Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, I

Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, I

Uploaded by

Louie Jay CabunocCopyright:

Available Formats

Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, I

Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, I

Uploaded by

Louie Jay CabunocOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, I

Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, I

Uploaded by

Louie Jay CabunocCopyright:

Available Formats

Table 2-1.

Allowable Stress on Fasteners, MPa

Allowable Shear g (Fv)

Allowabl Slip-Critical Connections e, i

e Oversized Long Slotted Holes

Description of Fasteners Bearing-type

Tension g Standard and Short

Transversei Parallelj connectionsl

(Ft) size Holes Slotted

Load Load

Holes

A502, Gr. 1, hot-driven rivets 158a 120f

a

A502, Gr. 2, hot-driven rivets 200 152f

a

A307 bolts 138 68.9b,f

Threaded parts meeting the

requirements of Sec A3.1 and

A3.4 and A449 bolts meeting 0.33Fu

a,c,h 0.17Fu h

the requirements of Sec A3.4

when threads are not

excluded from shear planes

Threaded parts meeting the

requirements of Sec A3.1 and

A3.4 and A449 bolts meeting

0.33Fu a,h 0.22Fu h

the requirements of Sec A3.4,

when threads are excluded

from shear planes

A325 bolts, when threads are

not excluded from shear 303d 117 103 82.7 68.9 145f

planes

A325 bolts, when threads are

303d 117 103 82.7 68.9 207f

excluded from shear planes

A490 bolts, when threads are

not excluded from shear 372d 145 124 103 89.6 193f

planes

A490 bolts, when threads are

372d 145 124 103 89.6 276f

excluded from shear planes

a

Static loading only

b

Threads permitted in shear planes

c

Tensile capacity of the threaded portion of an upset rode based upon the cross-sectional area at its major thread

diameter Ab shall be larger than the nominal body are of the rod before upsetting times 0.6F y.

d

For A325 and A490 bolts subject to tensile fatigue loading, See Sec 155.5. 1.5

e

Class A (slip coefficient 0.33). Clean mill scale and blast-cleaned surfaces with Class A coatings. When specified by the

designer, the allowable shear stress, F v, for slip-critical connection having special faying surface conditions may be

increased to the applicable value given in the RCSC Specifications.

f

When bearing-type connections used to splice tension members gave a fastener patterns whose length, measured

parallel to the line of force, exceed 1250mm, tabulated values shall be reduced by 20%.

g

See Section 501.5.2.

h

See Table 2. Numerical Values Section for values for specific ASTM steel soecifications.

I

For limitations on use of oversized and slotted holes, see Section 510.4.2.

j

For Direction of load application relative to long axis of slot.

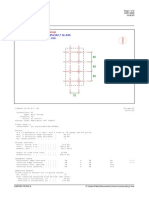

Table 2-2. Nominal Hole Dimensions, mm

Hole Dimensions, mm

Bolt

diam. Short-slot Long-slot

Standard Oversize

(mm) (width x (width x

(Diam) (Diam)

length) length)

12 14 16 14 x 17 14 x 32

16 17 21 17 x 22 17 x 40

20 21 24 21 x 25 21 x 48

22 24 27 24 x 28 24 x 55

25 27 32 27 x 33 27 x 63

(d + 1.6) x (d + 1.6) x

≥28 d + 1.6 d+8

(d + 10) (2.5 + d)

Table 2-3. Values of Spacing Increment, C1, mm

Slotted Holes

Nominal

Oversized Parallel to line of force

diameter of Perpendicular

Hole

fastener to line of force Short-slots Long-slots*

≤22 3.0 0 5.0 1.5d - 1.6

25 5.0 0 6.0 36

≥28 6.0 0 8.0 1.5d - 1.6

* When length of slot is less than maximum allowed in Table 2-2, C1 may be

reduced by the difference between the maximum and actual slot lengths.

Table 2-4. Minimum Edge Distance, mm

(Center of Standard Holea to Edge of Connected Part)

At Rolled Edges of Plates,

Nominal Diameter

At Sheared Edges Shapes or Bars, Gas Cut or

of Fastener

Saw-cut Edgesb

12 22 20

16 28 22

20 32 25

22 28c 28

25 45c 32

28 50 38

32 56 42

Over 32 1.75 x Diam. 1.25 x Diam.

a

For oversized or slotted holes, See Table 2-5

b

All edge distances in this column may be reduced 3mm when the hole is at a

point where stress does not exceed 25% of the maximum design strength in the

element.

c

These may be 32 mm at the ends of beam connection angle.

Table 2-5. Values of Edge Distance C2, mm

Nominal Slotted Holes

Oversized

diameter of Parallel to Perpendicular to Edge

Hole

fastener Edge Short-slots Long-slots*

≤22 1.5 0 3.0

25 3.0 0 3.0 0.75d

≥28 3.0 0 3.0

* When length of slot is less than maximum allowable (see Table 2-2), C2 may be

reduced by one-half the difference between the maximum and actual slot lengths.

Table 2-6. Minimum Pretension for Fully-tightened Bolts, kN*

Bolt Size

A325 Bolts A490 Bolts

(mm)

12 53.3 66.7

16 84.5 106

20 124 155

22 173 217

25 226 284

28 249 355

32 315 453

35 378 538

38 458 658

* Equal to 0.7 of minimum tensile strength of bolts as

specified in ASTM specification for A325 and A490 bolts

with UNC threads.

Table 2-7. Allowable Tensile Stress Ft for Fasteners in Bearing-type Connection in the Presence of Shear Stress ƒƲ

(MPa)

Description of Threads Included in Shear Threads Excluded from

Fasteners Planes Shear Planes

A307 bolts 179.2 – 1.8 ƒƲ ≤ 137.8

A325 bolts √(303)2 − 4.39ƒƲ 2 √(303)2 − 2.15ƒƲ 2

A490 bolts √(372)2 − 3.75ƒƲ 2 √(372)2 − 1.82ƒƲ 2

Threaded parts,

A449 bolts over 0.43 Fu – 1.8 ƒƲ ≤ 0.33 Fu 0.43 Fu – 1.4 ƒƲ ≤ 0.33 Fu

38mm diameter

A502 Gr. 1 rivets 207 – 1.3 ƒƲ ≤ 159

A502 Gr. 2 rivets 262 – 1.3 ƒƲ ≤ 200

ƒƲ = computed shearing stress, MPa

Fu = Specified minimum tensile strength of fastener, MPa

Table 2-8. Numerical values of Fy and Fu

ASTM

Item Fy (MPa) Fu (MPa)

Designation

A36 248 400 to 551

Shapes, Plates, Bars, Sheet and

A53 241 414

Tubing or Threaded Parts

A501 248 400

A529 290 414 to 586

276 379

A570

290 400

689 758 to 896

A514

620 689 to 896

310 448

A606

345 483

A852 483 621 to 758

634 827

Bolts A449 558 724

400 621

Table 2-9. Effective Net Area Coefficient for Fastener, U

Minimum number of

fasteners per line in

Types of members U

the direction of

tension

(a) All segments are connected to transmit

1 1

the tension

(b) W, M, or S sections

𝑏𝑓 2

≥ 3 0.90

𝑑 3

Connection to flange(s)

(c) Tees

𝑏𝑓 4

≥ 3 0.90

𝑑 3

Connection to flange

(d) W, M or S sections not meeting the

conditions of (b), Tees not meeting the

3 0.85

conditions of (c), and all other shapes,

including built-up sections

(e) All sections 2 0.75

You might also like

- Lacoste R., Edgeworth B. - CCNP Enterprise Advanced Routing ENARSI 300-410 Official Cert Guide (2020) PDFDocument1,883 pagesLacoste R., Edgeworth B. - CCNP Enterprise Advanced Routing ENARSI 300-410 Official Cert Guide (2020) PDFSrishti Baliyan65% (26)

- Module 1 Lesson 2 Basic Concepts For Construction DatabaseDocument23 pagesModule 1 Lesson 2 Basic Concepts For Construction DatabaseErza LeeNo ratings yet

- Ics Catalogue Distribution Boards and Control PanelsDocument10 pagesIcs Catalogue Distribution Boards and Control PanelsAbdellah SamadiNo ratings yet

- Module 1 (Database Management in Construction)Document42 pagesModule 1 (Database Management in Construction)MARTHIE JASELLYN LOPENANo ratings yet

- Database in ConstructionDocument1 pageDatabase in ConstructionﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞNo ratings yet

- Bolted Connections 1Document45 pagesBolted Connections 1Nicole ReyesNo ratings yet

- E4.3.1-2-3-4-5 - PTB-4-2019 PDFDocument17 pagesE4.3.1-2-3-4-5 - PTB-4-2019 PDFEdison CasallasNo ratings yet

- Mathematics For TeachersDocument869 pagesMathematics For TeachersRamón Marcelo Bustos MéndezNo ratings yet

- CE100 CE Orientation - SyllabusDocument6 pagesCE100 CE Orientation - SyllabusSweetie CagangNo ratings yet

- Syllabus Theory of StructureDocument4 pagesSyllabus Theory of Structureacurvz2005No ratings yet

- Types of Reports: Construction ReportDocument5 pagesTypes of Reports: Construction ReportAllyssa OpantoNo ratings yet

- Network ConstructionDocument11 pagesNetwork ConstructionDr. Mahmoud Abbas Mahmoud Al-Naimi100% (1)

- Management FunctionsDocument18 pagesManagement FunctionsKennethNo ratings yet

- Charging For Civil Engineering ServicesDocument19 pagesCharging For Civil Engineering ServicesMaria Elline FilloresNo ratings yet

- 1 PrelimDocument14 pages1 PrelimMaria Ellaine SorianoNo ratings yet

- CE Thesis Format (Based On RDCO Format)Document19 pagesCE Thesis Format (Based On RDCO Format)Jason Kent V. MecaresNo ratings yet

- Seismic Vulnerability Assessment of New Quirino Bridge Using Capacity Spectrum MethodDocument45 pagesSeismic Vulnerability Assessment of New Quirino Bridge Using Capacity Spectrum Methodearl vergille reveloNo ratings yet

- 4 CE502 Design ProjectDocument193 pages4 CE502 Design ProjectKaty PerryNo ratings yet

- Beams and Other Flexural Members PDFDocument52 pagesBeams and Other Flexural Members PDFJeyjay BarnuevoNo ratings yet

- Chegg - Chapter Three PDFDocument131 pagesChegg - Chapter Three PDFTeam DriveNo ratings yet

- Sample CE-3 (RCD) ComputationDocument12 pagesSample CE-3 (RCD) ComputationJustine LedesmaNo ratings yet

- Review MODULE - GEOTECHNICAL ENGINEERING (Soil Properties)Document1 pageReview MODULE - GEOTECHNICAL ENGINEERING (Soil Properties)I'm an EngineerNo ratings yet

- Formworks and Scaffolding & StagingDocument27 pagesFormworks and Scaffolding & StagingLa GantalaoNo ratings yet

- Case Study ProjectDocument28 pagesCase Study ProjectGemman Gabriel M. MapaNo ratings yet

- Ce182P-2 Ce Project 1 1 QTR SY2019-2020 July 2019 Structural Engineering Cluster F.A.A.UyDocument4 pagesCe182P-2 Ce Project 1 1 QTR SY2019-2020 July 2019 Structural Engineering Cluster F.A.A.UyemmaNo ratings yet

- Practice Exam # 2 Correl 1Document2 pagesPractice Exam # 2 Correl 1Dani LubosNo ratings yet

- 3 Story RC Building Load Combinations: Factored Load Combination (For Drift Check), NSCP 203.3.1Document3 pages3 Story RC Building Load Combinations: Factored Load Combination (For Drift Check), NSCP 203.3.1Jonathan SanchezNo ratings yet

- Module 4 - QuantityDocument12 pagesModule 4 - QuantityKimberly Wealth Meonada MagnayeNo ratings yet

- CEBEP Bridging Algebra 7Document7 pagesCEBEP Bridging Algebra 7jerrycho taccadNo ratings yet

- Engineering Management - Roberto MedinaDocument4 pagesEngineering Management - Roberto MedinaNeil Ivan Armario0% (1)

- Team Explore - Final ManuscriptDocument129 pagesTeam Explore - Final ManuscriptMark Joseph Ting LagutinNo ratings yet

- Module 1 Lesson 1Document26 pagesModule 1 Lesson 1Erza LeeNo ratings yet

- Octave LabDocument9 pagesOctave LabEULLYZEN RABANAL100% (1)

- Lateral Force On Non Building StructureDocument18 pagesLateral Force On Non Building Structurefebby016100% (1)

- Roof Framing Plan PDFDocument1 pageRoof Framing Plan PDFEugene MirasNo ratings yet

- ProposalDocument2 pagesProposalLenielle AmatosaNo ratings yet

- PP02B - Asep - NSCP 2015 Update On Appendix 1-BDocument10 pagesPP02B - Asep - NSCP 2015 Update On Appendix 1-BjimNo ratings yet

- Item 1018Document5 pagesItem 1018Ester MarianNo ratings yet

- Cmo 29., S. 2007 - PS For BsceDocument15 pagesCmo 29., S. 2007 - PS For Bscepicefeati100% (3)

- Fundamental Counting Principle and PermutationDocument12 pagesFundamental Counting Principle and PermutationSelerina VillasenorNo ratings yet

- Construction Project Organization, Legal Structure and Construction Project RequirementsDocument23 pagesConstruction Project Organization, Legal Structure and Construction Project RequirementsTEODORO AMATOSA JR.No ratings yet

- Steel Design TablesDocument6 pagesSteel Design TablesAdrian Christian LeeNo ratings yet

- Pulley SKFDocument84 pagesPulley SKFNguyễn NhẫnNo ratings yet

- 5 STOREY GDS SCBF Connection DesignDocument1 page5 STOREY GDS SCBF Connection DesigndantevariasNo ratings yet

- V PulleysDocument17 pagesV PulleysEduardoValdiviaNo ratings yet

- 7023exq Lecture 3 Bolted Steel ConnectionsDocument17 pages7023exq Lecture 3 Bolted Steel ConnectionsAkhil SurendranNo ratings yet

- BoltDocument4 pagesBoltMamaru Nibret DesyalewNo ratings yet

- Documento - MX Comp1Document10 pagesDocumento - MX Comp1Mangesh BanaleNo ratings yet

- Tension MembersDocument12 pagesTension MembersDivya ShahNo ratings yet

- Bapp 14399 9 Dti Washer AssemblyDocument8 pagesBapp 14399 9 Dti Washer AssemblySUMANTANo ratings yet

- F2143_ENDocument1 pageF2143_ENWali Ahmed KhanNo ratings yet

- Installation Instructions: AI-GC01-E Rev.4Document21 pagesInstallation Instructions: AI-GC01-E Rev.4kiranNo ratings yet

- Frame Fi Xing SXS: AccessoriesDocument2 pagesFrame Fi Xing SXS: AccessoriesMNo ratings yet

- CONNECTION: G1 - Bolt Group: Gusset Plate (Min.) : 152,2x25x342,7 Gr.A36 Bolts: 8 X 1" A325ST/N in 2 ColsDocument2 pagesCONNECTION: G1 - Bolt Group: Gusset Plate (Min.) : 152,2x25x342,7 Gr.A36 Bolts: 8 X 1" A325ST/N in 2 ColsmascalzoneNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Anonymous 0x2pwMCWgjNo ratings yet

- NSCP 2015 645Document1 pageNSCP 2015 645Gabriel Paolo CañeteNo ratings yet

- 1Document2 pages1irfanurozzaqNo ratings yet

- Denison LOKOMECDocument6 pagesDenison LOKOMECravrvdNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- Cst BBSDocument2 pagesCst BBSPrabhash AnantNo ratings yet

- Design of Tension Members Allowable Stresses (F)Document9 pagesDesign of Tension Members Allowable Stresses (F)Gerd del RosarioNo ratings yet

- One Way SlabDocument23 pagesOne Way SlabmeerahNo ratings yet

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 pagesNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaNo ratings yet

- Multiple Choice (Unit 2 Module 1)Document35 pagesMultiple Choice (Unit 2 Module 1)Anthony BensonNo ratings yet

- RC 2Document12 pagesRC 2Brian Emil MarronNo ratings yet

- Piping Welding Notes For Beginners Piping and Welding QAQCDocument38 pagesPiping Welding Notes For Beginners Piping and Welding QAQCيوسف عادل حسانين100% (3)

- The Memory Palace - A Quick Refresher For Your CISSP ExamDocument127 pagesThe Memory Palace - A Quick Refresher For Your CISSP Examjunyan.quNo ratings yet

- MessageDocument7 pagesMessageferluxNo ratings yet

- 4.3 - 10 Male Connector For 1 - 2 Superflexible CableDocument2 pages4.3 - 10 Male Connector For 1 - 2 Superflexible CableNavis HidayatNo ratings yet

- IT51Document4 pagesIT51prthiviraj goudaNo ratings yet

- 2 Chapter 1 Measurement and Unit Systems PDFDocument13 pages2 Chapter 1 Measurement and Unit Systems PDFملهم العبدالسلامةNo ratings yet

- Programming Language (C) : Nalini Vasudevan Columbia UniversityDocument29 pagesProgramming Language (C) : Nalini Vasudevan Columbia UniversityLenny BiambyNo ratings yet

- Electrical Panels Installation ChecklistDocument2 pagesElectrical Panels Installation ChecklistAlvin Badz100% (4)

- Magnetism and Matter Class 12Document28 pagesMagnetism and Matter Class 12GayathriNo ratings yet

- SAP - Smart Forms GuideDocument51 pagesSAP - Smart Forms Guidekhan.whatsappbackNo ratings yet

- Butterfly Valve Catalogue //: The Fort Vale Range of Butterfly ValvesDocument22 pagesButterfly Valve Catalogue //: The Fort Vale Range of Butterfly ValvesrohandiNo ratings yet

- Orbital Mechanics: 3. Keplerian OrbitsDocument13 pagesOrbital Mechanics: 3. Keplerian Orbitsfzfy3j2No ratings yet

- ColumnDocument4 pagesColumnAngelica Tejedo0% (1)

- Final FST 101 Exer 3 Carbohydrates: PolysaccharidesDocument11 pagesFinal FST 101 Exer 3 Carbohydrates: PolysaccharidesKamille BrouwersNo ratings yet

- Accuseal Plug ValveDocument20 pagesAccuseal Plug ValveTendai Felex Maduke100% (2)

- Risk Analysis For Design-Build Construction Projects: A Simplified ApproachDocument8 pagesRisk Analysis For Design-Build Construction Projects: A Simplified Approachyan energiaNo ratings yet

- EXCEL SHORTCUTS NINJA - These HotKeys Are The Formula To Easily Double Your Excel Productivity and Perform Your Job Functions Faster! (Excel Ninjas Book 3)Document97 pagesEXCEL SHORTCUTS NINJA - These HotKeys Are The Formula To Easily Double Your Excel Productivity and Perform Your Job Functions Faster! (Excel Ninjas Book 3)madmaxberNo ratings yet

- Common Errors in English Written in Telugu RarebookstkDocument108 pagesCommon Errors in English Written in Telugu RarebookstkscribdavakNo ratings yet

- Using The GNU Compiler Collection PDFDocument694 pagesUsing The GNU Compiler Collection PDFJean PaivaNo ratings yet

- Siggraph2019 HydraDocument114 pagesSiggraph2019 Hydra王璨No ratings yet

- Tsa HW03Document1 pageTsa HW03林妍汝No ratings yet

- 09 1 BasicElectroStaticDocument14 pages09 1 BasicElectroStaticMeeraNo ratings yet

- Design & Thermal Analysis of I.C. Engine Poppet Valves Using Solidworks and FEADocument9 pagesDesign & Thermal Analysis of I.C. Engine Poppet Valves Using Solidworks and FEAAnonymous kw8Yrp0R5rNo ratings yet

- Buhlmann Credibility Homework SolutionsDocument11 pagesBuhlmann Credibility Homework Solutionschitechi sarah zakiaNo ratings yet

- Question 2 of 4Document22 pagesQuestion 2 of 4Anton_Young_1962100% (1)