QMP-13 Production Control

QMP-13 Production Control

Uploaded by

om cncCopyright:

Available Formats

QMP-13 Production Control

QMP-13 Production Control

Uploaded by

om cncOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

QMP-13 Production Control

QMP-13 Production Control

Uploaded by

om cncCopyright:

Available Formats

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.

: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 1 of 9

ASWINI GROUP

REVISION CONTROL

The Revision Control format given below is used for updating revisions in the Procedures and issued along with the

document.

DETAILS

REV. REV. ISSUE

TOTAL NO. REVIEW DATE

NO. DATE DESCRIPTION OF REVIEW NO.

OF PAGES PAGE NO.

0.0 04.09.13 6 All New release 1.0 04.09.13

0.0 04.01.17 6 All In line with IATF Requirements 2.0 04.01.17

1.0 07.01.19 8 All Input-process-output introduced 2.0 07.01.19

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 2 of 9

ASWINI GROUP

EFFECTIVE

NAME SIGNATURE DATE

DATE

PREPARD &

RELEASED 07.01.2019

BY

07.01.2019

APPROVED H.GIRI

07.01.2019

BY (CEO)

1.0 Purpose

To establish, implement and manage a process for standardization of work, production planning, execution and process

monitoring and control online.

2.0 Scope

This Process is applicable to all products manufacturing within ASW, including outsourced processes.

3.0 Reference

IATF 16949:2016 Clause 8.5.1 (8.5.1.1, 8.5.1.2, 8.5.1.3 & 8.5.1.7), 8.5.6 (8.5.6.1, 8.5.6.1.1) and 9.1.1.1

4.0 Definition / Abbreviations

WI - Work instruction, SPC - Statistical process control, SOP – Standard Operating Procedure, RM – Raw Material, FG –

Finished Goods, QA – Quality Assurance, UCL – Upper Control Limit, LCL – Lower Control Limit, CP – Process Capability,

Cpk – Process Capability index, USL – Upper Specification Limit, LSL – Lower Specification Limit, UOM – Unit of

Measurement.

5.0 Responsibility

HOD: Production Head

Team: Production, Quality & Stores

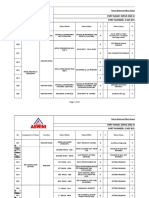

6.0 Input – Process – Output

Input Process (Activity) Output

Process Flow, Control Plan & SOP, Work Instructions &

Operation Standardization

PFMEA Visual Standards

Monthly Production Plan, RM

Production Capacity, Customer

Requirement Plan, Weekly

Schedule, RM Stock and FG Production Planning & Control

Production Plan and Daily

Stock

Machine Loading Plan

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 3 of 9

ASWINI GROUP

Monthly Production Plan, Finished Product, Daily

Weekly Production Plan and Production Report and In-

Production Run

Daily Machine Loading Plan & process Inspection Report –

Resources Operator Observation

Defect Prevention and Variation

Production Run Statistical Process Control

Reduction

Production Run Temporary Change of Process Controls Process Deviation Report

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 4 of 9

ASWINI GROUP

6.1 Work Instruction

Identifies the processes needed for the product and prepare Standard Operating Procedure (SOP). The process instructions

for the Standard Operating Procedure should be posted and should include set-up parameters such as machine speeds,

feeds, cycle time, etc., setting procedures, safety instructions, operator responsibilities, part application, process control

methods, in-house and customer complaints. It should be accessible to the operators and supervisors. These instructions

should be developed from the following inputs;

PFMEAs

Control plan(s)

Process flow chart

Floor plan layout

Characteristics matrix

Handling requirements

Customer inputs

Past experience

Engineering drawings, performance specifications, material specifications, visual standards and industry

standards.

6.2 Production Planning & Control

Input Production Planning - Activity Output

Production Capacity, Prepare monthly production plan based on Monthly production

Customer monthly the customer schedule, enquiry and oral order plan & RM

schedule, RM stock received from customer relation requirement plan.

and FG stock

Communicate to purchase/quality and

maintenance departments.

A

Monthly production Prepare Weekly machine loading plan for Weekly machine

plan & RM stock upcoming week. loading plan.

Weekly machine Daily machine loading

Prepare daily machine loading plan &

loading plan. plan

communicate to shop floor.

Communicate to production supervisor,

setters and operators

Monitor and update the actual production in

` the daily production report

Monthly production

plan, Weekly machine Review production plan every day with Changes of production

loading plan & Daily Production Head planning A

machine loading plan

Review production plan every month with

MD

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 5 of 9

ASWINI GROUP

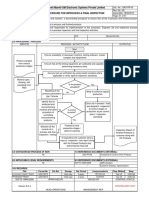

6.3 Production Run

Input Production Execution - Activity Output

Daily machine loading Organize manpower as per daily machine

plan and resources as loading plan and allocate job

necessary (plant layout)

Daily machine loading Job setup / job change / run the machine as

plan / SOP per the daily machine loading plan

SOP Inspect the setup samples and get approval First off Inspection

from line inspector.

No

Is approved by line Adjust / correct setting

inspector? and take new samples

Yes

Monitor production & inspect as per operator

SOP instruction plan mentioned in the SOP and

record the results in the operator observation

page of the in-process inspection report

No Stop Production and

Yes

Is the results are as per adjust / correct setting

specifications? And refer corrective

action procedure

Record the actual shift production in the daily

production report and machine loading plan and file it.

Record all the down times in the daily production

report and file it.

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 6 of 9

ASWINI GROUP

6.4 Statistical Process Control

Input Statistical Process Control - Activity Output

Safety and Significant, Open new X bar R control chart for safety

Characteristics and significant characteristics mentioned in

mentioned in the SOP the SOP by the symbol <SC> and <CC>

Draw the control limits from the previous

control chart

Select 5 consecutive samples measure and

record the values in the X bar R control chart

up to job change. Frequency – 1 Hour.

Calculate average, range and plot the value in

the X bar R control chart

Average = Sum of the subgroup value

divided by 5

Range = Maximum – Minimum value of

the subgroup.

Yes No Stop Production and

Is the plotted points are adjust / correct setting

with in the control and refer corrective

limits? action procedure

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 7 of 9

ASWINI GROUP

Input Statistical Process Control - Activity Output

Yes

Collect and file control chart after job change

and continue with the same chart whenever

the part is running.

Once the chart completed calculate control

limit, Cp and Cpk from the following

formulas.

Constants for sub group No. 5

A2 = 0.577, d2 = 2.326, D3 = 0, D4 = 2.114

X double bar (X dbar) = Average of X bar

R bar = Average of R

X bar Control limits,

UCL = Xbbar + A2*Rbar

LCL = Xbbar – A2*Rbar

R bar Control Limit

UCL = D4*Rbar

LCL = D3*Rbar

Sigma (S) = Rbar / d2

CP = Total Tolerance / (6*S)

Cpk = Min{( USL – Xdbar)/( 3*S), (Xdbar – LSL)/(3*S)

Are the Cp & Cpk value No Take CAPA to

>= 1.67 improve the process

Yes

Draw a new control limit and continue to

monitor the process again.

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 8 of 9

ASWINI GROUP

6.5 Temporary Change of Process Controls

Input Temporary Change Process Control - Activity Output

Temporary change in process Identify change/deviation

controls (operator, machine, against control plan in ongoing

tools, gauge, process control production process controls

parameters, location, etc.)

Stop the production and restore

Process Flow, PFMEA, Control Analyze the the process controls (as per the

Plan, CSR & Customer Risk control plan)

Feedback/Complaints (PFMEA)?

Prepare work instruction,

Alternate process controls

inspection/test, identification

(4Ms), inspection, test, etc.

and traceability requirements

methods/techniques

Prepare process deviation permit

with all necessary supporting

details

QA and/or Stop the production and restore

Customer the process controls (as per the

Approval? control plan)

Run the production process with

deviation permit and as per the

plan and instructions

Conduct inspection, testing,

verification, audit, etc. as per the

plan & instructions

QA and/or Stop the production, and recall

Customer the products in all stages, and

Approval? treat with control of NC product

Identify the lot with suitable Control on process deviation

means for easy identification and traceability at all

and traceability stages/Process Deviation Report

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 9 of 9

ASWINI GROUP

7.0 Further Reference

7.1 Documented Information

As per List of Documented Information to be maintained – RD-ASW-01

As per List of Documented Information to be retained – RD-ASW-02

You might also like

- RU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDocument4 pagesRU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDhananjay Patil100% (2)

- QMP-18 Initial Production ControlDocument5 pagesQMP-18 Initial Production Controlom cncNo ratings yet

- QMP-10 New Product DevelopmentDocument15 pagesQMP-10 New Product Developmentom cnc100% (1)

- Top Management, Stores and DispatchDocument4 pagesTop Management, Stores and DispatchBibhudutta mishraNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDocument1 page14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineers100% (1)

- Initial Supply ControlDocument3 pagesInitial Supply ControlKuldeep Chauhan100% (2)

- IB PHYSICS HL - Chapter 4 Waves PDFDocument10 pagesIB PHYSICS HL - Chapter 4 Waves PDFAna MariaNo ratings yet

- Lesson Plan From PDE SAS Website: "Building" Place Value: Subject: Mathematics Grade Level: 2 Duration: 1 Hour StandardsDocument3 pagesLesson Plan From PDE SAS Website: "Building" Place Value: Subject: Mathematics Grade Level: 2 Duration: 1 Hour Standardsapi-278899878No ratings yet

- QMP 07 TrainingDocument10 pagesQMP 07 Trainingom cncNo ratings yet

- QMP 15 Identification and TraceabilityDocument6 pagesQMP 15 Identification and Traceabilityom cncNo ratings yet

- QMP-02 - Control of RecordDocument5 pagesQMP-02 - Control of Recordom cncNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- QMP-05 - Corrective ActionDocument5 pagesQMP-05 - Corrective Actionom cnc100% (1)

- Suppliers Quality Assurance Manual (PDFDrive)Document135 pagesSuppliers Quality Assurance Manual (PDFDrive)umtNo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNo ratings yet

- Induction Training Text Format - StaffDocument5 pagesInduction Training Text Format - StaffJohn100% (1)

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- GP-9 Process Control Plan Audit Summary SheetDocument5 pagesGP-9 Process Control Plan Audit Summary SheetAsifNo ratings yet

- Product Audit FormDocument2 pagesProduct Audit Formcong da0% (1)

- Process Change NoteDocument1 pageProcess Change NoteSUBODHHNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- QSP 7.5 Documented Information Rev 01Document8 pagesQSP 7.5 Documented Information Rev 01Ulhas KavathekarNo ratings yet

- Incoming Inspection Procedure: Document Part No. Rev 100-0044 007 1 of 11Document11 pagesIncoming Inspection Procedure: Document Part No. Rev 100-0044 007 1 of 11Sandip Jawalkar100% (1)

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Process Audit Check Sheet Cum ReportDocument4 pagesProcess Audit Check Sheet Cum ReportLakshmanan Venkatesan100% (3)

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (3)

- Apqp - DR SHFTDocument60 pagesApqp - DR SHFTrajesh5000100% (2)

- P-01 Quality Assurance ProcedureDocument26 pagesP-01 Quality Assurance Proceduresharif1974100% (1)

- QAD Procedure - Lab Management P1Document1 pageQAD Procedure - Lab Management P1sumanNo ratings yet

- Quality Assurance ProceduresDocument35 pagesQuality Assurance Procedurestrikjoh100% (1)

- Ok Part NG: (Vendor Non-Conformance Report)Document2 pagesOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNo ratings yet

- Supplier Rating ProcedureDocument4 pagesSupplier Rating ProcedureAmine Chahi100% (2)

- 6 Team Feasibility STUDDYDocument6 pages6 Team Feasibility STUDDYkamalNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- Required Doc For IATFDocument3 pagesRequired Doc For IATFAbhayNo ratings yet

- SOP-QA-7.3.6.3-001 Production Part Approval Process (PPAP)Document7 pagesSOP-QA-7.3.6.3-001 Production Part Approval Process (PPAP)XionNo ratings yet

- DK Qap QHS 12-FR 03-R6 - CarDocument1 pageDK Qap QHS 12-FR 03-R6 - CarErlan Gus HermawanNo ratings yet

- Customer ComplientDocument1 pageCustomer Complientom cncNo ratings yet

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- Work Instruction: Action's Responsibility Change Parameters & CriteriaDocument2 pagesWork Instruction: Action's Responsibility Change Parameters & CriteriaSameer Saxena100% (2)

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit Singh100% (1)

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- APQP Supplier ProcedureDocument20 pagesAPQP Supplier ProcedurepharmatonNo ratings yet

- QSP Control of Documented InformationDocument2 pagesQSP Control of Documented InformationtriveshNo ratings yet

- Quality Plan - Incoming PaperDocument3 pagesQuality Plan - Incoming PaperSanjeev SharmaNo ratings yet

- SPTR Rev Check ListDocument5 pagesSPTR Rev Check ListSAKTHIVEL ANo ratings yet

- Turtle Diagrams - Stores + ShippingDocument1 pageTurtle Diagrams - Stores + Shippingcem electromechNo ratings yet

- Sta-P08-02 Non Conforming ProductDocument6 pagesSta-P08-02 Non Conforming ProductAnonymous B7pghh100% (1)

- Manufacturing Process AuditDocument1 pageManufacturing Process AuditSachin Kumbhar100% (1)

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- Ipc & Ipp Logbook or FlowDocument8 pagesIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- P-PRD-04 Initial Flow ControlDocument4 pagesP-PRD-04 Initial Flow ControlPk Nimiwal100% (1)

- Quality Manual: Duty Party Document Ref. Quality RecordDocument1 pageQuality Manual: Duty Party Document Ref. Quality RecordShida ShidotNo ratings yet

- Supplier System Audit Checklist - Action Plan (Updated As On 08.11.21)Document9 pagesSupplier System Audit Checklist - Action Plan (Updated As On 08.11.21)HR BGHNo ratings yet

- 39) Procedure For Inspection & Testing - 104931Document5 pages39) Procedure For Inspection & Testing - 104931Sagar DaundNo ratings yet

- Customer Complaint RegisterDocument3 pagesCustomer Complaint RegistermuthuselvanNo ratings yet

- Master List of RecordsDocument21 pagesMaster List of RecordsRaja DuraiNo ratings yet

- QMP-06 - Preventive ActionDocument5 pagesQMP-06 - Preventive Actionom cnc100% (1)

- QMP-01 - Control of DocumentDocument7 pagesQMP-01 - Control of Documentom cncNo ratings yet

- 12 CalibrationDocument6 pages12 Calibrationprincesudhansu9No ratings yet

- QMP-01 - Control of DocumentDocument7 pagesQMP-01 - Control of Documentom cncNo ratings yet

- QMP-06 - Preventive ActionDocument5 pagesQMP-06 - Preventive Actionom cnc100% (1)

- QMP-05 - Corrective ActionDocument5 pagesQMP-05 - Corrective Actionom cnc100% (1)

- Xods G8D1Document75 pagesXods G8D1om cncNo ratings yet

- RD ASW 22 Masterlist of APQPDocument1 pageRD ASW 22 Masterlist of APQPom cncNo ratings yet

- Customer ComplientDocument1 pageCustomer Complientom cncNo ratings yet

- 703 Fmea m3 LatestDocument24 pages703 Fmea m3 Latestom cncNo ratings yet

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocument10 pagesWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNo ratings yet

- Top 3 Rejections: Rejected Qty Rej %Document1 pageTop 3 Rejections: Rejected Qty Rej %om cncNo ratings yet

- CSCI 4020 Computer AlgorithmsDocument6 pagesCSCI 4020 Computer AlgorithmsByungHun LeeNo ratings yet

- Smoothed Particle Hydrodynamics (SPH) : An Overview and Recent DevelopmentsDocument52 pagesSmoothed Particle Hydrodynamics (SPH) : An Overview and Recent DevelopmentsPac Agathe100% (1)

- Cable Lan F/FTP Cat6: Not Yet Anatel ApprovedDocument2 pagesCable Lan F/FTP Cat6: Not Yet Anatel ApprovedAlerick VelascoNo ratings yet

- Elevator PressurizationDocument1 pageElevator Pressurizationneng oudomNo ratings yet

- Cima Standard Costing and Variance Analysis Session 1 QuestionsDocument13 pagesCima Standard Costing and Variance Analysis Session 1 QuestionsKiri chrisNo ratings yet

- CSE 1020 3.0 Introduction To Computer Science I Final Exam, Summer 2012 90 MinutesDocument8 pagesCSE 1020 3.0 Introduction To Computer Science I Final Exam, Summer 2012 90 MinutesexamkillerNo ratings yet

- Em Waves and Spectrum Notes Rev. 1Document15 pagesEm Waves and Spectrum Notes Rev. 1Cathlene GolpoNo ratings yet

- 3NW80111 Datasheet enDocument2 pages3NW80111 Datasheet enAnonymous chOEot9sNo ratings yet

- Lab 1: SNS: "Craters in Sand"Document7 pagesLab 1: SNS: "Craters in Sand"AASHIR AHMAD JASKANINo ratings yet

- THT WALL F EN v1Document5 pagesTHT WALL F EN v1gopinathdxb5No ratings yet

- Swabs CVDocument2 pagesSwabs CVGhanta Ranjith KumarNo ratings yet

- The ARC ProcessorDocument10 pagesThe ARC ProcessorDaniel LoveraNo ratings yet

- Data Base Linked in Profiles-South AfricaDocument16 pagesData Base Linked in Profiles-South AfricaManish_Kaushal_6867No ratings yet

- Finite Element AnalysisDocument2 pagesFinite Element Analysismythilispd_355305156No ratings yet

- Examview - 6th Grade Science Yearly Benchmark (Sy15-16)Document10 pagesExamview - 6th Grade Science Yearly Benchmark (Sy15-16)api-232424041No ratings yet

- Drop BoxDocument20 pagesDrop BoxJhosep MesiasNo ratings yet

- 2016-2018 Geo NewDocument18 pages2016-2018 Geo NewElenca KyweNo ratings yet

- Key Parameters For Air Cooled Condenser DesignDocument12 pagesKey Parameters For Air Cooled Condenser DesignmohantyomNo ratings yet

- Amity Institute of Pharmacy: B.Pharm, IV Sem Physical Pharmaceutics-II (Practical)Document12 pagesAmity Institute of Pharmacy: B.Pharm, IV Sem Physical Pharmaceutics-II (Practical)dipti_srivNo ratings yet

- 012 THURS - 215PM - 1450 Seidl - 0 - To - Safety - Accelerating - Functional - Safety - ProjectsDocument25 pages012 THURS - 215PM - 1450 Seidl - 0 - To - Safety - Accelerating - Functional - Safety - Projectswoof1800No ratings yet

- On Jarque-Bera Normality TestDocument10 pagesOn Jarque-Bera Normality Testkhaled EcoNo ratings yet

- Quick Guide:: in The Name of GODDocument4 pagesQuick Guide:: in The Name of GODpaiman100% (1)

- Vr7000 Installation ManualDocument156 pagesVr7000 Installation Manualmamuel013No ratings yet

- CLASS VII Physics HeatQADocument6 pagesCLASS VII Physics HeatQAtojendra laltenNo ratings yet

- An Improved Real-Time Handgun Detection System Using Yolov5 On A Novel DatasetDocument15 pagesAn Improved Real-Time Handgun Detection System Using Yolov5 On A Novel DatasetlaumunizNo ratings yet

- 5th SEM HT Assignment 1Document3 pages5th SEM HT Assignment 1Santosh AloneNo ratings yet

- Dynamic Mechanical Properties of Photo Resist Thin Films: Mechanical Science and TechnologyDocument6 pagesDynamic Mechanical Properties of Photo Resist Thin Films: Mechanical Science and TechnologyAnand NagarajanNo ratings yet

- HGI7000 Manual AGO21-ENDocument58 pagesHGI7000 Manual AGO21-ENdlauerNo ratings yet