DCD Material Test Standards - September - 2018

DCD Material Test Standards - September - 2018

Uploaded by

Ghayas JawedCopyright:

Available Formats

DCD Material Test Standards - September - 2018

DCD Material Test Standards - September - 2018

Uploaded by

Ghayas JawedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DCD Material Test Standards - September - 2018

DCD Material Test Standards - September - 2018

Uploaded by

Ghayas JawedCopyright:

Available Formats

4.

Façade and Exterior Wall Covering Systems

4.1. Applicability

4.1.1. The provision of this section specifies the minimum requirements for the classifica-

tion, combustibility, surface burning and flame spread ratings, design, installation,

inspection, and maintenance of exterior façade wall cladding, balcony coverings and

components such as, Metal Composite Panels, Aluminum Composite Panels, Polycar-

bonate Panels, EIFS, ETICS, GRC, GRFC, GRP, Glazing, insulation, sealants etc.

4.1.2. The weather protection of buildings is not the scope or intention of this section.

Thermal and Weather protection aspect of the building façade, such as protection

from temperature, wind, water, pressure etc., shall comply with Municipality regula-

tions, assembly tests and requirements.

4.1.3. The intention of this section is to ensure that flame spread on exterior façade is re-

stricted.

4.1.4. This section applies only to non load bearing exterior walls.

4.1.5. Where exterior walls are required to be loadbearing, such walls shall comply with

relevant sections of this Chapter.

4.2. Material Tests

4.2.1. Except for natural stones and concrete, only materials, tested, listed with Civil De-

fence and complying to the following sections shall be allowed on exterior facades,

based on the building height and occupancy types.

a. Metal Composite Materials (MCM, ACP) complying to Section 4.6.

b. Exterior Insulation and Finish Systems (EIFS) and External Insulation Composite

System (ETICS) complying to Section 4.7.

c. Polycarbonate External Wall and Façade System (PEWFS) complying to

Section 4.8.

d. Sandwich Panels complying to Section 4.9.

e. GRC /GRFC and GRP Systems to Section 4.10.

f. Glazing Systems complying to Section 5.

4.2.2. Where “Assembly Tests” are mandated by Section 4.2.1., the tests shall be conduct-

ed for the entire system assembly, that is intended for use on building façade, in-

cluding wall panels, cavities, insulation, panel rails, joints, sealants, seams, fasteners,

barriers and other construction details. Laboratories testing assembly tests shall en-

sure that the test specimen is duplicated as per intended final installation specifica-

tions, including dimensions, cavities, joints and sealants. Laboratories shall ensure

that façade assembly tests are not ‘over engineered’ purely to pass test criteria.

4.2.3. The tests shall clearly indicate “Pass” or “Fail” criteria and such results shall be clear-

ly noted on the Test Certificates (and CoC, Certificate of Compliance), in evaluation

of the following minimum requirements.

a. The wall assembly shall resist flame propagation over the face of the exterior wall.

b. The wall assembly shall resist flame propagation over the face of the interior of

the wall assembly and cavity.

c. The wall assembly shall resist flame propagation from one story to the next.

d. The wall assembly shall resist flame propagation from compartment of fire origin

to the adjacent compartment.

| CDGH-OP-25 | September 2018 Page 136 of 1348

4.3. Flame Spread on Exterior Façade

4.3.1. Building fires that envelope the façade may be initiated externally from outside the

building sources such as BBQ activity in the balconies, trash can fires, fire works dis-

plays, careless disposals of cigarette butts, electrical fires from cables running in fa-

çade cavities or arson. Fires can originate internally from internal room fire loads of

the building and spread to exterior façade through openings on the exterior walls

such as doors, windows, shattered glazing because of flashover.

4.3.2. Interior fires are intervened and controlled by automatic sprinkler system or by fire

fighters. However, when the fire outgrows fire fighter’s efforts or the sprinkler sys-

tem and reaches flash over stage, it leaps out from the openings onto the exterior

façade or cavities behind the façade of the building causing “leap frog” effect.

4.3.3. At this stage, if the façade material delaminates, exposing the core, if the core of the

facade material is combustible, if the cladding system components such as sealants,

linings, insulation are combustible, the flames start consuming the combustible ma-

terial on the façade, spreading along the surface of the façade and along the cavities

behind the façade.

4.3.4. If the floor slab fire stopping is absent or fire stop material is not approved and not

installed as per standards, if the curtainwall is not listed, the flames penetrate

through the gaps and reach for the upper floors. Flames can even propagate down-

wards if the material on façade is flammable.

4.3.5. Such propagated flames find the other openings of the building from exterior and

enter back into the buildings, feeding on the interior fire loads. This “Reverse leap

frog” effect continues along the building from floor to floor, to height and width,

consuming the building façade swiftly.

4.3.6. Cavity can be part of the façade system by design or cavity can be created by com-

bustible materials on façade system or poor integrity of the façade panels or poor

performance of perimeter joint systems and fire stopping systems or combinations

of these factors. As flame propagates and enters this cavity behind façade system, it

can elongate ten times its length in its search for oxygen in the confined space of

such cavity, thus burning behind the façade system unnoticed from outside for many

floors above the fire origin.

4.3.7. As the intense heat develops behind the façade and flames continue to grow, fa-

çade panels delaminate, exposing more core material to the flame, resulting in a

sudden engulfing of vast area and multiple stories of the building façade under fire.

4.3.8. Apart from combustible façade materials, poor installation, poor joint detailing, poor

mechanical detailing in fixing insulation and façade panels and poor railing system

installations contribute to the rapid façade flame spread and collapse of façade pan-

els and frames, making external fire fighting extremely difficult.

| CDGH-OP-25 | September 2018 Page 137 of 1348

4.3.9. Thus the whole mechanism involved in façade flame spread, after the initial ignition,

can be pin pointed to the following factors.

a. Readily Combustible Core of the façade material (Insulation/Sealants/Panels)

b. Inferior Façade Panel integrity (Poor Panel make and skin bonding)

c. Non tested and Non listed Façade, Sealants and Fire stopping systems

d. Poor installation of Façade and Fire stopping Systems

e. Lack of Thermal barriers and Cavity fire barriers

4.3.10. The initial ignition of the fire can be attributed to human behavior as well. See Chap-

ter 18., Section 2.21. Responsibilities of Residents.

4.4. Façade Approval from Civil Defence

4.4.1. Ten Point Approach to mitigate Façade Fires

Following 10 approaches have been adopted by UAE Civil Defence to tackle the caus-

es of Façade flame spread, pointed out in Section 4.3.9.

4.4.1.1. Core of the Façade material shall be tested in exposed form as per test

requirements of this code.

4.4.1.2. Façade panel as a product shall be tested as per test requirements of this

code.

4.4.1.3. Façade system as wall assembly shall be tested or listed as per test re-

quirements of this code.

4.4.1.4. Curtainwall, Perimeter joints and fire stopping shall be a listed system.

4.4.1.5. Cavity Fire Barrier bands shall be provided in concealed cavities between

façade and primary substrate, at every slab.

4.4.1.6. Fire Breaks shall be provided vertically on exterior façade.

4.4.1.7. Exterior Sprinklers should be considered for the balconies having com-

bustible facade. Interior window sprinklers should be considered for the

glazing. See Chapter 9.

4.4.1.8. Consultants shall have competent and qualified façade specialists in-

house or shall hire Civil Defence approved house of expertise who have

experience and expertise in façade consultancy for Façade design, system

selection and supervision of the façade contractor.

4.4.1.9. Façade contractor and fabricator shall be approved by Civil Defence, with

valid Civil Defence License.

4.4.1.10. Façade installation shall be inspected throughout installation process and

certified by Consultant or Civil Defence approved House of Expertise.

| CDGH-OP-25 | September 2018 Page 138 of 1348

4.4.2. Component (Product/Panel) Approval

4.4.2.1. Approval of “product” or “panel” or component is manufacturer’s responsi-

bility. Manufacturer or supplier shall test the individual product or compo-

nent as part of the assembly (TEST 1, as per Tables 1.14., 1.15., 1.16., 1.17.,

as applicable) to evaluate flame spread characteristics, droplets and smoke

emission of the core, the skin, adhesive, panel and the product, and obtain

approval and product registration from Civil Defence. The Civil Defence cer-

tificate shall only be for the product and permission to be installed “only on

low rise buildings”.

4.4.3. Wall System or Wall Assembly Approval

4.4.3.1. Approval of façade wall “system” intended to be used as “assembly” on

façade of a building shall be the responsibility of the consultant and façade

contractor. The consultant shall ensure that the façade contractors or fabri-

cators test the façade system as per Civil Defence regulation and configura-

tions. (TEST 2, as per Tables 1.14., 1.15., 1.16., 1.17. as applicable).

4.4.3.2. Where manufacturer or supplier undertakes both tests, TEST 1, as pre Sec-

tion 4.4.2.1. as well as TEST 2, as per Section 4.4.3.1., and produces the

“system” test certificates, the Civil Defence registration and certificate shall

be for the product including full system and permission to be installed on

exterior façade of any building, provided that the façade fabricator under-

takes that project façade arrangement matches the tested and certified

wall assembly arrangement.

4.4.3.3. The system manufacturer or supplier and the fabricators shall provide a

formal submittal to the Municipality and Civil Defence material approval

department for the product registration, that shall consist of the following.

a. Product Data – Manufacturer's Specifications, Technical Data and Materi-

al Safety Data Sheet for each material including the composition and lim-

itations, if any.

b. Design Listings and certifications – Core test certifications, Product test

certifications, Assembly test certifications, System design listing or test

certifications, including illustrations, from an accredited testing laborato-

ry as per referenced standards that is applicable to each system configu-

ration. Test reports without certification from accredited laboratories is

invalid.

c. Method Statement shall clearly define component list and the manufac-

turer’s installation instructions.

d. Statement of Manufacturer’s standard warranty for minimum of 10

years.

e. An undertaking letter in understanding with Civil Defence, that supplying

any material or system that is non compliant to this code is illegal and

punishable.

4.4.3.4. Where the building envelope is uniquely shaped and designed, or there is no clear dis-

tinction between vertical façade and horizontal roofing, or where a single envelope is

installed as roofing as well as façade envelope, such materials and system assembly

shall be tested for both façade as well as roofing requirements in accordance with Sec-

tion 4, Section 5 and Section 6 of this chapter.

| CDGH-OP-25 | September 2018 Page 139 of 1348

4.4.4. Design, Specifications and Proposal Approval

4.4.4.1. It is consultant’s responsibility to recruit Façade specialists in house or hire

Civil Defence approved House of Expertise to design the façade system in

complete compliance with this code.

4.4.4.2. Consultant’s façade design submittal to Civil Defence shall be during project

design NOC application, along with architecture, fire alarm, fire fighting and

smoke control proposals. See Annexure 1. Drawing Submission Require-

ments.

4.4.4.3. Consultant’s façade design shall be complete with system listings, material

approval certifications, drawings, sections, illustrations specifying installa-

tion methods as per manufacturer’s guide-lines, insulations, thermal barri-

ers, panel railing, cavity fire barrier locations/specifications, primary sub-

strate details and fixing details.

4.4.4.4. Engineering Judgments (EJ), if any, shall be permitted where Civil Defence

has no objections. Such Engineering Judgment submissions to Civil Defence

shall be site specific, prepared and stamped jointly by main consultant,

House of expertise, Cladding contractor, façade system manufacturers and

façade installers.

4.4.4.5. Where the building envelope is uniquely shaped and designed, or there is

no clear distinction between façade and roofing, or where a single envelope

is installed as roofing as well as façade envelope, such materials and system

assembly shall satisfy both façade and roofing test requirements and shall

be subjected to “mock-up” tests, if Civil Defence initiates such a require-

ment based on the proposal reviews.

4.4.5. Installation

4.4.5.1. It is consultant’s responsibility to ensure that the installers and fabricators

hired are qualified and approved by Civil Defence. See Chapter 18. Section

2.5. Consultant’s Responsibilities.

4.4.5.2. It is consultant’s responsibility to ensure that the installation is carried out

by Civil Defence and Municipality approved installers and fabricators as per

the design specifications, system manufacturer's installation instructions

and complies with code and the local construction regulations.

4.4.6. Installer Qualification

4.4.6.1. Installer specializing in façade and cladding system shall be trained as per

manufacturer’s standards and guidelines and certified by the system manu-

facturer.

4.6.6.2. The trained and experienced installer shall be qualified and licensed by Civil

Defence. The Civil Defence written examinations and license shall be based

on the training and certification provided by the system manufacturer to

install manufacturer’s products as per specified listed system requirements.

| CDGH-OP-25 | September 2018 Page 140 of 1348

4.4.7. Inspection

4.4.7.1. Special inspections shall be required for all façade and cladding systems.

Inspection shall take place in successive stages as installation proceeds.

Such successive stages shall be at every 20% intervals of the total building

height.

4.4.7.2. It is consultant’s responsibility to ensure that installer’s work is inspected

during construction and installation at each stage.

4.4.7.3. It is consultant’s responsibility to recruit in-house qualified façade engi-

neers for inspections or to hire façade inspection services of Civil Defence

approved House of Expertise.

4.4.7.4. Main consultant or house of expertise, who inspect the installation, shall

certify and signoff the façade and cladding installations undertaken during

progressive inspections at each successive stage of installations in report

which shall be part of the documentation required by Civil Defence during

final inspection and handing over.

4.4.7.5. Main consultant or Civil Defence approved House of Expertise individual

inspector undertaking Façade inspections shall have the following qualifica-

tions.

a. Accreditation to ISO/IEC 17020 or relevant IAS criteria or ICC Specialist

building inspection training and certification or an equivalent interna-

tional criteria acceptable to Municipality and Civil Defence.

b. Training and certification by system manufacturers.

c. 3 years experience in fire and life safety aspects of Façade inspections.

4.4.8. Façade Specialist Qualifications

4.4.8.1. The Façade Specialists of Consultant’s in-house team or of Civil Defence

approved House of Expertise, undertaking façade consultancy, design or

inspection shall have the following qualifications.

a. Bachelor’s degree in engineering.

b. 5 years experience in fire and life safety aspects of Façade engineering.

c. Training and certification by system manufacturers.

4.4.8.2. The Façade Specialists of Consultant’s in-house team or of Civil Defence

approved House of Expertise, undertaking façade consultancy, design or

inspection shall be certified by Civil Defence based on their qualifications as

required by Section 4.4.8.1., manufacturer’s training certifications and

written examination.

| CDGH-OP-25 | September 2018 Page 141 of 1348

4.5. General Requirements for Exterior Façade Systems

4.5.1. Coatings on primary substrate

4.5.1.1. Bitumen, bituminous products and flammable agents as anti-corrosion or

water-proofing coatings shall not be applied on primary substrates, either

on metals or concrete. Bitumen has fire point of 1750C and propagates

building envelope fires.

4.5.2. Building Fire Rating

4.5.2.1. Façade materials, exterior wall systems, claddings and insulation installed

on any building shall not reduce the fire resistance rating of the exterior

wall where required by other sections of this Chapter.

4.5.3. Thermal Barrier

4.5.3.1. Façade Cladding Materials such as MCM and ACP shall be completely sepa-

rated from the building interior and plenum by a thermal barrier, complying

to test standards of Section 7.1.11. of this chapter.

4.5.3.2. Required thermal barriers shall not be installed on the walls or frames with

adhesives alone. Thermal barriers shall be fixed mechanically on primary

substrate, structural frame or the wall or on rails as appropriate.

4.5.3.3. Thermal barrier is not mandatory only when MCM or ACP or cladding mate-

rials are used on balconies and minor architectural appendages on exterior

wall.

4.5.3.4. In all cases the Building Exterior Base wall must be imperforate and provide

a nominal 15 minutes fire resistance ( Insulation and integrity).

4.5.4. Cavity Fire Barrier

4.5.4.1. Cavity Fire Barriers shall be incorporated into façade designs, including ar-

chitectural features with uninterrupted vertical columns (e.g. High Rise

‘Fins’), at every floor horizontally around window openings on all sides to

limit fire breakout from a room into the adjacent cavity. This cavity barrier

shall not be a thermal bridge.

4.5.4.2. Cavity Fire Barriers shall be incorporated into façade design at every floor

vertically to restrict flame within continuous cavities or where cavities

bridge the perimeter firestopping. Perimeter Firestopping systems shall

be installed as per Section 3 of this chapter.

4.5.4.3. Cavity fire barrier shall be of Non combustible material, in accordance

with Section 7.1.45. of this chapter.

4.5.4.4. The cavity fire barrier shall be 100 mm high and, where the thermal insula-

tion is not of equivalent fire resistance to the cavity barrier, shall run

through insulation horizontally at each floor level and vertically on each

face of façade as required by Section 4.5.4.2.

| CDGH-OP-25 | September 2018 Page 142 of 1348

4.5.4.5. The installation shall ensure that compartmentation is established between

the façade skin and the primary substrate and no cavity exists for fire to

pass through. See figures 1.19.a and figure 1.19.b.

4.5.4.6. The cavity fire barrier shall be mechanically bonded to the primary sub-

strate or structural frame and extended or compressed behind the finish

façade panel to ensure that no fire path are created between the barrier

and substrate or external façade panel.

4.5.4.7. Where cavity is necessary part of ventilated façade design and cavity needs

to be maintained, an intumescent system, approved and listed for the pur-

pose shall be fixed as cavity fire barrier band. These intumescent bands

serve as fire barriers when exposed to flames and shall expand to seal the

gaps.

4.5.5. Fire Breaks

4.5.5.1. It is highly recommended to provide “fire breaks” where cladding materials

are installed on exterior façade by restricting the vertical length of building

envelope of cladding materials to not more than 15 m, followed by 6 m of

non-combustible material as envelope finish such as concrete or tiles or

materials approved as per Section 7.1.45. , in an alternative manner along

the building envelope’s face.

| CDGH-OP-25 | September 2018 Page 143 of 1348

4.5.6. Groove Sealants, Gaskets, Backer Rod and vapour barrier systems

4.5.6.1. Use of flammable silicon or fillers or non rated groove sealants, materials

in between panel joints is not permitted unless these joint fillers are test-

ed as per Section 7.1.45 and part of their full wall assembly and were used

in achieving “pass criteria” as the Wall Assembly “Large Scale Tests”. See

figures 1.19.a and figure 1.19.b.

4.5.6.2. Vapour Barrier systems (VBS) and membranes are generally provided to

resist water vapour and are often an essential part of the façade system.

Vapour barriers, particularly rubber, bituminous based materials, maybe

combustible by their nature and may affect the overall performance of

the façade system in respect of fire development and spread. Therefore

the VBS product should be checked against the MSDS for base content

(See Section 4.5.1.1). VBS products must be registered and Licensed by

the Civil Defence and must achieve EN13501-1 Class A as per Section

7.1.45.

4.5.6.3. EPDM products, Rubber sheeting and architectural carpets are creating

new design possibilities as building skins. EPDM rubber (ethylene propyl-

ene diene monomer rubber) and similar rubber products must not be

used as a full VBS/Façade Liner. However it is acceptable in other dis-

crete locations, such as Curtain Wall Gaskets or window waterproofing

provided the fire performance achieves a minimum of EN 13501-1 C,

S2,d0., as per Section 7.1.45.

4.5.6.4. Artificial turf has been typically used for sports grounds or indoor solu-

tions, but now this surface covering is being used in the design of indoor

and outdoor spaces in horizontal and vertical applications. Where such

applications are used as floor coverings they shall be tested to EN 13501

-1 and achieve a minimum of Cfl,S1 where the premises are provided

with a sprinkler system or, with the exception of areas being used for

Assembly, where the installation is completely out doors. Where the

material is being used as an internal wall covering it must comply with

Section 7.1.4. or when proposed as an External wall covering, it shall

comply with the requirements of chapter 1 Section 4, achieve ASTM E84

class A and EN13501-1 Class A2 minimum. The Façade system which the

material forms a part must also be tested to NFPA 285 and NFPA 268

( ‘no ignition at 12.5 kw/m2 at 20 minutes)

4.5.7. Openings (Window, Doors, Ventilation) Flashing

4.5.7.1. Window (opening) flashing where cladding materials intersect shall be of

steel formed and fixed mechanically or an appropriate and Civil Defence

approved Fire Stopping/safing system fire to completely line windows or

openings and overlap onto both exterior and interior surfaces of wall as-

sembly. It must be ensured that any void or cavity between the exterior

and interior surfaces of the façade system is protected to prevent fire ac-

cessing the space. See figures 1.19.a and figure 1.19.b.

| CDGH-OP-25 | September 2018 Page 144 of 1348

4.5.8. Architectural features

4.5.8.1. Architectural features shall comply to all the relevant requirements of Sec-

tion 4.

4.5.9. Openings on the exterior walls

4.5.9.1. Openings on exterior walls in adjacent stories shall be separated vertically

to protect against fire spread on the exterior of the buildings where the

openings are within 1524 mm of each other horizontally. Such openings

shall be separated vertically not less than 914 mm by spandrel gird-

ers, exterior walls or other similar assemblies that have a fire-resistance

rating of not less than 1 hour, rated for exposure to fire from both sides, or

by flame barriers that extend horizontally not less than 762 mm beyond

the exterior wall. Flame barriers shall have a fire resistance rating of not

less than 1 hour.

4.5.9.2. Where a Spandrel Panel is used to satisfy the requirement in Section

4.5.9.1., it shall be ensured that the materials used and spandrel panel as

system provides a minimum of 60 minutes fire resistance from BOTH sides

of the panel. All transoms and Mullions must be protected in this respect.

4.5.9.3. Fire safing forming the perimeter edge protection must ensure the same

performance as the structural floor slab in respect of F and T ratings.

4.5.9.3. Aluminium Back Pans shall not be accepted.

4.5.10. Installation of Exterior Façade Lighting

4.5.10.1. Façade lighting fixtures have high intensity light and heat. When over heat-

ed or poorly installed, these fixtures emit intense heat and can be cause of

fire ignition source when in contact with readily combustible materials.

4.5.10.2. Flood Lighting fixtures shall not be installed directly on façade surface,

wood, plastic, insulation, façade cavity with combustible material etc. Flood

lighting fixtures shall be installed such that lighting fixture heat is not dissi-

pated directly onto the façade surface. Appropriate steel framing and non

combustible thermal insulation shall separate the lighting fixtures from fa-

çade surface.

| CDGH-OP-25 | September 2018 Page 145 of 1348

4.5.11. Installation of Electrical Equipment on Facade

4.5.11.1. Installation of electrical equipment such as Air Conditioning units, Kitchen

Exhaust ducts, Heaters, Boilers, Diesel generators directly in contact with

Façade surface can be source of fire ignition.

4.5.11.2. Poor installation, poor wiring and overheating of such electrical equipment

and its contact with combustible insulation or façade material shall be

avoided. Electrical equipment shall be separated from façade surface with

proper steel frames, steel lining, metal conduit for wiring and non combus-

tible insulation coverings.

4.5.11.3. Façade cavity shall not be used for routing electrical cabling, LPG or natural

gas piping and hot water piping.

4.5.11.3. Regular maintenance of the electrical equipment shall be ensured to keep

the equipment in good working condition.

4.5.12. Installation of Advertising Banners and Hoardings on Facade

4.5.12.1. Installation of non approved advertising billboard material on approved

façade material can compromise the exterior wall’s safety.

4.5.12.2. Sign boards, billboards, advertising banners shall comply with Table 1.9.56.

4.5.12.2. Flammable, Combustible, Plastic and Foam materials shall not be used for

advertising or billboard on façade envelope.

4.5.13. Housekeeping

4.5.13.1. Competent house keeping shall be ensured in every building to keep exteri-

or façade surface clean and free from flammable and combustible materials

within the vicinity. Trash accumulation near façade surface shall be avoid-

ed. Trash cans shall not be placed adjacent to exterior façade surface.

| CDGH-OP-25 | September 2018 Page 146 of 1348

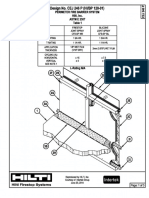

Figure 1.19.a.: Typical MCM / ACP Installation on Block wall

| CDGH-OP-25 | September 2018 Page 147 of 1348

Figure 1.19.b..: Typical MCM / ACP Installation on Frame

| CDGH-OP-25 | September 2018 Page 148 of 1348

4.6. Metal Composite Materials and Panels (MCM, ACP)

4.6.1. Metal Composite Panels (such as Aluminium Composite Panels, ACP), other than

sandwich panels used on façade and exterior wall assembly shall comply with gen-

eral requirements of Section 4.5 and the specific requirements of Section 4.6.

4.6.2. Definition

4.6.2.1. A factory manufactured panel consisting of metal skins bonded to both fac-

es of a “core”. All MCM’s shall be tested and approved at the maximum

thickness intended for use and intended assemblies. However, MCM’s

(Such as ACP’s) shall have a minimum exterior skin thickness of 0.019 in.

(0.5 mm), a minimum interior skin thickness of 0.010 in. (0.25 mm) and a

maximum panel thickness of ¼ in. (6.3 mm) where installed on facades and

exterior walls.

| CDGH-OP-25 | September 2018 Page 149 of 1348

4.6.3. Specific Requirements

4.6.3.1. MCM/ACP shall be permitted to be installed on the façade and exterior of

buildings classified as Type I, Type II, Type III, or Type IV construction, as

defined in Chapter 1, Table 1.7., and such installation shall not change the

construction classification or fire performance of the building.

4.6.3.2. MCM/ACPs shall be Marked/labeled to verify its certification mark from

accredited certification body.

4.6.3.3. MCM/ACP Core shall not be of foam plastic insulation or LDPE (Low Density

Polyethylene) or any such expanded plastic having density less than 320 kg/

m3).

4.6.3.4. MCM/ACP Core shall be tested and evaluated separately. Core (exposed

without skin) used in Cladding and façade Panels can be of plastic or miner-

al or combination of such material having flame and smoke spread charac-

teristics as per TEST 1 in accordance with Table 1.14.a. and Table 1.14.b.

test requirements.

4.6.3.5. The fire resistance performance of Fire Rated façade system is a function of

the base exterior wall when tested to ASTM E119 (or equivalent) and NOT

only the MCM/ACP panel element. It must be made clear by the MCM/ACP

manufacturer that their products have no Resistance to Fire qualities when

tested as a system in accordance with Table 1.14.b. unless the MCM/ACP

panel has been tested as an individual component product to ASTM E119.

4.6.4. Test Certifications

4.6.4.1. MCM/ACP panels and facade systems on non-fire resistance rated and non

load bearing exterior wall coverings shall comply with Table 1.14.a.

4.6.4.2. MCM/ACP panels and facade systems on fire resistance rated exterior and

non-load bearing wall assembly coverings shall comply with Table 1.14.b.

4.6.5. Application

4.6.6.1. The occupancies and type of buildings that are allowed to have MCM or

ACP shall be in accordance with Table 1.14.a. and Table 1.14.b.

| CDGH-OP-25 | September 2018 Page 150 of 1348

Table 1.14.a.: MCM and ACP On Non-Fire Resistance rated and Non-Load bearing Exterior wall

coverings-Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

MCM/ ACP CORE AND MCM/ ACP PANELS WITH

PANEL AS PRODUCT WALL ASSEMBLY

1. SUPER HIGHRISE BUILDING i. Core shall be tested to the v. BS 8414 –1 Or 2

criteria iii and iv. With pass criteria

2. HIGHRISE BUILDING ii. Panel shall be tested with as per BRE 135

the thickness intended to

3. MALLS the criteria iii and iv. OR

4. THEME PARKS iii. EN 13501-1 vi. NFPA 285

With pass criteria With pass criteria

A1 OR A2-s1-d0 “Pass”

5. SCHOOLS

AND OR

6. HOSPITALS

iv. ASTM D1929 vii. FM 4881

7. ASSEMBLY MCM/ACP shall have self With pass criteria

ignition temperature of not “Pass”

less than 3430C.

OR

viii. ISO 13785-2

With pass criteria

“Pass”

8. LOWRISE BUILDING i. Core shall be tested to the v. BS 8414 –1 Or 2

criteria iii and iv. With pass criteria

9. MIDRISE BUILDING ii. Panel shall be tested with as per BRE 135

the thickness intended to

10. WAREHOUSE the criteria iii and iv. OR

11. INDUSTRIAL iii. EN 13501-1 vi. NFPA 285

With pass criteria With pass criteria

B-s1-d0 “Pass”

AND OR

iv. ASTM D1929 vii. FM 4881

MCM/ACP shall have self With pass criteria

ignition temperature of not “Pass”

less than 3430C.

OR

viii. ISO 13785-2

With pass criteria

“Pass”

| CDGH-OP-25 | September 2018 Page 151 of 1348

Table 1.14.b.: MCM and ACP on Fire Resistance rated Exterior wall coverings-Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

MCM/ ACP CORE AND MCM/ ACP PANELS IN

PANEL AS PRODUCT WALL ASSEMBLY

1. ANY BUILDING WITH ANY HEIGHT i. Core shall be tested to the v. ASTM E 119

AND ANY OCCUPANCY criteria iii and iv. With pass criteria

ii. Panel shall be tested with “1 Hr or 2 Hr OR 3 Hr as

HAVING REQUIREMENT OF FIRE the thickness intended to per required fire rating of

RESISTANCE RATED EXTERIOR the criteria iii and iv. the wall.

WALL CONSTRUCTION, WHERE

OR

REQUIRED BY OTHER SECTIONS OF iii. EN 13501-1

THIS CHAPTER. With pass criteria vi. UL 263

A1 OR A2-s1-d0 With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

AND per required fire rating of

the wall.

iv. ASTM D1929

MCM/ACP shall have self OR

ignition temperature of not

less than 3430C. vii. EN 1362-3

With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

OR

viii. EN 1362-4

With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

| CDGH-OP-25 | September 2018 Page 152 of 1348

4.7. Exterior Insulation and Finish Systems (EIFS) and External

Thermal Insulation Composite System (ETICS)

4.7.1. Exterior Insulation and Finish Systems (EIFS) and External Thermal Insulation Compo-

site System (ETICS) used on façade and exterior wall assembly shall comply with gen-

eral requirements of Section 4.5 and the specific requirements of Section 4.7.

4.7.2. Definition

4.7.2.1. Exterior insulation and finish systems (EIFS) are materials, assemblies made up of

layers of foam plastic insulation or expanded polystyrene or mineral insulation

with adhesives and fiber reinforcement, used in exterior non load bearing walls as

wall coverings and exterior cladding systems

| CDGH-OP-25 | September 2018 Page 153 of 1348

4.7.3. Specific Requirements

4.7.3.1. EIFS and ETICS shall be constructed such that it meets the performance

characteristics required as per ASTM E 2568.

4.7.3.2. EIFS and ETICS shall be certified and listed by a third party independent

testing and Certification body, approved by Civil Defence.

4.7.3.3. EIFS and ETICS shall be Marked/labeled to verify its certification mark from

accredited certification body.

4.7.3.4. The layers and core materials shall be tested separately and entire assem-

bly including ornaments, trims and moldings’ with intended thickness,

joints, seams, fasteners and wall arrangement shall be tested in accordance

with Table 1.15.a.

4.7.3.5. Where EIFS or ETICS is installed on Fire rated or load bearing walls, the wall

arrangement shall be tested in accordance with Table 1.15.b.

4.7.3.6. EIFS shall be specified in accordance with ANSI/EIMA 99-A (Latest Edition)

‘American National Standard for EIFS’. ETICS shall meet the performance

requirements as per ETAG 004 (Latest Edition) ‘Guidelines for European

Technical Approval of ETICS with Rendering’

4.7.3.7. Requirements of the ANSI/EIMA 99-A or ETAG 004 guidelines shall be fol-

lowed independently. Using parts from each of the guidelines is not per-

mitted.

4.7.4. Test Certifications

4.7.4.1. EIFS and ETICS panels and facade systems on non-fire resistance rated and

non load bearing exterior wall coverings shall comply with Table 1.15.a.

4.7.4.2. EIFS and ETICS panels and facade systems on fire resistance rated exterior

wall assembly coverings shall comply with Table 1.15.b.

4.7.5. Application

4.6.6.1. The occupancies and type of buildings that are allowed to have EIFS and

ETICS shall be in accordance with Table 1.15.a. and Table 1.15.b.

Points to Ponder

Governments all over the world advocate usage of green building products,

which contribute to high energy efficient performances of buildings and

reduce the carbon footprints.

However, there is a conflict when these sustainable building products are

challenged with their fire resistance performance.

| CDGH-OP-25 | September 2018 Page 154 of 1348

Table 1.15.a.: EIFS and ETICS on Non-Fire Resistance rated and Non-Load bearing Exterior wall

coverings-Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

EIFS/ETICS EIFS/ETICS AS

COMPONENTS AND WALL ASSEMBLY

PANEL AS PRODUCT

1. ANY BUILDING i. All components of the EIFS iii. BS 8414 –1 Or 2

(All layers including EPS/ With pass criteria

2. ANY INSTALLATION XPS, coating, insulation, as per BRE 135

mesh, adhesive and finish.)

3. ANY AESTHETICS shall be class A (Flame OR

spread 0-25, Smoke devel-

opment 0-450) when indi- iv. NFPA 285

vidually tested to With pass criteria

ASTM E 84 or UL 723 “Pass”

AND OR

ii. NFPA 268 v. FM 4881

With pass criteria With pass criteria

2

“No Ignition at 12.5 kw/m “Pass”

at 20 minutes”

OR

vi. ISO 13785-2

With pass criteria

“Pass”

| CDGH-OP-25 | September 2018 Page 155 of 1348

Table 1.15.b.: EIFS and ETICS on Fire Resistance rated Exterior wall coverings-Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

EIFS/ETICS EIFS/ETICS AS

COMPONENTS AND WALL ASSEMBLY

PANEL AS PRODUCT

1. ANY BUILDING i. All components of the EIFS iii. ASTM E 119

(All layers including With pass criteria

2. ANY INSTALLATION coating, insulation, mesh, “1 Hr or 2 Hr OR 3 Hr as

adhesive and finish.) shall per required fire rating of

3. ANY AESTHETICS be class A when individual- the wall.

ly tested to ASTM E 84 or

UL 723 OR

AND iv. UL 263

With pass criteria

ii. NFPA 268 “1 Hr or 2 Hr OR 3 Hr as

With pass criteria per required fire rating of

“No Ignition at 12.5 kw/m2 the wall.

at 20 minutes”

OR

v. EN 1362-3

With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

OR

vi. EN 1362-4

With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

| CDGH-OP-25 | September 2018 Page 156 of 1348

4.8. Polycarbonate External Wall and Façade System (PEWFS)

4.8.1. Polycarbonate External Wall and Façade System (PEWFS) used on façade and exteri-

or wall assembly shall comply with general requirements of Section 4.5 and the spe-

cific requirements of Section 4.8.

4.8.2. Definition

4.8.2.1. Polycarbonate is a type of thermoplastic, a polymer that becomes pliable or

moldable above a specific temperature and returns to a solid state on cool-

ing. Polycarbonate is an engineering thermoplastics.

| CDGH-OP-25 | September 2018 Page 157 of 1348

4.8.3. Specific Requirements

4.8.3.1. PEWFS shall be certified and listed by a third party independent Testing and

Certification body, approved by Civil Defence.

4.8.3.2. PEWFS shall be Marked/labeled to verify its certification mark from accred-

ited certification body.

4.8.3.3. The entire assembly including ornaments, trims and moldings with intended

thickness, joints, seams, fasteners and wall arrangement shall be tested in

accordance with Table 1.16.a.

4.8.4. Test Certifications

4.8.4.1. PEWFS panels and facade systems on non-fire resistance rated and non

load bearing exterior wall coverings shall comply with Table 1.16.a.

4.8.4.2. EIFS and ETICS panels and facade systems on fire resistance rated exterior

wall assembly coverings shall comply with Table 1.16.b.

4.8.5. Application

4.8.5.1. The occupancies and type of buildings that are allowed to have PEWFS shall

be in accordance with Table 1.16.a. and Table 1.16.b.

| CDGH-OP-25 | September 2018 Page 158 of 1348

Table 1.16.a.: PEWFS on Non-Fire Resistance rated and Non-Load bearing Exterior wall coverings-

Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

PEWFS PANEL AS PEWFS AS

PRODUCT WALL ASSEMBLY

1. SUPER HIGHRISE BUILDING i. EN 13501-1 iii. BS 8414 –1 Or 2

With pass criteria With pass criteria

2. HIGHRISE BUILDING A1 OR A2-s1-d0 as per BRE 135

3. MALLS AND OR

4. THEME PARKS ii. ASTM D1929 iv. NFPA 285

With pass criteria With pass criteria

PEWFS shall have self igni- “Pass”

5. SCHOOLS

tion temperature of not

less than 3430C OR

6. HOSPITALS

v. FM 4881

7. ASSEMBLY With pass criteria

“Pass”

OR

vi. ISO 13785-2

With pass criteria

“Pass”

8. LOWRISE BUILDING i. EN 13501-1 iii. BS 8414 –1 Or 2

With pass criteria With pass criteria

9. MIDRISE BUILDING B-s1-d0 as per BRE 135

10. WAREHOUSE AND OR

11. INDUSTRIAL ii. ASTM D1929 iv. NFPA 285

With pass criteria With pass criteria

PEWFS shall have self igni- “Pass”

tion temperature of not

less than 3430C OR

v. FM 4881

With pass criteria

“Pass”

OR

vi. ISO 13785-2

With pass criteria

“Pass”

| CDGH-OP-25 | September 2018 Page 159 of 1348

Table 1.16.b.: PEWFS on Fire Resistance rated Exterior wall -Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

PEWFS PANEL AS PEWFS IN

PRODUCT WALL ASSEMBLY

1. ANY BUILDING i. EN 13501-1 iii. ASTM E 119

With pass criteria With pass criteria

2. ANY INSTALLATION A1 OR A2-s1-d0 “1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

3. ANY AESTHETICS AND the wall.

ii. ASTM D1929 OR

With pass criteria

PEWFS shall have self igni- iv. UL 263

tion temperature of not With pass criteria

less than 3430C “1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

OR

v. EN 1362-3

With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

OR

vi. EN 1362-4

With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

| CDGH-OP-25 | September 2018 Page 160 of 1348

4.9. Sandwich Panels

4.9.1. Sandwich Panels shall comply with general requirements of Section 4.5, where used

on façade and exterior wall and the specific requirements of Section 4.9.

4.9.2. Sandwich Panels used in other applications such as internal partitions, cold storage

or roofing shall comply with the specific requirements of Section 4.9.

4.9.3. Sandwich panels shall be tested for the intended applications such as external, inter-

nal, roofing or cold storages and shall not be interchanged in their end applications.

4.9.4. Definition

4.9.4.1. Sandwich panels are foam plastic insulated sandwich panels (FISP) or mineral

core insulated panels or self supporting double skin metal faced insulating

panels.

| CDGH-OP-25 | September 2018 Page 161 of 1348

4.9.4.2. Generally cores used in the sandwich panels based on their intended appli-

cation are Polyisocyanurate Foam (PIR), Polyurethane Foam (PUR), Expanded

or Extruded Polystyrene (EPS and EXPS) or Non-combustible mineral wool or

fiberglass.

4.9.4.3. Sandwich panels are generally used as external wall systems in low rise

building such as warehouses and roofing. As internal partitions and ceiling

applications, sandwich panels are used in, cold storages, food industries,

warehouses and industries.

4.9.5. Specific Requirements

4.9.5.1. Where Sandwich panels are installed on the exterior walls, they shall not

reduce the fire resistance rating of the wall.

4.9.5.2. Sandwich panels shall be Marked/labeled to verify its certification mark

from accredited certification laboratory with its intended end use and appli-

cation (Such as Internal wall, External wall, cold storage, roofing etc.), in

compliance with this code.

4.9.5.3. Sandwich panels installed as exterior walls shall be completely separated

from the building interior and plenum by a thermal barrier, complying to

test standards of Section 7.1.11. of this chapter.

4.9.5.4. Thermal barrier shall not be required in masonry or concrete wall, floor or

roof constructions where the sandwich panel is covered on each face by

concrete or masonry with a minimum thickness of 25 mm.

4.9.5.5. Thermal barrier shall not be required in fully Sprinkler protected cooler or

freezer or cold rooms and the rooms they are located in, when sandwich

panel is minimum 4 inch thick and has Class A rating as per UL 723 or ASTM

E 84 (FSI-25, SDI-450 or less), when tested both core and panel. Moreover,

sandwich panel shall have self ignition temperature, not less than 4270C in

accordance with ASTM D 1929.

4.9.5.6. Thermal barrier shall not be required in roof assemblies where sandwich

panels are separated from the interior of the building by wood structural

sheathing not less than 12 mm in thickness. And the sandwich panel is part

of roof covering assembly tested and passes with FM 4450 or UL 1256 or

FM 4471.

4.9.5.7. Foam plastic insulation, exterior facings an coatings shall be tested sepa-

rately in the thickness of intended use as per Table 1.17.c.

| CDGH-OP-25 | September 2018 Page 162 of 1348

4.9.6. Test Certifications

4.9.6.1. Sandwich panels shall be permitted to be installed as exterior walls when

tested in accordance with Table 1.17.a.

4.9.6.2. Sandwich panels as fire resistance rated exterior wall assembly coverings

shall comply with both Table 1.17.a. and Table 1.17.b.

4.9.6.3. Sandwich panels used in applications other than as exterior walls shall com-

ply with test requirements in accordance with Table 1.17.c.

4.9.7. Application

4.9.7.1. The occupancies and type of buildings that are allowed to have sandwich

panels in their exterior wall facades shall be in accordance with Table

1.17.a. and Table 1.17.b.

| CDGH-OP-25 | September 2018 Page 163 of 1348

Table 1.17.a.: Sandwich Panels on Non-Fire Resistance rated and Non-Load bearing Exterior wall

coverings-Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

SANDWICH PANEL AS SANDWICH PANEL IN

PRODUCT WALL ASSEMBLY

1. SUPER HIGHRISE BUILDING i. Core shall be tested to the v. BS 8414 –1 Or 2

criteria iii and iv. With pass criteria

2. HIGHRISE BUILDING as per BRE 135

ii. Panel shall be tested with

the thickness intended to OR

3. MALLS

the criteria iii and iv.

4. THEME PARKS vi. NFPA 285

iii. EN 13501-1 With pass criteria

With pass criteria “Pass”

5. SCHOOLS A OR A2-s1-d0

OR

6. HOSPITALS AND

vii. FM 4881

7. ASSEMBLY iv. ASTM D1929 With pass criteria

With pass criteria “Class 1”

PEWFS shall have self igni-

tion temperature of not OR

less than 3430C.

viii. ISO 13785-2

With pass criteria

“Pass”

8. LOWRISE BUILDING i. Core shall be tested to the vi. BS 8414 –1 Or 2

criteria iii or iv and v. With pass criteria

9. MIDRISE BUILDING as per BRE 135

ii. Panel shall be tested with

the thickness intended to OR

10. WAREHOUSE

the criteria iii or iv and v.

11. INDUSTRIAL vii. NFPA 285

With pass criteria

iii. EN 13501-1 “Pass”

With pass criteria

B-s1-d0 OR

OR viii. FM 4881

With pass criteria

iv. FM 4880 “Class 1”

With pass criteria

“Non-combustible core” OR

AND ix. ISO 13785-2

With pass criteria

v. ASTM D1929 “Pass”

Shall have self ignition

temperature of not less

than 3430C.

| CDGH-OP-25 | September 2018 Page 164 of 1348

Table 1.17.b.: Sandwich Panel on Fire Resistance rated Exterior wall -Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

SANDWICH PANEL AS SANDWICH PANEL IN

PRODUCT WALL ASSEMBLY

1. ANY BUILDING WITH ANY HEIGHT i. Core shall be tested to the vi. ASTM E 119

AND ANY OCCUPANCY criteria iii or iv and v. With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

ii. Panel shall be tested with per required fire rating of

(SHALL BE TESTED FOR THE the thickness intended to the wall.

THICKNESS INTENDED TO BE USED) the criteria iii or iv and v.

OR

iii. EN 13501-1 vii. UL 263

With pass criteria With pass criteria

A OR A2-s1-d0 “1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

OR the wall.

iv. FM 4880 OR

With pass criteria

“Non-combustible core” viii. EN 1362-3

With pass criteria

AND “1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

v. ASTM D1929 the wall.

Shall have self ignition

temperature of not less OR

than 3430C.

ix. EN 1362-4

With pass criteria

“1 Hr or 2 Hr OR 3 Hr as

per required fire rating of

the wall.

| CDGH-OP-25 | September 2018 Page 165 of 1348

Table 1.17.c.: Sandwich Panel in various applications -Test Requirements

APPLICATIONS TEST 1 TEST 2

SANDWICH PANEL AS SANDWICH PANEL IN

PRODUCT WALL ASSEMBLY

1. INTERNAL NON FIRE RESISTANCE i. EN 13501-1 NOT REQUIRED

RATED WALLS AND PARTITIONS With pass criteria

B-d0-S1

OR

(SHALL BE TESTED FOR THE

THICKNESS INTENDED TO BE USED) i. ASTM E 84/ UL 723

With pass criteria

“Class A”

OR

i. BS 476 Part 7

With pass criteria

“Class 1”

OR

i. FM 4880

With pass criteria

“Non-combustible core”

AND

i. ASTM D1929

Shall have self ignition

temperature of not less

than 3430C.

2. INTERNAL FIRE RESISTANCE i. EN 13501-1 iv. FM 4881

RATED WALLS AND PARTITIONS With pass criteria With pass criteria

B-d0-S1 “Class 1”

OR

(SHALL BE TESTED FOR THE

OR

THICKNESS INTENDED TO BE USED) v. UL 1715

ii. FM 4880 With pass criteria

With pass criteria “1 Hr or 2 Hr OR 3 Hr as

“Non-combustible core” per required fire rating of

the wall.

AND OR

iii. ASTM D1929 vi. UL 1040

Shall have self ignition With pass criteria

temperature of not less “1 Hr or 2 Hr OR 3 Hr as

than 3430C. per required fire rating of

the wall.

| CDGH-OP-25 | September 2018 Page 166 of 1348

Table 1.17.c.: Sandwich Panel in various applications -Test Requirements

APPLICATIONS TEST 1 TEST 2

SANDWICH PANEL AS SANDWICH PANEL IN

PRODUCT WALL ASSEMBLY

3. COLD STORAGE WALLS i. EN 13501-1 NOT REQUIRED

With pass criteria

(SHALL BE TESTED FOR THE B-d0-S1

THICKNESS INTENDED TO BE USED)

OR

ii. FM 4880

With pass criteria

“Non-combustible core”

AND

iii. ASTM D1929

Shall have self ignition

temperature of not less

than 3430C.

4. ROOFING-SPRINKLERED i. ASTM D1929 ii. NFPA 256

BUILDINGS Shall have self ignition With pass criteria

temperature of not less “Class B”

than 3430C. OR

(SHALL BE TESTED FOR THE

THICKNESS INTENDED TO BE USED) iii. ASTM E 108

With pass criteria

“Class B”

OR

iv. EN 13501-5 +A1

With pass criteria

“Class Broof t4”.

OR

v. UL 790

With pass criteria

“Class B”

| CDGH-OP-25 | September 2018 Page 167 of 1348

Table 1.17.c.: Sandwich Panel in various applications -Test Requirements

APPLICATIONS TEST 1 TEST 2

SANDWICH PANEL AS SANDWICH PANEL IN

PRODUCT WALL ASSEMBLY

5. ROOFING-NON SPRINKLERED i. ASTM D1929 ii. NFPA 276

BUILDINGS Shall have self ignition With pass criteria

temperature of not less “Class 1”

than 3430C. OR

(SHALL BE TESTED FOR THE

THICKNESS INTENDED TO BE USED) Iii. ASTM E 108

With pass criteria

“Class A”

OR

Iv. EN 13501-5 +A1

With pass criteria

“Class Broof t4”.

OR

v. UL 790

With pass criteria

“Class A”

OR

vi. FM 4470 Or FM 4471

With pass criteria

“Pass”

| CDGH-OP-25 | September 2018 Page 168 of 1348

4.10. GRC/GRFC and GRP Systems

4.10.1. GRP/GRFC and GRP systems shall comply with general requirements of Section 4.5,

where used on façade and exterior wall and the specific requirements of Section

4.10.

4.10.2. GRP/GRFC and GRP systems may be used in a variety of building exterior envelope

and Façade systems, many of which may be project based and of a specific design.

However Manufacturers, Consultants, Design Teams, Contractors and Testing labor-

atories must ensure that these systems comply in the first instance with the Reac-

tion to Fire, Surface Spread of Flame and Resistance to Fire performance require-

ments and intent of the UAE Fire and Life Safety Code of Practice. This also includes

selection of non-combustible formers, appropriate Fire Stopping and buildability of

the tested system against the field application.

4.10.3. Definition

4.10.3.1. Glass fiber reinforced concrete or GFRC is a type of fiber-reinforced concrete. The

product is also known as glass fiber reinforced concrete or GRC. Glass fiber con-

cretes are mainly used in exterior building façade panels and as architectural pre-

cast concrete.

| CDGH-OP-25 | September 2018 Page 169 of 1348

4.10.3.2. Glass-reinforced plastic (GRP), also known as glass fibre reinforced plastic (GRFP)

is a fibre reinforced polymer made of a plastic matrix reinforced with Glass Fi-

bres.

4.10.4. Specific Requirements

4.10.4.1. GRP(GRFP) shall be constructed such that it meets the performance char-

acteristics required as per ASTM D3841.

4.10.4.2. GRC/GRFC and GRP systems shall be certified and listed by a third party

independent testing and Certification body, approved by Civil Defence.

4.10.4.3. GRC/GRFC and GRP systems shall be Marked/labeled to verify its certification

mark from accredited certification laboratory.

4.10.4.4. The Base layers and core materials shall be tested separately and entire as-

sembly including ornaments, trims and moldings’ with intended thickness,

joints, seams, fasteners and wall arrangement shall be tested in accordance

with Table 1.18.a.

4.10.4.5. Where GRC/GRFC and GRP systems are installed on Fire rated or load

bearing walls, the wall arrangement shall be tested in accordance with

Table 1.18.b.

4.10.4.6. Reaction to Fire Testing of GRC/GRFS/GRP Products to EN13501-1 MUST in-

clude EN 13823 and EN ISO 11925 testing as a panel with the thickness and

form of intended use, including consideration of air space behind the formed

panel. Mounting on non-combustible substrates for the EN ISO 11925 test is

not appropriate should the intended use not be reflected during reaction to

fire testing.

4.10.5. Test Certification

4.10.5.1. GRC/GRFC and GRP panels and facade systems on non-fire resistance rated

and non load bearing exterior wall coverings shall comply with Table 1.18.a.

4.10.5.2. GRC/GRFC and GRP panels and facade systems on fire resistance rated exteri-

or wall assembly coverings shall comply with Table 1.18b.

4.10.6. Application

4.10.6.1. The occupancies and type of buildings that are allowed to have GRC/GRFC

and GRP shall be in accordance with Table 1.18.a. and Table 1.18.b.

| CDGH-OP-25 | September 2018 Page 170 of 1348

Table 1.18.a.: GRC/ GRFC and GRP Panels on Non-Fire Resistance rated and Non-Load bearing

Exterior wall coverings-Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

GRC/ GRFC/ GRP AS GRC/ GRFC/ GRP AS

PRODUCT WALL ASSEMBLY

1. SUPER HIGHRISE BUILDING i. EN 13501-1 vi. BS 8414 –1 Or 2

With pass criteria With pass criteria

2. HIGHRISE BUILDING A OR A2-s1-d0 as per BRE 135

3. MALLS WITH OR

4. THEME PARKS ii. EN 13823 vii. FM 4881

With pass criteria

AND “Pass”

5. SCHOOLS

iii. EN ISO 11925 OR

6. HOSPITALS

AND viii. ISO 13785-2

7. ASSEMBLY With pass criteria

iv. ASTM D1929 “Pass”

Shall have self ignition

temperature of not less

than 3430C.

OR

v. ASTM D3841 for GRP only

with category CC1

8. LOWRISE BUILDING i. EN 13501-1 iv. BS 8414 –1 Or 2

With pass criteria With pass criteria

9. MIDRISE BUILDING B-s1-d0 as per BRE 135

10. WAREHOUSE OR OR

11. INDUSTRIAL ii. ASTM D1929 v. FM 4881

Shall have self ignition With pass criteria

temperature of not less “Pass”

than 3430C.

OR

OR

ix. ISO 13785-2

iii. ASTM D3841 for GRP only With pass criteria

with category CC2 “Pass”

| CDGH-OP-25 | September 2018 Page 171 of 1348

Table 1.18.b.: GRC/ GRFC and GRP Panels on Fire Resistance rated and Non-Load bearing Exterior

wall coverings-Test Requirements

OCCUPANCY AND TYPE OF TEST 1 TEST 2

BUILDING

GRC/ GRFC/ GRP AS GRC/ GRFC/ GRP AS

PRODUCT WALL ASSEMBLY

1. ANY BUILDING i. EN 13501-1 vi. ASTM E 119

With pass criteria With pass criteria “1 Hr or

2. ANY INSTALLATION A OR A2-s1-d0 2 Hr or 3 Hr as per re-

quired fire ratings of the

3. ANY AESTHETICS WITH wall.

ii. EN 13823 OR

AND vii. UL 263

With pass criteria “1 Hr or

iii. EN ISO 11925 2 Hr or 3 Hr as per re-

quired fire ratings of the

AND wall.

iv. ASTM D1929 OR

Shall have self ignition

temperature of not less viii. EN 1362-3

than 3430C. With pass criteria “1 Hr or

2 Hr or 3 Hr as per re-

OR quired fire ratings of the

wall.

v. ASTM D3841 for GRP only

with category CC1 OR

ix. EN 1362-4

With pass criteria “1 Hr or

2 Hr or 3 Hr as per re-

quired fire ratings of the

wall.

| CDGH-OP-25 | September 2018 Page 172 of 1348

5. Glazing Systems

5.1. Intention

5.1.1. The provisions of this document shall specify the minimum requirements for the

certification and listing, design, installation, inspection and maintenance of glazing

systems to achieve acceptable levels of Fire resistance, Reaction to fire, Perime-

ter fire protection, Safety of people from impact with glass.

5.1.2. The weather protection of buildings is not within the scope or intention of this sec-

tion. Weather protection aspect to buildings, such as protection from wind and

water, seismic pressure etc., shall comply with Municipality regulations and re-

quirements.

5.1.3. The intention of this section is to ensure that flame spread on exterior glazed fa-

çade, or glazed room radiation or radiation from glazed fire doors is restricted to

ensure safety of people.

5.2. Applications of Glazing Systems where glazing is specified

as part of fire compartmentation

Photo Caption

Figure 1.20.: Glazing Applications in a building

| CDGH-OP-25 | September 2018 Page 173 of 1348

5.3. Glazing Testing and Acceptance

5.3.1. The requirement for fire rated glazing in any building shall be based on the Civil

Defence approved Fire and Life Safety Drawings and strategy for the building,

which identifies the following.

a. The type of Fire resistance required according to EN standards or Fire re-

sistance rating & Fire protection rating according to American standards.

b. The duration of fire resistance required (30 min, 45 min, 60 min, 90 min, 120

min etc.)

c. Whether the glazing should be ‘integrity’ only or ‘integrity and insulation’.

5.3.2. The Glazing shall comply with the relevant general requirements of Section 4.5.,

Table 1.18: Glazing Test requirements.

GLAZING APPLICATION IN TEST A TEST B

THE BUILDING WHERE FIRE RESISTANCE RATING SAFETY GLAZING TESTS

IS REQUIRED (Resistance to impact either without

breaking, or breaking in way such

that persons may not sustain pierc-

ing or cutting injuries.)

1. NON LOAD BEARING TESTED WITH ANY OF THE FOLLOWING, EN 12600

CURTAINWALL WITH WHERE FIRE RESISTANCE RATING IS OR

GLAZING, REQUIRED ANY OF THE FOLLOWING

Pass as assembly with NFPA 251 ANSI Z97.1, A FOR < 0.9 m2 ,

Pass as assembly with EN 1364-3 B FOR > 0.9 m2

Pass as assembly with UL 263 CPSC 16 CR 1202, I FOR < 0.9 m2 ,

Pass as assembly with ASTM E119 II FOR > 0.9 m2

2. NON LOAD BEARING TESTED WITH ANY OF THE FOLLOWING, EN 12600

WALLS WHERE FIRE RESISTANCE RATING IS OR

REQUIRED ANY OF THE FOLLOWING

ANSI Z97.1, A FOR < 0.9 m2 ,

Pass as assembly with EN 1364-1 B FOR > 0.9 m2

Pass as assembly with NFPA 251 CPSC 16 CR 1202, I FOR < 0.9 m2 ,

Pass as assembly with UL 263 II FOR > 0.9 m2

Pass as assembly with ASTM E119

3. CEILING TESTED WITH ANY OF THE FOLLOWING, EN 12600

WHERE FIRE RESISTANCE RATING IS OR

REQUIRED ANY OF THE FOLLOWING

Pass as assembly with EN 1364-2 ANSI Z97.1, A FOR < 0.9 m2 ,

Photo Caption Pass as assembly with NFPA 251 B FOR > 0.9 m2

Pass as assembly with UL 263 CPSC 16 CR 1202, I FOR < 0.9 M2 ,

Pass as assembly with ASTM E119 II FOR > 0.9 m2

4. LOAD BEARING TESTED WITH ANY OF THE FOLLOWING, EN 12600

ELEMENTS WHERE FIRE RESISTANCE RATING IS OR

(FLOOR AND ROOF) REQUIRED ANY OF THE FOLLOWING

Pass as assembly with EN 1365-2 ANSI Z97.1, A FOR < 0.9 m2 ,

Pass as assembly with NFPA 251 B FOR > 0.9 m2

Pass as assembly with UL 263 CPSC 16 CR 1202, I FOR < 0.9 m2 ,

Pass as assembly with ASTM E119 II FOR > 0.9 m2

| CDGH-OP-25 | September 2018 Page 174 of 1348

Table 1.18: Glazing Test requirements.

GLAZING APPLICATION IN TEST A TEST B

THE BUILDING SAFETY GLAZING TESTS

(Resistance to impact either without

breaking, or breaking in way such

that persons may not sustain pierc-

ing or cutting injuries.)

5. DOORS AND VISION TESTED WITH ANY OF THE FOLLOWING, EN 12600

PANELS WHERE FIRE RESISTANCE RATING IS OR

REQUIRED ANY OF THE FOLLOWING

Pass as assembly with UL 10 C ANSI Z97.1, A FOR < 0.9 m2 ,

Pass as assembly with NFPA 252 B FOR > 0.9 m2

Pass as assembly with EN 1634-1 CPSC 16 CR 1202, I FOR < 0.9 m2 ,

Pass as assembly with BS 476 Part 22. II FOR > 0.9 m2

6. WINDOWS TESTED WITH ANY OF THE FOLLOWING, EN 12600

WHERE FIRE RESISTANCE RATING IS OR

REQUIRED ANY OF THE FOLLOWING

Pass as assembly with UL 9 ANSI Z97.1, A FOR < 0.9 m2 ,

Pass as assembly with NFPA 257 B FOR > 0.9 m2

Pass as assembly with EN 1634-1:2014 CPSC 16 CR 1202, I FOR < 0.9 m2 ,

II FOR > 0.9 m2

7. BATHING/SHOWER No Requirements EN 14428

ENCLOSURE/SCREEN/ AND

SWIMMING/ WET AREAS Also shall comply with safety glass re-

(SLIP RISK) quirements of Section 5.4.2.

| CDGH-OP-25 | September 2018 Page 175 of 1348

5.4. Design, Installation, Inspection & Maintenance

5.4.1. Fire Resistant Glazing - Design / Specification

5.4.1.1. Fire resistant glazing systems shall be designed by a specialist manufac-

turer.

5.4.1.2. It is the consultant’s responsibility to ensure that qualified glazing spe-

cialist is involved in the design, in full compliance with this code.

5.4.1.3. In addition to the fire strategy Approved by Civil Defence, the following

points shall be addressed by the glazing installer to ensure they are con-

sistent with the fire strategy and overall intent of the proposed glazing

system:

a. The minimum fire rating specified relates to a full system of compo-

nents. All elements of the fire barrier being created must collectively

provide the performance required as part of a fire resistant assembly.

b. The final glazing system installed must be the same as the system that

has been tested in accordance with the Civil Defence requirements.

Project-specific differences should be discussed with the manufactur-

er and system certifier.

c. The system selected must be capable of performing in the environ-

ment in which it is intended to be installed, in particular internal or

external environments.

d. The impact-resistance of the glazing has to be met as specified by the

impact rating as per Table 1.18.

e. For unidirectional systems, the direction of the fire-side should be

labeled and easily identifiable on the glass, profiles or accessories.

Where the direction of fire is not known, only bi-directional fire-rated

glazing components should be used.

f. Fire-rated glazing in inclined and horizontal applications shall be test-

ed and approved separately to fire rated glazing in vertical applica-

tions. Vertically tested systems cannot be assumed to work in hori-

zontal or inclined glazing applications.

g. The specified system should have a label with scope based on the

type of fire represented during the fire test of the system (For exam-

ple, a fire resistant system tested for domestic fires may not sustain

conditions of industrial fires).

h. Considerations for the glazing system design shall include but not be

limited to the overall screen size, fenestration layout within the

screen, materials used in construction of the profile (such as the

gauge, quality, thickness, finish, etc.) and the amount of edge cover

and edge clearance.

i. Standard impact safety toughened or safety / security laminated glass

is not necessarily fire-rated and the same cannot be used without it

being tested and approved.

| CDGH-OP-25 | September 2018 Page 176 of 1348

5.4.2. Safety Glazing - Design / Specification

5.4.2.1. The Safety Glazing is required in critical locations (2,3,4,5,6,7,8 and 11)

described in doors, side panels and low level glazing as shown in the

Figure 1.21 and 1.22.

Figure 1.21.: Safety Glazing at Door and adjacent areas Figure 1.22.: Safety Glazing at Windows

5.4.2.2. Minimum classification Requirements of safety glass or safety plastics

to be used in critical locations (Such as Gymnasiums, places of energetic

activities, play areas etc.,) shall be as per Table 1.19.

5.4.2.3. Where glazing is only accessible from one side (3.a, 4.a), the testing and

classification can be from only that side.

Table 1.19: Minimum Classification for Safety Glazing requirements.

CRITICAL LOCATION GLAZING PANE DIMENSION SAFETY GLASS SAFETY PLASTICS

1. DOORS > 900 mm 2(β)Φ Class B

≤ 900 mm 3(β)Φ Class C

2. DOOR SIDE PANEL > 900 mm 2(β)Φ Class B

≤ 900 mm 3(β)Φ Class C

3. FULLY BACKED MIRROR > 900 mm 2(β)Φ Class B

GLAZING (A)

Photo Caption

≤ 900 mm 3(β)Φ Class C

4. UNBACKED MIRROR > 900 mm 2(β)Φ Class Bo

GLAZING (A)

≤ 900 mm 3(β)Φ Class Co

5. LOW LEVEL AREAS Irrespective of pane dimensions 3(β)Φ Class C

6. BATHING AREAS Irrespective of pane dimensions 3(β)Φ Class C

7. AREAS OF SPECIAL RISK Irrespective of pane dimensions 3(β)Φ Class C

| CDGH-OP-25 | September 2018 Page 177 of 1348

5.4.2.4. Glass Safety classification as per EN 12600 shall be as per Table 1.20.

and Table 1.21.

Table 1.20: Glass Classification as per EN 12600.

PVB LAMINATED PVB FILM THICKNESS GLASS THICKNESS CLASS AS PER

GLASS CODE EN 12600

33.1 0.38 mm 6.4 mm 2(B)2

44.1 0.38 mm 8.4 mm 2(B)2

55.1 0.38 mm 10.4 mm 1(B)1

33.2 0.76 mm 6.8 mm 1(B)1

44.2 0.76 mm 8.8 mm 1(B)1

44.4 1.52 mm 9.5 mm 1(B)1

44.6 2.28 mm 10.3 mm 1(B)1

55.2 0.76 mm 10.8 mm 1(B)1

66.2 0.76 mm 12.8 mm 1(B)1

88.2 0.76 mm 16.8 mm 1(B)1

Table 1.21: Tempered Glass Classification as per EN 12600.

THICKNESS OF MINIMUM REQUIRED CLASSIFICATION AS PER

TEMPERED GLASS EN 12600

4 mm 1(C)2

6 mm 1(C)2

8 mm 1(C)2

10 mm 1(C)1

12 mm 1(C)1

5.4.3. Labeling / Manifestation

5.4.3.1. Under some conditions of lighting, large areas of transparent glazing

used to subdivide a building might not be readily apparent. The risk of

human impact with this glazing is greatest if adjacent areas within or

immediately outside the building are at the same level so that a person

might reasonably assume unimpeded passage from one part to anoth-

er.

5.4.3.2. If the presence of such glazing is not sufficiently well indicated by mulli-

ons, transoms, door frames, large door handles, stall risers or other

components of the glazing system, it shall be made apparent by some

form of manifestation.

| CDGH-OP-25 | September 2018 Page 178 of 1348

5.4.3.3. The manifestation employed should be of a sufficient size to make it im-

mediately obvious.

5.4.3.4. It shall take the form of broken or solid lines, patterns or company logos

or similar, positioned between 600 mm and 1500 mm above floor level

at appropriate horizontal intervals. The manifestation should preferably

be permanent, e.g. etching of the glazing, but alternatively, if applied

materials are used they should be durable and not easily removed.

5.4.4. Overhead glazing

5.4.4.1. Glass used in overhead glazing shall be required to remain in position

post-breakage.

5.4.4.2. Overhead glazing shall be laminated and include a post-breakage con-

tainment system, such that if the glass breaks the glass is held in place

until it can be replaced.

5.4.4.3. Broken glass shall be replaced promptly.

5.4.4.4. Examples of post-breakage containment systems are:

a. Silicone structural adhesives

b. Mechanically fixed batten bars

c. Adhesively fixed batten bars

d. Polyester and acrylic foam tapes

e. Structural washers

f. Adhesive-backed polymeric film applied to glass in conjunction with

one of the retention systems listed above.

5.4.4.5. Injury from objects falling through the glass are not considered in these

requirements. A specific risk assessment should be conducted to evalu-

ate this. However, consideration at design stage may enable selection of

suitable glazing materials / measures to mitigate this situation.

5.4.4.6. This section does not consider the risk of injury to persons who may fall

onto the non-vertical (sloping) overhead glazing.

5.4.4.7. CWCT TN66 shall be used to evaluate the safety and fragility of glazed

roofing.

| CDGH-OP-25 | September 2018 Page 179 of 1348

5.4.5. Glass Floors and Staircases

5.4.5.1. The use of glass in floors or staircases shall be limited to pedestrian foot

traffic only. (see GGF data sheet 7.3: Guidelines for the use of glass in

floors and stairs)

5.4.5.2. For the specification of the design floor loads for the specific use of the

building the following standard shall be used.

a. EN 1991-1-1: 2002: Eurocode 1 –Actions on structures –General ac-

tions –densities, self-weight, imposed loads for buildings.

b. Glass required to be walkable shall be designed in accordance with

CWCT TN66 using the following standard in relation to the danger of

slippage and minimum coefficients of friction. Slip resistance shall not

depend on the use of specialized footwear.

c. BS 5395-1: 2010 Stairs. Code of practice for the design of stairs with

straight flights and winders.

5.4.5.3. The strength of the supports shall be calculated by a competent structur-

al engineer, with the deflection of the frame limited to an appropriate

value for the glass type.

5.4.5.4. Consideration shall be given to the complete design process. The follow-

ing list comprises a number of topics that shall be considered alongside

the regulatory requirements. The list is not exhaustive but relates to the

common considerations:

a. Imposed loadings from design code

b. Surface finish

c. Strength of supporting glazing system

d. Impact by falling or thrown objects

e. Exposure to solar radiation and water

f. Post-fracture behavior

g. Deflection

5.4.5.5. A risk analysis shall be based on the following:

a. Frequency of use

b. Potential for exposure to water and slipping

c. Potential for glazing breakage from impacts

d. Consequences of glazing failure, i.e. Post-breakage behavior of the

glazing material.

5.4.5.6. The ability of a broken pane to remain in situ is dependent upon the

loads being applied, the glass type, the temperature, the number of frac-

tured plies and the type of interlayer considered in the construction.

| CDGH-OP-25 | September 2018 Page 180 of 1348

5.4.6. Installation

5.4.6.1. The installation shall be carried out by an Civil Defence and Municipality

approved installer or fabricator as per system manufacturer's installation

instructions and shall comply with local regulations and the construction

documents.

5.4.7. Installer Qualification

5.4.7.1. Installer and fabricator specializing in Glazing system installation and

certified by the system manufacturer shall be listed with Municipality

and Civil Defence Authority.

5.4.7.2. The installer and fabricator license shall be based on the training and

certification by the system manufacturer to install manufacturer’s prod-

ucts as per specified listed system requirements.

5.4.8. Inspection

5.4.8.1. Special inspection shall be required for all Glazing system. Inspection

shall take place in successive stages as installation progresses.

5.4.8.2. The manufacturer’s guidelines shall be available to and used by the glaz-

ing specialist.

5.4.8.3. It is consultant’s responsibility to recruit qualified glazing specialists to

inspect the glazing systems or to hire the services of Civil Defence ap-

proved house of expertise.

5.4.8.4. It is consultant’s responsibility to ensure that installer’s work is inspect-

ed during construction and installation at each stage.

5.4.8.5. Consultant or Civil Defence approved house of expertise undertaking glaz-

ing inspections shall have the following qualifications.

a. Accredited to ISO/IEC 17020 or relevant IAS criteria or ICC specialist

training and certification or equivalent international criteria accepta-

ble to Municipality and Civil Defence.

b. 2 glazing specialists, qualified as per Section 5.4.9.

c. 3 years experience in fire and life safety aspect of glazing systems’

inspections.

| CDGH-OP-25 | September 2018 Page 181 of 1348

5.4.9. Glazing Specialist Qualification

5.4.9.1. The glazing specialists of consultant’s in-house team or Manufacturer’s

representative or Civil Defence approved house of expertise, undertaking

design, consultancy, inspection shall have the following qualifications.

a. Bachelor’s degree in engineering

b. 5 years experience in glazing systems design and inspections

c. Training and certifications by the glazing system manufacturers.

5.4.9.2. The glazing specialists from consultants or manufacturers or house of ex-

pertise shall be registered and licensed by Civil Defence based on their

qualifications as required by Section 5.4.9.1. and written examination.

5.4.10. Civil Defence Acceptance of the installation

5.4.10.1. The main consultant and his hired façade consultant or house of expertise

shall be responsible for the glazing design specifications, material selec-

tion, fabricator selection, initiation of laboratory tests, verification of test

results, progressive inspection during construction and commissioning.