0 ratings0% found this document useful (0 votes)

L300 Calibration

L300 Calibration

Uploaded by

jujuroyaleMass Spectrometer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

L300 Calibration

L300 Calibration

Uploaded by

jujuroyale0 ratings0% found this document useful (0 votes)

Mass Spectrometer

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Mass Spectrometer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

L300 Calibration

L300 Calibration

Uploaded by

jujuroyaleMass Spectrometer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1/ 10

INSTRUCTIONS

L300 AND PROCAL

CALIBRATION SYSTEM

(PROBE + PROBE PUMP + LONG HOSES)

Ref: CD02.02.06 Issue 2

1300 Operation Procedure

(PROBE + PROBE PUMP + LONG HOSES)

Run up Procedure

fi

ea

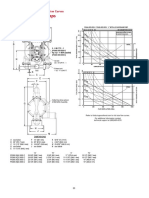

Connect leak detection package as shown in Fig 1.

Connect mains lead to Procal, L300 and Rotary Vacuum Pump

and turn on.

The L300 will take approximately 5 minutes to run up to

standby mode

(a beep will be heard and standby will be displayed). Fig 2.

Press the Start button on the L300 control panel.

The L300 will enter test mode and the display will show the

leak rate and the leak rate unit. Fig 3

The leak detection package is now operational and ready for

calibration.

Calibration Procedure

1

v

Insert the probe into the quick release connection on the front of

the Procal, the flowrate of the probe should be set to

approximately 1200ce/min for optimum performance. Fig 4.

Partially inflate the sample bladder with you calibration gas (1%

He 99% N? recommended).

Connect the sample bladder to the sample bladder inlet.

Open the valve fully on the front of the Procal (this allows a

large helium signal to purge through the Procal) when the L300

reaches a peak signal, back the valve off to read 95-100 seffyr.

Fig 4.

Allow the reading on the L300 to settle, if the leak rate

displayed is the same as shown on the Procal then recalibration

is not necessary.

Ref: CD02.02.06 Issue 2

Remove the probe from the Procal and allow the reading to

settle at its lowest point. This reading is the background signal,

press the zero button on the L300 control panel to ‘zero’ out

this background reading.

If the reading on the L300 does not equal the reading on the

Procal then calibration is required.

Reinsert the probe into the Procal and set the valve to read 100

seffyr.

Press the eal button on the L300. Fig 5.

The display will read ‘please select desired calibration type’ Fig

6. select external to move to the next stage.

Select ‘edit leak rate’ to set the leak rate to 1.0E+2, before

pressing OK ensure that the Procal is still reading 100scf/yr. Fig

7.

Press start button on display (NOT main start/stop button).

The display will read ‘Please press OK if signal stable’. Fig 8.

Ensure reading on control panel is stable then press OK.

The L300 will now autotune. Fig 9.

When ‘sniff air’ is displayed Fig 10, remove the probe from the

Procal and press OK.

The display will read ‘please press ok if signal is stable’ Fig 11.

When the leak rate on the control panel displayed has reached

its lowest point then press OK again to complete calibration.

Press the zero button to zero out any background signal.

Fig 13.

Reinsert the probe into the Procal and check calibration, if

calibration is correct then remove probe from the Procal, leak

detection system is now ready for use. If the leak rate is not

correct then repeat the calibration procedure.

Ref: CD02.02.06 Issue 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good Life4/5 (6052)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You Are4/5 (1142)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On It4.5/5 (916)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space Race4/5 (946)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy Answers4.5/5 (360)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New America4.5/5 (273)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first Century3.5/5 (2283)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True Story3.5/5 (233)

- HYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionNo ratings yetHYD691 Datasheet: Introducing The Hyd691... Standard Materials of Construction4 pages

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1No ratings yetDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev13 pages

- Kinetics of Low Temperature Polyester Dyeing With High Molecular Weight Disperse Dyes by Solvent Microemulsion and Agrosourced AuxiliariesNo ratings yetKinetics of Low Temperature Polyester Dyeing With High Molecular Weight Disperse Dyes by Solvent Microemulsion and Agrosourced Auxiliaries12 pages

- CH 3 Kinematics Analysis of Serial ManipulatorsNo ratings yetCH 3 Kinematics Analysis of Serial Manipulators20 pages

- Allen-Bradley 1783-US5T Switch, Unmanaged, 5 Ports, RJ45 Copper, AC or DCNo ratings yetAllen-Bradley 1783-US5T Switch, Unmanaged, 5 Ports, RJ45 Copper, AC or DC4 pages

- CircuitTheory of ReluctanceMachines - PartIINo ratings yetCircuitTheory of ReluctanceMachines - PartII11 pages

- Valves, Fittings and Tubing: Medium and High Pressure Condensed CatalogNo ratings yetValves, Fittings and Tubing: Medium and High Pressure Condensed Catalog20 pages

- [FREE PDF sample] Introduction to Linear Algebra 2nd edition Edition Whitelaw ebooksNo ratings yet[FREE PDF sample] Introduction to Linear Algebra 2nd edition Edition Whitelaw ebooks67 pages

- JNTU Kakinada - M.Tech - THEORY OF ELASTICITY FRNo ratings yetJNTU Kakinada - M.Tech - THEORY OF ELASTICITY FR1 page

- Automatic Control 4th Year For Power and DesignNo ratings yetAutomatic Control 4th Year For Power and Design74 pages

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768No ratings yetInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 76833 pages

- mtm-2016-8-12 TRUCK MOUNTED CRANES DURING LOAD LIFTING - DYNAMIC ANALYSIS AND REGULATION USING MODELLING AND SIMULATIONSNo ratings yetmtm-2016-8-12 TRUCK MOUNTED CRANES DURING LOAD LIFTING - DYNAMIC ANALYSIS AND REGULATION USING MODELLING AND SIMULATIONS4 pages

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good Life

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You Are

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On It

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space Race

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy Answers

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic Future

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of Cancer

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy Living

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New America

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first Century

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True Story

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham Lincoln

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New Deal

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New America

- HYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionHYD691 Datasheet: Introducing The Hyd691... Standard Materials of Construction

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1

- Kinetics of Low Temperature Polyester Dyeing With High Molecular Weight Disperse Dyes by Solvent Microemulsion and Agrosourced AuxiliariesKinetics of Low Temperature Polyester Dyeing With High Molecular Weight Disperse Dyes by Solvent Microemulsion and Agrosourced Auxiliaries

- Allen-Bradley 1783-US5T Switch, Unmanaged, 5 Ports, RJ45 Copper, AC or DCAllen-Bradley 1783-US5T Switch, Unmanaged, 5 Ports, RJ45 Copper, AC or DC

- Valves, Fittings and Tubing: Medium and High Pressure Condensed CatalogValves, Fittings and Tubing: Medium and High Pressure Condensed Catalog

- [FREE PDF sample] Introduction to Linear Algebra 2nd edition Edition Whitelaw ebooks[FREE PDF sample] Introduction to Linear Algebra 2nd edition Edition Whitelaw ebooks

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768

- mtm-2016-8-12 TRUCK MOUNTED CRANES DURING LOAD LIFTING - DYNAMIC ANALYSIS AND REGULATION USING MODELLING AND SIMULATIONSmtm-2016-8-12 TRUCK MOUNTED CRANES DURING LOAD LIFTING - DYNAMIC ANALYSIS AND REGULATION USING MODELLING AND SIMULATIONS