B - Boehler NiMo 1-IG - de - en - 5

B - Boehler NiMo 1-IG - de - en - 5

Uploaded by

cristian popescuCopyright:

Available Formats

B - Boehler NiMo 1-IG - de - en - 5

B - Boehler NiMo 1-IG - de - en - 5

Uploaded by

cristian popescuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

B - Boehler NiMo 1-IG - de - en - 5

B - Boehler NiMo 1-IG - de - en - 5

Uploaded by

cristian popescuCopyright:

Available Formats

BÖHLER NiMo 1-IG

Solid wire low-alloyed, high strength

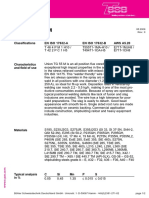

Classifications

EN ISO 16834-A EN ISO 16834-B AWS A5.28 AWS A5.28M

G 55 6 M21 Mn3Ni1Mo G 62A 6 M21 3M1 N2M2T ER90S-G ER62S-G

G 55 4 C1 Mn3Ni1Mo G 626A 4 C1 3M1 N2M2T

Characteristics and typical fields of application

Copper coated GMAW wire for high strength, quenched and tempered fine-grained constructional

steels. The wire is suited for joint welding in boiler, pressure vessel, pipeline, and crane construction as

well as in structural steel engineering. The typical composition of the wire fulfils the requirements of the

NORSOK- regulation for "water injection systems". Due to the precise addition of micro alloying

elements NiMo 1-IG wire features excellent ductility and crack resistance in spite of its high strength.

Good cryogenic impact energy down to –60 °C, low hydrogen contents in the deposit, best feed ability

and a low copper content.

Base materials

Fine-grained steels and quenched and tempered fine-grained steels

S460N, S460M, S460NL, S460ML, S460Q-S555Q, S460QL-S550QL, S460QL1-S550QL1,

460N,P460NH, P460NL1, P460NL2, L415NB, L415MB-L555MB, L415QB-L555QB, alform 500 M, 550

M, aldur 500 Q, 500 QL, 500 QL1, aldur 550 Q, 550 QL, 550 QL1, 20MnMoNi4-5, 15NiCuMoNb5-6-4

ASTM A 572 Gr. 65; A 633 Gr. E; A 738 Gr. A; A 852; API 5 L X60, X65, X70, X80, X60Q, X65Q, X70Q,

X80Q

Typical analysis of solid wire (wt.-%)

C Si Mn Mo Ni

wt.-% 0.08 0.6 1.8 0.3 0.9

Mechanical properties of all-weld metal

Condition Yield Tensile Elongation Impact work

strength strength R m A ISO-V KV J

R p0,2 (L 0 =5d 0 )

MPa MPa % +20 °C –40 °C –60 °C

u 620 (≥ 550) 700 (640 – 820) 23 ( ≥18) 140 110 ≥ 47

u2 590 680 (620 – 770) 22 ( ≥20) 120 (≥ 100) ≥ 47

u untreated, as welded – shielding gas Ar + 15 – 25 % CO 2

u2 untreated, as welded – shielding gas 100 % CO 2

Operating data

Polarity: Shielding gases: ø (mm)

DC ( + ) Argon + 15 – 25 % CO 2 0.9

Argon + 0 – 5 % CO 2 + 3 – 10 % O 2 1.0

100 % CO 2 1.2

Preheating and interpass temperature as required by the base metal.

Approvals

TÜV (11763.), DB (42.014.06), GL (4Y55S), SEPROZ, NAKS (1,2 mm), Gazprom (1,2 mm), CE,

VG 95132

All information provided is based upon careful investigation and intensive research. 03/2014

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Lesson Plan - The Solar SystemDocument2 pagesLesson Plan - The Solar Systemapi-32071503060% (5)

- FDT Catalogue Rotarex ENDocument68 pagesFDT Catalogue Rotarex ENcristian popescu100% (1)

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- B - Boehler CN 25 9 CuT IG - TRDocument1 pageB - Boehler CN 25 9 CuT IG - TRalbertorebellatoNo ratings yet

- B - Boehler EMK 6 - de - en - 5 PDFDocument1 pageB - Boehler EMK 6 - de - en - 5 PDFburakNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- EMK 6 - DatasheetDocument1 pageEMK 6 - Datasheetronaldb322No ratings yet

- B_Boehler-er-80-s-ni-1-ig_ss_en_5aDocument1 pageB_Boehler-er-80-s-ni-1-ig_ss_en_5aMuhammed SulfeekNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- B Boehler X 70-IG de en 5Document1 pageB Boehler X 70-IG de en 5Jorge RushNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- Diamondspark X80 RC-Pipe: Classifi CationsDocument1 pageDiamondspark X80 RC-Pipe: Classifi CationssajawalNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Tenacito 70Document1 pageTenacito 70Luis Angel Unocc FernandezNo ratings yet

- Boehler NiCu1 Ti T-FD - CWDocument1 pageBoehler NiCu1 Ti T-FD - CWbrayanNo ratings yet

- B Boehler CM 5-IG de en 5Document1 pageB Boehler CM 5-IG de en 5PT. CATUR MATRA NusantaraNo ratings yet

- L1 8581 en Diamondspark 44 BC CU03100F 3379759 ENDocument1 pageL1 8581 en Diamondspark 44 BC CU03100F 3379759 ENRaviTeja BhamidiNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Bohler SG2 PDFDocument1 pageBohler SG2 PDFInaamNo ratings yet

- L1 10913 en BOEHLER X 70 IG 2HA3510G 3376575 ENDocument1 pageL1 10913 en BOEHLER X 70 IG 2HA3510G 3376575 ENk.sourenaNo ratings yet

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- ETC PH25S DRYDocument1 pageETC PH25S DRYstefavaNo ratings yet

- Boehler CN 22 9 N-IG DUPLEX REALINOXDocument1 pageBoehler CN 22 9 N-IG DUPLEX REALINOXRAHINE AmineNo ratings yet

- Böhler SG 2: Solid Wire, UnalloyedDocument1 pageBöhler SG 2: Solid Wire, Unalloyedrombi aritonangNo ratings yet

- B Boehler Ti 80 T-FD Fde en 5Document1 pageB Boehler Ti 80 T-FD Fde en 5Valentin Hernández TrianoNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- Diamond Spark Ni2 RC-SRDocument1 pageDiamond Spark Ni2 RC-SRThejeshNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- Böhler Er 70 S-2Document1 pageBöhler Er 70 S-2brayanNo ratings yet

- 3dprint AM P22: Material TypeDocument1 page3dprint AM P22: Material TypeKara WhiteNo ratings yet

- BÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28Document1 pageBÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28JORAMNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- C12-ER1682-MetrodeDocument1 pageC12-ER1682-MetrodeDoni AfrizalNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Product Data Sheet - OK Tigrod 13.09 PDFDocument2 pagesProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Datasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1Document3 pagesDatasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1bhuvandesignNo ratings yet

- E71T-GS Gasless Flux Cored Welding WireDocument1 pageE71T-GS Gasless Flux Cored Welding WireMarius BarNo ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Supercito E: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito E: MMA Electrodes C-MN and Low-Alloy Steelsantonio111aNo ratings yet

- Low Alloy13Document5 pagesLow Alloy13Branko FerenčakNo ratings yet

- 01112015000000B - Boehler EMK 8 - Solid WireDocument2 pages01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- TMG+ +Membership+BlueprintDocument20 pagesTMG+ +Membership+Blueprintcristian popescu100% (2)

- BOHLER WELDING GHID EN-GL-UTP - Cement - WEBDocument36 pagesBOHLER WELDING GHID EN-GL-UTP - Cement - WEBcristian popescuNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- Module 2 Sptopics PDFDocument60 pagesModule 2 Sptopics PDFSha Sibayan0% (1)

- Particle Properties of WavesDocument27 pagesParticle Properties of WavesSwastik LenkaNo ratings yet

- Chemical Bonding and Periodic Properties AssignmentDocument10 pagesChemical Bonding and Periodic Properties AssignmentRamNo ratings yet

- DPP No.30 (Org) With Ans (Advaned) Reaction Mechanism-IVDocument6 pagesDPP No.30 (Org) With Ans (Advaned) Reaction Mechanism-IVanmol pandeyNo ratings yet

- Erx 5 3 035058Document11 pagesErx 5 3 035058madhusudhansNo ratings yet

- Preflash DrumDocument27 pagesPreflash DrumGarry David100% (1)

- A. 50 B. 30 C. 15 D. 5: 5.12 Practice Exam #4 PAGE 1 Short Questions 1-8 3 Points Each)Document7 pagesA. 50 B. 30 C. 15 D. 5: 5.12 Practice Exam #4 PAGE 1 Short Questions 1-8 3 Points Each)Armando Shehi SayhellotogoodbyeNo ratings yet

- Mixtures Pure and Impure Substances Homework Activity Sheet - Ver - 2Document2 pagesMixtures Pure and Impure Substances Homework Activity Sheet - Ver - 2Sarah KKCNo ratings yet

- Combined ReportDocument118 pagesCombined ReportArijit SahaNo ratings yet

- IOT POSTER (Smart Greenhouse)Document1 pageIOT POSTER (Smart Greenhouse)igashnewNo ratings yet

- CYN002 - Organometallic Chemistry - DR Dheeraj (2023) - Lects 1-3 PDFDocument39 pagesCYN002 - Organometallic Chemistry - DR Dheeraj (2023) - Lects 1-3 PDFIniyan I T100% (1)

- Principles and Applications of Building Science: Module ContentsDocument25 pagesPrinciples and Applications of Building Science: Module ContentsFarheen BanoNo ratings yet

- Preparation of Solutions 2Document9 pagesPreparation of Solutions 2Louise Jiodielynne Salvador LandichoNo ratings yet

- Datasheet Kabel Power Prysmian N2RXY E22 PCI 002 Issue3 CSI 19.05.22 Halaman 7 8Document2 pagesDatasheet Kabel Power Prysmian N2RXY E22 PCI 002 Issue3 CSI 19.05.22 Halaman 7 8Joko SchumacherNo ratings yet

- FME Unit 2 f1Document51 pagesFME Unit 2 f1fahadsiddiquie58No ratings yet

- Hollosep Trial in SpainDocument10 pagesHollosep Trial in SpainGandrig F VendrisNo ratings yet

- Atomic PhyDocument31 pagesAtomic PhymwagweNo ratings yet

- Mock Test Paper: Full Length Practice PaperDocument16 pagesMock Test Paper: Full Length Practice PaperCHANDRA DEYNo ratings yet

- Enabling Lightweight Design Structural Tapes Patches PresentationDocument30 pagesEnabling Lightweight Design Structural Tapes Patches Presentationjasonguo901No ratings yet

- Antioxidant Properties of Thyme (Thymus Vulgaris L.) and Wild Thyme (Thymus Serpyllum L.) Essential OilsDocument11 pagesAntioxidant Properties of Thyme (Thymus Vulgaris L.) and Wild Thyme (Thymus Serpyllum L.) Essential OilsDIey ChokiEyNo ratings yet

- Science 7 Summative Test 1Document2 pagesScience 7 Summative Test 1Merwinson ManzanoNo ratings yet

- Rheological Properties of Biopolymers Drilling Fluids PDFDocument7 pagesRheological Properties of Biopolymers Drilling Fluids PDFadib assoliNo ratings yet

- OxalateDocument5 pagesOxalateTarun KumarNo ratings yet

- Science Reviewer Quiz Direction: Write The Correct Answer On A Piece of PaperDocument6 pagesScience Reviewer Quiz Direction: Write The Correct Answer On A Piece of PaperJoy TibayanNo ratings yet

- MottDocument4 pagesMottWilder Jeanson Huaman fernandezNo ratings yet

- Handout CHE F343Document3 pagesHandout CHE F343Aryan ShuklaNo ratings yet

- Tangit PVC U Can 500gDocument7 pagesTangit PVC U Can 500gSaravanan SekarNo ratings yet

- Forced Degradation Studies. ReviewDocument11 pagesForced Degradation Studies. Reviewsean_goh_8No ratings yet

- 8464 P 1H QP CombinedScienceTrilogy G 13nov20 AMDocument28 pages8464 P 1H QP CombinedScienceTrilogy G 13nov20 AMzak061214No ratings yet