manual FullDocument557 pagesFSI King Air C90GTi Pilot Training Manual FullAnders Mard100% (2)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Arkel ArLine User Manual.V123.EnDocument33 pagesArkel ArLine User Manual.V123.EnPaul DiazNo ratings yet

- DB460 Use & Maintenance ManualDocument252 pagesDB460 Use & Maintenance ManualJustice MachiwanaNo ratings yet

- Pa44 Fact SheetDocument8 pagesPa44 Fact SheetPatrick HerreraNo ratings yet

- Tools 3500 CaterpillarDocument22 pagesTools 3500 CaterpillarAsaad L Hassan100% (15)

- S053-PPT - Mobile Elevated Work Platforms REVDocument71 pagesS053-PPT - Mobile Elevated Work Platforms REVAisha KhanNo ratings yet

- Mik-El Elektronik San. Tic. Ltd. Şti.: Operation Manual of MD-2012 Speed Regulator For Elevator ApplicationDocument37 pagesMik-El Elektronik San. Tic. Ltd. Şti.: Operation Manual of MD-2012 Speed Regulator For Elevator ApplicationmustafaNo ratings yet

- Manual Bluelight Bl6-UDocument238 pagesManual Bluelight Bl6-UYok Mulyono100% (2)

- AREM Hardware Manual.V110.EnDocument3 pagesAREM Hardware Manual.V110.Enmicrocheriet100% (1)

- ARCODE Error Descriptions V11.EnDocument15 pagesARCODE Error Descriptions V11.EnKs Bharathiyar100% (9)

- AKUS & Wittur Hydra Plus - Selcom Door Connection DiagramDocument1 pageAKUS & Wittur Hydra Plus - Selcom Door Connection Diagramsulthan1975100% (1)

- Manual IV5 ENG V1.0 160218 PDFDocument277 pagesManual IV5 ENG V1.0 160218 PDFyounesNo ratings yet

- Royal Dutch Shell SWOT Analysis (BSP Group 4)Document6 pagesRoyal Dutch Shell SWOT Analysis (BSP Group 4)Bogdan ManoleNo ratings yet

- List A To Z TransportationDocument6 pagesList A To Z TransportationSyauqi ZamryNo ratings yet

- Arcode: Hizli Kurulum KilavuzuDocument34 pagesArcode: Hizli Kurulum KilavuzuMDR 8434No ratings yet

- Wiring For Arcode Elevator Control SystemDocument12 pagesWiring For Arcode Elevator Control SystemAhmed100% (1)

- Schaefer VVD Flyer Arkel Arcode enDocument2 pagesSchaefer VVD Flyer Arkel Arcode enadda chariNo ratings yet

- AREM Buttons and Descriptions.V100.EnDocument3 pagesAREM Buttons and Descriptions.V100.EnRadenko SkoroNo ratings yet

- ARCODE Compatible Absolute Encoders.V150.EnDocument3 pagesARCODE Compatible Absolute Encoders.V150.EnSaighi HamzaNo ratings yet

- Firmware Updater Manual v13Document11 pagesFirmware Updater Manual v13paul5791No ratings yet

- Arcode Controller PID Gain Settings - En-V1.1Document12 pagesArcode Controller PID Gain Settings - En-V1.1مصطفى البياتيNo ratings yet

- Arem Mobile User Manual.V101.enDocument8 pagesArem Mobile User Manual.V101.enmicrocherietNo ratings yet

- Gearless SerialDocument38 pagesGearless SerialKrishan singhNo ratings yet

- Arcode Pit Entry Reset Procedure.V110.enDocument3 pagesArcode Pit Entry Reset Procedure.V110.enAhmedNo ratings yet

- ADrive MANUAL For Elevator PDFDocument80 pagesADrive MANUAL For Elevator PDFAssir El Djazairi50% (2)

- n0 - ARCODE Parameter Reference V11.enDocument75 pagesn0 - ARCODE Parameter Reference V11.enمحمد حسين100% (2)

- ISTRUZDocument32 pagesISTRUZhziarabNo ratings yet

- KM-10 User Guide.V111.enDocument18 pagesKM-10 User Guide.V111.enSalah SalahNo ratings yet

- ADrive & Lift Controllers Connection PrincipleDocument1 pageADrive & Lift Controllers Connection Principlesulthan1975No ratings yet

- Arl-200 & Adrive Connection DiagramDocument1 pageArl-200 & Adrive Connection Diagramthanggimme.phanNo ratings yet

- Arcube Quick Installation Guide V10.enDocument21 pagesArcube Quick Installation Guide V10.enducthangbk100% (2)

- Reference Manual: INR-SI47-1909-EDocument246 pagesReference Manual: INR-SI47-1909-EAtaur RahamanNo ratings yet

- Arcode Quick Installation Guide.V210.EnDocument27 pagesArcode Quick Installation Guide.V210.EnFidan LatifiNo ratings yet

- Arcode Quick Install enDocument22 pagesArcode Quick Install enAhmed67% (3)

- Akus-Sd Combi User Manual v12Document20 pagesAkus-Sd Combi User Manual v12Ahmad Hamouda100% (3)

- KM 10Document18 pagesKM 10microcheriet100% (1)

- Arcode Operations.V150.enDocument10 pagesArcode Operations.V150.enMohammed Qaid Alathwary100% (1)

- Arl-300 Electrical Diagrams V15Document112 pagesArl-300 Electrical Diagrams V15MajidKholadi100% (1)

- G&Z SD Card Reconfiguration - V1.1 - enDocument8 pagesG&Z SD Card Reconfiguration - V1.1 - enAbenetherNo ratings yet

- Arcode Param Ref ManDocument41 pagesArcode Param Ref ManAhmed67% (3)

- Startup VDL200 Geared EngDocument7 pagesStartup VDL200 Geared EngSamih AlraghbanNo ratings yet

- Arl 200sDocument12 pagesArl 200sNenad Simonović75% (8)

- PU3200 English ManualDocument71 pagesPU3200 English Manualعلاء صقرNo ratings yet

- PDF Arcode Error Descriptions V20en - Compress PDFDocument37 pagesPDF Arcode Error Descriptions V20en - Compress PDFhoangvanxuanNo ratings yet

- Documents - Tips - Arl 100 User Manual v21 PDFDocument16 pagesDocuments - Tips - Arl 100 User Manual v21 PDFyounesNo ratings yet

- ARCODE Firmware Update V21.enDocument7 pagesARCODE Firmware Update V21.enaissa lakehal0% (1)

- 3-FRENIC Lift PDFDocument48 pages3-FRENIC Lift PDFMoran Martines100% (1)

- Arl-100 Electrical Diagrams v10Document57 pagesArl-100 Electrical Diagrams v10mahfoud ascenseursNo ratings yet

- Arkel Arlift Arline English MailDocument5 pagesArkel Arlift Arline English MailRana SahabNo ratings yet

- ARCODE EN81-21 Reset Instructions.V110.EnDocument3 pagesARCODE EN81-21 Reset Instructions.V110.EnSaighi HamzaNo ratings yet

- Arl-500 Programming Manual v18Document137 pagesArl-500 Programming Manual v18Anoop KumarNo ratings yet

- Car Connection Diagram PDFDocument1 pageCar Connection Diagram PDFHenri KleineNo ratings yet

- ARL-300 & ADrive Relevelling For Electric Lifts - en PDFDocument4 pagesARL-300 & ADrive Relevelling For Electric Lifts - en PDFHenri Kleine100% (2)

- Mikrolift: CAUTION: These Cables Must Be 2,5mm NYAF !Document19 pagesMikrolift: CAUTION: These Cables Must Be 2,5mm NYAF !Dmitriy ShevchenkoNo ratings yet

- ARL500 Error Messages ENG V19Document6 pagesARL500 Error Messages ENG V19Henri KleineNo ratings yet

- Arcode Control System Offer Request / Ordering Form:::: VAC (Phase To Phase) A BDocument2 pagesArcode Control System Offer Request / Ordering Form:::: VAC (Phase To Phase) A BNour BenNo ratings yet

- Bl2000 BHT V22english Two SpeedDocument55 pagesBl2000 BHT V22english Two SpeedhabibullaNo ratings yet

- Liftsense User Manual.V135.enDocument6 pagesLiftsense User Manual.V135.enEdhem SmailbegovićNo ratings yet

- ARL-200S: Lift ControllerDocument12 pagesARL-200S: Lift ControllerWesam Wesam100% (1)

- User Guide NICE900 Series Integrated Door Operator ControllerDocument99 pagesUser Guide NICE900 Series Integrated Door Operator ControllerCoil98No ratings yet

- InvDocument5 pagesInvKs Bharathiyar100% (1)

- ARKEL Vision Setup and User Manual V14Document18 pagesARKEL Vision Setup and User Manual V14paul5791100% (1)

- U-STO Parameter Manual V1.02 EngDocument36 pagesU-STO Parameter Manual V1.02 EngYacine Mariche100% (1)

- ARS CX-DX User Manual.V150.enDocument14 pagesARS CX-DX User Manual.V150.enNora HotelNo ratings yet

- EVD Evolution Twin: User ManualDocument68 pagesEVD Evolution Twin: User ManualcamdentownNo ratings yet

- User Manual: Μrack Standard Compressor Racks Single/Two CircuitDocument44 pagesUser Manual: Μrack Standard Compressor Racks Single/Two CircuitChí Khang NguyễnNo ratings yet

- ArdDocument1 pageArdyounesNo ratings yet

- Explanation For The Terminals On ARL-200S Control Card:: Short-Circuit With JumperDocument1 pageExplanation For The Terminals On ARL-200S Control Card:: Short-Circuit With JumperyounesNo ratings yet

- ServosanDocument4 pagesServosanyounesNo ratings yet

- Certificate ATLAS 2 1 EC Rev.5Document19 pagesCertificate ATLAS 2 1 EC Rev.5younesNo ratings yet

- Stratos User Manual 2017Document35 pagesStratos User Manual 2017younesNo ratings yet

- Modernisation Kits: A3 / EN81-21 / Transformation / Cabin MaximisationDocument5 pagesModernisation Kits: A3 / EN81-21 / Transformation / Cabin MaximisationyounesNo ratings yet

- Loher Dynasys SDocument39 pagesLoher Dynasys SyounesNo ratings yet

- Gearless Xaf: Installation and MaintenanceDocument44 pagesGearless Xaf: Installation and MaintenanceyounesNo ratings yet

- EmaykatalogDocument12 pagesEmaykatalogyounesNo ratings yet

- Falezyum Residence Mod TeklifiDocument7 pagesFalezyum Residence Mod TeklifiyounesNo ratings yet

- p11 Engspec Feca Te 106aDocument5 pagesp11 Engspec Feca Te 106ayounesNo ratings yet

- PM 2 000354 en 01Document32 pagesPM 2 000354 en 01younesNo ratings yet

- Zeus User's ManualDocument117 pagesZeus User's ManualyounesNo ratings yet

- Summary eDocument16 pagesSummary eyounes100% (1)

- Elevator Installation Guide PDFDocument12 pagesElevator Installation Guide PDFyounesNo ratings yet

- Galaxy IV Manual m1000 AcDocument318 pagesGalaxy IV Manual m1000 AcyounesNo ratings yet

- Manual IV5 ENG V1.0 160218Document16 pagesManual IV5 ENG V1.0 160218younesNo ratings yet

- 01 Escalator Sec1Document48 pages01 Escalator Sec1younesNo ratings yet

- CM1000 ManualDocument12 pagesCM1000 ManualyounesNo ratings yet

- Ett-6 PD enDocument2 pagesEtt-6 PD enyounesNo ratings yet

- Xj-Siemens Solaris Passenger ElevatorDocument24 pagesXj-Siemens Solaris Passenger Elevatoryounes100% (2)

- Kenwood - Sigma-Drive Technical GuideDocument24 pagesKenwood - Sigma-Drive Technical Guideyounes100% (2)

- Pms Levage CableDocument15 pagesPms Levage CableyounesNo ratings yet

- Breaker DMB250Document3 pagesBreaker DMB250ALI RAZAVINo ratings yet

- Know Your Cooling SystemDocument115 pagesKnow Your Cooling SystemDeividas B100% (1)

- 04 6001 1100Document1 page04 6001 1100Gm IqbalNo ratings yet

- 7 - Periodic Maintenance Schedule P400Document2 pages7 - Periodic Maintenance Schedule P400zainahmedscribdNo ratings yet

- C1 - 중국- 철강 홍보자료 - EDM - 4급 - v0.1Document62 pagesC1 - 중국- 철강 홍보자료 - EDM - 4급 - v0.1Vinh Chu VănNo ratings yet

- English 02: Unit 3 - TransportDocument21 pagesEnglish 02: Unit 3 - Transportqui25252525No ratings yet

- 3M Series 05 Spray Gun Owner's Manual Series 05 de 3M Pistola Aplicadora en Spray Manual Del UsuarioDocument22 pages3M Series 05 Spray Gun Owner's Manual Series 05 de 3M Pistola Aplicadora en Spray Manual Del UsuarioJavier Berríos AvilésNo ratings yet

- Session25-Effective Quality Management of Automotive ECUDocument27 pagesSession25-Effective Quality Management of Automotive ECUMuhammad Mubeen KhanNo ratings yet

- Ot5304 Subsea Construction & Operational Support Assignment 1 Research of Autonomous Underwater Vehicles TechnologiesDocument40 pagesOt5304 Subsea Construction & Operational Support Assignment 1 Research of Autonomous Underwater Vehicles TechnologiesWeilun OngNo ratings yet

- Highlights ESI (Tronic) 2.0 Vehicle Coverage ESI (Tronic) 2.0 UpdatesDocument2 pagesHighlights ESI (Tronic) 2.0 Vehicle Coverage ESI (Tronic) 2.0 UpdatesYogendra DwivediNo ratings yet

- K11 DF100 115 140 99011 90J11 03aenDocument57 pagesK11 DF100 115 140 99011 90J11 03aenBrunoDondaNo ratings yet

- Edited - Capstone Project Proposal Draft Armand DeuDocument6 pagesEdited - Capstone Project Proposal Draft Armand Deuapi-690863028No ratings yet

- Shell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsDocument2 pagesShell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsWajahat RasoolNo ratings yet

- Mock Test 1Document18 pagesMock Test 1LOETOENo ratings yet

- Hydraulic - Steering - Semi-Platform MF4708Document54 pagesHydraulic - Steering - Semi-Platform MF4708krisnaNo ratings yet

- Hyundai - Hl757 - 7aDocument550 pagesHyundai - Hl757 - 7aRealmac Assistência50% (2)

- 45 Rally Islas Canarias European Rally Championship Entry ListDocument2 pages45 Rally Islas Canarias European Rally Championship Entry ListJohn SmithNo ratings yet

- P1271 - Fault FindingDocument11 pagesP1271 - Fault FindingGarage76 Automotive100% (1)

- 7FBR10 FichaDocument23 pages7FBR10 FichaJhon WilliamsNo ratings yet

- Check First Aid KitDocument3 pagesCheck First Aid Kitx7c56d5zy8No ratings yet

- Benefits of Solar EnergyDocument22 pagesBenefits of Solar EnergyVinith GopalakrishnanNo ratings yet