WPS Sa 517

WPS Sa 517

Uploaded by

DHANANNJAI SINGH -Copyright:

Available Formats

WPS Sa 517

WPS Sa 517

Uploaded by

DHANANNJAI SINGH -Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

WPS Sa 517

WPS Sa 517

Uploaded by

DHANANNJAI SINGH -Copyright:

Available Formats

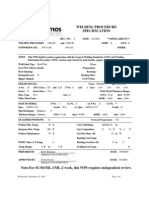

WELDING PROCEDURE

SPECIFICATION

WPS - 3001-11B REV. NO.: 0 DATE: 10/6/2004 **APPLICABILITY**

WELDING PROCESS/ES: GMAW and GMAW ASME: X AWS: X

SUPPORTING PQR: Z-WS-8-G-V Z-WS-8-H OTHER: AISC

JOINT This WPS shall be used in conjunction with the General Welding Standards (GWS) and Welding

Fabrication Procedure (WFP) sections and criteria for joint details, repairs, NDE, inspection etc.

Weld Joint Type: Groove/fillet Class: Full/partial penetration

See GWS 1-06 for joint details Preparation: Mechanical/thermal

Root Opening: 1/16"- 3/16" Backing: None

Backgrind root: Root/second side Backing Mat.: CS Strap/ring when used

Bkgrd Method: Grind/chip/arc gouge GTAW Flux: N/A Backing Retainer: N/A

FILLER METALS: Class: ER-1xxS-x and ------------

A No: 12 SFA Class: 5.28 and ---- F No: 6 and ---- Size: .045 ---- ---- ----

Insert: N/A Insert Desc.: N/A Weld Metal Thickness Range:

Flux: Type: N/A Size: N/A AWS: 0.187 thru 8.000

Filler Metal Note: ASME: 0.187 thru 8.000

BASE MATERIALS: P No. 11B Gr No. All to: P No. 11B Gr No. All

Spec. SA-517 Grade: ** to: Spec. SA-517 Grade: **

Qualified Pipe Dia Range: = : 0

Qualified Thickness Range: AWS: 0.187 thru 8.000 ASME: 0.187 thru 8.000

QUALIFIED POSITIONS: All-plate ------------ Vertical Progression: V-UP

Preheat Min. Temp.: *70 °F GAS: Shielding: CO2 or ------------

Interpass Max. Temp.: 500 °F Gas Composition: 100 % 0 % 0 %

Preheat Maintinance: *70 °F Gas Flow Rate cfh: 25 to 40

Backing Gas/Comp: None 0 %

PWHT: Time @ °F Temp. N/A Backing Gas Flow cfh: 0 to 0

Temp. Range: 0 °F to 0 °F Trailing Gas/Comp: None %

PREPARED BY: KG Fellers DATE: 10/6/2004

Signature on file at FWO-DECS

APPROVED BY: Tobin oruch DATE: 10/6/2004

Signature on file at FWO-DECS

Note:For SC/SS/ML-1/ML-2 work, this WPS requires independent review.

Wednesday, October 13, 2004 Page 1 of 2

WPS NO: 3001-11B

WELDING CHARACTERISTICS:

Current: DCEP and ---- Tungsten type: N/A Transfer Mode: Spray

Ranges: Amps 180 to 0 Pulsing Cycle: N/A to N/A

Volts 20 to 0 Background Current: N/A

Fuel Gas: N/A Flame: N/A Braze temp. °F N/A to N/A

WELDING TECHNIQUE: For cleaning, grinding, and inspection criteria refer to Volume 2, Welding

Fabrication Procedures

Technique: Semi-auto Cleaning Method: Grind/chip/arc gouge

Single Pass or Multi Pass: M Stringer or Weave bead (S/W): S/W Oscillation: N/A

GMAW Gun Angle °: 5 to 15 Forehand or Backhand for GMAW (F/B): FH

GMAW/FCAW Tube to work distance: 3/8" - 1/2"

Maximum K/J Heat Input: N/A Travel speed: As required Gas Cup Size: 1/2"-3/4"

No single pass shall deposit greater than 1/2" thickness of material.

PROCEDURE QUALIFIED FOR:

Charpy "V" Notch: N/A Nil-Ductil Transition Temperature: N/A Dynamic Tear: N/A

Comments: (1) *IPT and Preheat for material =3/4" = 225 °F min. (2) **Grade #s A,B,E,F,J&P

Weld Manual Filler Metals Nozzel

Layer Process Size Amp Range Volt Range Travel/ipm Angle Other

1 GMAW ER-1xxS-x .045 180 to 220 20 to 24 4 to 5 5 - 15

2 GMAW ------------ ---- 0 to 0 0 to 0 ----- to -----

3

GMAW ------------ ---- 0 to 0 0 to 0 ----- to -----

4

5 ----

6

7

8

REM. * Weld layers are representative only - actual number of passes and layer sequence may vary due to

variations in joint design, thickness and fitup.

Use of LANL Welding Procedures and Welder Qualifications for non-LANL work shall be at the sole risk and

responsibility of the Subcontractor, and the Subcontractor shall indemnify and save LANL and the Government

harmless from any and all claims, demands, actions or causes of action, and for any expense or loss by reason of

Subcontractor's and their employees posession and use of LANL procedures and qualifications.

Wednesday, October 13, 2004 Page 2 of 2

You might also like

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Inspection & Testing Plan For Installation of GRP PipesDocument3 pagesInspection & Testing Plan For Installation of GRP Pipessandeep reshmaNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan Guru100% (1)

- BCM Captiva 1 ConectorDocument4 pagesBCM Captiva 1 Conectorjulio montenegroNo ratings yet

- Phanikumar TransportPhenomenaNotes 01feb2010Document109 pagesPhanikumar TransportPhenomenaNotes 01feb2010aalisafa50% (2)

- SQL Questions & AnswersDocument9 pagesSQL Questions & AnswersTsehayou SieleyNo ratings yet

- Lastec 421d PartsDocument145 pagesLastec 421d PartsCharles WernerNo ratings yet

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- Asme Sec Ix - Welding Procedure and Performance QualificationDocument44 pagesAsme Sec Ix - Welding Procedure and Performance QualificationLaith SalmanNo ratings yet

- Visual Inspection of Weld Joints Welding and NDTDocument7 pagesVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- Pipe Instalation ChecklistDocument4 pagesPipe Instalation ChecklistYuwantoniAlNo ratings yet

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- Sample - F-06 Imir-Material Inspection Report (Se) 1Document1 pageSample - F-06 Imir-Material Inspection Report (Se) 1Structures ProductionNo ratings yet

- Job Procedure For Earthing SystemDocument7 pagesJob Procedure For Earthing SystemNisith SahooNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Baking ProcedureDocument2 pagesBaking Proceduregopuvinu4uNo ratings yet

- Welding Electrode: The Hashimite Kingdom of JordanDocument23 pagesWelding Electrode: The Hashimite Kingdom of JordanAhmad OmarNo ratings yet

- Inspection and Testing of Piping Systems ES-14-602-02Document44 pagesInspection and Testing of Piping Systems ES-14-602-02Edmund MoraldeNo ratings yet

- Work Method Statement For De-Watering Drying and Purging After HydrotestDocument12 pagesWork Method Statement For De-Watering Drying and Purging After Hydrotestalinor_tnNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- Process Pipes Handling and Storage Material Procedure-3 Additional SpheresDocument16 pagesProcess Pipes Handling and Storage Material Procedure-3 Additional Spheresqaqc.nimerlawzi1No ratings yet

- BS en 26848-1991Document13 pagesBS en 26848-1991rafaelpolNo ratings yet

- Test Certificate: D&H Secheron Electrodes Pvt. LTDDocument1 pageTest Certificate: D&H Secheron Electrodes Pvt. LTDAmit DamaNo ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Weld Manual 4 PowerDocument77 pagesWeld Manual 4 PowerGyanendra Narayan NayakNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Safety Alert Space HeatersDocument2 pagesSafety Alert Space HeatersRamadan KareemNo ratings yet

- Duct BOQDocument2 pagesDuct BOQmoosa ibrahaim100% (1)

- HDPE FittingsFeb2013Document117 pagesHDPE FittingsFeb2013Felicia Glass100% (1)

- D P Extension LetterDocument1 pageD P Extension LetterSwapnil ShahNo ratings yet

- Method Statement For Paint Repair Procedure For Piping PDF FreeDocument16 pagesMethod Statement For Paint Repair Procedure For Piping PDF Freeumuhuza salomonNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Calibration Certificates.Document48 pagesCalibration Certificates.Erfan KhanNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- FJC KP 00R 11 Jan 23Document1 pageFJC KP 00R 11 Jan 23Aulia AchmadNo ratings yet

- B 898 - 99 - Qjg5oaDocument6 pagesB 898 - 99 - Qjg5oaPoovelan ViswanathanNo ratings yet

- PIPE SUPPORT-STR - Welding Inspection ReportDocument1 pagePIPE SUPPORT-STR - Welding Inspection ReportBWQNo ratings yet

- Testing of Double Deck Floating Roofs: GeneralDocument2 pagesTesting of Double Deck Floating Roofs: GeneralVishvjeet Prakash TiwariNo ratings yet

- 14 Procedure For Shop and Field PaintingDocument24 pages14 Procedure For Shop and Field PaintingdnbinhNo ratings yet

- HBP-QMS-WI 15-14 - Control and Issue of Welding Consumables Rev 01Document6 pagesHBP-QMS-WI 15-14 - Control and Issue of Welding Consumables Rev 01ElMacheteDelHuesoNo ratings yet

- Boiler Tube Repair PracticeDocument1 pageBoiler Tube Repair PracticejagyanduttaNo ratings yet

- Tds of Eterset 2844Document2 pagesTds of Eterset 2844Nandkumar PawarNo ratings yet

- Report No. TA-V-1456Document2 pagesReport No. TA-V-1456u04ajf3No ratings yet

- Job Procedure For Hot Insulation Work of Piping & Equipment1Document13 pagesJob Procedure For Hot Insulation Work of Piping & Equipment1ravi00098100% (1)

- COOLING TOWER FAN Erection Quality ChecklistsDocument1 pageCOOLING TOWER FAN Erection Quality ChecklistsBudoy Smith100% (1)

- PWHTDocument3 pagesPWHTharishcsharmaNo ratings yet

- Contoh ItpDocument3 pagesContoh Itphafiz elektroNo ratings yet

- RFI-157 Request For NDT (Only RT) Acceptance For PQR JointsDocument1 pageRFI-157 Request For NDT (Only RT) Acceptance For PQR JointsT C Hasan DmrNo ratings yet

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- MTC Certificate - Doc CHASEDocument1 pageMTC Certificate - Doc CHASEERIC GERARDNo ratings yet

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpNo ratings yet

- DPR - Product Storage Tank 07.06.2023Document6 pagesDPR - Product Storage Tank 07.06.2023ashfaque khanNo ratings yet

- Anson Steel Tanks and Parts Catalog 2015Document12 pagesAnson Steel Tanks and Parts Catalog 2015Juan P RuizNo ratings yet

- Reliance Industries Limited Line History Sheet For Low Alloy Steel PipingDocument2 pagesReliance Industries Limited Line History Sheet For Low Alloy Steel PipingRavi ShankarNo ratings yet

- Kespet Product Catalogue 2019 4Document62 pagesKespet Product Catalogue 2019 4Dovydas Prialgauskas100% (1)

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationWaranya Musika100% (1)

- 1000 XXXX HY80 HSLA100Document2 pages1000 XXXX HY80 HSLA100srb metallurgNo ratings yet

- Aluminim WPSDocument2 pagesAluminim WPSmahmoud_allam3No ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- GWAW Welding SpecificationDocument2 pagesGWAW Welding SpecificationSaurabh GuptaNo ratings yet

- H630 01 Paper Dec 17Document8 pagesH630 01 Paper Dec 17Karman BattuNo ratings yet

- 2021 HRMT Essay TurnDocument4 pages2021 HRMT Essay TurngillNo ratings yet

- Psychosocial Status and Quality of Life of Adolescent Girls in Karnataka, IndiaDocument8 pagesPsychosocial Status and Quality of Life of Adolescent Girls in Karnataka, Indiavarunendra pandeyNo ratings yet

- Fallacies in ReasoningDocument36 pagesFallacies in ReasoningRanNo ratings yet

- WL Wordlist Business Partner B1 A ZDocument42 pagesWL Wordlist Business Partner B1 A ZChâu VũNo ratings yet

- Model 549: General & Small Parts PhantomDocument3 pagesModel 549: General & Small Parts PhantomMiguel De Los Santos PavisicNo ratings yet

- Fact Sheet - Electrician (General)Document4 pagesFact Sheet - Electrician (General)Saravanan Rasaya100% (1)

- Partha Moulik: HSE Officer at Ashoka Buildcon LimitedDocument3 pagesPartha Moulik: HSE Officer at Ashoka Buildcon LimitedparthaNo ratings yet

- TF Series: Panametrics Aluminum Oxide Moisture ProbeDocument4 pagesTF Series: Panametrics Aluminum Oxide Moisture ProbejhonaNo ratings yet

- A. T. S. - Switching Line BoardDocument6 pagesA. T. S. - Switching Line BoardAsif ShahNo ratings yet

- Gear TrainDocument26 pagesGear TraingowthamarajNo ratings yet

- Orientation ScriptDocument7 pagesOrientation ScriptJoeylhyn Pagaduan GuerreroNo ratings yet

- BSBMGT608 Manage Innovation and Continuous Improvement: BSB60215 Advanced Diploma of BusinessDocument9 pagesBSBMGT608 Manage Innovation and Continuous Improvement: BSB60215 Advanced Diploma of BusinessKOKOWARA VIANo ratings yet

- Grade 7 Math Fractions RecapDocument3 pagesGrade 7 Math Fractions RecapNandini PilaniNo ratings yet

- Lubrication Features of A Large Diesel EngineDocument17 pagesLubrication Features of A Large Diesel EngineKarim Sowley DelgadoNo ratings yet

- Connectors 3 1 PDFDocument246 pagesConnectors 3 1 PDFZian HennNo ratings yet

- Washer Kit ZWDK5R100Document2 pagesWasher Kit ZWDK5R100MaxNo ratings yet

- Eiph2 Eiph3 Eiph5 Eiph6: Internal Gear PumpsDocument24 pagesEiph2 Eiph3 Eiph5 Eiph6: Internal Gear PumpsHahaha HahahaNo ratings yet

- 7 Times Table Maths Mastery MatDocument2 pages7 Times Table Maths Mastery MatPooja MaldikarNo ratings yet

- Selling ConceptDocument6 pagesSelling ConceptDhurba Bahadur BkNo ratings yet

- MenonAbh Onboarding NDA Form V1Document7 pagesMenonAbh Onboarding NDA Form V1paravakl767699No ratings yet

- 33.ladel Coate L100Document3 pages33.ladel Coate L100purchase2No ratings yet

- FS 4Document92 pagesFS 4nissi guingab87% (15)

- Analyse Signal EMGDocument12 pagesAnalyse Signal EMGAlfonso Molina RamirezNo ratings yet

- An Introduction To LexicologyDocument28 pagesAn Introduction To LexicologyCati BuragaNo ratings yet

- P4 - U8 Vocabulary & Reading ExtensionDocument4 pagesP4 - U8 Vocabulary & Reading ExtensionTran Ngoc LinhNo ratings yet