Prefabricated Strucures

Prefabricated Strucures

Uploaded by

MamthasenaCopyright:

Available Formats

Prefabricated Strucures

Prefabricated Strucures

Uploaded by

MamthasenaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Prefabricated Strucures

Prefabricated Strucures

Uploaded by

MamthasenaCopyright:

Available Formats

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

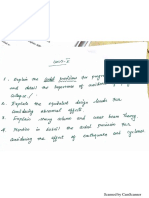

UNIT -1

INTRODUCTION

PART A

1. Define prefabrication.

Prefabrication is the Practice of assembling components of a structure in a factory or other

Manufacturing site and transporting complete assemblies to the construction site where the

structure is to / be located.

2. What is meant by Modular co-ordination?

Modular coordination means the interdependent arrangement of a dimension based on a

primary value accepted as a module. The strict observance of rules of modular coordination

facilitated, 1. Assembly of single components into large components. 2. Fewest possible different

types of component. 3. Minimum wastage of cutting needed

3. What are the characteristics of Modular concept .

I) The basic module is small in terms of add size in order to provide design flexibility , yet

large enough to promote simplification in the component variation in sizes . II) Industry friendly

features that not only for manufacturing but also the transportation and assembly requirements . III)

Internationally accepted to support international market .

4. Write out the advantages of prefabricarion .

ADVANTAGES: I) Self supporting readymade components are used ,so the need for formwork ,

shuttering and scaffolding is greatly reduced .

II) On-site construction and condition is minimized .

III) Less waste may occur .

5.Write out the disadvantages of prefabrication ?

Disadvantages : I)Careful handling of prefabricated components such as concrete panels (or) steel

and glass Panels is reduced .

II) Similarly leaks can form at joints is prefabricated component .

6. Define the term Off-site fabrication .

Off-site fabrication is the process that incorporates prefabrication and preassemble the

process involves the design and manufacture of units usually remote from the work site and the

installation at the site to form the permanent work at the site.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

7. Write short note on Production process .

The production of concrete blocks consists of four basic process They are, 1) Mixing 2)

Moulding 3) Curing 4) Cubing

8. List out the limitations of prefabrication .

I) Extra reinforcement is required to take care of handling and erection stresses . II)

Tempraray props may be required in some cases ,before the un-site concrete joints achieve strength

. III) The cracks may develop at the joints between the precart in –site concrete due to shrinkage and

temperature stresses . To overcome them extra steel is required across joint.

9. What are all the Prefab materials ?

Structural insulated panels (SIPs)

. Insulating concrete forms (ICFS).

Prefab foundation system .

Steel framing . Concrete framing .

Large - modular system

10. Define Insulating concrete forms :

Insulating concrete forms (ICE) are a prefab construction material consisting of hollow EPS

foam blocks that are stacked and glued together on-site , creating the form that is filled with

reinforcing bars and concrete.

11. Write short note on Principles of MC Concept ?

The principle objective of implanting MC is to improve productivity through the reduction of

wastages in the production,installation process,to improve quality in the construction industry and

to encourage an open system.

12. Write any two principles of prefabrication.

-Reduce building complexity.

-simplify and standardize connection details.

-Design of reusable materials.

13.Define basic module.

The fundamental module used modular co-ordination the size of which is selected for

general application to building and its componenets. The symbol of basic module is M and the value

is choosen as 100mm for the maximum flexibility and convenience.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

14.Define standardization.

For speedy construction we have to use repetitive use of building elements.Thus

standardization of prefabrication elements becomes essential.

Unchanging dimension of column from storey to storey .one type of floor beam supported

by columns can be made.

15. What are the methods of prefabrication.

-individual method

-battery form method.

-tilting mould method.

-flow line production method.

16.What are the characteristic of material.

-easy available,light weight,economy in cost,sound insulation.

17. List system of prefabrication

-large panel systems.

-frame system

-slab-column system.

-partial prefabrication

18.Name the methods for manufacture of precast concrete elements.

-Factory prefabrication.

-site prefabrication.

19. What are the works included in erection process.

-slinging of elements.

-welding of cleats.

-removing of necessary scaffoldings.

20.What are the production system.

-stand system

-aggregate system.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

PART -B

1.What are the uses, advantages and disadvantages of prefabrication?

Uses of Prefabrication :

1. The most widely used from of prefabrication in building and civil engineering is the use of

Prefabricated Concrete & prefabricated steel sections in structures where a particulars part on form

is repeated many line.

2. Pouring Concrete section in a factory brings the advantages of being able to re-use moulds and

the concrete cab be mixed on the spot without having to be transported to and pumped wet on a

congested construction site.

3. Prefabricating Steel sections reduces on site cutting and welding costs as well as the associated

hazard’s.

4. Prefabrication techniques are wood in the construction of apartment slacks and housing

developments with repeated housing units.

5. The technique is also used in office blocks, warehouses and factory buildings.

6. Prefabricated Steel and glass sections are widely used for the exterior of large buildings.

7. Prefabricated bridge elements and systems offer bridge designers & Contractors significant

advantages in terms of construction time, safety environmental impact construct liability and cost.

8. Prefabrication can also help minimize the impact from bridge building.

9. Radio bowers for mobile phone and other service often consist of multiple prefabricated sections.

10. Prefabricated has become widely used in the assembly of aircraft and space craft with

component such as wings and fuselage sections after being manufactured in different countries or

states from the final assembly site

ADVANTAGES

Self supporting readymade components are used. So. The need for work shuttering and scaffolding

is greatly reduced.

Construction time is reduced and buildings are completed sooner allowing an earlier return of the

capital invested.

On site construction and congestion is mini mixed.

Quality control can be easier in a factory assembly line setting than a construction site setting

Prefabrication can be located where skilled labour is more readily available and costs of labour,

power, materials, space and overheads are lower.

Time spend in bad weather or hazardous environments at the construction site is minimized.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

Disadvantages of Prefabrication

1. Careful handling of Prefabricated components such as concrete panels or steel and glass panels is

required.

2. Attention has to be paid to the strength and corrosion-resistance of the joining of prefabricated

sections to avoid failure of the joint.

3. Similarly, leaks can form at joints in prefabricated components.

4. Transportation costs may be higher for Voluminow. Prefabricated sections than for the materials

of which they are made, which can often be packed more efficiently.

5. Large Prefabricated Structures require heavy-duty cranes & Precision measurement and handling

to place in position.

6. Large group of buildings from the same type of Prefabricated elements tend to look drab and

monotonous. 7. Local jobs are last.

2.Explain the principle of frefabrication ?

The Main reasons to choose Precast Construction method over conventional in method.

1. Economy in large scale project with high degree of repetition in work construction.

2. Special requirement in finishing.

3. Consistency in structural quality control.

4. Fast speed of construction.

5. Constraints in availability of site resources(e.g. materials & Laborites )

6. Other space & environmental constraints.

7. Overall assessment of some or all of the above factors which points to the superiority of adopting

precast construction over convention method. The following details gives. The cost implications of

precast construction & conventional in situ method.

8. Large groups of buildings from the same type of prefabricated elements tend to look drab and

monotonous. Local Jobs are last.

The main reasons to choose.-Precast Construction method over conventional in situ method.

1. Economy in large scale project with high degree of repetition in work execution.

2. Special architectural requirement in finishing.

3. Colysistonay in structural quality control.

4. Fast speed of construction.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

5. Constraints in availability of site resources ce.g.materials & labour etc..

6. Other space & environmental constraints.

7. Overall assessment of some or all of the above factors which points to the superiority of adopting

precast construction over conventional method.

3.What are the different classifications of prefabrication and explain it briefly.

The Prefabrication is classified as follow from the view of degree of Precast

construction.

1. Small prefabrication

2. Medium Prefabrication

3. Large Prefabrication

4. Cast in Site Prefabrication

5. Off-Site (or) factory Prefabrication

6. Open system of prefabrication

7.Closed system of prefabrication

8. Partial prefabrication

9. Total prefabrication

Small Prefabrication : The first 3 types are mainly classified according to their degree of precast

Elements using in that construction for eg.:brick is a small unit precast and used in building. This is

called as small prefabrication. That the degree of precast element is very low.

Medium Prefabrication : Suppose the roofing systems and horizontal members are provided with

pretested elements those construction are known as medium prefabricated construction here th

degree of precast elements are moderate.

Large Prefabrication : In large prefabrication most of the members like wall panels, roofing /

flooring Systems, beams and columns are prefabricated. Here degree of precast elements are high.

Cast – in – site prefabrication : OFF – site (factory) prefabrication : One of the main factor which

affect the factory prefabrication is transport. The width of mad walls, mode of transport, vehicles are

the factors which prefabrication is to be done on site on factory. Suppose the factory situated at a

long distance from the construction site and the vehicle have to cross a congested traffic with heavy

weighed elements the cost in side prefabrication is preferred even though the same condition are

the cast in site prefabrication is preferred only when number of houses and more for small elements

the conveyance is easier with normal type of lorry and trailers. Therefore we can adopt factory (or)

OFF site prefabrication for this type of construction.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

Open system of prefabrication :

In the total prefabrication systems, the space framers are casted as a single

unit and erected at the site. The wall fitting and other fixing are done on site. This type of

construction is known as open system of prefabrication.

Closed system of prefabrication : In this system the whole things are casted with fixings and

erected on their position.

Partial prefabrication :

In this method of construction the building element (mostly horizontal)

required are precast and then erected. Since the costing of horizontal elements (roof / floor) often

take there time due to erection of from work the completion of the building is delayed and hence

this method is restored. In most of the building sites this method is popular more. Son in industrial

buildings where the elements have longer spans. Use of double tees, channel units, cored stabs,

slabs, hyperboloid shall etc., are some of the horizontal elements. This method is efficient when the

elements are readily available when the building reached the roof level. The delay caused due to

erection of formwork, delay due to removal eliminated completely in this method of construction

Suitable for any type of building provided lifting and erection equipments are available.

Total Prefabrication :

Very high speed can be achieved by using this method of construction. The

method can be employed for frame type of construction or for panel type of or the total

prefabrication can be on site or off-site. The choice of these two methods depend on the situations

when the factory produced elements are transported and erected site we call if off-site

prefabrication. If this method is to be adopted then we have a very good transportation of the

products to site. If the elements are cast near the building site and erected, the transportation of

elements can be eliminated, but we have consider the space availability for establish such facilities

though it is temporary. The choice of the method of construction also depends on the following; 1.

Type of equipment available for erection and transport. 2. Type of structural scheme ( linear

elements or panel) 3. Type of connections between elements. 4. Special equipment devised for

special method construction.

4.Briefly explain modular coordination.

Modular coordination means the interdependent arrangement of a dimension

based on a primary value ccepted as a module. The strict observance of rules of modular

coordination facilitated,

1. Assembly of single components into large components.

2. Fewest possible different types of component.

3. Minimum wastage of cutting needed.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

Modular coordination is the basis for a standardization of a mass production of component. A set of

rules would be adequate for meeting the requirements of conventional and prefabricated

construction. These rules are adaptable for,

a. The planning grid in both directions of the horizontal plan shall be 1. 3M for residential and

institutional buildings,

2. For industrial buildings, 15M for spans up to 12m 30M for spans between 12m and 18m 60M for

spans over 18m The centre lines of load bearing walls shall coincide with the grid lines

b. In case of external walls the grid lines shall coincide with the centre line of the wall or a line on the

wall 5 cm from the internal face of the wall

C. The planning module in the vertical direction shall be 1M up to and including a ht of2.8M.

d. Preferred increments foa the still heights,doors,windows and other fenestration shall be1M. e.

In case of internal coluums the grid lines shall coincide with the centre lines of columns.

In case of external columns,the grid lines shall coincide with the centre lines of the columns in the

storey or a line in the column from the internal face of the column in the topmost storey.

A basic module can be represented as module andfor larger project modules are represented a Mp.

For eg: For a project module in horizontal coordination,the component can be of 30cm and for

vertical component size be of 10cm.

5. Explain production,transportation and erection of prefabricated structures.

TRANSPORTATION

Transportation and Hosting of refabricates: Truck cranes, Gantry cranes , Mast cranes, Derrick cranes

Twinned mast cranes .

Truck cranes: Truck cranes consists of chasis includinig mortar and pivoting upper part. These cranes

are mobile and an travel on their own needs. Different features are: 1. Weight of the crane while

travelling is 31.8 tonnes 2. Maximum height of hoisting hook is 36.6m 3. Crane can rotate through

360º.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

Disadvantage: Needs firm and compact soil.

Gantry Cranes: These cranes are used mainly to serve the operation of manufacturing and storing

areas in prefabrication plants. Capacity 5T, Total weight 4.5T Horizontal distance between 2 tracks is

7.8m Maximum height is up to 11m Mast height 10.9m and it can hoist up to 20 tonnes in operation.

Mast Cranes: These are wide spread hoisting devices,simple and cheap. Operation requires great

skill and practice. Useful in hoisting prefabricates in vertical direction. Suspension load can be slightly

moved forward by slackening the rear staying cable. Hoisting load is done by a winch. Twinned mast

cranes: It is used for hoisting member to great height. It consists of two steel column assembled

from sections and connected at top by bridging structure. Hoisting capacity using two cranes each of

35-70 T Operation of the crane required minimum 16 workers.

The crane can be transferred but takes 1-2 days and is suitable for high lifting but difficult to

operate. These are now a days replaced by 30T mast cranes hinged in 2 directions.

Derrick cranes: Highly efficient lifting machines .It is stable or movable Capacity 20-40T Suitable for

prefabrication halls These cranes have booms which can move in horizontal directions.

Prefabricated structurers are erected in coonvinient sections which when fixed correctly should be

sufficiently rigid in all directions. Normal sequence of erection is

a. Structure units- external load bearing walls, columns,etc

b. Non structure units- internal walls, partition walls ,etc

c. Floor panels, balconies, stair units

d. Specialized prefabricated units- chimney flumes. Ventilators, sanitary installation.

If the external walls are hand laid from small blocks or bricks, all necessary materials should be

hoisted by crane and stacked near the ultimate position. The mansonry work is begun after the floor

immediately above is laid. The tolerances are comparatively strict and are normally complied with

the use of a skilled reaction gang. The distance between the walls are measured with the steel tape

and the thickness of joint with rule having mm scale. The accuracy is verified by means of surveying

instruments after all joints are connected or erected.

Hosting of Columns:

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

The hoisting machine for small column is less than five tones. First of all pick up gear must be

assembled on to the column and the column is then under pinned. Thereafter the column is lowered

temporarily on to a sheep shoe assembled at the foot and the roller track is pushed under the shoe.

When column is hoisted the pick up points moves vertically and bottom resting on the roller tracks

shifts towards the footing. When the column is lifted to the required height, the retaining cable is

used to decrease and finally stop the swinging motion of the column.

1. Pick up and hoisting Beams in general are liftedat two points depending on the

weight and dimmensioons as well as the load bearing capacity of hoisting machines.

2. The hoisting grider which is heavy to a great can be executed with hydraulic

jacks. The jacks are lowered and the beam is placed to the required position to the column.

Suspension: For lifting up of trusse and large beams of length 25-30m. care is taken to lift

the rocker in uniform rate with two hoisting machines otherwise the beams would be

subjected to distortion during the lifting leading to cracks.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

UNIT –II

PREFABRICATED COMPONENTS

1. Define LONG WALL SYSTEM .

The main beam (or) load bearing wall are placed to the long axis of building . it is

applied to the building with large prefabricated and similar to traditional brickwork . The

longitudinal wall crosses the floor load must posses not only thermal .

2. How are roofing members in prefabricates classified ?

Small roofing members.

Large roofing members.

Reinforced planks (or) ties .

Light weight concrete roofing members .

Small reinforced concrete roofing members .

Purlins .

3. How are the prefabricated component classified ?

a) Based on the area (or ) size of prefabricates .

b) Based on weight of prefabricates

c) Based on the function .

d) Based on the shape .

e) Based on the material .

4. What are the space bordering ?

These members are used to give spaces like walls both load carrying and partition

walls . this may (or ) may not contain doors and windows the provision for the same is as per the

requirement . Another example for the space bordering member are floor slabs .

5.What is the meant by surface forming members ?

In the case of surface forming members, the load carrying and surface bordering

are united and a uniform load carrying surface is found loaded by complex forces and economic

shapes. Example : Shell structures folded plates structures etc.

6. Differentiate between synclastic and Anticlastic .

In the case the synclastic the curve of the shell in the same side (eg : emispherical

shell ) where as in the case of anticlastic the curvature of the shell is in opposite direction eg:

hyperbolic shell (saddle shell ).

7. Write a short on dome structure .

A dome is a space structure covering a more (or ) less square (or ) irregular area .

The best known example is the dome of revolution , and it is one of the earliest of the shell

structure. Excellent examples are still is existence that were built in Roman times .

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

8. Define shear wall .

These are simple type and these shear walls under forces and horizontal shear

along its length are subjected to bending and shear walls. To resist these forces, the uniform

distribution of steel along its length is used in simple shear.

9. Different classification of shear walls.

1) Plain rectangular shear wall 2) Bar bell type . 3) Framed shear wall . 4) Coupled shear wall. 5) Care

type .

10). What is ring system?

Load bearing walls and beams are placed in both ways longitudinally and

transversely . In the building with ring system of support floors are normally supported on all four

edges and span is two direction . In skeleton construction these floors are placed directly on

columns .

11. Define large panel construction

Large panel systems refers to multi-storey structures composed of large wall and

floor concrete panels connected in the vertical and horizontal directions so that the wall panels

enclose appropriate spacesfor the rooms with in a building.

12.What are the classifications of precast large elements.

-cross wall sysyetm

-longitudinal wall system

-two way system.

13. What are the forces acting on the shear wall.

-shear forces

-uplift forces.

14.Name the classifications of shear wall.

1.simple rectangukar type and flanged wall.

2.coupled shear walls

3.Rigid frame shear wall.

4.core type shear wall.

15.Name the types of shear wall based on materials.

-RC shear wall.

-Plywood shear wall

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

-RC hollow concrete shear wall.

-steel plate shear wall.

- midplay shear wall.

16.Name the types of roof and floor slab.

`-solid flat slab

-hollow core slab

-double tee slab

-single tee slab

-composite beam and plank.

17. Define wall panel.

The wall panels are casted with all fixings like door, ventilator, window

frames.These wall panels are non load bearing wall.

18.What are the classifications of wall panel.

-exterior wall panel

-interior wall panel

19.write the advantages of steel plates shear wall to resist lateral load

Compared to reinforced concrete shear walls the steel shear wall is much lighter

which can result in less weight to be carried by the columns and foundations as well as less seismic

load due to reduced mass of the structure.

20.Name the type of prefabricated structural component.

-roof,slab,joist,beams,wall panels,columns.

PART – B

1.Explain the behaviour of structural componenet.

Precast reinforced structures are many types, because almost all reinforced

concrete structures can be prefabricated. The members of structural components can be classified in

to Lead-carrying structural members ,Space-bordering members ,Surface forming structural

members Load carrying structures generally act in their own plans. Space bordering members have

as a rule of plane surface. These also play a role in the carrying of loads, but this role is of a lower

order. Thus. Space-bordering members are Load-carrying structures of a lower order, the load is

transferred from the structures of lower order through the structures of higher order to the

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

footings. Load carrying structures can be classified in various ways from the view point of

fabrication, load carrying structures can be divided in to main groups according to their disuniting in

to members of straight members of entire rigid frames of members joined at points of minimum

moments of orched members limited in to two-hinged of three hinged arches. Roofing slabs or

corrugated asbestos cement sheets laid on purlins

These are the most popular forms of roof covering used in central Europe. This is

not surprising considering the simplicity of manufacture of purlins and the availability from stock of

factory made lightweight roofing slab and panels. The structural system of the purlins may be a)

Freely supported beam b) The cantilever girder c) The continuous girder. The connection of the

purlins over the support are designed only to absorb a limited BM. Normal purlins spans between 5

and 10m. The purlins are spaced at intervals of 2 to 3m.

Purlins:-Purlins are usually solid web members. For long spans they may lattice girders or trussed

beam. Freely supported purlins are designed as let flanged or fish-belly members. Purlins designed

as cantilever grilles (articulated griders) are usually llel flanged members. The c/s feature depend on

the spans of purlins & on the slope of the roof.

The purlins for flat roofs are usually rectangular T-section or (prestressed concrete) T-Section

members forsteeply sloped roofs it the loaded also in biaxial bending L-Sections or channel sections

are used. Purlins section & the approximate spans associated with them for a purlins spacing of 3m

are indicated for flat roofs. The dimensions relate to freely supported purlins.

1) The end of each purlins is reduced the depth to form a nib which rests on the other hand, when

recesses have to be formed in the top of the beams, concreting presents-difficulties Besides the

recesses weaken the top flange unless it is possible the supports. Because of beam.

2) The diaphragm on the top flanges of the roof beam is provided with nibs or corbels for supporting

the purlins. Purlins based on the principles of the cantilever girder. Provided with hinges which are

so located as to ensures statical determining have not proved satisfactory.

The reason for this are a) Halved joints:- The requirements of careful workmanship are more

stringent than are normally considered acceptable in practice. By large force will develop, more

particularly in the purlins of long buildings, the failure of one member is liable to result in the

collapse of the whole structure. This has indeed happened in a number of buildings. The roofing

slabs laid on the purlins of flat roofs are usually 0.5 TO 1.0m wide & have sparts of about 2.0 to 5.0m

these slabs also comprise the thermal insulation and where necessary, also the cement mortar

screed for the gravel roof. The wt of slabs varies bet 10 & 150kg/m depending on the bulk density of

the insulating materials and on the span. a) Ordinary concrete : “Waffle” slabs with a shell thickness

of only 1cm have been produced by the firm of press AG. The concrete bad a specified 28 days

strength of 600kg /m 2 . b) layer, are manufactured on vibrating tables in Hungary the output per

vibrating table is about 100 slabs per day. The slabs have standardized dimensions of 0.5 x 3.0m.

Waffle Slabs:- Recalled waffle slabs are characterized by having transverse ribs which perform a

structural function & which may be so arranged as to form a series of approximately square panels

with the longitudinal ribs or may alternatively be spaced close together.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

As a result of this arrangement the actual slabs can be made very thin. Thus they are actual slabs

can be made very thin. Thus they are the lightest of in terms of material quantities the most

economical type of roof unit. The width of the units ranges from 1 to 3m.

The span range from 5 to 12 m, depth. The longitudinal ribs are interconnected by welding or by

means of grout & left projecting from the slabs. It is rectangular cavities combine numberous

advantages with regard to material requirements & wt they are significantly more favourable than

roof units with circular cavities. Sections possess high torsional & present a flat surface on the under

side. Besides they can very suitable be pre stressed. The only drawback is that manufactured

involving the removal of the cores for forming the cavities is somewhat more expensive than for

ribbed slabs. Bearings for roof units With regard to the bearings of slab-type roof units on the main

beams a distinction must be made as to whether the unit is used for a flat roof or for a north light

roof & as to whether or not the unit is provided with a transverse rib at the bearing.

3. What is the necessity of providing shear walls in the precast structures? Also discuss the

different types of shear walls (MAY/JUNE 2009)

These are simple type & these shea walls under forces & horizontal shear along its

length are subjected to bending & shear.To resist the forces the uniform distribution of steel along

its length is used in simple shear walls.In case of bar bell type 2 boundary elememts are provided on

either side.Minimum steel is provided over the 0.7 to 0.8L & the remaining steel is placed steel is

placed @ 0.12 to 0.15L.

These walls are designed in such a way that they never fail in shear but only by yielding of steel in

bending.Shear failures are sudden & brittle.

One disadvantage of this type of wall is that during EQ the shear walls attract all the earthquake

forces & dissipates the forces in to the wall.The loss of energy by cracking of the wall is difficult to

repair .This can be eliminating by providing coupled shear wall.

Coupled shear wall: If two straight walls are joined together by relatively short span beams they are

called as Coupled shear wall. The stiffness of resultant wall increases in addition to the structure cqn

dissipate most of the energy by yielding the coupling beams with no damage to the main walls.It is

easy to repair the coupling beams than repairing the walls. The action of the couping beams of the

shear walls.The beams are displaced vertically they tend to bend in a double curvature. consistent

shear can reduce the axial force in the upwind wall by a large amount & reduce pressure can lower

tne shear capacity of the wall. To take up for this force diagonal lateral steel is more effective.

Framed shear wall: Framed shear walls can be provided with or without brick

4. Explain the methods of construction of roof and floor slab. Also explain the

precautions taken during the manufacturing process. (MAY/JUNE 2012)& (NOV/DEC2013)

These are load bearing structures having curved surface.The advantage of shells is

that it provides large column free area for the monolithic construction.The cost of shuttering

& scaffolding is very high but if manufactured in a precast factory in large scale.The

production cosh can be considerably reduced. The shell structure can have ribs in the centre

& provided with curved membranelikee roof.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

The shells built of precast members used in the construction of industrial buildings are

many.The thickness of shell varies from 2 to 10cm.Some precast shell,,s are produced with

dimensions which are very difficult to transport. To avoid such difficulty large size shells are

precast near to the restting or construction place. The transportable or small size shell

members can be precast in factories & these are transported to the site.Examples: Barrel

shells,Saddle or hyperboloid shells. cupola or paraboloid shells.

Single barrel:

The structure above is a single barrel with edge beams.The shell has been allowed

to project beyond the edge of the stiffener in order to show the shape of the shell. Stiffeners

are required at columns.They do not necessarily have to be complete diaphragms but may

be arches with a horizontal tie. The thickness is based on design of a slab element,the

thickness of the barrel shell is usually based on the minimum thickness required for covering

the steel for fireproofing,plus the space required for three layers of bars,plus some space for

tolerance. If these bars are all half inch rounds,a practical minimum would be 3 ¼ inches.

Near the supports the thickness may be greater for containing the larger longitudinal bars. If

more than one barrel is placed side by side,the structure is a multiple barrel structure & if

more than one span,it is called as multiple span structure.

Multiple barrel structure: This structure shows a multiple barrel with vertical edge beams at

the outside edges.The stiffeners have been place over a roof. The advantage of having the

stiffeners on top is that there are no interruptions to the space inside the shell so both the

inside appearance & the utility are better.

The movable formwork may be used which will slide with little decentering

lengthwise of the shell. The multiple span structure should have an occasional expansion

joint to reduce shrinkage & thermal stresses.This can be accomplished by cantilevering half

the span from eachadjacent stiffener.A small upturned rib placed soon each side of the joint

& accordion type sheet metal flashing is arranged to prevent roof leakage.

The maximum spans for this type shell are again limited by the geometry off the

cros section .Assuming the maximum width of barrel to be 50 feet & maximum end slope to

be 45,the rise would be about 14 feet,the maximum span would be in the order of 150 feet.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

North light shells:

This type of shell structure is used to provide large areas of north light windows

for factories requiring excellent natural lighting.The windows may be slanting or may be

vertical.The member at the bottom forms a drainage trough with the curved shell &

materially assists in stiffening the structure. The effective depth of the shell is not the

vertical distance between the two ends but is morely represented b the depth if the shellis

laid flat with the ends of the circle on the same horizontal line.

Folded plate:

A folded plate structure with 3 segments for each barrel.The forces from the reactions of the

sloping plates on these rigid frames will be quire large and at an outside column they will not

be balanced by thrusts from the adjacent plates.The size of the frames may be reduce by

using a steel tie between the tops of the columns.The dimensions of the plate are

dependent on both the with of the barrel & on the span.The depth of the shell should be

about 0.10 timess the span & the maximum slope of a plate should not be greater than

40.For example,assume that the span is 60feet & the baywidth is 24 feet.The depth of the

shell should be about 6 feet & the horizontal width of each plate with a 3 segment plate

should be about 8 feet.

plate consist of 1.inclined plate 2.edge plate which must be used to wide

plate.3.Stiffeners to carry the loads to the supports & to hold the plate.4.Column to support

the structure in the air.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

5. Write briefly about walls.

system. Walls:

Generally classified based on the function as load bearing & non load bearing

walls.Eg.partition wall.They taansfer self weight only & they are provided to create barriers that can

be visual,thermal on acoustic. Stiffening walls: Provides 3 dimentional stiffness .The load bearing

walls which are referred to as supported walls do not posses foundation o f their own but are either

carried by beams or slabs or directly attached to load bearing walls. The supported walls can form on

integral part of structure or remain as non structural depending on stiffness.

Depending on the orientation of the main beams or load bearing walls relative to

long axis of the building. Prefabricated wall system are classified as, Long wall system Cross wall

system Ring or two way system Long wall system: The main beams are load bearing walls are placed

parallel to the long axis of building. It is applied to the building with large prefabricates and is similar

to traditional brick work technique .

The longitudinal external walls which carry the floor loads must posses not only thermal properties

but also sufficient load carrying capacity . The long wall system construction is typical with large

blocked structure and special pier blocks between the windows which carry loads from lintel and the

walls above. The horizontal still blocks are not loaded .

In some designs space between the piers is filled by prefabricated unit consisting

of RC window frame complete with window. The internal wall blocks are normally of full storey

height subject to limitations imposed by lifting equipments available. Both internal and external

walls are made of some materiel.

Cross wall system : Load bearing walls and beams are placed at right angles to the longitudinal axis

of the building . In this system the floor units are provided with two way structural units which

distributes the to the cross walls and this system is more prominent. The internal walls are made of

ordinary concrete for load bearing walls and the external walls and the external walls are made of

light weight concrete to reduce the weight of the structure. Generally the room size is nearly square

in this system.

Ring system : Load bearing walls and beams are placed in both ways longitudinally and transversely.

In the building with the ring system of support floor are normally supported on all four edges and

span in two directions. In skeleton construction these floors are placed directly on columns. In this

system, the floor slabs are designed to span in both direction and are loaded on to the supporting

walls. For large load panels cross beams are hidden within the thickness of the panel.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

UNIT - III

DESIGN PRINCIPLES

PART-A

1. Explain briefly the disuniting of structures.

The solution for the problems connected with the transportation and placing of

structures demands the disuniting the larger member into smaller members.

2. Write the advantages of disuniting of structures.

Easy to transport the members from casting yard to site. Ease in placing in required

position

3. How do the materials used in construction affect the design of

structural element?

In the production of prefabrication structures we can have strict quality control, so we

can utilize the entire strength of materials with minimum factor of safety.It will lead to

economical design and dimension of structures. But while design, allowance should be given

for stresses developed during handling of structures.

4. Explain Joint deformation.

Since joints in the structure of disunited members are flexible some deformations is

allowed at the joints. Joint deformation is allowed at joints. Joints deformation refers to

have the joint behaves in regard to the far field stresses.

5. Mention some important requirements of joint flexibility.

The constant of joint should be easy The joint should require minimum material

The cast should be minimum Joint should not take more labour

6. Differentiate between rigid joint and hinged joint in prefabricated

construction.

The rigid joints are generally used for joining individual members to another but

for rigid joint considerable man power is required. The hinged joints are executed simply and

require less time than the rigid joint. The hinge joints are those which can transmit forces

passing through the hinge itself allow sudden motion and rotation.

7. Explain joint flexibility.

While disuniting structures the members is designed as semi rigid frame, in which

the columns and beams are connected in such a way that there is some flexibility at the

joints. Joints that hold two parts together so that, one can swing relative to other.

8. List the disadvantages of precast construction.

Careful handling of prefabricated components such as concrete panels or steel and

glass panels is required. Attention has to be paid to the strength and corrosion resistance

of joining of prefabricated sections of avoid failure of joint

9. At what point in the members disuniting should be done?

Disuniting can be done at corners or points of maximum moments, to make the

hoisting of these smaller members possible using simpler equipments.

10. Write the disadvantages of disuniting the structures.

The identifying joint location is a problem in disuniting the structures In frames it

is easy to disunite at corners but it is the point of maximum bending moments.\

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

11. What are dry joint and wet joint?

Dry joint: The dry joint used for simply placing of two members on each other and

connecting them. This kind of joint which requires not only a casting with cement mortar but

also a continuous or subsequent. Wet joint: Wet joint are more adequate to bear the forces

and less sensitive to be inaccuracy than by joint.

12. What is the advantage of Scaffolding?

Hoisting or lifting method is very simple Auxiliary scaffolding is not necessary.

13. What are the important requirements of joints?

The constant of joint should be easy The joint should required little material Joints

should not consume more labour The cast should be minimum

14. What are the problems involving in design due to joint flexibility?

There are difficulties and problem if the joints of various elements are not proper. It joints

not strong then the failure will occur in the structure.

PART –B

1. Discuss the necessity of disuniting of structures and explain

in detail with sketch(NOV/DEC2012)& (MAY/JUNE 2012)& &MAY/JUNE

2013&(NOV/DEC2013)

Construction of roof and floor slabs:-

Roofing members:-

Roofing members can be divided into two groups. short span and long span roofing

members. The short span members rest on purlins. While long span one are directly supported

by the main girders. The short span roofing members the reinforced planks mode of porus

hollow tiles, light weight concrete, roofing material and small reinforced concrete roofing

members will be dealt with here. Among the long span roofing members the reinforced concrete

members are discussed.

(a) Reinforced planks mode of porous hollow tiles:-

These roofing members consist of porous tiles having longtidutional circular holes. The

thickness placed in to these graces. Which are subsequently fined with cement mortar. In this way

reinforced porous tile planks having a length of 2.3m, a thickness of 6-10 cm and a width of 20cm

can be produced of these tiles, two kinds exist.

The first kind is heat insulating and has a unit weight of 750kg/m3 , the second kind is load

bearing, its unit weight is 1100kg/m3 , this is used for production of reinforced planks. The

disadvantage of using the porous hollow tiles in question for roof covering is that the material of the

latter is highly moisture absorbing, and therefore not frast resistant. Thus the roof cover should

protected from moisture and hence it should be rough rendered with lime cement mortar.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

The value of the limit moment is obtained from the following expression 0.9 − 3−1 Where, Mi

= limit moment Maco= arithmetic mean of the ultimate moment m i = Value of the ultimate

moments belonging to the individual planks, where (i=1.............N)

(b) Light weight concrete roofing members:-

Light weight concrete roofing members play a role. In additional to space brodering and

load bearing. In heat insulating and so the application of a separate heat insulating layer is not

necessary. Light weight concrete roofing members can only be applied if there is a possibility of

their reinforcement.

It requires a bond between the steel and the light weight concrete for ensuring the

transmission of the tensile force acting in steel bars to the concrete with the steel bars sliding,

hence it is necessary to protect the reinforcement against corrosion.

From the view point of strength light weight concrete of the quality Lc 70 or Lc 1000

are quite suitable on the production of roofing members with a rectangular c/s and a thickness

of in 25cm of 7.5=25cm and a length of 1.75-6.00m Prefab roofing members can be produced of

concrete mode in the usual way, using light weight materials on gravel and sand for aggregates.

In the case of prefab structures the steel wires must be embedded in to a concrete the availity of

which is at least C300.

b) Small Reinforced - concrete roofing members. The small reinforced-concrete

roofing member is essentially a pre cast simply supported, ribbed reinforced-concrete slab. The

width of the member is 50-120 cm The large reinforced-concrete roofing members resting

directly on the main girders of structures represents a more advanced kind of pre cast roofing

structure. These members are manufactured in a length corresponding to the spacing of the

frames (6-10m) their width is 1.30-1.80m. They are directly supported by the main girders so

that purlins are not required.

A large roofing member consist of two longitudinal edge ribs, cross, ribs and a

slab having thickness of 2.5 -3.0 cm, and the two way reinforcement. These members connected

to each other and to the frame girders form a unified continuous roofing structure.

2. Explain the problems in design because of joint flexibility.

Discuss with regard to various location. (MAY/JUNE 2012) (NOV/DEC2013)

a. Joining column to footing:

This joint is usually rigid but also can be hinge. A rigid joint can be made by placing

the column into a calyx of the footing or by using a welded joint the figure shows the three

variations of the this method. a) Can be used for smaller b) for average and for large footings .

The opening of the calyx is 6-10 cm greater in all directions than the c/s of the

column. This is enable the vibrator to be operated while concreting at the bottom of the calyx &

checked by leveling before concreting. A similar steel plate is also put on the lower end of the

column when positioning the column. These two steel plates must be on each other. The dimensions

of these steel plates are from 100 x 100 x 10 to 150 x 150 x 10mm an chored in to the concrete after

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

the column is put in placed properly plumbed tow advantages of the calyx joint should be

mentioned.

1. The placing plumbing and fixing of the column as well as the

subsequent filling of the calyx with concrete is far simpler and requires less time then

in the case of a welded joint.

2 The method is least sensitive to inaccuracies occurring during the construction. The

disadvantages of the calyx Joint is more suitable for small columns.

c.In the case of large columns requiring a calyx depth of which is greater than 1.0m. One members of

joining a merge like joint consists either of placing to beams on to as small cantilever protracting

trans the column or of putting it on the bottom of an adequately shaped opening deft out of the

column shaft.

The beam rests temporarily on a tongue like extensist on a steel plate placed in this opening on the

supporting surface the tongue is also furnished with a steel plate anchored in to the concrete. The

other parts of the tongue are supported after the placing has been finished with concrete cast

through an opening left for this purpose.

d. Lengthing of columns:- Columns are usually lengthened at floor levels.An intermediate

lengthening should be avoided it possible. The lengthening of columns can be executed similarly to

the joining with fooling, accordingly reinforcement are joined by overlapping looped steel bars a

welding. Thereafter the stirrups have to be placed & finally the joint must be concreted.

e. Design of joints for post tensioned structures:- Post tensioned structures can generally be joined

for more simply then the usual reinforced concrete structures, By using post tensioning it can be

ensured that in the entire structure. The joints included only compressive can develop consequently

the problem of joining can be solved in a very easy manner namely by placing plane surfaces side by

side and then filling the gaps with cement mortar.

precast member.: Thus in post tensioned structures the forming of joints does not cause difficults.

Sketches solutions of principles relating to the joining of post tensioned structure are to be

illustrated in the fig. All these joints are of course rigid and moment bearing.

It is not permissible for the mortar which is to be poured into the gaps to follow in to the

ducts of the stressing lables to arid this cable ducts are jointed by placing a shore piece of tube or

rubber ring into the duct itself. A rigid point of their kind established between a columned two

girders supported by the former after the casting of the gaps & hardening of the mortar, the short

inserted cables are stressed and so rigid joint is established.

3. Explain how the material selection impacts the design efficiency of a precast element.

In multi storey buildings the panels are either installed as spandrel panels between the columns

or they may take the form of large panels which contain the windows the spendrel panels may also

be supported by the floor slabs the bracing panel may be disposed horizontally or vertically in the

later casting and should be so interconnected as not to go any relative movement. replaced by

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

reinforced concrete wall panels. The external surface of these panels is usually finished like a last

stone facing.

This giving them an attractive appearance. Wall panels are adequate for resisting wind load

which acts 1st to their own plane for bearing forces acting led to the longitudinal axis of the building.

This ensures the rigidity of the building in the longitudinal direction without using any other bracing

structures. Wall panels can be made of light wt concrete reinforced concrete or partly of reinforced

and partly light weight concrete when reinforced concrete is used a heat insultating layer it

necessary is subsequently laid Wall panels can be divided into two groups to first belong the panels

which transfer their own weight or other vertical forms by same means to the column or flames.

These are called horizontal wall panels.

The second group involves panels resting on and borne

directly by the footing or footing beams. These panels don’t transfer any vertical forces to the

columns or frames and are called vertical (slanting) wall panels. In both groups solid windowed and

must be distinguished.

Horizontal (lying) wall panels having a width of 0.6-2.00 m are self bearing between

too adjacent frames and transfer their load directly to the columns. A horizontal (lying) wall panel

being a compound of light weight and reinforced concrete is to be seen in fig. The length of this

panel is 5.98 m. The width is 1.18 m to the thickness is 0.2m.

The outer surfaces is formed by a 2.5 cm thick reinforced concrete slab covered

with a cast-stone like layer made of crushed limestone. The other parts of the panel are made of

concrete using formed blast furnace slag and aggregate the quality of this concrete is LC too it also

reinforced. The embedded paces for angles steel for foiling and for hoisting hooks however are

made.

The total weight is 33,000 kg the height up to the upper hinges is 41.55 m the

gauge of the rail tracks is 12-14m for the same machine but with columns assembled of 4 sections

the data are total weight of 20,000 kg height 20m, track gauge 9m. The maximum hosting capacity is

in both cases 35 tons using two cranes to tons.

The possible deviation of the hoisting by a mortar built into the structure of its

permissible to move it in the unloaded state only. Hoisting is performed by a 27 HP mortar tilting by

a 6HP are The permitted tilting movements with the load on the crane, performed with motar

power, are 50cm in the longitudinal and 70cm in the traverse direction both to the right and to the

left of the basic position. These movements enable the hoisted member to be accurately placed.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

UNIT – IV JOINTS IN STRUCTURAL MEMBERS

PART-A

1. What is the importance of joints in precast structures when

compared to cast in situ structures?

In cast insitu structures the joints are provided to relieve the stresses due to

temperature and shrinkage and also to accommodate the construction sequence for the

placement of concrete.

2. What is the need for expansion joint in precast structures?

Expansion joints allow expansion and contraction of a member without generating

potentially damaging forces within the member itself.

3. What are connections?

In a precast member to overcome operational difficulties the members are disunited into

smaller elements. Connections are used to get required structures by joining the separate

smaller elements.

4. What are the different types of connections?

Wet connection Dry connection

5. What are the points to be considered while designing the

connections?

Loading under working conditions Stability of structures Load conditions during

construction Effects of shrinkage creep and temperature.

6. What are the different connections made in prefabricated

structures?

Column to column connection Beam to beam connection Main beam to secondary beam

connection

7. What are the different types of joints?

Expansion joint Contraction joint Crack control joint

8. What are the materials used for concrete joints?

Flexible board Dowels Sealants

9. Based on the location within a building how connections

can be classified.

Vertical Horizontal joints

10. What are the functions of joints?

Joints between internal and external wall panels shall be designed to resist the forces

acting on them without excessive deformation and cracking. They shall also be able to

accommodate the deviations in the dimensions of the wall panels during production and

erection.

11. Write note on Expansion joint.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

Expansion joints are usually a complete gap between adjacent bases. i.e, there is a definite

break in the concrete and any reinforcing steel that maybe present.

12. Define – Contraction Joint.

It is also known as shrinkage joint. These types of joints allow only for contraction or

shrinkage of the slab as can be anticipated during the curing process.

13. What is flexible board?

A fibrous, compressible, flexible biard such as flexcell, it is cheap and readily available from

builder’s merchants in precut strips of the required depth especially for creating expansion

joints.

14. Define – Sealants.

The sealants tend to bond dry joint and throughout to be kept free from traffic for the first 24

hours. The temporary cover maybe placed over the joint to prevent accidental trafficking.

15. What are the types of sealants?

Hot poured Cold applied Performed elasto metric

16. What are the advantages of main beam to secondary beam

connection?

No insitu concrete is required The connections leads to fastest possible erection

Maintenance cost is nil.

17. What are the advantages of beam to beam connection?

It provides good accessibility for proper welding and also to erect columns. Maintenance

cost is nil. This connection provides the permanent protection against connection.

PART B

1. Explain expansion joint in retaining wall. MAY/JUNE 2012

A design specification shall be prepared for each expansion joint application. Prior to

writing the expansion joint design specification it is imperative that the system designer

completely review the structural system layout, and other items which may affect the

performance of the expansion joint. Particular attention shall be given to the following items.

The system should be reviewed to determine the location and type of expansion joint which is

most suitable for the application. Both the EJMA Standards and most reliable expansion joint

manufacturers’’ catalogs provide numerous examples to assist the user in this effort.

The availability of supporting structures for anchoring and guiding of the system, and the

direction and magnitude of thermal movements to be absorbed must be considered when

selecting the type and location of the expansion joint.

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

Conventional rubber expansion joint Expansion joints are designed to provide stress relief in

piping systems that are loaded by thermal movements and mechanical vibration. To deal with

the various forces on the joint they require fibre reinforcement which guarantees both flexibility

and strength. Conventional expansion joints are reinforced using prefabricated fibre plies. The

use of these fabric plies makes it impossible to control the orientation of the fibres on complex

shapes such as the bellow of an expansion joint. In both cases the inability to use the fibres in an

optimal way leads to the following disadvantages:

High Material Cost: More fibres needed than necessary More rubber needed than necessary

Additional parts such as metal reinforcement rings necessary with multiple bellows.

Lower Performance

High rubber wall thickness and fibre pack make product less flexible

Undesired radial and axial expansion under pressure.

1) Introduction 2) Necessity 3) Advantages 4) Pre requisites 5)

Types of prefabrications

Pre-fabrication means that the structure is disunited in its disunited in its members and

these are precast in factor built and equipped particularly this purpose or in temporary plants

establish on the site. Then the precast reinforced core members are shipped to the place where

they used. Here they are hoisted set into their fix places and assembled in the form of a

complete structure.

The stages involved are

1) The structure is divided into no of units.

2) The different units are precast in permanent plants. Permanent prefabrications - plant

prefabrication. Temporary plants (sheds) - Site prefabrication

3) Transported to the site

4) Hoisted and put into their places Prefabrications eliminates the use of scaffle.

2. What are the recommendations for the design of an expansion joint? (MAY/JUNE 2009)

Design of expansion joint:

1. Basic Dimensions This is the dimension between the axes defined by the dimensional grid.

The dimensional grid is the two dimensional co-ordinate system of reference line defining the layout

of the buildings

2. Nominal or theoretical dimensions It is the planned dimension of the prefabricate arrived

from it’s basic dimension and it’s joints.

3. Actual dimensions It is the dimension of the prefabricate when produced If the

interdependent arrangement of the basic dimensions of the building based on the primary unit

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

accepted components so that they apply to any building that is laid out on the 10cm (4”) modular

basis without cutting or altering at the site.

4. Planning module (Mp) It is a multiple of the basic module for specified applications. The

planning module Mp = 3 cm is the common horizontal dimension or Mp= 1M is used for the vertical

dimension, when Mp=60 cm for the length dimensions.

5. Modular grid This is a particular case of the dimensional grid consisting of two dimensional

co- ordinate system of reference lines (modular lines) at a distance equal to the basic module or the

multi module (Mp). This multi module may be the same or different for each of the two dimensions

of the reference system. The area between the modular lines is called the modular zone of the

component. The dimensions of the prefabricates are fixed from the modular grid by fitting in the

elements after taking into account their tolerances and dimensions of the joints.

The limits of deviation in the dimensions the shape of the prefabricates. This depends very much on

the type of moduls, wooden, steel, concrete or plastic, the tolerance also depends on the nominal

dimension, nature of prefabricate and its position during casting.

3.Explain about column to column connection (MAY/JUNE 2009)

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

4.Explain about beam to beam connection. (MAY/JUNE 2009)

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

5. Explain in detail the different structural connection adopted in a framed precast building with

sketches.

Connection between foundation and wall

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

UNIT – V DESIGN FOR ABNORMAL LOADS

PART-A

1. Explain equivalent design loads.

In the arrangement the bearing is subjected to generally acitng forces in various magnitudes,

at various rotational speeds and with different acting speed. From the point of view of

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

calculating methodology the acting forces should be recalculated into constant load, by

which the bearing load will have the same life as it reaches in the conditions of actual load.

2. What is meant by progressive collapse?

Progressive collapse is a situation where local failure of a primary structural component

leads to the collapse of adjoining members which in terms leads to additional collapse.

3. Explain the importance factor and response reduction

factor used in static analysis for calculating seismic forces design.

The importance factor originated with the seismic shear base equation in uniform

building code. The concept at that time the importance factor increased the design seismic

forces in order to provide additional seismic resistance.

4. What are the advantages of progressive collapse?

The plastic hinges are not assumed; rather, automatically calculated and generated

without any user intervention. Collapses are not assumed; Automatic mesh adjustment

Automatic spring generation.

5. Define – Abnormal loads.

Loads other than conventional design loads for structures such as air blast pressures

generated by an explosion or by impact of vehicles etc..,

6. Explain non linear dynamic analysis.

Non linear static procedures use equivalent SDOF structural models and represent seismic

ground motion with response spectra. Storey drifts and component actions are related

subsequently to global demand parameter.

7. What are the approaches to avoid progressive collapse?

Redundancy Local resistance Inter connection

8. Define – Degree of Progressivity.

It is defined as the ratio of total collapsed area or volume damaged directly by the

triggering event.

9. List the codes and standards for progressive collapse.

ASCE7 – 02 ACI 319 – 02 GSA PBS facilities and standard 2003

10. How to achieve structural integrity in structures?

Connection between structural components should be ductile. Good plan layout. By

changing the direction of span of floor slab.

11. Write the assumptions for dynamic analysis procedure.

The structure is modelled as two dimensional Effects of large deflections are neglected.

Elastic perfectly plastic moment rotation relationship used.

12. What are the special requirements for buildings in high

seismic zone?

Large panel building in high seismic zones are recommended to be constructed with

closed symmetrical lay out The height of building shall generally restricted to 10 storey in

zone 4 and 7 storey in zone 5 The vertical and horizontal joints for wall panels shall be

defined as keyed joints

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

13. What are the requirements to increase resistance to

progressive collapse?

All perimeter columns must have sufficient shear capacity to devolep the full plastic

flexural moment. All floors and roofs must be able to withstand a prescribed net upward

load applied to each bay. The uplift forces not applied to all bays simultaneously.

14. What are the features of progressive collapse?

Structural components can be removed either simultaneously or at custom

intervals. Through the true modelling of structural components centenary action and other

structural response are considered

15.What is meant by progressive collapse analysis?

Extreme loading for structure software allows structural engineers to accurately

analyse and visualize progressive collapse resulting from combinations like severe wind load,

blast load, dynamic load and impact load.

16.Define – Response Spectrum Analysis.

This approach the multiple modes of response of building to be taken into account. This is

required in many building codes for all except except for very simple or very complex structures.

It is defined as combination of many shapes.

17. Define – Linear Dynamic Analysis.

Static procedures are appropriate when higher mode effects are not significant. This is

generally true for short regular buildings; therefore for all tall buildings, buildings with

tensional rigidities or non orthogonal systems, a dynamic procedure is required.

18. What is strong column weak beam concept?

In a building a column is more important than a beam because it supports the load till

the foundation. If a beam breaks it will results in a partial collaspse. But if column breaks it

will results in catastrophic failure.

19. What are the provisions made in prefabricated RC floors in

a cyclone prone zone?

Prefabricated RC elements of various designs placed side by side whereas RC slabs are rigid

in their own planes, the other types will require their integration through diagonal bracing or

topping RC screed.

20. What are the causes of abnormal loads?

Accidental impact Faulty construction Foundation failure Violent changes in air

pressure

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

PART-B

1. Mention in detail the codal provision for considering the

effect of earthquake and cyclones. (MAY/JUNE 2012)

Definition Progressive Collapse: Progressive collapse occours when a key member

or members of a structure fail. The isolated failure of this key member or section then

initiates a sequences of events, causing failure of the entire structure. Progressive collapse

basics Progressive collapse can be defined as collapse of all or a large part of a structure by

failure or damage of a relatively small part of it.

The general services Administration (GSA,2003b) offers a somewhat more specific

description of the phenomenon:

“Progressive collapse is a situation where local failure of a primary structural component

leads to the collapse of adjoining members which, in turn, leads to additional collapse.

It has also been suggested that the degree of “Progressivity” in a collapse be defined as the

ration of total collapsed area or volume to the area or volume damaged or destroyed

directly by the triggering event.

Codes and standards

ASCE 7-02

The American Society of Civil Engineers Minimum Design Loads for Buildings and

Other Structures shall be designed to sustain local damage with the structural system as a

whole remaining stable and not being damaged to an extent disproportionate to the original

local damage. This shall be achieved through an arrangement of the structural elements that

provides stability to the entire structural System by transferring loads from any locally

damaged region to adjacent regions capable of resisting those lads without collapse. This

shall be accomplished by providing sufficient continuity, redundancy, or energy-dissipating

capacity (ductility), or a combination thereof, in the members of the structure.

“Clearly, the focus in the ASCE standard is on redundancy and alternate load paths

over all other means of avoiding susceptibility to disproportionate collapse. But the degree

of redundancy is not specified, and the requirements are entirely threat-independent.

ACI 318-02

The American Concrete Institute Building Code Requirements for Structural

Concrete (ACI,2002) include extensive “Requirements for structural integrity” in the chapter

on reinforcing steel details. Though the Commentary states that it “is the intent of this

section... to improve... 6 redundancy” there is a explicit mention of redundancy or alternate

load paths in the Code. The Code provisions include a general statement that “In the

detailing of reinforcement and connections, members of a structure shall be effectively tied

together to improve integrity of the overall strucute” and many specific prescriptive

requirements for continuity of reinforcing steel and interconnection of components. There

are additional requirements for the tying together of precast structural components. None

of the ACI provisions are thereat-specific in any way.

GSA PBS Facilities Standards 2003

The 2003 edition of the GSA’s Facilities Standards for the Public Buildings Service

(GSA,2003a) retained the “Progressive Collaps” heading from the 200 edition. GSA

Progressive Collapse Guidelines 2003 The GSA Progressive Collapse Analysis and Design

DEPARTMENT OF CIVIL ENGINEERING - SJCE

CE6016 PREFABRICATED STRUCTURES VIII SEMESTER

Guidelines for New Federal Office Buildings and Major Modernization Projects (GSA, 2003b)

begins with a process for determining whether a building is exempt from progressive

collapse considerations.

Exemption is based on the type and size of the structure (for instance, any building of

over ten stories is nonexempt) and is unrelated to the level of threat. Typical non-exempt

buildings in steel or concrete have to be shown by analysis collapse. Considerable detail is

provided regarding the features of the analysis and the acceptance criteria.

GSA Progressive Collapse Guidelines 2003

The GSA Progressive Collapse Analysis and Design Guideliness for New Federal Office

Buildings and Major Modernization Projects (GSA, 2003b) begins with a process for

determining whether a building is exempt from progressive collapse considerations.

Exemption is based on the type and size of the structure (for instance, any buildings of over

ten stories is nonexempt) and is unrelated to the level of threat. Typical non-exempt

buildings in steel or concrete have to be shown by analysis to be able to tolerate removal of

one column or one 30-ft length of bearing wall without collapse. Considerable detail is

providing regarding the features of the analysis and the acceptance criteria.

2. Explain Equalent design loads for considering abnormal

effects like earthquake and cyclones (MAY/JUNE 2012) (MAY/JUNE 2013) (MAY/JUNE

2009)& (NOV/DEC2013)

Hoisting & placing differ from those arising in their final position. Owing to this

additional reinforcement would be required which after the placing is finished becomes

unnecessary. The additional stresses as well as the reinforcement required to resist them

should be eliminated. The methods will differ from each individual problem.

The most simple solution for the elimination of erection stresses & surplus

reinforcement connected with the latter consists in the firm attachment of a steel beam to

the member. The figure shows the hoisting of a framewhere ends of the steel beam are

wedged to the stanchion while its middle is it down. In this way the developing BM due to

the dead load is bome partly by the steel beam as marked in the figure & the remaining part

can be bome by the stanchion itself without any additional reinforcement. After the beam

has been hoisted by 45”, the temporary reinforcing steel beam becomes unnecessary & can

be removed. The same solution applied during hoisting a multi storyed frame.

For large structures the above method, owing to great length & strong forces is no

longer satisfactory & so here heavy latticed steel structures would be necessary. Erection

stresses developing during hoisting in column & girders of high halls may be eliminated most

suitably by post tensioning with cables. The stressing cables applied on bothsides of the

column are tensioned by gas threated jacks assembled to one end of the column by a