Pipe Support As Per Asme 31.1

Pipe Support As Per Asme 31.1

Uploaded by

udaysaichand kolliparaCopyright:

Available Formats

Pipe Support As Per Asme 31.1

Pipe Support As Per Asme 31.1

Uploaded by

udaysaichand kolliparaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Pipe Support As Per Asme 31.1

Pipe Support As Per Asme 31.1

Uploaded by

udaysaichand kolliparaCopyright:

Available Formats

ASME B31.

1-2016

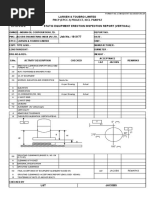

an allowable stress value of 30% of yield strength (0.2% Table 121.5 Suggested Steel Pipe Support (16)

offset) at room temperature may be used at temperatures Spacing

not exceeding 650°F (345°C). The yield strength shall be Suggested Maximum Span

determined through a tensile test of a specimen of the

Water Steam, Gas,

material and shall be the value corresponding to 0.2% Nominal Diameter

Pipe Size, Nominal, Service or Air Service

permanent strain (offset) of the specimen. The allowable

stress values for such materials shall not exceed 9,500 psi NPS DN ft m ft m

(65.5 MPa). 1 25 7 2.1 9 2.7

(D) The allowable shear stress shall not exceed 80% 2 50 10 3.0 13 4.0

3 80 12 3.7 15 4.6

of the values determined in accordance with the rules

4 100 14 4.3 17 5.2

of (A), (B), and (C) above. 6 150 17 5.2 21 6.4

(E) The allowable compressive stress shall not exceed

8 200 19 5.8 24 7.3

the value as determined in accordance with the rules of

12 300 23 7.0 30 9.1

(A), (B), or (C) above. In addition, consideration shall 16 400 27 8.2 35 10.7

be given to structural stability. 20 500 30 9.1 39 11.9

(F) The allowable bearing stress shall not exceed 160% 24 600 32 9.8 42 12.8

of the value as determined in accordance with the rules

of (A), (B), or (C) above. GENERAL NOTES:

(a) Suggested maximum spacing between pipe supports for hori-

(G) The allowable stress in tension determined from

zontal straight runs of standard and heavier steel pipe at maxi-

(A), (B), or (C) above shall be reduced 25% for threaded mum operating temperature of 750°F (400°C).

hanger rods. (b) Does not apply where span calculations are made or where

(H) The allowable stress in partial penetration or fillet there are concentrated loads between supports, such as

welds in support assemblies shall be reduced 25% from flanges, valves, specialties, etc.

those determined in accordance with (A), (B), (C), or (c) The spacing is based on a fixed beam support with a bending

stress not exceeding 2,300 psi (15.86 MPa) and insulated pipe

(D) above for the weaker of the two metals joined.

filled with water or the equivalent weight of steel pipe for

(I) If materials for attachments have different allow- steam, gas, or air service, and the pitch of the line is such

able stress values than the pipe, then the allowable stress that a sag of 0.1 in. (2.5 mm) between supports is

for the weld shall be based on the lower allowable stress permissible.

of the materials being joined.

(J) Increases in the allowable stress values shall be

permitted as follows:

(J.1) an increase of 20% for short time overloading

during operation.

Class 2 fit turnbuckles and adjusting nuts shall have

(J.2) an increase to 80% of the minimum yield the full length of thread in engagement. Means shall be

strength at room temperature during hydrostatic testing. provided for determining that full thread length is in

Where the material allowable stress has been established engagement. All screw and equivalent adjustments shall

in accordance with the rules of (C) above, the allowable be provided with suitable locking devices.

stress value during hydrostatic testing shall not exceed

16,000 psi (110.3 MPa).

121.5 Hanger Spacing

121.3 Temperature Limitations Supports for piping with the longitudinal axis in

Parts of supporting elements that are subjected princi- approximately a horizontal position shall be spaced to

pally to bending or tension loads and that are subjected prevent excessive sag, bending and shear stresses in the

to working temperatures for which carbon steel is not piping, with special consideration given where compo-

recommended shall be made of suitable alloy steel, or nents, such as flanges and valves, impose concentrated

shall be protected so that the temperature of the support- loads. Where calculations are not made, suggested maxi-

ing member will be maintained within the appropriate mum spacing of supports for standard and heavier steel

temperature limits of the material. pipe are given in Table 121.5. Vertical supports shall be

spaced to prevent the pipe from being overstressed from

(16) 121.4 Hanger Adjustments the combination of all loading effects.

Hangers used for the support of piping, NPS 2 1⁄2

121.6 Springs

(DN 65) and larger, shall be designed to permit adjust-

ment after erection while supporting the load. Screwed The springs used in variable or constant effort type

adjustments shall have threaded parts to conform to supports shall be designed and manufactured in accor-

ASME B1.1. dance with MSS SP-58.

50

You might also like

- Inlet Diffuser CalculationDocument1 pageInlet Diffuser CalculationMohammed Faizal NvNo ratings yet

- Dimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchDocument6 pagesDimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchPozii Ziipunii PaulNo ratings yet

- External Load On PipelineDocument21 pagesExternal Load On PipelineindeskeyNo ratings yet

- GRP PipeDocument9 pagesGRP Pipesethu1091No ratings yet

- PSV Calculation PSV-201Document1 pagePSV Calculation PSV-201ASHWINI BHOSALENo ratings yet

- Standard Pipe Support SpanDocument1 pageStandard Pipe Support SpanDineshpatel1983100% (1)

- Shree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetDocument1 pageShree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetSalman KhanNo ratings yet

- Pipeline Lowering CalculationDocument5 pagesPipeline Lowering CalculationrabeemhNo ratings yet

- Calculation of Pipe Support Mercury Removal Inlet Filter Coalescer 180kg CAPACITY, 1.533 M LENGTHDocument2 pagesCalculation of Pipe Support Mercury Removal Inlet Filter Coalescer 180kg CAPACITY, 1.533 M LENGTHRidho Ziska0% (1)

- Reference Target Torque ValuesDocument1 pageReference Target Torque ValuesloqNo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IISikandar_30100% (1)

- Dummy Leg JacobsDocument1 pageDummy Leg Jacobsananyo_sengupta50% (2)

- Expansion Calculation and Loop Sizing001Document2 pagesExpansion Calculation and Loop Sizing001Joseph R. F. David100% (1)

- Expansion Loop DesignDocument61 pagesExpansion Loop DesignTauqueerAhmad50% (2)

- Steam BoilerDocument3 pagesSteam BoilerMohammad AzlanNo ratings yet

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDocument1 pageBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNo ratings yet

- Blowers Fans Supply Verification ITPDocument7 pagesBlowers Fans Supply Verification ITPgauravamberkarNo ratings yet

- ASME B 31.3 Table 304.1.1 Coefficient (Y)Document1 pageASME B 31.3 Table 304.1.1 Coefficient (Y)groshan20No ratings yet

- Blind Thickness CalculatorDocument2 pagesBlind Thickness CalculatorTejas Patel100% (1)

- Concentric ReducerDocument2 pagesConcentric ReducerGousePeerzade0% (1)

- Method Statement For Constructing The Cooling TowersDocument9 pagesMethod Statement For Constructing The Cooling TowersmohamedNo ratings yet

- Pipemill 4-02 User GuideDocument87 pagesPipemill 4-02 User GuideAyaz0% (1)

- Appx-A Formula and CalculationDocument20 pagesAppx-A Formula and CalculationapiscobainNo ratings yet

- Pipes SupportDocument19 pagesPipes SupportoliveiralauroNo ratings yet

- Few Important Points For Stress Analysis Based On ASME B 31Document4 pagesFew Important Points For Stress Analysis Based On ASME B 31Nilesh GohelNo ratings yet

- Hdpe Pipe Wall Thickness CalculationsDocument1 pageHdpe Pipe Wall Thickness CalculationsTsouki Tsouki100% (1)

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- Pipe Support SpacingDocument2 pagesPipe Support Spacingvenka07No ratings yet

- DESIGN CALCULATION FOR MANIFOLD 500 Bars - CS PDFDocument1 pageDESIGN CALCULATION FOR MANIFOLD 500 Bars - CS PDFWandi Sudarwan100% (1)

- Piping Stress Engineer DJ PAULDocument7 pagesPiping Stress Engineer DJ PAULJanakiraman MalligaNo ratings yet

- Jacketed Piping CalculationDocument9 pagesJacketed Piping CalculationKamran Shaikh50% (2)

- ASME B 31.3 Table A 1B Weld Joint Quality Factor (E)Document3 pagesASME B 31.3 Table A 1B Weld Joint Quality Factor (E)groshan20No ratings yet

- Steel Beam Flexural CapacityDocument6 pagesSteel Beam Flexural CapacitykstayroskNo ratings yet

- SOP02 - F26 - R00 Pipe Stringing Report 1Document12 pagesSOP02 - F26 - R00 Pipe Stringing Report 1Faiz IshakNo ratings yet

- Nozzle Dim 12th EdnDocument16 pagesNozzle Dim 12th EdnBTENo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- Piping Line List Template 2018-05-29Document1 pagePiping Line List Template 2018-05-29Trevor Kanode100% (1)

- Calculation of Pipe SupportDocument6 pagesCalculation of Pipe Supportnaveen_86No ratings yet

- Pipe Spacing From Perisher Handbook PG 194Document8 pagesPipe Spacing From Perisher Handbook PG 194Asif Haq100% (1)

- 4 - Pipe Insulation With PU BASF 2012 05 08Document24 pages4 - Pipe Insulation With PU BASF 2012 05 08dzungNo ratings yet

- Hydrotest CalculationDocument1 pageHydrotest CalculationkiranNo ratings yet

- Caesar II TutorialDocument35 pagesCaesar II TutorialOctavio fnNo ratings yet

- Flange Torque Recommendations GF PDFDocument2 pagesFlange Torque Recommendations GF PDFTulioLopezJ100% (2)

- Method Statement Jacking SystemDocument10 pagesMethod Statement Jacking SystemHenri Purnomo SinagaNo ratings yet

- 31 1 Static Equipment Vertical ErectionDocument2 pages31 1 Static Equipment Vertical Erectionpunitg_2No ratings yet

- Pipe Spacing ChartDocument1 pagePipe Spacing ChartAlvin Smith100% (4)

- Atmospheric Foam TankDocument5 pagesAtmospheric Foam TankAndro SidhomNo ratings yet

- P 2 X Tadj X .35 X SMYS X Ej Do: N-G-PI-305: Hot Tap & Stopples Procedure - Hot Tap Fitting Selection ChartDocument1 pageP 2 X Tadj X .35 X SMYS X Ej Do: N-G-PI-305: Hot Tap & Stopples Procedure - Hot Tap Fitting Selection Chartorqh007No ratings yet

- Shell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.EngDocument8 pagesShell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.Engkhabiran100% (1)

- Manhole. API 650-2021Document3 pagesManhole. API 650-2021jose luis100% (1)

- Pipe Weight With WaterDocument8 pagesPipe Weight With Waterdheerajdorlikar100% (2)

- Guidelines For Pipe Support AnalysisDocument31 pagesGuidelines For Pipe Support AnalysisgvlanushaNo ratings yet

- Radiography Calculation SheetDocument2 pagesRadiography Calculation SheetpraveentienNo ratings yet

- Pages From ASME B31.1-2018Document2 pagesPages From ASME B31.1-2018Alexey BerkovskiyNo ratings yet

- ASME B31.1-2001-12 Table 121.5Document1 pageASME B31.1-2001-12 Table 121.5karim hilalNo ratings yet

- 120 Loads On Pipe-Supporting Elements: 120.2.3 Anchors or GuidesDocument3 pages120 Loads On Pipe-Supporting Elements: 120.2.3 Anchors or GuidesFabrício Lima de BritoNo ratings yet

- Asme B31.4 - Allow Stress Sa - Factor FDocument1 pageAsme B31.4 - Allow Stress Sa - Factor Fjoaquin torrano veraNo ratings yet

- Asme B31.8 - Allow Stress SaDocument1 pageAsme B31.8 - Allow Stress Sajoaquin torrano veraNo ratings yet

- MemorandumDocument5 pagesMemorandumpio.mirandaNo ratings yet

- Redox EquilibriumDocument18 pagesRedox EquilibriumRomeoNo ratings yet

- Hard FacingDocument5 pagesHard Facingfrankp_147No ratings yet

- Itp Concrete WorksDocument1 pageItp Concrete WorksengmalaahendyNo ratings yet

- Ipc-4413 TocDocument4 pagesIpc-4413 TocЛеонид Зорин100% (1)

- 11 - Air and Water: Learning ObjectiveDocument4 pages11 - Air and Water: Learning ObjectiveAjay LakshmananNo ratings yet

- Astm D 4221 99 Doble Hidrometro PDFDocument3 pagesAstm D 4221 99 Doble Hidrometro PDFHayatoNo ratings yet

- Faculty of Engineering: Student Name: Mellisa Z Ncube Student Number: N0161145V Supervisor: Ms S BhebheDocument67 pagesFaculty of Engineering: Student Name: Mellisa Z Ncube Student Number: N0161145V Supervisor: Ms S BhebheDolce NcubeNo ratings yet

- Experimental Measurement of Coe Cient of Thermal Expansion For Graded Layers in Ni-Al O FGM Joints For Accurate Residual Stress AnalysisDocument5 pagesExperimental Measurement of Coe Cient of Thermal Expansion For Graded Layers in Ni-Al O FGM Joints For Accurate Residual Stress Analysispeter sihotangNo ratings yet

- Prediction of Water-Absorption Capacity and Surface Softness of Tissue Paper Products Using PhotoclinometryDocument8 pagesPrediction of Water-Absorption Capacity and Surface Softness of Tissue Paper Products Using PhotoclinometryDanish KhanNo ratings yet

- Alta Conference 2010 Presentation FINAL Part 1Document10 pagesAlta Conference 2010 Presentation FINAL Part 1avilloutNo ratings yet

- UNEP POPS COP CONVTEXT C.EnDocument5 pagesUNEP POPS COP CONVTEXT C.EnHendy Dwi WarmikoNo ratings yet

- Certilas - Nickel Solid Wire Rod Strip MSDS - Rev2 - 23 (EN)Document18 pagesCertilas - Nickel Solid Wire Rod Strip MSDS - Rev2 - 23 (EN)Mody htiNo ratings yet

- FIELD ASSESSMENT OF OLD JETTY IN MALAYSIA - AbstrakDocument4 pagesFIELD ASSESSMENT OF OLD JETTY IN MALAYSIA - AbstrakseptiaNo ratings yet

- Large Scale Production of High Performance Fiber Metal Laminates by Prepreg Press TechnologyDocument6 pagesLarge Scale Production of High Performance Fiber Metal Laminates by Prepreg Press TechnologyMuhammad Abbas MehdiNo ratings yet

- Sfa-5 31Document10 pagesSfa-5 31Sarvesh MishraNo ratings yet

- Ep-Gis 36-320 - b05Document77 pagesEp-Gis 36-320 - b05Matteo Colombo100% (1)

- Fossil Fuel Burning and Generating HandbookDocument132 pagesFossil Fuel Burning and Generating HandbookepriyonoNo ratings yet

- AS Chemistry Revision Seminar 9701Document32 pagesAS Chemistry Revision Seminar 9701Jhoshna MuniandyNo ratings yet

- Facade 101 PDFDocument35 pagesFacade 101 PDFAlaym AguilarNo ratings yet

- Acme GB PDFDocument20 pagesAcme GB PDFpadmanabanNo ratings yet

- Silo - Tips - Chapter 5 The Gaseous StateDocument18 pagesSilo - Tips - Chapter 5 The Gaseous StateJerich Ivan PaalisboNo ratings yet

- Steel Structure Chapter-2 ExampleDocument17 pagesSteel Structure Chapter-2 Examplebini1221No ratings yet

- The Sixth Decadeofthe ThyristorDocument6 pagesThe Sixth Decadeofthe ThyristorGeorge AcostaNo ratings yet

- A Selection of Generally Used or Traded Scheduled ChemicalsDocument45 pagesA Selection of Generally Used or Traded Scheduled ChemicalsHovoFunnyNo ratings yet

- Legrand Weatherproof Plug Cover Flyer (Edited) (2) - 0Document2 pagesLegrand Weatherproof Plug Cover Flyer (Edited) (2) - 0Hein Thu AungNo ratings yet

- Dissolved Air Flotation SystemDocument3 pagesDissolved Air Flotation SystemTeuku Rafly AzisNo ratings yet

- Paint Pollution Harmful Effects On EnvironmentDocument4 pagesPaint Pollution Harmful Effects On EnvironmentGihanNo ratings yet

- Chapter 4: Heat: Fill in The BlanksDocument1 pageChapter 4: Heat: Fill in The BlanksravilullaNo ratings yet

- Topic 4 - CWDocument3 pagesTopic 4 - CWTrần Lê QuânNo ratings yet

- Smoke Bombs GrenadesDocument9 pagesSmoke Bombs Grenadesrajpalbanna009No ratings yet