Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)

Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)

Uploaded by

juan moralesCopyright:

Available Formats

Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)

Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)

Uploaded by

juan moralesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)

Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)

Uploaded by

juan moralesCopyright:

Available Formats

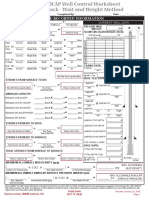

Drill Collar Performance Sheet

www.NOV.com/GrantPrideco Phone: +1 (281) 878-8000

Drill Collar Configuration

Connection 4-1/2 IF (NC50)

Drill Collar OD 6.500 (in)

Drill Collar ID (in) 2.813 Connection ID (in) 2.813

Min Yield Strength (SMYS) (psi) 110,000 Bevel Diameter (in) 6.109

Wall Thickness (in) 1.844

Approximate Length (ft) 31.5

BSR (Bending Strength Ratio) 2.02

Friction Factor 1.0

Connection Performance 4-1/2 IF (NC50) ( 6.500 (in) OD X 2.813 (in) ID ) 110,000 (psi)

Applied Make-up Tension at Shoulder Tension at Connection

Torque Separation Yield

Tool Joint Dimensions

(ft-lbs) (lbs) (lbs) Balanced OD (in) 6.594

Maximum Make-up Torque 32,600 Tensile Limited 1,077,000

Minimum Make-up Torque 29,700 Tensile Limited 1,236,000

Tool Joint Torsional Strength (ft-lbs) 52,200

Tool Joint Tensile Strength (lbs) 1,375,000

Drill Collar Properties Drill Collar Length 31.5 (ft)

Best Estimates

Adjusted Weight (lbs/ft) 91.69

Fluid Displacement (gal/ft) 1.40

Fluid Displacement (Bbls/ft) 0.0334

Fluid Capacity (gal/ft) 0.32

Fluid Capacity (Bbls/ft) 0.0077

Drift Size (in) 2.688

Note: Oil field barrel equals 42 US gallons.

Note: Drill Collar assembly values are best estimates and may vary due to length.

Drill Collar Body Properties Drill Collar Configuration ( 6.500 (in) OD X 2.813 (in) ID )

Nominal

Calculated plain end weight (lbs/ft) 91.689

Cross Sectional Area of Pipe Body (in^2) 26.970

Cross Sectional Area of OD (in^2) 33.183

Cross Sectional Area of ID (in^2) 6.213

Section Modulus (in^3) 26.016

Polar Section Modulus (in^3) 52.032

Moment of inertia drill collar body (in^4) 84.55

Polar moment of inertia drill collar body (in^4) 169.11

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill collar properties are calculated based on uniform OD and wall thickness. No safety factor is applied. It is the responsibility of the customer and the end user to determine the appropriate

performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box ID’s, tool

joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback Customer Created 06-18-2014

You might also like

- Latch Type Drilling JAR ManualDocument41 pagesLatch Type Drilling JAR ManualMuhammad Zikry Alfindy HazNo ratings yet

- Tube-to-Tubesheet Joints - BaherDocument51 pagesTube-to-Tubesheet Joints - BaherNAMO100% (4)

- Polymer Rheology. Theory and Practice - Yuri G. YanovskyDocument308 pagesPolymer Rheology. Theory and Practice - Yuri G. YanovskyJose RdzNo ratings yet

- Installation Manual: General Information Open SystemDocument83 pagesInstallation Manual: General Information Open SystemhamzehNo ratings yet

- Drill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFDocument1 pageDrill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFИнженер Луис А. ГарсиаNo ratings yet

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- Cougar DLLG Solutions FaqDocument5 pagesCougar DLLG Solutions FaqLenis CeronNo ratings yet

- Volant Crti and CrteDocument4 pagesVolant Crti and CrteSudish Bhat100% (2)

- Ttt2b Drillable TlsDocument26 pagesTtt2b Drillable TlsMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Iadc Dull GradingDocument1 pageIadc Dull GradingSaeed AlshamsiNo ratings yet

- Sara Sae - Manual TongDocument5 pagesSara Sae - Manual Tonganon_374733272No ratings yet

- CPST Pressure Setting Tool PDFDocument1 pageCPST Pressure Setting Tool PDFmahsaNo ratings yet

- Lift Caps: General RequirementsDocument2 pagesLift Caps: General Requirementsislam atif100% (1)

- WFT Composite PlugsDocument11 pagesWFT Composite Plugsahmad haqkim muhamad malackNo ratings yet

- 2 .875 Spec.Document35 pages2 .875 Spec.Daniel VanLiereNo ratings yet

- Down HoleDocument14 pagesDown HoleGhinet Teodor-ioanNo ratings yet

- Iadc WW Surfacestack Field 012214Document3 pagesIadc WW Surfacestack Field 012214DirafNo ratings yet

- 90-90-988-TS (BEM-650 Tech Specification)Document9 pages90-90-988-TS (BEM-650 Tech Specification)leoNo ratings yet

- Drill Pipe Connection Care and HandlingDocument20 pagesDrill Pipe Connection Care and HandlingGuzman CharlesNo ratings yet

- IDM Basic Training - ModrillDocument30 pagesIDM Basic Training - ModrillThomas Du100% (1)

- AOI TM-511 Drift Indicator Systems Manual - 4th Ed - Jan 07Document142 pagesAOI TM-511 Drift Indicator Systems Manual - 4th Ed - Jan 07Tri CahyadiNo ratings yet

- PDC Drilling ProceduresDocument8 pagesPDC Drilling ProceduresJosue FishNo ratings yet

- DDR N°1 - Atk29 - TP180 - 08022017Document3 pagesDDR N°1 - Atk29 - TP180 - 08022017Nour MohammedNo ratings yet

- Improving The Accuracy of Mechanical Backoff in Stuck Pipe Situation During DrillingDocument9 pagesImproving The Accuracy of Mechanical Backoff in Stuck Pipe Situation During DrillingJorgito AriasNo ratings yet

- T-82 Hydraulic Ram-Type BOP: Available Sizes/pressure Ratings Available OptionsDocument2 pagesT-82 Hydraulic Ram-Type BOP: Available Sizes/pressure Ratings Available OptionsDani Osorio100% (1)

- Engineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Document2 pagesEngineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Bala KrishnanNo ratings yet

- Shearing Blind Rams SBRDocument8 pagesShearing Blind Rams SBRDavid OrtegaNo ratings yet

- Jar IntensifierDocument2 pagesJar IntensifierMicNo ratings yet

- Rig 14 Inventory Rev 3Document17 pagesRig 14 Inventory Rev 3sitemaster60100% (1)

- Cup TesterDocument22 pagesCup Testermiguel mendoza0% (1)

- Operation Manual: TQ340/35Y Power Casing TongDocument20 pagesOperation Manual: TQ340/35Y Power Casing TongNgwe Min TheinNo ratings yet

- MSP Drillex BOP AnularDocument21 pagesMSP Drillex BOP AnularDavid GonzalezNo ratings yet

- Strength of Casing and Tubing - PetroWiki PDFDocument15 pagesStrength of Casing and Tubing - PetroWiki PDFLuis David Concha Castillo100% (1)

- Instrumentation Catalog PDFDocument14 pagesInstrumentation Catalog PDFPrejit Radhakrishna100% (1)

- Mechanical Setting Procudere of CR & Bridge PlugDocument7 pagesMechanical Setting Procudere of CR & Bridge PlugChandra FadhillahNo ratings yet

- Shock Tool Manual PDFDocument23 pagesShock Tool Manual PDFAbboud KingNo ratings yet

- Fishing Diagram - Stabilizer Jar Pony Collar - BHA#10Document10 pagesFishing Diagram - Stabilizer Jar Pony Collar - BHA#10abhijitrathiNo ratings yet

- Volant Specs CRTi3-7.01 PDFDocument4 pagesVolant Specs CRTi3-7.01 PDFRaymond ChuNo ratings yet

- 6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualDocument19 pages6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualAnonymous F2tu2TrzVtNo ratings yet

- Annular Bops D Bop DL Bop: To Contents PageDocument6 pagesAnnular Bops D Bop DL Bop: To Contents PageDavid Ortega100% (1)

- 20009K CRTi4 7.0 Specification Summary PDFDocument5 pages20009K CRTi4 7.0 Specification Summary PDFRichard PinontoanNo ratings yet

- Api Products: Hammer UnionsDocument9 pagesApi Products: Hammer UnionsMohitNo ratings yet

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelNo ratings yet

- MODEL 4500 Hydraulic Tubing Tong Operations and Service ManualDocument39 pagesMODEL 4500 Hydraulic Tubing Tong Operations and Service ManualDano CustodioNo ratings yet

- Onshore Make-Up of BHA Assemblies: Performance CriteriaDocument2 pagesOnshore Make-Up of BHA Assemblies: Performance Criteriaislam atifNo ratings yet

- 9 - What Is A Special Drift CasingDocument2 pages9 - What Is A Special Drift CasingLuis David Concha CastilloNo ratings yet

- Float Valve Recess DimensionsDocument1 pageFloat Valve Recess DimensionsQuality controllerNo ratings yet

- The Accelerator Tool Gives You Up To Twice The Impact From Your Hydra-JarDocument4 pagesThe Accelerator Tool Gives You Up To Twice The Impact From Your Hydra-JarAlexander KlmNo ratings yet

- Mud Standpipe ManifoldsDocument2 pagesMud Standpipe ManifoldsJose PrasobhNo ratings yet

- Osm-099 55000-150Document80 pagesOsm-099 55000-150Taller cncNo ratings yet

- Restsco01 PDFDocument13 pagesRestsco01 PDFAly Kamal SabbahNo ratings yet

- Technical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Document16 pagesTechnical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Riski KurniawanNo ratings yet

- Table of Contents:: Drilling Motors 2-6Document9 pagesTable of Contents:: Drilling Motors 2-6BelkhirAouaribNo ratings yet

- JFEBEAR - JFEBEAR Interchangeability Rules Rev 0 PDFDocument2 pagesJFEBEAR - JFEBEAR Interchangeability Rules Rev 0 PDFnayrNo ratings yet

- 21 - Pressure Control Equipment PDFDocument50 pages21 - Pressure Control Equipment PDFKhaled Yazid100% (1)

- Dicks Oilfield Satellite Auto DrillerDocument16 pagesDicks Oilfield Satellite Auto Drillertoxa0707100% (1)

- S Speed Loc ClampsDocument3 pagesS Speed Loc ClampsAdrian Petrascu100% (1)

- Casing Drive System STD PDFDocument2 pagesCasing Drive System STD PDFcristian sanchezNo ratings yet

- Kahraman C-181 (ST-1)Document3 pagesKahraman C-181 (ST-1)Islam AtifNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- 6023Document6 pages6023SHAFEEK A RNo ratings yet

- Micro Crack AdvantagesDocument2 pagesMicro Crack AdvantageshycromeNo ratings yet

- Curriculum-Vitae Gaurav Kumar SethDocument3 pagesCurriculum-Vitae Gaurav Kumar SethKrishna SwamyNo ratings yet

- Carnot Vapor Compression SystemsDocument1 pageCarnot Vapor Compression SystemsSUMITNo ratings yet

- Chapter 1: Introduction To Fracture Mechanics: Conventional Design PhilosophyDocument6 pagesChapter 1: Introduction To Fracture Mechanics: Conventional Design Philosophypavans29No ratings yet

- Differentiate Between Absolute Humidity and Relative HumidityDocument6 pagesDifferentiate Between Absolute Humidity and Relative Humiditysameen100% (1)

- Torres Colon PDFDocument1 pageTorres Colon PDFGonzalo de la CruzNo ratings yet

- Periodicity: The Periodic Table and Physical PropertiesDocument25 pagesPeriodicity: The Periodic Table and Physical PropertiesJi Min LimNo ratings yet

- If You Have You Need To Replace It With : Standards Cross-Reference GuideDocument2 pagesIf You Have You Need To Replace It With : Standards Cross-Reference Guideavabhyankar9393No ratings yet

- Estimating Methane Content of Bituminous Coalbeds From AdsorptionDocument26 pagesEstimating Methane Content of Bituminous Coalbeds From AdsorptionAdhitya KuswantoroNo ratings yet

- Wave PropertyDocument44 pagesWave PropertyREAL MAE DAYACUS100% (1)

- Practical 5: Bernoulli'S Principle & Equation: Foundation in Science Taylor's University MalaysiaDocument3 pagesPractical 5: Bernoulli'S Principle & Equation: Foundation in Science Taylor's University MalaysiaKwek Su ChinNo ratings yet

- Guimaraes Taylor Snell Eaves etal-JPhysC85 PDFDocument5 pagesGuimaraes Taylor Snell Eaves etal-JPhysC85 PDFPaulo GuimaraesNo ratings yet

- Gear Safety, Service and Application FactorsDocument3 pagesGear Safety, Service and Application Factorsluis_dominguezeNo ratings yet

- Centrifugal Fans Using Vibration Analysis To Detect ProblemsDocument3 pagesCentrifugal Fans Using Vibration Analysis To Detect ProblemsGivon Da Anneista100% (2)

- Lesson 1 in Organic Chemistry (MBS 524)Document29 pagesLesson 1 in Organic Chemistry (MBS 524)id.villegas.sciencenorthNo ratings yet

- Bloxide®: An Aluminum-Base Weldable PrimerDocument1 pageBloxide®: An Aluminum-Base Weldable PrimerBHARANINo ratings yet

- Impact of Machine Magnetization State On Permanent Magnet Losses in Permanent Magnet Synchronous MachinesDocument9 pagesImpact of Machine Magnetization State On Permanent Magnet Losses in Permanent Magnet Synchronous MachinesVahid KarimiNo ratings yet

- Report - The Solubility of Some Salts of Group II ElementsDocument4 pagesReport - The Solubility of Some Salts of Group II Elements赵美怡No ratings yet

- Elastomeric BearingDocument5 pagesElastomeric Bearingjrjdengineers100% (1)

- 2-Hydrodynamic Methods (Sedimentation, Centrifugation and UltracentrifugationDocument24 pages2-Hydrodynamic Methods (Sedimentation, Centrifugation and UltracentrifugationEKANo ratings yet

- Boiler and Steam EnginesDocument13 pagesBoiler and Steam EnginesCass Austria100% (1)

- Multidimensional Flow Modeling of The Compression Test of A Gaede Pump Stage in The Viscous RegimeDocument9 pagesMultidimensional Flow Modeling of The Compression Test of A Gaede Pump Stage in The Viscous RegimeAsif HameedNo ratings yet

- The Ultimate Bearing Capacity of Foundation On SlopesDocument3 pagesThe Ultimate Bearing Capacity of Foundation On SlopesGutnar Gomez ChaconNo ratings yet

- RTAF XSE CatalogueDocument8 pagesRTAF XSE Cataloguepraveen yadavNo ratings yet

- E.4 Leg Support CalculationDocument2 pagesE.4 Leg Support Calculationnaim100% (2)