Saudi Aramco Inspection Checklist: Pump & Component Installation For Lift Stations SAIC-G-2023 30-Apr-17 Plumb

Saudi Aramco Inspection Checklist: Pump & Component Installation For Lift Stations SAIC-G-2023 30-Apr-17 Plumb

Uploaded by

karthi51289Copyright:

Available Formats

Saudi Aramco Inspection Checklist: Pump & Component Installation For Lift Stations SAIC-G-2023 30-Apr-17 Plumb

Saudi Aramco Inspection Checklist: Pump & Component Installation For Lift Stations SAIC-G-2023 30-Apr-17 Plumb

Uploaded by

karthi51289Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saudi Aramco Inspection Checklist: Pump & Component Installation For Lift Stations SAIC-G-2023 30-Apr-17 Plumb

Saudi Aramco Inspection Checklist: Pump & Component Installation For Lift Stations SAIC-G-2023 30-Apr-17 Plumb

Uploaded by

karthi51289Copyright:

Available Formats

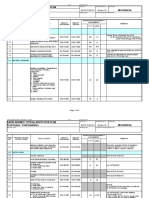

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pump & Component Installation for Lift Stations SAIC-G-2023 30-Apr-17 Plumb

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements (SAES-S-020)

Each lift station have 2 sets of pumps, 1 set to handle normal incoming

flow, & the other set to handle maximum incoming flow.

Exceptions: 1.This requirement is not applicable to controlled drainage of

diked area. In this case the lift station shall have at least one set of

pumps to handle normal incoming flow. SAES-S-020

A1 2. Sumps, outside diked areas, for bulk plants and air fueling operations Para 4.14.3

shall be sized to hold 32,000 liters plus a maximum of five minutes of

deluge flow per SAES-B-070 as a minimum.

3.If the difference between normal and maximum flows is 10% or less, a

single set of pumps sized for the maximum flow condition may be used.

Item A2 below ( from SAES-A-104) also applies

Each lift station must have at least 2 pumps of the same capacity.

Capacity of each lift station must exceed peak hourly wastewater flow. SAES-A-104

A2

The lift system must be designed such that it can pump the peak hourly Para 6.2.2.2

wastewater flow with the largest pump out of service.

The Pump Set handling Normal flow meet the following requirements:

a) The Pump Set consists of one pump or a group of pumps of equal

operating capacity and one equal capacity standby pump. SAES-S-020

A3 b) The total capacity of operating pumps is based on normal washdown, Para 4.14.4

sampling, vessel drainage, etc.

c) The pumps may have a common power source. For

Ref See Att-1

SAES-S-020

The Pump Set handling maximum consists of one pump or a group of

A4 Para 4.14.5

pumps of equal operating capacity and one equal capacity standby pump.

The total capacity of operating pumps are based on the flows stated in

SAES-S-020.Section 4.4.Exception: SAES-S-020

A5 Sumps for bulk plants and air fueling operations shall have at least one Para 4.14.5

maximum flow pump, sized to handle the design basis of the foam system

but in no case less than 63 L/s (1000 gpm)

SAES-S-020

The Max Flow pump's driving motors are connected to Two independent

A6 Para 4.14.5

power sources, each with its own transformer.

Non Suction Lift Pumps are specifically designed for pumping sewage and SAES-S-020

A7 are nonclog type complying with SAES-G-005. and SAES-A-104. Para 4.14.2,

Exception: Self priming pumps as per SAES-G-005 are acceptable 4.14.13, 14

There are no physical connection between any potable water supply and a

SAES-A-104

A8 wastewater lift station, which under any conditions might cause

Para 5.6.3.1

contamination of the potable water supply.

Saudi Aramco: Company General Use

SAES-S-20

A9 The pumps are spaced to prevent vortexing cavitations during operating

4.14.15

SAES-S-20

A10 The pumps are removable without disturbing the discharge piping

4.14.16

Pumps on lift stations complies with electrical area classification SAES-S-20

A11

requirements per SAES-B-068. 4.14.23

SAES-S-20

A12 Toe walls are provided at hydrocarbon pump bases.

4.7.1

The lift station shall be provided with not less than two radar level

SAES-S-20

A13 transmitters, in a redundant configuration, for level measurement and

4.14.8.1.1

control of the normal and high flow pumps.

Each lift station normal and high flow pump shall be fitted with a dedicated

SAES-S-20

A14 flow transmitter. This flow transmitter shall be installed on the pump

4.14.8.1.3

discharge piping, upstream of connection to common pump header piping.

The lift station shall be supplied with a control panel mounted at least 3 SAES-S-20

A15

meters (10 feet) away from the closest edge of the lift station. 4.14.8.2.1

Each lift station level transmitter and pump flow transmitter shall have an SAES-S-20

A16

analog local indicator mounted on the control panel. 4.14.8.2.2

Each pump shall be provided with a local hand-off-auto (HOA) switch and SAES-S-20

A17

start pushbutton, mounted on the panel. 4.14.8.2.3

B Other Requirements (SAES-A-104)

Wastewater lift station pumps are designed in accordance with SAES-S- SAES-A-104

B1

010 and SAES-S-020, as applicable. Para 6.2.1.1

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pump & Component Installation for Lift Stations SAIC-G-2023 30-Apr-17 Plumb

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Pumps handling raw wastewater are preceded by readily accessible bar

racks with clear openings not exceeding 50 mm unless pneumatic SAES-A-104

B2

ejectors are used or the pump is fitted with a grinder system at the pump Para 6.2.2.3

inlet.

Pumps in wet well service are either be submersible or self priming unless SAES-A-104

B3

approval is obtained from General Supervisor, EED. Para 6.2.2.4

Where the pump pit is below the ground surface or within an enclosure,

mechanical ventilation is required which shall ventilate the dry well & the SAES-A-104

B4

wet well independently. Note:Interconnections between wet well & dry Para 6.2.3.2

well ventilating systems are prohibited

SAES-A-104

B5 Dampers are not used on exhaust or fresh air ducts.

Para 6.2.3.3

Pump failure alarms per SAES-S-010/SAES-S-020, for both sanitary and

industrial wastewater are Provided and connected to the responsible

area's Control System. (Where a sanitary wastewater facility in a SAES-A-104

B6

community or construction camp does not have 24-hour shift coverage, lift Para 6.2.4.2,3

station alarms shall be telemetered to a manned location. An audiovisual

device (a light) shall be installed at the lift station for external observation).

Grit removal equipment are located upstream of pumps and comminuting SAES-A-104

B7

devices. Para 7.2.1.2

SAES-A-104

B8 Trash pumps are used for skimmed oil and oily sludge pumping needs.

Para 8.1.2.1.2.3

Sludge pumps in secondary or activated sludge systems have sufficient

NPSH or they are self-priming, and Return activated sludge pumps are

SAES-A-104

B9 capable of providing a variable capacity between 25 and 150% of design

Para 12.2.2

flow for conventional (plug-flow) processes and 25 to 200% for extended

aeration processes.

Sludge pumps are installed below the sludge hoppers,( in Oily wastewater

SAES-A-104

B10 containing sludge in concentrations higher than indicated in Section

Para 8.1.2.1.2

7.1.2.1.1 of SAES-A-104.

REMARKS:

REFERENCE DOCUMENTS:

SAES-A-104 -- Wastewater Treatment, Reuse and Disposal, (28 December 2011)

SAES-S-020 -- Industrial Drainage and Sewers, (13 March 2011)

SAES-B-068 -- Electrical Area Classification, (14 August 2014)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pump & Component Installation for Lift Stations SAIC-G-2023 30-Apr-17 Plumb

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pump & Component Installation for Lift Stations SAIC-G-2023 30-Apr-17 Plumb

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

4.14.2 The selection and installation of oily water lift station pumps shall be in accordance with SAES-A-104 and SAES-G-005 as applicable.

4.14.3 Each lift station shall have two sets of pumps, one set to handle normal incoming flow, and the other set to handle the maximum

incoming flow.

Exceptions:

1. Controlled drainage of diked areas; lift station shall have at least one set of pumps to handle normal incoming flow.

2. Bulk plants and air fueling operations; lift stations shall be in accordance with SAES-B-070.

3. As stated in Paragraph 4.14.6 of this Standard

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pump & Component Installation for Lift Stations SAIC-G-2023 30-Apr-17 Plumb

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

4.14.2 The selection and installation of oily water lift station pumps shall be in accordance with SAES-A-104 and SAES-G-005 as applicable.

4.14.3 Each lift station shall have two sets of pumps, one set to handle normal incoming flow, and the other set to handle the maximum

incoming flow.

Exceptions:

1. Controlled drainage of diked areas; lift station shall have at least one set of pumps to handle normal incoming flow.

2. Bulk plants and air fueling operations; lift stations shall be in accordance with SAES-B-070.

3. As stated in Paragraph 4.14.6 of this Standard

Saudi Aramco: Company General Use

You might also like

- SAES-L-109 PDF Download - Selection of Flanges, Stud Bolts and Gasket - PDFYARDocument5 pagesSAES-L-109 PDF Download - Selection of Flanges, Stud Bolts and Gasket - PDFYARZahidRafiqueNo ratings yet

- 79.01-A-Aux. Boiler Techincal Instructions For Wet PreservationDocument7 pages79.01-A-Aux. Boiler Techincal Instructions For Wet PreservationaironyxNo ratings yet

- New Removal of Bore Pump SWIDocument11 pagesNew Removal of Bore Pump SWIchrisNo ratings yet

- 031Document5 pages031Mohamad ShafeyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 14-May-18Document10 pagesSaudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 14-May-18Domie Neil Bucag SalasNo ratings yet

- Satip A 004 03 PDFDocument3 pagesSatip A 004 03 PDFAbdul Gafoor ShaikhNo ratings yet

- SAIC-A-2005 Rev 8Document4 pagesSAIC-A-2005 Rev 8Syed ImranNo ratings yet

- PM 100.08 Deferral ProcessDocument3 pagesPM 100.08 Deferral ProcessmmfakhryNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanDomie Neil Bucag SalasNo ratings yet

- 1 SATIP NDE UT 01 Ultrasonic Testing Rev1Document1 page1 SATIP NDE UT 01 Ultrasonic Testing Rev1eldobie3No ratings yet

- QM-R83-PL-4024 Procedure For Notification of Inspection ActivitiesDocument15 pagesQM-R83-PL-4024 Procedure For Notification of Inspection ActivitiesGaneshNo ratings yet

- 230Materials&EnergyModule (1) PS CAPECODocument5 pages230Materials&EnergyModule (1) PS CAPECOPradeep SutharNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydrotest) SAIC-A-2013 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydrotest) SAIC-A-2013 15-Dec-09 MechEagle SpiritNo ratings yet

- Monitor RequirementDocument1 pageMonitor Requirementcoolsummer1112143No ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- KPIs For Inspection UnitDocument1 pageKPIs For Inspection UnitSyed Hassan GardeziNo ratings yet

- Saes e 007Document15 pagesSaes e 007Neeraj kumarNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldDocument9 pagesSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- Saes B 061Document4 pagesSaes B 061SIVANo ratings yet

- Saep 306Document13 pagesSaep 306Narvis RinconNo ratings yet

- 01 Introduction To DunlopDocument33 pages01 Introduction To DunlopFikret YenenNo ratings yet

- Saep 1026Document18 pagesSaep 1026paul cafeNo ratings yet

- 32 Samss 008Document26 pages32 Samss 008naruto256100% (1)

- SATIP E 004 01 Heat ExchangerDocument10 pagesSATIP E 004 01 Heat Exchangermohammedtaufeeq8No ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- 00 Saip 73Document8 pages00 Saip 73Selvakpm06No ratings yet

- Saep 310Document38 pagesSaep 310paul cafeNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03failureanalystNo ratings yet

- Saes G 115Document9 pagesSaes G 115junaidNo ratings yet

- Saep 317Document22 pagesSaep 317paul cafeNo ratings yet

- Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manual Issuing Org.: SubjectDocument11 pagesSaudi Arabian Oil Company (Saudi Aramco) General Instruction Manual Issuing Org.: SubjectAldrien CabinteNo ratings yet

- Saes A 005Document37 pagesSaes A 005Ziyad ShaathNo ratings yet

- PT2SB-MNT-WI-060 Thickness Measurement Via Ultrasonic Testing & Thickness Measurement Location Corrosion - R1Document19 pagesPT2SB-MNT-WI-060 Thickness Measurement Via Ultrasonic Testing & Thickness Measurement Location Corrosion - R1idham.sautiNo ratings yet

- ICM-CD-6119.06 Check Sheet PSVDocument1 pageICM-CD-6119.06 Check Sheet PSVShivani DubeyNo ratings yet

- Saep 122Document12 pagesSaep 122Tahir MubeenNo ratings yet

- STD-171 Preservation of Idle Static & Rotary Mechanical EquipmentDocument29 pagesSTD-171 Preservation of Idle Static & Rotary Mechanical Equipmentyohanneti.riniNo ratings yet

- Section 8 - Quality Assurance/Quality Control PlanDocument3 pagesSection 8 - Quality Assurance/Quality Control PlanJoemon T JoyNo ratings yet

- Saep 1125Document6 pagesSaep 1125pravinNo ratings yet

- Chemical Wash-Saudi AramcoDocument37 pagesChemical Wash-Saudi AramcoOmid LarkiNo ratings yet

- Saes B 069Document9 pagesSaes B 069Cane CirpoNo ratings yet

- GU-611 - PDO Guide To Engineering Standards and ProceduresDocument1 pageGU-611 - PDO Guide To Engineering Standards and ProceduresSahbi FattNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNo ratings yet

- RCER-2015-Volume IIDocument197 pagesRCER-2015-Volume IIYasir UrfatNo ratings yet

- Welding ProcedureDocument11 pagesWelding ProcedureAziz RanaNo ratings yet

- Satip e 004 01Document2 pagesSatip e 004 01Anonymous 4e7GNjzGWNo ratings yet

- SAIC-H-2026 Coating Equipment InspectionDocument3 pagesSAIC-H-2026 Coating Equipment Inspectionqq343923571No ratings yet

- Saudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalDocument3 pagesSaudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalOmer aliNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Material Control Flow ChartDocument8 pagesMaterial Control Flow CharthosseinNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanOmer ali100% (1)

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- SAEP-127 - Security and Control of Saudi Aramco Engineering DataDocument9 pagesSAEP-127 - Security and Control of Saudi Aramco Engineering DataAnonymous PkAjjOZB100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Satip y 101 01Document12 pagesSatip y 101 01spravin231No ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- AMIEP-61 - 2 - Geotechnical Engineering Procedures-OnshoreDocument23 pagesAMIEP-61 - 2 - Geotechnical Engineering Procedures-OnshoreSeungtai JeongNo ratings yet

- Saic G 2023Document2 pagesSaic G 2023Noor Mohamed AzeezNo ratings yet

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- TWAD - Hdpe Certificate - 75231 Sudhakar 90mmDocument2 pagesTWAD - Hdpe Certificate - 75231 Sudhakar 90mmkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18Document5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18karthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Group 2 Air Pollution Control: What Can The CWTS Do To Help Clean The Air?Document2 pagesGroup 2 Air Pollution Control: What Can The CWTS Do To Help Clean The Air?ALFA SPORTSCITYNo ratings yet

- Project Sample I S H V A R ADocument35 pagesProject Sample I S H V A R APrime VideoNo ratings yet

- Börner and Hegger, 2018Document11 pagesBörner and Hegger, 2018Dinar WerdhaniNo ratings yet

- CWIS Experiance GWSCDocument26 pagesCWIS Experiance GWSCJeevan RoyNo ratings yet

- Environmental Law NotesDocument30 pagesEnvironmental Law NotesSenelwa Anaya50% (4)

- Remotesensing 12 03613 s001Document4 pagesRemotesensing 12 03613 s001jacob ayalNo ratings yet

- Vilandco - EDGEDocument13 pagesVilandco - EDGENguyen DuongNo ratings yet

- Group 3Document10 pagesGroup 3Ronan NabloNo ratings yet

- DissertationDocument62 pagesDissertationRaj NaveenNo ratings yet

- BNITC InductionDocument47 pagesBNITC InductionTope100% (2)

- EY Turkey Sustainability Report FY14 PDFDocument72 pagesEY Turkey Sustainability Report FY14 PDFataktosNo ratings yet

- Grundfos Pumps All Products BrochureDocument17 pagesGrundfos Pumps All Products BrochurekashviNo ratings yet

- Adelgazador - Acrolon R7K15Document4 pagesAdelgazador - Acrolon R7K15Fredy Galindo GNo ratings yet

- Safety Data Sheet P3-Oxonia ActiveDocument14 pagesSafety Data Sheet P3-Oxonia Activeziauddin bukhariNo ratings yet

- National Green TribunalDocument17 pagesNational Green TribunalKirti GargNo ratings yet

- MULTIDISCIPLINARY PROJECT (MDP) Class VDocument7 pagesMULTIDISCIPLINARY PROJECT (MDP) Class VPriyanka 283No ratings yet

- EN Invisivent Air ComfortDocument24 pagesEN Invisivent Air ComfortlilianaNo ratings yet

- Vandana ShivaDocument2 pagesVandana Shivashankargu36No ratings yet

- The Benefits of Waste ManagementDocument14 pagesThe Benefits of Waste Managementsupreme sabarish100% (1)

- Sabod SabodDocument4 pagesSabod SabodDanilo Chestere BerjaNo ratings yet

- Esia Access RoadsDocument506 pagesEsia Access RoadsOdhiamboOdhiamboNo ratings yet

- Carbon Imprints and Their Significance in Climate Change MitigationDocument15 pagesCarbon Imprints and Their Significance in Climate Change Mitigationdelacruzjr.enrique.bsceNo ratings yet

- sample bridge site investigation reportDocument8 pagessample bridge site investigation reportአምባቸው ገብሬNo ratings yet

- A Fistful of Feathers - ScreenDocument6 pagesA Fistful of Feathers - ScreenCrapal ZNo ratings yet

- Thomsen Et Al.2009Document62 pagesThomsen Et Al.2009Shaheen WahabNo ratings yet

- EcoMatpro HDSW - ECM-70 Access Mat Technical specifications-ISO-standardDocument4 pagesEcoMatpro HDSW - ECM-70 Access Mat Technical specifications-ISO-standardLukarsa2013No ratings yet

- Q2Document13 pagesQ2K60 Trần Thị Kiều TrinhNo ratings yet

- Marine Methanol Report Methanol Institute May 2023Document61 pagesMarine Methanol Report Methanol Institute May 2023pabloNo ratings yet

- 2.1 Diversion HeadworkDocument171 pages2.1 Diversion HeadworkHod CivilNo ratings yet

- BSCI Audit - SampleDocument7 pagesBSCI Audit - SampleNakul ChandakNo ratings yet