Gear Motors: Solid and Reliable

Gear Motors: Solid and Reliable

Uploaded by

Alexis BriseñoCopyright:

Available Formats

Gear Motors: Solid and Reliable

Gear Motors: Solid and Reliable

Uploaded by

Alexis BriseñoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Gear Motors: Solid and Reliable

Gear Motors: Solid and Reliable

Uploaded by

Alexis BriseñoCopyright:

Available Formats

Gear motors

SOLID AND RELIABLE

GEAR MOTORS FOR DOMESTIC AND PROFESSIONAL USE

SERIES MR 330

These motors are characterized by their compact dimensions, high flexibility and extremely high quality,

guaranteed by a careful choice of materials and great attention in the manufacturing stage.

OPERATION

The Milano Componenti MR 330 Series of gear motors offers a wide range of models for both continuous

and intermittent duty.

In particular for the intermittent duty, there are some solutions:

Normal intermittent duty at 50%: 10” ON and 10” OFF

Reduced intermittent duty at 30%: 6” ON and 4” OFF

Base time for intermittent duty is 20 seconds and the MR 330 Series gear motors for intermittent usage are

available in the self-locking model: AB version, usually with a horizontal shaft. This AB model enables the

elimination of rotor inertia, by acting against the inertia of the units to which the gear motor is applied and

cancelling any active load torque.

The ambient temperature must be between 10°C and 80°C, observing the over-temperature limits laid down

by current regulations for windings. Prior to regular running, it is therefore necessary to carry out winding

over-temperature tests on the motor mounted on the equipment, by selecting the most severe duty cycle.

APPLICATIONS

Vending machines

Units for coffee machines

Ice makers

Ice-cream machines

Industrial rotisseries

Rotating display stands

Change machines

Valve operation

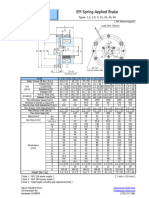

Fig. 1

MILANO COMPONENTI S.R.L. Via Carlo D’Adda 28 – 20143 MILANO

Tel.: +39 02 89421465 – fax.: +39 02 83249533 - Email: info@milanocomponenti.com – www.milanocomponenti.com

Fig. 2

CONSTRUCTIONAL SPECIFICATIONS

Die-cast aluminium gear box, available in two versions (Figure A):

L1 – for speeds from 0.5 to 5.8 min –1 / L2 – for speeds from 7 to 196 min –1

high-speed gears in polyamide for noise reduction

low-speed gears in sintered steel

gear shafts in tempered steel embedded in the reducer casing

TECHNICAL SPECIFICATIONS AC Version

Voltage and frequency (normal usage): 220 V / 50 Hz – 110 V / 60 Hz

Two-pole single-phase induction motor with short-circuited phase windings

Class F winding insulation

Rotor supported by rotating bushing on fixed shaft

TECHNICAL SPECIFICATIONS DC Version

Voltage (normal usage): 12 V o 24 V

Permanent-magnet commutator motor

Anti-interference impedances mounted on motor

Electrical connections: Faston 6.3 x 0.8 mm

MILANO COMPONENTI S.R.L. Via Carlo D’Adda 28 – 20143 MILANO

Tel.: +39 02 89421465 – fax.: +39 02 83249533 - Email: info@milanocomponenti.com – www.milanocomponenti.com

GUIDE TO THE CHOICE OF THE GEAR MOTOR TYPE MR 330

To choose the model best suited to your requirements, identify:

Operating voltage and frequency

Required rotational speed

Torque needed, according to the duty type (continuous or intermittent), referring to Table 2

Preferred constructional solution, referring to the following figures

The table 1 defines the gear box dimensions in the different Constructional solutions (fig. 3)

Slow-speed shaft output. The gear motor can be purchased equipped with the standard shaft or in the

shaftless version (for application of client shaft).

Fig. A Gear box dimensions Fig. 3 Constructional solutions

Standard Autosganciante (AS) Autobloccante (AB)

L1 M1

Standard Autosganciante (AS) Autobloccante (AB)

L2 M2

Soluzione chiusa Soluzione in C.C.

M3 M4

MILANO COMPONENTI S.R.L. Via Carlo D’Adda 28 – 20143 MILANO

Tel.: +39 02 89421465 – fax.: +39 02 83249533 - Email: info@milanocomponenti.com – www.milanocomponenti.com

OVERALL DIMENSIONS OF THE GEAR MOTORS

Table 1

Standard AB Self-locking Enclosed CC Current

Type of installation

M1S M2S M1AB M2AB M3 M4

Type of the box L1 L2 L1 L2 63,5 57,3

H12 61,5 54,5 61,5 54,5

Type of motor

Overall H20 69,5 62,5 69,5 62,5 88,5 81,5 88,5 81,5

dimensions

H30 79,5 72,5 79,5 72,5 98,5 91,5 98,5 91,5

Q in mm

fig. 3 H40 89,5 82,5 89,5 82,5 109 102 109 102

C.C. 109 102

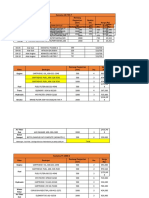

STANDARD PERFORMANCE

Maximum torque values in Kg-cm

Table 2

Motor casing

H12 H20 H30 H40 C.C.

height

Gear box Duty Continuous Continuous

cycles

Inter. 50% Continuous Inter. 50% Continuous Inter. 50% Continuous

min¯¹ Kg cm Kg cm Kg cm Kg cm Kg cm Kg cm Kg cm Kg cm

0,5 160

0,7 120

1 100

L1 2 50 85

3 38 65 70

4,5 23 45 120 60

5,8 20 35 90 70 50

7 19,5 31,5 88 68 45

8,5 15 28 65 50 120 120 35

12 10 20 45 35 95 95 25

18 8 16 35 25 70 70 20

22 13 28 20 50 50 15

32 8,5 18 15 35 35 9

45 6,5 14 12 28 28 7

L2 50 5 12,5 11 27 27 6

57 3 11 9 24 24 5

68 9 7,5 20 20 4,5

75 6,5 18,5 18,5 4

85 5 16 16 3,5

107 3,5 13 13 2

175 2,5 8,5 8,5 1

196 1,5 6,5 6,5 0,7

MILANO COMPONENTI S.R.L. Via Carlo D’Adda 28 – 20143 MILANO

Tel.: +39 02 89421465 – fax.: +39 02 83249533 - Email: info@milanocomponenti.com – www.milanocomponenti.com

SERIES MR 323

The gear motors series MR 323 are designed for domestic appliances

for example roasters and electrical or gas ovens, these motors are

noiseless, have a long-life and are highly reliable.

CERTIFICATIONS

IMQ Approved

VDE Approved

UL Approved

OPERATION

The gear motors series MR 323 are projected to be used in high

temperature appliance, as traditional ovens and pyrolytic cleaning.

Two versions of the MR 323 gear motors are available, according to

the ambient operating temperature:

Class F gear motor: maximum ambient temperature 90°C

Class H gear motor: maximum ambient temperature 125°C

APPLICATIONS

Roasters and spits for ovens and kitchen

Door locks for pyrolytic ovens

Barbecue

Automatic macchine

CONSTRUCTIONAL SPECIFICATIONS

Single-phase synchronous motor (4 watt); direction of rotation not predetermined

Rotor in sintered ceramic oxides with high magnetization

Class H motor insulation

Slow-speed shaft revolution 1.8 min

Gear support in pressed sheet metal

Cover in deep-drawn galvanized sheet metal

Molybdenum bisulphide grease 0for lifelong lubrication

Electrical connections: tinned brass faston 6.3 x 0.8

Power supply: AC: 220/240 V 50/60 Hz and DC: 4.5 V / 12 V

Coupling in deep-drawn galvanized sheet metal, pressure-fitted on the slow-speed shaft,

Knurled in various versions

MILANO COMPONENTI S.R.L. Via Carlo D’Adda 28 – 20143 MILANO

Tel.: +39 02 89421465 – fax.: +39 02 83249533 - Email: info@milanocomponenti.com – www.milanocomponenti.com

MOTOR FANS UNITS

SERIES VR

The VR Series motor-fan units have been developed to respond to the ever-increasing demands in terms of

cooking technologies, which nowadays require temperatures inside the oven to be as uniform as possible.

They are characterized by high durability and extremely high quality, guaranteed by a careful choice of

materials and great attention in the manufacturing stage.

APPLICATIONS

Ventilated ovens

Multifunction ovens

Combi ovens

CONSTRUCTIONAL SPECIFICATIONS

Fan in aluminized steel, die-cast aluminium, sintered bronze and tempered steel

Two-pole single-phase asynchronous induction motor with short-circuited phase windings

Class F or H motor insulation

Stator and rotor lamination pack made with low-loss sheet which permits reduced power absorption

Squirrel-cage rotor in die-cast aluminium

Mounting and assembly supports in die-cast aluminium

Self-aligning motor bearings in sintered bronze and with lifelong lubrication

Lubricant for high temperatures

Driveshaft in tempered steel

Permissible voltage (normal usage): from 24 Volt to 400 Volt

Permissible frequency (normal usage): from 50 Hz to 60 Hz

Electrical connections: faston terminals 6.3 x 0.8

Fan locking guaranteed by milling and lock nut

Large motor-cooling fan mounted directly on the shaft

MILANO COMPONENTI S.R.L. Via Carlo D’Adda 28 – 20143 MILANO

Tel.: +39 02 89421465 – fax.: +39 02 83249533 - Email: info@milanocomponenti.com – www.milanocomponenti.com

VENTILATORI TANGENZIALI - SERIE TG

The TG Series motor-fan units are tangential fans

characterized by noiselessness, compact dimensions

and high reliability.

The rotation of the impeller creates a vortex

motion that directs the airflow by means of a

special guide system.

APPLICATIONS

Air treatment (forced heating, convectors, air conditioners, convection fans, heat regenerators, heat

accumulators, balanced discharge burners and air cleaners)

Equipment cooling (computers, power supply units, printers, office machines, power boards and control

cabinets)

Room ventilation (smoke extraction, air curtains and room fans)

Domestic appliances (ovens, stoves, hobs, clothes dryers and humidifiers)

Refrigerated display cases

Vending machines

CONSTRUCTIONAL SPECIFICATIONS

Pressed scroll in pre-galvanized steel sheet, completely seamed or welded according to the model

Impeller obtained using sheets cut from calibrated aluminium strip

Two-pole single-phase induction motor with short-circuited phase windings

Class F (155° C) and class H (180-200° C) motor insulation

Motor supports in die-cast aluminium and zamak

Self-aligning motor bearings in sintered bronze

Large “Permawich” tank

Oil recuperators

Fan support bearings in Teflon-carbon and latilub assembled in three components

Driveshaft in tempered steel

Permissible voltage (normal usage): from 24 Volt to 400 Volt

Permissible frequency (normal usage): from 50 Hz to 60 Hz

Electrical connections: faston terminals 6.3 x 0.8

SPECIAL VERSIONS

TG Series motor-fan units are available in the following lengths: 120 / 180 / 240 / 270 / 300 / 360 mm

MILANO COMPONENTI S.R.L. Via Carlo D’Adda 28 – 20143 MILANO

Tel.: +39 02 89421465 – fax.: +39 02 83249533 - Email: info@milanocomponenti.com – www.milanocomponenti.com

You might also like

- Eixo Transmissao e Polia Conjunto 84MM (Wynn Marine PN 1588-009-117) PDFDocument44 pagesEixo Transmissao e Polia Conjunto 84MM (Wynn Marine PN 1588-009-117) PDFAugusto RezendeNo ratings yet

- (Andy - Van - Den - Dobbelsteen, - Smart Building in A Changing Climate (BookFi) PDFDocument251 pages(Andy - Van - Den - Dobbelsteen, - Smart Building in A Changing Climate (BookFi) PDFKenshi BallaNo ratings yet

- The Tesla Disk Turbine by W M J Cairns PDFDocument44 pagesThe Tesla Disk Turbine by W M J Cairns PDFramakantinamdar100% (1)

- Electromagnetic Two Disc, Spring Set BrakeDocument1 pageElectromagnetic Two Disc, Spring Set BrakeAnonymous Ts0uMLFOJNo ratings yet

- PX 55 Flow Component - ValveDocument64 pagesPX 55 Flow Component - ValveKal JNo ratings yet

- Manual Straightline Type D-1Document25 pagesManual Straightline Type D-1Murat AltparmakNo ratings yet

- Motor SelemaDocument7 pagesMotor SelemaAhmed Abd elhafezNo ratings yet

- Clarke Electric MotorsDocument1 pageClarke Electric MotorsFloNo ratings yet

- Temporiti Electromagnetic Fail Safe Brake Type AcDocument1 pageTemporiti Electromagnetic Fail Safe Brake Type AcmaheshvarmastdznNo ratings yet

- Pump Questions PDFDocument11 pagesPump Questions PDFStefan De BeerNo ratings yet

- 546 DatasheetDocument11 pages546 Datasheetwilfredo mercedesNo ratings yet

- Monninghoff 546 - DatasheetDocument11 pagesMonninghoff 546 - DatasheetirfannadineNo ratings yet

- Ocrim PlansifterDocument8 pagesOcrim PlansifterGavriel Dhean AlvaroNo ratings yet

- Vortex Flowmeter User's Manual QTDocument32 pagesVortex Flowmeter User's Manual QTVincent BuensucesoNo ratings yet

- DC Single-Acting High Performance Solenoids DatasheetDocument8 pagesDC Single-Acting High Performance Solenoids Datasheetbarghsaze.abpakhshNo ratings yet

- l5lb Sellsheet EngDocument2 pagesl5lb Sellsheet EngsalesNo ratings yet

- Check Valve Keystone F85Document4 pagesCheck Valve Keystone F85Robi KeiNo ratings yet

- AI152986482525en 000404Document4 pagesAI152986482525en 000404Sukoco EgiNo ratings yet

- Screenshot 2022-07-14 at 12.30.24Document44 pagesScreenshot 2022-07-14 at 12.30.24zakkNo ratings yet

- AI152986482525en 000404Document4 pagesAI152986482525en 000404Saeed MahmoudabadiNo ratings yet

- AC Servomotor 110SFDocument4 pagesAC Servomotor 110SFrumenNo ratings yet

- Technical Guidelines For HydroPlast U-PVC FittingsDocument20 pagesTechnical Guidelines For HydroPlast U-PVC FittingsOsama AhmedNo ratings yet

- MNB 2Document1 pageMNB 2Phan Thanh BảoNo ratings yet

- Sling CapacityDocument1 pageSling Capacityultiyeda1No ratings yet

- FT Series: FTB12-150 12V150AhDocument2 pagesFT Series: FTB12-150 12V150AhJohn Edwin MuñozNo ratings yet

- 6-Ali3 2015 - enDocument4 pages6-Ali3 2015 - enKundan RokadeNo ratings yet

- Acoples WCC - Jaw CouplingsDocument3 pagesAcoples WCC - Jaw CouplingsJuan Gabriel Galvis ZuluagaNo ratings yet

- A63 A64 Multi Position CylinderDocument2 pagesA63 A64 Multi Position CylinderBiswanath LenkaNo ratings yet

- HSP_ENDocument16 pagesHSP_ENAlvin NgNo ratings yet

- Chapter 10. Piping WorkDocument29 pagesChapter 10. Piping WorkSastra Winata100% (1)

- 2680 4500lb Y-Pattern GloveValveDocument1 page2680 4500lb Y-Pattern GloveValveBrion Bara IndonesiaNo ratings yet

- Iwde7125 PDFDocument21 pagesIwde7125 PDFdsliskNo ratings yet

- Bs638 (Part 4) 0361Tq Welding Cable Single CoreDocument2 pagesBs638 (Part 4) 0361Tq Welding Cable Single CoreAdnan KhanNo ratings yet

- Motosol Soft StarterDocument29 pagesMotosol Soft StarterMichael Diaz AgustinesNo ratings yet

- Fta12 200HTDocument2 pagesFta12 200HTMohammedAbdulfattahNo ratings yet

- VSF - Torque LimiterDocument5 pagesVSF - Torque Limiterneyah21554No ratings yet

- A2L-A4L Data Sheet en 01Document10 pagesA2L-A4L Data Sheet en 01zibbex555No ratings yet

- en - 5 MSP 50 HZ - Rev01 - 05 2023Document4 pagesen - 5 MSP 50 HZ - Rev01 - 05 2023giselle kennedyNo ratings yet

- Prova BlowByDocument4 pagesProva BlowByRenatoNo ratings yet

- Straight Line Wiper ManualDocument20 pagesStraight Line Wiper ManualIsmail HashmiNo ratings yet

- Grade 100 Alloy ChainDocument1 pageGrade 100 Alloy ChainPanthNo ratings yet

- Heavy-Duty Slide 2 For Heavy LoadsDocument2 pagesHeavy-Duty Slide 2 For Heavy LoadsawemetalNo ratings yet

- Blow byDocument3 pagesBlow bymahmoudsaiedegyNo ratings yet

- K91.31 Fig T302-M3 B302-S13 en FinalDocument1 pageK91.31 Fig T302-M3 B302-S13 en FinaladrianioantomaNo ratings yet

- Desch KB 16 GB Lutex LKBDocument6 pagesDesch KB 16 GB Lutex LKBchodgemNo ratings yet

- gui00011Document24 pagesgui00011f GoingNo ratings yet

- Flowcon Ab-Ejust Tech - 2012 AprDocument11 pagesFlowcon Ab-Ejust Tech - 2012 AprJomar BustamanteNo ratings yet

- The Wear-Resistant SteelDocument16 pagesThe Wear-Resistant SteelredNo ratings yet

- Metallic Gaskets - Installation & Torque - October 2020Document6 pagesMetallic Gaskets - Installation & Torque - October 2020Alberto CaveroNo ratings yet

- FT Series: FTB12-100 12V100AhDocument2 pagesFT Series: FTB12-100 12V100Ahari yuniantoNo ratings yet

- Transmotec Datasheet SDS80120ADocument1 pageTransmotec Datasheet SDS80120Asaxadi4814No ratings yet

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsNo ratings yet

- Buss NH Ultra-Rápidos Talla 000 A 3 690vac Doble Indicador - NewDocument2 pagesBuss NH Ultra-Rápidos Talla 000 A 3 690vac Doble Indicador - NewsunliNo ratings yet

- Md310 Quick ManualDocument55 pagesMd310 Quick ManualHitesh PanigrahiNo ratings yet

- Inova Ball Joints JBDocument2 pagesInova Ball Joints JBSympatyagaNo ratings yet

- Tiger Chain BlockDocument5 pagesTiger Chain BlockAntonio CardosoNo ratings yet

- SCHMIDT ServoPressesDocument4 pagesSCHMIDT ServoPressesgmkumar.indNo ratings yet

- OF Effective: Pitch Diameter (MM) Diameter + (2Document1 pageOF Effective: Pitch Diameter (MM) Diameter + (2srinivas murthyNo ratings yet

- Three Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESDocument6 pagesThree Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESsugirinNo ratings yet

- 40LCM30AA853Document1 page40LCM30AA853surya1392No ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- Advances in Delayed CokingDocument8 pagesAdvances in Delayed Cokingjojumathew100% (1)

- Cooling Load Rule of ThumbDocument18 pagesCooling Load Rule of ThumbQaz Zaq100% (1)

- Integrated Membrane System For Low Fouling RO Desalting of Municipal WastewaterDocument56 pagesIntegrated Membrane System For Low Fouling RO Desalting of Municipal Wastewaterzerocool86No ratings yet

- Process Integration Through Pinch AnalysisDocument7 pagesProcess Integration Through Pinch AnalysisCORNELIUS CHIRUMENo ratings yet

- AA200 CH 06 The Conservation Equations CantwellDocument38 pagesAA200 CH 06 The Conservation Equations CantwellbhargavNo ratings yet

- EE-455 Electrical PowerSystem Protection - F2013Document48 pagesEE-455 Electrical PowerSystem Protection - F2013Vinícius Mota SilvaNo ratings yet

- Susmita Dasgupta Economic Research Unit, Joint Plant CommitteeDocument24 pagesSusmita Dasgupta Economic Research Unit, Joint Plant CommitteezillionpplNo ratings yet

- Electrical Paper IIDocument18 pagesElectrical Paper IIAymaNo ratings yet

- Made By-Simmi Bhatia (1253) Vedant Sharma (1271Document21 pagesMade By-Simmi Bhatia (1253) Vedant Sharma (1271anshuman500No ratings yet

- Thesis PartDocument55 pagesThesis Partshanjida tomaNo ratings yet

- Sathyabama University: 414601-614601-614PT501-614PT501 (2007)Document7 pagesSathyabama University: 414601-614601-614PT501-614PT501 (2007)kannan09No ratings yet

- Industrial Services TUV Nord MalaysiaDocument25 pagesIndustrial Services TUV Nord MalaysiaPaolo NgNo ratings yet

- Copeland-Cr42k6-Pfv-Recip-Compressor-Technical SpecificationsDocument1 pageCopeland-Cr42k6-Pfv-Recip-Compressor-Technical SpecificationscarlosmochimaNo ratings yet

- Catálogo General Contactores y Relés Térmicos TemContact2 Ref.15-I75EDocument74 pagesCatálogo General Contactores y Relés Térmicos TemContact2 Ref.15-I75EJose maria HolgueraNo ratings yet

- New Generation Electric Vehicles I To 12 PDFDocument384 pagesNew Generation Electric Vehicles I To 12 PDFvinay kumar100% (1)

- Capsun (Radial Thru-Hole) SWN SeriesDocument2 pagesCapsun (Radial Thru-Hole) SWN Serieshes545No ratings yet

- Arc-Flash Analysis Approaches For Medium-Voltage DistributionDocument8 pagesArc-Flash Analysis Approaches For Medium-Voltage DistributionCarlos Lino Rojas AgüeroNo ratings yet

- Requirements 11.06.17Document1 pageRequirements 11.06.17Mustafa DemirolNo ratings yet

- Komatsu HD 785Document7 pagesKomatsu HD 785Salim BazzryNo ratings yet

- Course ObjectivesDocument4 pagesCourse ObjectivesHyjanJacobNo ratings yet

- 15 Mott Macdonald Torres HuangDocument24 pages15 Mott Macdonald Torres HuangMahdi MahnazNo ratings yet

- CGAM Chiller Technical Details PDFDocument8 pagesCGAM Chiller Technical Details PDFoumar gadjigoNo ratings yet

- IEEE STD 492™ (1999) - Guide For Operation and Maintenance of Hydro-GeneratorsDocument70 pagesIEEE STD 492™ (1999) - Guide For Operation and Maintenance of Hydro-GeneratorsRaúl Luque100% (2)

- Power-Miser 12 Water Heater ManualDocument32 pagesPower-Miser 12 Water Heater ManualClaudeVanDammNo ratings yet

- Steel Pipes IndustryDocument3 pagesSteel Pipes Industryvik05345No ratings yet

- Solar Operated Crane SystemDocument3 pagesSolar Operated Crane Systemankush belkar100% (1)

- VoltAir Owners ManualDocument11 pagesVoltAir Owners ManualRudolf MyerNo ratings yet