Solenoid Valves 2/2 225: Direct Operated 1/8

Solenoid Valves 2/2 225: Direct Operated 1/8

Uploaded by

vineeth8624Copyright:

Available Formats

Solenoid Valves 2/2 225: Direct Operated 1/8

Solenoid Valves 2/2 225: Direct Operated 1/8

Uploaded by

vineeth8624Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Solenoid Valves 2/2 225: Direct Operated 1/8

Solenoid Valves 2/2 225: Direct Operated 1/8

Uploaded by

vineeth8624Copyright:

Available Formats

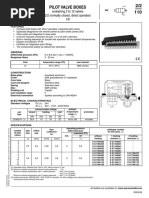

SOLENOID VALVES 2/2

Series

direct operated 2

1/8 NC 225

1

FEATURES

• Direct operated 2/2 NC solenoid valve

• Valves do not require a minimum operating pressure

• Valve operation is not affected by mounting position

• Internal parts are accessible for cleaning

• The solenoid valves satisfy all relevant EC directives

GENERAL

Differential pressure See «SPECIFICATIONS» [1 bar =100 kPa]

Maximum viscosity 65 cSt (mm2/s)

Response time 5 - 25 ms

fluids (✴)

air, inert gas, water, oil

temperature range (TS)

- 20°C to + 90°C

seal materials (✴)

NBR (nitrile)

FPM (fluoroelastomer)

C

MATERIALS IN CONTACT WITH FLUID

(✴) Ensure that the compatibility of the fluids in contact with the materials is verified

Brass body Stainless steel body

Body Brass AISI 303 SS

Core tube Stainless steel Stainless steel

Core and plugnut Stainless steel Stainless steel

Springs Stainless steel Stainless steel

Seat Stainless steel Stainless steel

Seals NBR FPM

Disc NBR FPM

Shading coil Copper Copper

ELECTRICAL CHARACTERISTICS

Coil insulation class F

Connector Spade plug (cable Ø 6-8 mm)

Connector specification DIN 43650, 11 mm, industry standard B

Electrical safety IEC 335

Electrical enclosure protection Moulded IP65 (EN 60529)

Standard voltages DC (=) : 24V - 48V

(Other voltages and 60 Hz on request) AC (~) : 24V - 48V - 115V - 230V / 50 Hz

power ratings operator

replacement coil

prefix inrush holding hot/cold ambient

temperature type (1)

1 2

option ~ ~ = range (TS) ~ =

(VA) (VA) (W) (W) (C°) 230 V/50 Hz 24 V DC

- - - 5 / 6,9 -20 to + 75 - 400125-142

SC 01

14,5 11 6,3 - -20 to + 40 400125-217 -

(1)

Refer to the dimensional drawings on the following page.

Availability, design and specifications are subject to change without notice. All rights reserved.

SPECIFICATIONS

operating pressure options

flow catalogue

pipe orifice differential (bar) power coil

coefficient number

man. operator

size size max. (PS) (W)

maintained

Kv

EPDM

PTFE

min. air (✴) water/oil (✴) brass stainless steel

FPM

CR

G (mm) (m3/h) (l/min) ~ = ~ = ~ = ~/= ~/=

NC - Normally closed

SCG225B001 - MO V E J T

1,2 0,05 0,8 0 35 14 35 14 6,3 6,9

- SCG225B005 - V E J T

SCG225B002 - MO V E J T

1,6 0,08 1,3 0 20 9 20 9 6,3 6,9

- SCG225B006 - V E J T

1/8

SCG225B003 - MO V E J T

2,4 0,15 2,5 0 12 2 12 2 6,3 6,9

- SCG225B007 - V E J T

SCG225B004 - MO V E J T

3,2 0,2 3,3 0 8,5 1,5 8,5 1,5 6,3 6,9

- SCG225B008 - V E J T

00030GB-2006/R01

All leaflets are available on: www.asconumatics.eu

Pneutrol International Ltd are Platinium Distributors for ASCO Numatics V220-1

Contact us : 5 Caulside Drive, Antrim, Northern Ireland, BT41 2DU www.valves-direct.com sales@pneutrol.com Tel: +44 (0) 28 9448 1800

SOLENOID VALVES SERIES 225

OPTIONS

• Valves can also be supplied with FPM (fluoroelastomer), EPDM (ethylene-propylene), CR (chloroprene) and PTFE seals and

discs. Use the appropriate optional suffix letter for identification

• Explosionproof enclosures for use in zone 22, category 3 to ATEX Directive 94/9/EC (see “Explosionproof solenoids” section)

• Leaded coils

• Compliance with “UL”, “CSA” and other local approvals available on request

• Other pipe connections are available on request

• Plug with visual indication and peak voltage suppression or with cable length of 2 m (see Solenoids, Coils & Accessories section)

INSTALLATION

• The solenoid valves can be mounted in any position without affecting operation

• Solenoid valves have 2 mounting holes in body

• Threaded pipe connection is standard: G = G (ISO 228/1)

• Installation/maintenance instructions are included with each valve

ORDERING EXAMPLES:

SC G 225 B 001 230V / 50 Hz

SC G 225 B 002 MO 115V / 50 Hz

SC G 225 B 007 V 24V / DC

SC G 225 B 008 E 230V / 50 Hz

prefix

pipe thread voltage

basic number suffix

DIMENSIONS (mm), WEIGHT (kg)

TYPE 01

Prefix “SC” Solenoid

Epoxy moulded

IEC 335 /DIN 43650

IP65

59 22

28

17

360˚

75

61

25

1 2

Availability, design and specifications are subject to change without notice. All rights reserved.

25

15 Bottom view

15

1 2 mounting holes Ø M4, depth 9 mm

type prefix option weight (1)

01 SC 0,2

(1)

including coil and connector.

00030GB-2005/R01

All leaflets are available on: www.asconumatics.eu

V220-2 Pneutrol International Ltd are Platinium Distributors for ASCO Numatics

Contact us : 5 Caulside Drive, Antrim, Northern Ireland, BT41 2DU www.valves-direct.com sales@pneutrol.com Tel: +44 (0) 28 9448 1800

You might also like

- Green Bill: Scan & PayDocument3 pagesGreen Bill: Scan & Payvineeth8624100% (1)

- Green Bill: Scan & PayDocument3 pagesGreen Bill: Scan & Payvineeth8624No ratings yet

- Sigma Fluid PDFDocument2 pagesSigma Fluid PDFHubertt Chacon AntonioNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- Anti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceDocument2 pagesAnti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceMehrzadNo ratings yet

- Series 222LT - ASCO Pilot Operated Hung Piston Cryogenic Solenoid Valves G1-2-G3-4Document2 pagesSeries 222LT - ASCO Pilot Operated Hung Piston Cryogenic Solenoid Valves G1-2-G3-4abaileyNo ratings yet

- Series 263LT - ASCO Direct Operated Cryogenic Solenoid Valves G1-8-G3-8 1Document2 pagesSeries 263LT - ASCO Direct Operated Cryogenic Solenoid Valves G1-8-G3-8 1Andrea Raggi100% (1)

- ASCO 210 Solenoid Valve Pilot OperatedDocument2 pagesASCO 210 Solenoid Valve Pilot OperatedNaveed IrshadNo ratings yet

- ASCO Solenoid Valves Serie SCB316Document2 pagesASCO Solenoid Valves Serie SCB316katja kafkaNo ratings yet

- European Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Document4 pagesEuropean Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Roger Gustavo Gutierrez HuanquiriNo ratings yet

- Valvula Solenoide Serie 121 AscoDocument2 pagesValvula Solenoide Serie 121 AscoBase SistemasNo ratings yet

- Solenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBDocument2 pagesSolenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBtreborNo ratings yet

- ASCO Solenoid ValvesDocument2 pagesASCO Solenoid Valvesjmathew_984887No ratings yet

- Catalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892Document3 pagesCatalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892raobenNo ratings yet

- Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesPressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2влад камрNo ratings yet

- Catalog Europe Solenoid Valves General Service 262 Stainless Steel Asco en 4877374Document10 pagesCatalog Europe Solenoid Valves General Service 262 Stainless Steel Asco en 4877374srushtiNo ratings yet

- 222LT Cryogenic Solenoid ValvesDocument2 pages222LT Cryogenic Solenoid ValvesRachiahi TarikNo ratings yet

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Document2 pagesEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaNo ratings yet

- Solenoid Valves 2 - 2 Stainless Steel Body 262 CAT 00032GBDocument2 pagesSolenoid Valves 2 - 2 Stainless Steel Body 262 CAT 00032GBmohsenNo ratings yet

- Series E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Document4 pagesSeries E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Carlos Enrique De Gumucio VargasNo ratings yet

- Válvulas Neumáticas-Asco NumaticsDocument4 pagesVálvulas Neumáticas-Asco NumaticsSamuel PlasenciaNo ratings yet

- Series S290 - ASCO Pressure Operated Clamp or Butt WeldingDocument4 pagesSeries S290 - ASCO Pressure Operated Clamp or Butt WeldingKevin Mero ConstantinoNo ratings yet

- Valvula Asiento Inclinado Serie E290 AscoDocument3 pagesValvula Asiento Inclinado Serie E290 AscoBase SistemasNo ratings yet

- European Catalog Solenoid Valve 2 2 Brass Body 272 1 4 1 2 Asco en 6868880Document2 pagesEuropean Catalog Solenoid Valve 2 2 Brass Body 272 1 4 1 2 Asco en 6868880SonyNo ratings yet

- Solenoid Valves-Dust Collector-353-CAT-60059GBDocument2 pagesSolenoid Valves-Dust Collector-353-CAT-60059GBangelosNo ratings yet

- ASCO - Catalog Sheet for Solenoid Valve,Document2 pagesASCO - Catalog Sheet for Solenoid Valve,bridgeswordfishNo ratings yet

- European Catalog Pulse Valve Dust Collector Single Stage 353 Asco en 5084844Document2 pagesEuropean Catalog Pulse Valve Dust Collector Single Stage 353 Asco en 5084844Sina MahmoudiNo ratings yet

- Solenoid Valve SCE272ADocument2 pagesSolenoid Valve SCE272AVictor Ruiz FuentesNo ratings yet

- Solenoid Valves 2/2 272: Direct Operated 1/4Document2 pagesSolenoid Valves 2/2 272: Direct Operated 1/4Rafael GustavoNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- Proportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Document2 pagesProportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Priya KaleNo ratings yet

- ASCO Series 353-2-2 Pulse Valves Single Stage 4Document2 pagesASCO Series 353-2-2 Pulse Valves Single Stage 4Peter UhuleNo ratings yet

- ASCO Series 290 390 - ASCO Pressure Operated Solenoid Pilot Valves G1-8 1Document2 pagesASCO Series 290 390 - ASCO Pressure Operated Solenoid Pilot Valves G1-8 1Lassané KINDONo ratings yet

- European Catalog Pressure Operated Valves Pn40 298 Asco en 5083020Document4 pagesEuropean Catalog Pressure Operated Valves Pn40 298 Asco en 5083020srushtiNo ratings yet

- European Catalog Pilot Valve Boxes Series c20 Asco en 7028706Document2 pagesEuropean Catalog Pilot Valve Boxes Series c20 Asco en 7028706ChangHuiChuanNo ratings yet

- Asco Motorised Control ValveDocument2 pagesAsco Motorised Control ValveBuddhikaNo ratings yet

- Pilot Valve Boxes SG110ADocument2 pagesPilot Valve Boxes SG110AVictor Ruiz FuentesNo ratings yet

- Pilot Valve BoxesDocument8 pagesPilot Valve BoxesAmit AGRAWALNo ratings yet

- ASCO Series 353 2-2 Pules Valves Dual StageDocument2 pagesASCO Series 353 2-2 Pules Valves Dual StageAdnan AliNo ratings yet

- A 700000009393666Document10 pagesA 700000009393666hongyu duanNo ratings yet

- ASCO 551 553 Solenoid Valves NAMUR - 1 4 1 2 Aluminium ATEX Approved Hazardous Area Pilot Valve Data SheetDocument10 pagesASCO 551 553 Solenoid Valves NAMUR - 1 4 1 2 Aluminium ATEX Approved Hazardous Area Pilot Valve Data Sheetmiri.ibrahimov1983No ratings yet

- Solenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesSolenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Samuel ZabalaNo ratings yet

- ASCO 551 553 Solenoid Valves NAMUR - 1 4 3 8 1 2 Date SheetDocument8 pagesASCO 551 553 Solenoid Valves NAMUR - 1 4 3 8 1 2 Date SheetDiego NunesNo ratings yet

- Rgs Reflex Solenoid ActuatorDocument2 pagesRgs Reflex Solenoid ActuatorDaniel MarNo ratings yet

- Catalog Series 209 2 Way NC Direct Operated 1 8" 1 4" Thread Asco en 8681392Document5 pagesCatalog Series 209 2 Way NC Direct Operated 1 8" 1 4" Thread Asco en 8681392Praveen kumarNo ratings yet

- SEL-3555 3555#R2B0 RTAC Rear and Front ViewDocument1 pageSEL-3555 3555#R2B0 RTAC Rear and Front ViewMuathNo ratings yet

- ASCO 189 Solenoid ValvesDocument2 pagesASCO 189 Solenoid Valvessahraoui brahimNo ratings yet

- Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesPilot Operated Hung Diaphragm 3/8 To 1 1/2Yasir MehmoodNo ratings yet

- VALVEDocument2 pagesVALVEmadesh mNo ratings yet

- European Catalog Series 263 264 Air Operated Poppet Valves en 5143066Document2 pagesEuropean Catalog Series 263 264 Air Operated Poppet Valves en 5143066BalotileNo ratings yet

- Asco Valves Series T298Document2 pagesAsco Valves Series T298OceanexNo ratings yet

- Solenoid Valves 3/2 327Document4 pagesSolenoid Valves 3/2 327ARTURO TZITZIHUA HERNANDEZNo ratings yet

- Power Pulse Valves S353A720+730+Document2 pagesPower Pulse Valves S353A720+730+Victor Ruiz FuentesNo ratings yet

- Single Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1Document2 pagesSingle Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1VM ExportNo ratings yet

- Asco Keystone CompatibilityDocument2 pagesAsco Keystone CompatibilityalexmontellNo ratings yet

- European Catalog Single Stage Pulse Valves Series 353 Asco en 7028704Document2 pagesEuropean Catalog Single Stage Pulse Valves Series 353 Asco en 7028704AirteamNo ratings yet

- Solenoid Valves 3/2 327: No Voltage Release (Tamperproof)Document6 pagesSolenoid Valves 3/2 327: No Voltage Release (Tamperproof)Priya KaleNo ratings yet

- 327 MR PDFDocument6 pages327 MR PDFPriya KaleNo ratings yet

- VODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFDocument8 pagesVODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFvineeth8624No ratings yet

- VODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFDocument8 pagesVODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFvineeth8624No ratings yet

- SANHA Technical ManualDocument32 pagesSANHA Technical Manualvineeth8624No ratings yet

- CatalogueDocument22 pagesCataloguevineeth8624No ratings yet

- Chiller MaintenanceDocument7 pagesChiller Maintenancevineeth8624No ratings yet

- 1.method Statement For Installation of VRF SystemDocument4 pages1.method Statement For Installation of VRF Systemvineeth8624No ratings yet

- Installation Manual VRV III BSVQ - PVJU - DaikinDocument17 pagesInstallation Manual VRV III BSVQ - PVJU - Daikinvineeth8624No ratings yet

- Wrap Clamp™ Leak Repair Clamps Wrap Clamp™ WC1 Leak Repair ClampsDocument2 pagesWrap Clamp™ Leak Repair Clamps Wrap Clamp™ WC1 Leak Repair ClampsPaul Dennis Buitron VelardeNo ratings yet

- Practical Guide To HNBR Chapter 2Document8 pagesPractical Guide To HNBR Chapter 2Azizol WahabNo ratings yet

- CPT Us BrochureDocument4 pagesCPT Us BrochureSIMON S. FLORES G.No ratings yet

- Gates Uk PDFDocument293 pagesGates Uk PDFZMCONTROLNo ratings yet

- Ck040 CUPLA 72dpi PDFDocument158 pagesCk040 CUPLA 72dpi PDFMochammad Waris S100% (1)

- Specification Details of TC - 76 GasketDocument3 pagesSpecification Details of TC - 76 GasketR P SINGHNo ratings yet

- FVMQDocument115 pagesFVMQNguyên NguyễnNo ratings yet

- Rubber Chemicals Lab Line Rubber Chemical PDFDocument2 pagesRubber Chemicals Lab Line Rubber Chemical PDFLab Line EnterprisesNo ratings yet

- T128 Chemical Resistence ChartDocument32 pagesT128 Chemical Resistence ChartVincent IrawanNo ratings yet

- Polychloroprene ProductionDocument1 pagePolychloroprene ProductionBramJanssen76No ratings yet

- Specification Nitrile Rubber Sheet BS2751Document4 pagesSpecification Nitrile Rubber Sheet BS2751Brion Bara IndonesiaNo ratings yet

- Elastomer Compatibility Guide: Name of Product Pumped Elastomer Material Viscous Behavior Type NBR Epdm FPM PtfeDocument4 pagesElastomer Compatibility Guide: Name of Product Pumped Elastomer Material Viscous Behavior Type NBR Epdm FPM PtfeLeandro SantosNo ratings yet

- A Technical Review On RubberDocument14 pagesA Technical Review On RubbergintaniNo ratings yet

- N236 - SpecDocument2 pagesN236 - SpecSrikanth KrishnamurthyNo ratings yet

- DPD No 1 (GB)Document6 pagesDPD No 1 (GB)Khulan Bat-erdeneNo ratings yet

- Catalogo CLARKSON - KGD Wafer Style Slurry Knife Gate ValveDocument4 pagesCatalogo CLARKSON - KGD Wafer Style Slurry Knife Gate ValvemuahdibNo ratings yet

- Breather Dryers BDL, BDM: 1. Technical SpecificationsDocument4 pagesBreather Dryers BDL, BDM: 1. Technical SpecificationsĐặng Trung AnhNo ratings yet

- Hydrocol Kan BaseDocument5 pagesHydrocol Kan Basethedevil666No ratings yet

- 0607 Carcoseal Un Data SheetDocument2 pages0607 Carcoseal Un Data SheetMarco FranceseNo ratings yet

- 2015-16 Hose Tubes and Ducting SectionDocument98 pages2015-16 Hose Tubes and Ducting SectionadhityaNo ratings yet

- TODO Data Sheet PDFDocument70 pagesTODO Data Sheet PDFJake ZyrusNo ratings yet

- sd7100 - SYLOBEAD® MS 512 (MADE IN EU) - (IN1)Document9 pagessd7100 - SYLOBEAD® MS 512 (MADE IN EU) - (IN1)dilip matalNo ratings yet

- Section A PipeDocument18 pagesSection A PipeOsama sayedNo ratings yet

- TEB0041 - Rubber BrochureDocument12 pagesTEB0041 - Rubber BrochuremmpambharNo ratings yet

- Oring Us enDocument160 pagesOring Us enroger1231175No ratings yet

- PVC Pressure Fittings: Technical SpecificationsDocument14 pagesPVC Pressure Fittings: Technical SpecificationsПетр НикольскийNo ratings yet

- Plastics Materials - J. A. Brydson - 7th Edition - AbbreviationsDocument5 pagesPlastics Materials - J. A. Brydson - 7th Edition - AbbreviationsCristianeHenschelNo ratings yet

- CDI Packing Design GuideDocument12 pagesCDI Packing Design GuideJIMNo ratings yet

- TD Quintolubric 888 68 PDFDocument2 pagesTD Quintolubric 888 68 PDFaneesh awasthiNo ratings yet