Boehler CN 22 9 N-IG DUPLEX REALINOX

Boehler CN 22 9 N-IG DUPLEX REALINOX

Uploaded by

RAHINE AmineCopyright:

Available Formats

Boehler CN 22 9 N-IG DUPLEX REALINOX

Boehler CN 22 9 N-IG DUPLEX REALINOX

Uploaded by

RAHINE AmineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Boehler CN 22 9 N-IG DUPLEX REALINOX

Boehler CN 22 9 N-IG DUPLEX REALINOX

Uploaded by

RAHINE AmineCopyright:

Available Formats

BÖHLER CN 22/9 N-IG

TIG rod, high-alloyed, highly corrosion resistant

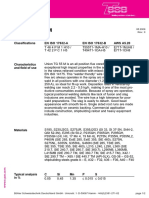

Classifications

EN ISO 14343-A EN ISO 14343-B AWS A5.9

W 22 9 3 N L SS2209 ER2209

Characteristics and typical fields of application

GTAW rod of type W 22 9 3 NL / ER2209 designed for welding ferritic-austenitic duplex steels like

1.4462 / UNS 31803. The deposit possess, in addition to high tensile strength and toughness, also

excellent resistance to stress corrosion cracking and pitting (Huey-test ASTM A 262-79 practice C).

The operating temperature range is –60 °C up to 250 °C. To ensure particularly good weld metal

properties care must be taken to achieve controlled dilution and thorough back purging. In case of

severe corrosion requirement, small amounts of N2 can be added to the shielding respectively

purging gas.

BÖHLER CN 22/9 N-IG is characterised by a precisely alloyed composition which includes

extremely low oxygen content. It offers very high quality standards for ease of operation and good

mechanical properties.

Base materials

Same-alloyed duplex steels, as well as similar-alloyed, ferritic-austenitic steels with higher tensile

strength

1.4462 X2CrNiMoN22-5-3, 1.4362 X2CrNiN23-4,

1.4462 X2CrNiMoN22-5-3 with 1.4583 X10CrNiMoNb18-12,

1.4462 X2CrNiMoN22-5-3 with P235GH/ P265GH, S255N, P295GH, S355N, 16Mo3

UNS S31803, S32205

Typical analysis of the TIG rods (wt.-%)

C Si Mn Cr Ni Mo N PREN

wt-% ≤ 0.015 0.4 1.7 22.5 8.8 3.2 0.15 ≥ 35

Mechanical properties of all-weld metal

Condition Yield strength Tensile strength Elongation Impact work

Rp0.2 Rm A (L0=5d0) ISO-V KV J

MPa MPa % +20 °C –40 °C

u 600 (≥ 450) 800 (≥ 550) 33 (≥ 20) 150 ≥ 47

u untreated, as welded – shielding gas Argon

Operating data

Polarity: Shielding gases: Rod marking: ø (mm)

DC ( – ) 100 % Argon front: W 22 9 3 NL 1.6

Argon + 1 – 2 % N2 back: ER 2209 2.0

2.4

3.2

Preheat and post weld heat treatment is generally not required. Interpass temperature should not

exceed 150 °C.

Approvals

TÜV (04484.), ABS, DNV GL, LR, NAKS, CE

All information provided is based upon careful investigation and intensive research. 03/2019

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Oxidation Pond Guidelines 2005Document25 pagesOxidation Pond Guidelines 2005maxsteel05No ratings yet

- Filter Paper Catalase Enzyme Lab SLDocument2 pagesFilter Paper Catalase Enzyme Lab SLEmi JiHyeon KimNo ratings yet

- Duplex UNS 32205Document1 pageDuplex UNS 32205Ercan YilmazNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- B - Boehler CN 25 9 CuT IG - TRDocument1 pageB - Boehler CN 25 9 CuT IG - TRalbertorebellatoNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- T - Thermanit 22 - 09 - de - en - 5Document1 pageT - Thermanit 22 - 09 - de - en - 5brayanNo ratings yet

- OK-67.50Document3 pagesOK-67.50TadilakshmikiranNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- ER316L Ss en 1Document1 pageER316L Ss en 1brayanNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- B_Boehler-er-80-s-ni-1-ig_ss_en_5aDocument1 pageB_Boehler-er-80-s-ni-1-ig_ss_en_5aMuhammed SulfeekNo ratings yet

- L1 34428 en B Boehler-AWS-ER309L Ss en 1Document1 pageL1 34428 en B Boehler-AWS-ER309L Ss en 1Edgar HornusNo ratings yet

- EN12073T19123L PC/Mi: - Chemical Composition of All-Weld MetalDocument1 pageEN12073T19123L PC/Mi: - Chemical Composition of All-Weld Metalmohamed AdelNo ratings yet

- Avesta: Welding Wire TIGDocument1 pageAvesta: Welding Wire TIGErenBaşaraNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- Böhler Er 70 S-2Document1 pageBöhler Er 70 S-2brayanNo ratings yet

- Bohler Aws Er308lDocument1 pageBohler Aws Er308lJuan ShunaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Bohler EAS 2-IG TDSDocument1 pageBohler EAS 2-IG TDSIvan DulicNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocument1 pageThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocument1 pageCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNo ratings yet

- 235 oerlikon inertfil 310Document1 page235 oerlikon inertfil 310stefavaNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- EJ Handbook.A5Document261 pagesEJ Handbook.A5ElMacheteDelHuesoNo ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- BOEHLER Q T 309L TIG RodDocument1 pageBOEHLER Q T 309L TIG RodbrayanNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- 03112015000000B - Boehler FOX NIBAS 617 - CeDocument1 page03112015000000B - Boehler FOX NIBAS 617 - CeMorteza YazdizadehNo ratings yet

- ISO Standards On Mech Test of MetalsDocument1 pageISO Standards On Mech Test of MetalsKiran NikateNo ratings yet

- 02112015000000B - Boehler FOX EV 65 - CeDocument1 page02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Avesta 2205 - MIGDocument1 pageAvesta 2205 - MIGgonzomapsNo ratings yet

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- 01112015000000B - Boehler EMK 8 - Solid WireDocument2 pages01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNo ratings yet

- 01112015000000B - Boehler FA-IG - Tig Rod1.4820Document1 page01112015000000B - Boehler FA-IG - Tig Rod1.4820ArielNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- nr400 EngDocument2 pagesnr400 EngThomas SpiessNo ratings yet

- Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVDocument1 pageSdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVsadiqNo ratings yet

- Phoenix 7018 Phoenix 6013Document1 pagePhoenix 7018 Phoenix 6013Pedro SilvaNo ratings yet

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Asil Katalog 2021 1Document12 pagesAsil Katalog 2021 1RAHINE AmineNo ratings yet

- Welding InspectionDocument40 pagesWelding InspectionnazarasimNo ratings yet

- 84 Dstu en So 14731 2019 Koordinac Ya Zvaryuvalnih Rob TDocument15 pages84 Dstu en So 14731 2019 Koordinac Ya Zvaryuvalnih Rob TRAHINE AmineNo ratings yet

- Rapport Technique: Iso/Tr 25901-3Document2 pagesRapport Technique: Iso/Tr 25901-3RAHINE AmineNo ratings yet

- Avantec 2014 eDocument120 pagesAvantec 2014 eRAHINE AmineNo ratings yet

- Application of CHEMKIN and COMSOL Programs in The Calculations of Chemical Composition of Natural Gas Combustion ProductsDocument21 pagesApplication of CHEMKIN and COMSOL Programs in The Calculations of Chemical Composition of Natural Gas Combustion ProductszerunxiongNo ratings yet

- Lecture 05-ConsistencyAtterberg Limits and Indices (Last Update 25-Nov-2021)Document41 pagesLecture 05-ConsistencyAtterberg Limits and Indices (Last Update 25-Nov-2021)Mohd IdreesNo ratings yet

- Effect of Concentration in Rate of ReactionDocument3 pagesEffect of Concentration in Rate of ReactionblablaNo ratings yet

- Chapter 1Document16 pagesChapter 1Prinshu RawatNo ratings yet

- Caldo Nutritivo - CondaDocument9 pagesCaldo Nutritivo - CondaLiseth VargasNo ratings yet

- Rocket EngineDocument22 pagesRocket Enginedevhx100% (1)

- Carbohydrates - 2Document3 pagesCarbohydrates - 2Omnia A. ElsharawyNo ratings yet

- Cold CreamDocument7 pagesCold CreamDarshanSakharkarNo ratings yet

- The Periodic Table - 9.3 LessonDocument5 pagesThe Periodic Table - 9.3 LessonSri Charitha ANo ratings yet

- Fosroc Thioflex 600Document3 pagesFosroc Thioflex 600lutfiNo ratings yet

- Viday Vikas Polytechnic College: Materials For Engineering (20ME11T) Unit I-NotesDocument16 pagesViday Vikas Polytechnic College: Materials For Engineering (20ME11T) Unit I-NotesThanmay JS100% (1)

- Analysis of Strip Residual CurvaturesDocument9 pagesAnalysis of Strip Residual CurvaturesSachin JadhavNo ratings yet

- Lesson 1 - Electronics1Document41 pagesLesson 1 - Electronics1Ron Neil MicosaNo ratings yet

- Coating Spec 01 PDFDocument5 pagesCoating Spec 01 PDFWINNo ratings yet

- PracticeDocument3 pagesPracticeShivam YadavNo ratings yet

- Numerical Questions Chapter 3Document5 pagesNumerical Questions Chapter 3DARMESHNo ratings yet

- AHMT Assignment 01Document2 pagesAHMT Assignment 01shubhamNo ratings yet

- AminesDocument6 pagesAminesatharvbaghel4444No ratings yet

- D3 2019 396652 BibliographyDocument2 pagesD3 2019 396652 Bibliographydwi kuntoroNo ratings yet

- Navigating The New Aisc: Steel Construction ManualDocument31 pagesNavigating The New Aisc: Steel Construction ManualAdhi ErlanggaNo ratings yet

- 6x1500x6000 S235Document3 pages6x1500x6000 S235Kovács ZsoltNo ratings yet

- CE Calculator Rev July 2013pDocument2 pagesCE Calculator Rev July 2013pJuan CogolludoNo ratings yet

- KMno4 Mohr's Salt. Exp-7 12thDocument4 pagesKMno4 Mohr's Salt. Exp-7 12thdevanshupadhyay28042007No ratings yet

- Volvo Flow Document Oil AnalysisDocument5 pagesVolvo Flow Document Oil Analysisgilar herliana putraNo ratings yet

- 8 DistillationDocument18 pages8 DistillationPhạm ChiếnNo ratings yet

- Chem 2 Homework 5Document3 pagesChem 2 Homework 5Albert YanNo ratings yet

- Molten Sulphur Rail Tank Car Loading and Unloading Operations Final With AppendicesDocument68 pagesMolten Sulphur Rail Tank Car Loading and Unloading Operations Final With AppendicesvlabdulazeemNo ratings yet

- Seminar Report On Gas WeldingDocument17 pagesSeminar Report On Gas WeldingMohd Sohail AliNo ratings yet