Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing Plan

Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing Plan

Uploaded by

Naveen NagisettiCopyright:

Available Formats

Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing Plan

Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing Plan

Uploaded by

Naveen NagisettiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing Plan

Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing Plan

Uploaded by

Naveen NagisettiCopyright:

Available Formats

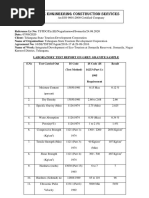

QUALITY ASSURANCE PLAN

FOR MANUFACTURE OF DUCTILE IRON PIPES, INSPECTION AND TESTING PLAN

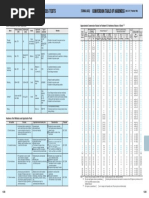

Component / Characteristics Quantum of Reference Acceptance Format of

SL NO. Category Type of Check Agency Remarks

Material Check Check Documents Norms Record

I Raw Material M TPI B

As per As per

BF Liquid Metal %C, %SI, %MN, One Per Lot or

1 Major Chemical Manufacturers Manufacturers MTC W R R

or Pig Iron %S, %P Batch

standard standard

As per As per

One Per Lot or

2 Ferro Silicon %SI, %AL Major Chemical Manufacturers Manufacturers MTC W R R

Batch

standard standard

Silica Sand / Sieve Analysis One Per Lot or As per IS 8329 As per IS 8329

3 Major Chemical MTC W R R

River Sand Compaction Batch -2000/IS 383 -2000

One Per Lot or As per IS 8329 As per IS 8329

4 Magnesium Purity of Mg Major Chemical MTC W R R

Batch -2000 -2000

As per As per

One Per Lot or

5 Zinc Purity of Zn Major Chemical Manufacturers Manufacturers MTC W R R

Batch

standard standard

Material Physical and One Per Lot or As per IS 8112/

6 Cement Major As per IS 8112 MTC W R R

Conformation Chemical Batch IS 12330

As per As per

One Per Lot or

7 Bitumen Paint Specific Gravity Major Specific Gravity Manufacturers Manufacturers MTC W R R

Batch

standard standard

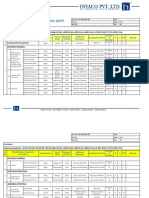

II Process Control

Temperature As per As per

Heat Treatment

1 Heat Treatment Recording Time Major - 100% Manufacturers Manufacturers W R R

Chart

Cycle standard standard

Manufacturers

2 Zinc Coating Deposit of Zn Major - One Per Batch IS 8329 - 2000 IS 8329 - 2000 W R R

internal Record

III Inspection & Testing M TPI B

As per IS - 8329 - As per IS 8329- As per IS 8329- Manufacturer

1 Visual Major Visual 100% W W R

2000 2000 2000 Report

1of 2 Sheet5 D:\user\TA-3\434959737.xls.xls\D

Component / Characteristics Quantum of Reference Acceptance Format of

SL NO. Category Type of Check Agency Remarks

Material Check Check Documents Norms Record

As per IS - 8329 - As per IS 8329- As per IS 8329- Manufacturer

2 Dimensional Major Measurement 100% W W R

2000 2000 2000 Report

As per IS - 8329 - One test per lot As per IS 8329- As per IS 8329- Manufacturer

3 Mechanical test Major Physical W W R

2000 or batch 2000/ IS 11606 2000 Report

As per IS - 8329 - As per IS 8329- As per IS 8329- Manufacturer

5 Hydrostatic test Major Physical 100% W W R

2000 2000 / IS 11606 2000 Report

As per IS - 8329 - As per IS 8329- As per IS 8329- Manufacturer

6 Lining Thickness Major Physical Random Check W W R

2000 2000 / IS 11606 2000 Report

Bitumen Coating As per IS - 8329 - As per IS 8329- As per IS 8329- Manufacturer

7 Major Physical Random Check W W R

Thickness 2000 2000 / IS 11606 2000 Report

Compression test As per IS - 8329 - One test per lot As per IS 8329- As per IS 8329- Manufacturer

8 Major Physical W R R One per Lot

of Cubes 2000 or batch 2000 / IS 11606 2000 Report

Gasket Fitment

As per IS - 8329 - One Per Lot or As per IS 8329- As per IS 8329- Manufacturer

9 and leak Major Physical W R R

2000 Batch 2000 / IS 11606 2000 Report

tightness test

Marking on As per IS - 8329 - As per IS 8329- As per IS 8329- Manufacturer

10 Major Physical Random Check W W R

Pipes 2000 2000 / IS 11606 2000 Report

Note:

1. Manufacturer shall carryout 100% inspection on final product

2. All measuring instruments should be calibrated.

3. Cement used for lining shall conform to IS 8112 or IS 12330 depending on the usage of pipeline

4. The rubber gasket shall conform to IS 5382 / 1985

5. Legend : M: Manufacturer, B: KUWS & DB , TPI: Third Party Inspection, R: Review, W: Witness

Reviewed items may be randamly witnessed by the concerned if necessary. All measuring instruments and testing equipments shall be calibrated periodically

and put up for verification to Third Party Inspection agency.

2of 2 Sheet5 D:\user\TA-3\434959737.xls.xls\D

You might also like

- TUNNEL II - BOQ (Part1)Document16 pagesTUNNEL II - BOQ (Part1)Naveen Nagisetti75% (4)

- Quality Assurance Plan: Product Name: Hdpe PipesDocument3 pagesQuality Assurance Plan: Product Name: Hdpe PipesNaveen Nagisetti100% (1)

- Wear Prediction and Maintenance Frequencies of Slurry Pipes For TBM TunnelingDocument5 pagesWear Prediction and Maintenance Frequencies of Slurry Pipes For TBM TunnelingMacarena Arriagada AguilarNo ratings yet

- Organic Chemistry ReagentsDocument7 pagesOrganic Chemistry ReagentsRishabhNo ratings yet

- Manufacturing Process For TMTDocument6 pagesManufacturing Process For TMTKratagya SinghalNo ratings yet

- Specification of Steel Billets Specifications and GradesDocument2 pagesSpecification of Steel Billets Specifications and GradesMada TetoNo ratings yet

- Certified Reference Materials (CRM) : Csir-National Metallurgical Laboratory JAMSHEDPUR-831007, INDIADocument6 pagesCertified Reference Materials (CRM) : Csir-National Metallurgical Laboratory JAMSHEDPUR-831007, INDIAShiv PandeyNo ratings yet

- Is 1730Document11 pagesIs 1730maheshkbandari0% (1)

- SG Insert SpecificationDocument16 pagesSG Insert SpecificationRaamkriss Raja100% (2)

- Is 228 Part 1 - 1987Document4 pagesIs 228 Part 1 - 1987ferozNo ratings yet

- Indian Standard Testing Is 13015 - 1991Document11 pagesIndian Standard Testing Is 13015 - 1991joseNo ratings yet

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocument3 pagesAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationRaghav Tiwary0% (1)

- JSW CRS TMT RebarDocument16 pagesJSW CRS TMT Rebarsri projectssNo ratings yet

- Bolt GradeDocument2 pagesBolt GradeguthaleNo ratings yet

- Ramsarup IndustriesDocument34 pagesRamsarup IndustriesImran YounusNo ratings yet

- Asian Pipes CatalogueDocument7 pagesAsian Pipes Cataloguerutuja roge100% (1)

- Blast Furnace (Askmemetallurgy)Document42 pagesBlast Furnace (Askmemetallurgy)Sk BeheraNo ratings yet

- Amendment 1 of IS - 1786-2008Document11 pagesAmendment 1 of IS - 1786-2008sukanta420No ratings yet

- Reconditioning of Points and CrossingsDocument1 pageReconditioning of Points and CrossingsAditya RajNo ratings yet

- Is 228 (Part1) - Methods For Chemical Analysis of Steels - Determination of Carbon by Volumetric MethodDocument4 pagesIs 228 (Part1) - Methods For Chemical Analysis of Steels - Determination of Carbon by Volumetric Methodjjosej100% (1)

- JJM Project Interview QuestionDocument8 pagesJJM Project Interview QuestionRomee SahuNo ratings yet

- Laser Beam Welding of Quenched and Tempered Astm A 517 GR.B SteelDocument7 pagesLaser Beam Welding of Quenched and Tempered Astm A 517 GR.B SteelbiancogallazziNo ratings yet

- Is 513 Amendment-1Document2 pagesIs 513 Amendment-1sanjeev00747488No ratings yet

- Hardening and Hardness Tests Conversion Table of Hardness: Materials Technical DataDocument1 pageHardening and Hardness Tests Conversion Table of Hardness: Materials Technical DataalexmontellNo ratings yet

- Metallurgy of SteelDocument52 pagesMetallurgy of Steelprasanth bhadran100% (1)

- Taihong Catalogue-2018Document16 pagesTaihong Catalogue-2018SoLe Gahona100% (1)

- Aggregate Lab ManualDocument24 pagesAggregate Lab ManualnikhilNo ratings yet

- A Wholly Owned Subsidiary of Greenply Industries Limited) : Page 1 of 6 Is List - BPPLDocument6 pagesA Wholly Owned Subsidiary of Greenply Industries Limited) : Page 1 of 6 Is List - BPPLsri projectssNo ratings yet

- Is Phosphorus Bad For SteelDocument19 pagesIs Phosphorus Bad For SteelKarun Dev100% (1)

- Amendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument3 pagesAmendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - Specificationraviteja036100% (1)

- Bar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationDocument22 pagesBar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationPratik KharmateNo ratings yet

- DSR 2013-14 - E&mDocument44 pagesDSR 2013-14 - E&mAHMED SOHEL50% (2)

- Is 2062 E350 - Fe 490 Steel Plate - Steel PlateDocument4 pagesIs 2062 E350 - Fe 490 Steel Plate - Steel PlateAmit GauravNo ratings yet

- TMT Hand Book: Storage & HandlingDocument11 pagesTMT Hand Book: Storage & HandlingHiren Desai100% (1)

- Analysis of Quality and Defects in Lost Foam Casting ProcessDocument26 pagesAnalysis of Quality and Defects in Lost Foam Casting ProcessGurudutta MishraNo ratings yet

- IS Code of Cement & ConcreteDocument8 pagesIS Code of Cement & ConcreteKuldeep UpadhyayNo ratings yet

- Site Visit Report: Brief Report On Crushing PlantDocument5 pagesSite Visit Report: Brief Report On Crushing Plantsuchita PatilNo ratings yet

- Steel Slag For Road PavementDocument14 pagesSteel Slag For Road PavementSherlockNo ratings yet

- Weight of Ms AngleDocument7 pagesWeight of Ms AngleprashantNo ratings yet

- Is.15961.2012 (AZ150) PDFDocument12 pagesIs.15961.2012 (AZ150) PDFChoudhary Archit SangwanNo ratings yet

- Foundations Lighting ColumnsDocument2 pagesFoundations Lighting ColumnsAzizah AriffinNo ratings yet

- M&C-PCN-100-2013 DraftDocument31 pagesM&C-PCN-100-2013 DraftManoj KumarNo ratings yet

- ME1130 Mechanism of SolidificationDocument15 pagesME1130 Mechanism of SolidificationShivam RajNo ratings yet

- IS 2062 Hot Rolled Steel Specs.Document13 pagesIS 2062 Hot Rolled Steel Specs.Yasir Abbas100% (1)

- Is 1786 2008Document19 pagesIs 1786 2008Anonymous YHcvra8Xw6No ratings yet

- Cost Analysis For Industrial BLDGDocument4 pagesCost Analysis For Industrial BLDGGautam UmariaNo ratings yet

- IS-2800 - 1 Construction of TubewellDocument14 pagesIS-2800 - 1 Construction of TubewellRam Balak Roy100% (2)

- Ahmedabad Municipal Corporation: Tender DocumentDocument33 pagesAhmedabad Municipal Corporation: Tender DocumentKamlesh SheladiyaNo ratings yet

- TSL Bhushan - Colour CoatedDocument21 pagesTSL Bhushan - Colour Coatedabdul jawad100% (1)

- Chemical Quality of TMT Bars: View Previous Topic View Next TopicDocument6 pagesChemical Quality of TMT Bars: View Previous Topic View Next Topicpatrik710No ratings yet

- UpvcDocument1 pageUpvcannamalaicvNo ratings yet

- IS Code ListDocument4 pagesIS Code Listasif_rahman06No ratings yet

- Is 269 Final Product ManualDocument14 pagesIs 269 Final Product ManualBiswajit MansinghNo ratings yet

- 12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Document3 pages12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Shaikh MohammedHanifSultanNo ratings yet

- IS 4031 - Part15Document8 pagesIS 4031 - Part15Nagaraju ChintaNo ratings yet

- Somasila Grey Granite Test ReportDocument2 pagesSomasila Grey Granite Test ReportRakesh Reddy0% (1)

- High Carbon Steel Wire Rod: Company Standard As Per JIS G 3506Document2 pagesHigh Carbon Steel Wire Rod: Company Standard As Per JIS G 3506Mada TetoNo ratings yet

- RCC-DI-AC PipeDocument10 pagesRCC-DI-AC PipeNaveen NagisettiNo ratings yet

- Common Quality Assurance PlanDocument3 pagesCommon Quality Assurance PlanQASWA ENGINEERING IMRANNo ratings yet

- QAP LotahalDocument1 pageQAP LotahalRahul YadavNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- 06 Part A-1 CIVIL WORKS PR PDFDocument104 pages06 Part A-1 CIVIL WORKS PR PDFNaveen Nagisetti100% (1)

- Vol 1 2.0 Itb-MylmDocument50 pagesVol 1 2.0 Itb-MylmNaveen NagisettiNo ratings yet

- VOL 1 0.1 Index-MYLMDocument7 pagesVOL 1 0.1 Index-MYLMNaveen NagisettiNo ratings yet

- VOL 1 0.0 Cover Page MYLMDocument10 pagesVOL 1 0.0 Cover Page MYLMNaveen NagisettiNo ratings yet

- Technical Specification Canal - 02Document203 pagesTechnical Specification Canal - 02Naveen Nagisetti100% (1)

- T2 Tender Notice 23.9.19Document15 pagesT2 Tender Notice 23.9.19Naveen NagisettiNo ratings yet

- Existing Drain LevelsDocument1 pageExisting Drain LevelsNaveen NagisettiNo ratings yet

- Please Enable Macros To View Boq InformationDocument2 pagesPlease Enable Macros To View Boq InformationNaveen NagisettiNo ratings yet

- S.No. Name of The Material Qty (No's) E-Procurement CodeDocument2 pagesS.No. Name of The Material Qty (No's) E-Procurement CodeNaveen NagisettiNo ratings yet

- Schedule - 6 Schedule of General Terms and Conditions (To Be Enclosed in The Part-I Pre-Qualification Bid)Document2 pagesSchedule - 6 Schedule of General Terms and Conditions (To Be Enclosed in The Part-I Pre-Qualification Bid)Naveen NagisettiNo ratings yet

- Item Rate Boq: Validate Print HelpDocument7 pagesItem Rate Boq: Validate Print HelpNaveen NagisettiNo ratings yet

- "Mekastar/Jhalani/Taparia/ Mitutoyo Make "T & P" For Water System in 1X500 MW KTPS-VI Stage"Document4 pages"Mekastar/Jhalani/Taparia/ Mitutoyo Make "T & P" For Water System in 1X500 MW KTPS-VI Stage"Naveen NagisettiNo ratings yet

- 39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionDocument56 pages39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionNaveen NagisettiNo ratings yet

- Boq1 268515Document32 pagesBoq1 268515Naveen NagisettiNo ratings yet

- Percentage Boq: Validate Print HelpDocument12 pagesPercentage Boq: Validate Print HelpNaveen NagisettiNo ratings yet

- Government of Odisha: Office of The Engineer-In-Chief, Public Health Odisha, BhubaneswarDocument1 pageGovernment of Odisha: Office of The Engineer-In-Chief, Public Health Odisha, BhubaneswarNaveen NagisettiNo ratings yet

- QAP CI Flsnged PipesDocument11 pagesQAP CI Flsnged PipesNaveen NagisettiNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanNaveen NagisettiNo ratings yet

- Tata SteelDocument32 pagesTata Steelpatrik710No ratings yet

- Design of Machine ElementsDocument4 pagesDesign of Machine Elementsyogeshkmr01No ratings yet

- Sms Institute of Technology, LucknowDocument5 pagesSms Institute of Technology, LucknowarugeetNo ratings yet

- Darcy Weisbach EquationDocument1 pageDarcy Weisbach EquationJuan Victor Chipana BramonNo ratings yet

- DFT Biocompatible Wire: Advanced Materials and Processes October 2002Document5 pagesDFT Biocompatible Wire: Advanced Materials and Processes October 2002Moustafa AnwarNo ratings yet

- Method Statement For Pre FabricationDocument5 pagesMethod Statement For Pre FabricationFs67% (3)

- Acticated Atmosfere Case Hardening of SteelsDocument127 pagesActicated Atmosfere Case Hardening of SteelsUlises Quintana CarhuanchoNo ratings yet

- 730 378Document2 pages730 378slymn100% (1)

- ICP Vs AASDocument6 pagesICP Vs AASĐầm Già Xì XìNo ratings yet

- 3 Inoculant Alloy CompositionDocument2 pages3 Inoculant Alloy CompositionAdams GodoyNo ratings yet

- Laboratory Furniture - MSTDocument15 pagesLaboratory Furniture - MSTwafikmh4No ratings yet

- 45-BC AVK Gate Valve OSYDocument2 pages45-BC AVK Gate Valve OSYAnonymous X3PnFL6No ratings yet

- QCS-2010 Section 21 Part 21 Lightning ProtectionDocument4 pagesQCS-2010 Section 21 Part 21 Lightning Protectionbryanpastor106No ratings yet

- Chemical Reactions: Reactants ProductsDocument16 pagesChemical Reactions: Reactants ProductsRSL100% (1)

- Science Form1 Chapter 7Document27 pagesScience Form1 Chapter 7Sue Suraya Naza100% (1)

- Elements of Machine DesignDocument18 pagesElements of Machine DesignDexter Frank Virtucio CalderonNo ratings yet

- Welding GrooveDocument8 pagesWelding GrooveTuTuy AnNo ratings yet

- Sa 516 GR 70 Properties PDFDocument2 pagesSa 516 GR 70 Properties PDFAnonymous jlLBRMAr3O0% (1)

- 5 - Aluminium Alloys 2010-2011Document52 pages5 - Aluminium Alloys 2010-2011Busta137No ratings yet

- Surface TreatmentDocument35 pagesSurface TreatmentAnshul VermaNo ratings yet

- Group 1 - Metals and AlloysDocument9 pagesGroup 1 - Metals and AlloysJohn Jim Paul DunesNo ratings yet

- Mineral Resources PDFDocument28 pagesMineral Resources PDFannayaNo ratings yet

- EXERCISESDocument3 pagesEXERCISESraishaNo ratings yet

- Electrode Selection LPDocument9 pagesElectrode Selection LPRehan sheikhNo ratings yet

- GX5CrNi19-10 - 1Document2 pagesGX5CrNi19-10 - 1Joe ClarkeNo ratings yet

- Peningkatan Nilai Tambah MIneral PDFDocument38 pagesPeningkatan Nilai Tambah MIneral PDFIndraNo ratings yet

- Uses of IronDocument2 pagesUses of IronmaterialmindedNo ratings yet

- ANSI C29.2 - Aislador SuspensionDocument29 pagesANSI C29.2 - Aislador SuspensionAngel Anibal50% (2)