(Full Permission)

(Full Permission)

Uploaded by

mohamadi42Copyright:

Available Formats

(Full Permission)

(Full Permission)

Uploaded by

mohamadi42Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

(Full Permission)

(Full Permission)

Uploaded by

mohamadi42Copyright:

Available Formats

Producer/Injector Ratio: The Key to

Understanding Pattern Flow Performance

and Optimizing Waterflood Design

C.E. Hansen, SPE, EOG Resources Inc., and J.R. Fanchi, SPE, Colorado School of Mines

Summary waterflood design processes, or field-specific experience. Given

When designing a waterflood, the important aspect of processing that differences in flow capacity can be quite significant depending

rate with respect to pattern selection has not been addressed ad- on the mobility conditions of the reservoir, a trial-and-error ap-

equately in the literature. It has not been possible, using the ex- proach could be unpredictable and in turn have a negative effect on

isting analytical background, to determine and compare the flow- the economics realized from a waterflood project. Therefore, a

rate performance of all the patterns for any given rock/fluid (mo- more complete analytical understanding of pattern flow behavior

bility) system. While general two-phase equations exist for the is necessary to enable the more effective use of all available

five-spot and line-drive patterns, flow equations for other patterns design tools.

either have not been presented (e.g., the seven-spot) or are not This paper presents new analytical relationships describing the

sufficiently general (e.g., the nine-spot) to apply to all mobil- two-phase, steady-state flow-rate performance of repeated patterns

ity conditions. A general treatment of skin effect also has not in homogeneous, isotropic reservoir systems. These relationships

been given. represent a general, comprehensive pattern flow theory that greatly

This paper presents a new, comprehensive analytical treatment extends the range of applicability to all patterns, mobility condi-

of pattern flow for isotropic, homogeneous reservoirs that applies tions, and stages of the flood. The theoretical development is

to all patterns and mobility conditions. This is made possible by a founded on a new equation for the volumetric average reservoir

new equation for the volumetric average reservoir pressure of pressure of patterns. We show how pattern average pressures and

regularly spaced, repeated patterns. The new formulas demonstrate flow rates are a function of P/I and MT. Depending on MT, sub-

how the producer/injector ratio (P/I) controls reservoir pressures stantial differences can exist in the throughput rates achievable

and flow rates and (for the first time) allow the differences in the with the different patterns. For any MT, there is a P/I that provides

flow capacity of patterns to be quantified. The mobility character- the highest flow capacity relative to all others. The relative differ-

istics that control flow rates are described fully by a newly defined ences in flow capacity become more pronounced as MT gets in-

total mobility ratio, MT. The form of the new equations allows for creasingly larger or smaller than unity. The form of the new equa-

modifications for skin effect and reservoir heterogeneity. We show tions also allows a general treatment of skin effect and reservoir

how skin effect can act disproportionately with injectors and pro- heterogeneity. As shown, skin effect acts as an adjustment to the

ducers because of its interaction with P/I and MT. physical P/I; as such, the pattern flow rate can be influenced

disproportionately by the skin effect of one type of well (i.e.,

Introduction injectors or producers) over the other.

As also presented, MT can be correlated to the endpoint mo-

The economics of a waterflood depend on two primary variables bility ratio, M, and the oil relative permeability curve shape for the

that engineers seek to optimize when designing a flooding scheme: prewater-breakthrough period. The correlation is based on numeri-

(1) the processing, or throughput rate, and (2) the incremental oil cal results and is useful in determining the economically optimum

recovery. Depending on the characteristics of the reservoir, one of pattern in isotropic reservoirs using the equations presented. The

these objectives can take a more dominant role in the determina- new equations apply equally well to augmented waterfloods, such

tion of the optimum flooding pattern. For example, if there is as polymer floods.

significant permeability anisotropy, incremental recovery will take

precedence because of its strong dependency on producer/ injector

Background

orientation. Conversely, in isotropic reservoirs, considerations of

flow rate will drive pattern selection because incremental recovery The theory of injection patterns, or networks, extends back to the

in these reservoirs is largely independent of pattern type. In both 1930s, where Muskat1 presented analytical solutions for several

types of reservoirs, an adequate recovery rate is paramount to an patterns using “ideal” flow assumptions, which include a single-

economically viable project. phase, incompressible fluid of constant viscosity flowing at steady-

When attempting to optimize the flow rate of waterfloods in state conditions in a horizontal, homogeneous, and isotropic res-

isotropic reservoirs, however, one quickly finds that the existing ervoir. Deppe2 later presented flow equations for the ideal nine-

literature does not provide sufficient background to accomplish spot pattern. The single-phase assumption also has been referred to

this. While waterflooding has, for the most part, a well-established in the literature as being equivalent to the unit-mobility ratio con-

technical basis, the analytical development for two-phase pattern dition for two-phase systems (that is, when the endpoint mobility

flow rates is incomplete, most notably for the seven-spot and nine- ratio, M, is equal to 1). However, as shown in this paper, this is not

spot patterns. Also, the existing theoretical background does not a sufficient criterion to apply “ideal” pattern equations to real

identify the fundamental mechanisms controlling pattern rates. As reservoir systems. The sufficient condition that must exist is that

a result, there has been an overall lack of insight into factors the total mobility ratio, MT, as defined here, is equal to one. This

controlling pattern rates and the flow-capacity differences that ex- condition can exist in systems where M⫽1.0 and does not neces-

ist between the patterns for any two-phase system. This has re- sarily exist when M⳱1.0. Only when MT=1.0 can the single-phase

quired that the engineer rely largely on trial and error, numerical equations be used. Thus, the applicability of the single-phase equa-

tions is limited to a small subset of reservoirs.

The flow theory for nonunit total mobility systems is not nearly

as well developed. Several investigators have studied nonunit mo-

Copyright © 2003 Society of Petroleum Engineers

bility ratio pattern flow behavior using a variety of techniques,2–8

This paper (SPE 86574) was revised for publication from paper SPE 75140, first presented with the five-spot pattern being studied most frequently. These

at the 2002 SPE/DOE Improved Oil Recovery Symposium, Tulsa, 13–17 April. Original

manuscript received for review 8 March 2002. Revised manuscript received 10 February

techniques have included a potentiometric model,3 an X-ray shad-

2003. Paper peer approved 29 July 2003. owgraph study,4 a scaled flow-model study,5 and a potentiometric

October 2003 SPE Reservoir Evaluation & Engineering 317

model with corresponding formulas6 of the five-spot pattern. Stud- In Eq. 3, Teff(j) is the effective total mobility of the oil and water

ies for other patterns are much less abundant and include the for a given well within the pattern element, defined from the

skewed four-spot,7 direct-line drive,8 and nine-spot.2 Other nine- wellbore radius to the average reservoir pressure contour (see fur-

spot studies have been limited to the investigation of recovery ther definition below), and f(j) is the fraction of the well’s total flow

curves and sweep efficiencies,9–11 not flow rates. It must be em- rate contributed to the pattern element.

phasized that these methods2–8 assume an idealized displacement For example, consider an element of symmetry of the inverted

mechanism (i.e., there is no saturation gradient and thus no mo- nine-spot pattern shown in Fig. 1. TP, the average effective total

bility gradient within the swept region). This is equivalent to the mobility of production, is calculated according to Eq. 3b as

assumption of pistonlike displacement, which can be valid when

M<<1.0, but which is a very poor assumption when M>1.0. In 0.25Teff( 2) + 0.25Teff( 3) + 0.25Teff( 4)

TP = , . . . . . . . . . . . . . . . ( 4)

most cases, there will be a saturation gradient in the swept region 0.25 + 0.25 + 0.25

that is dependent on the shape of the relative permeability curves, while TI, the average effective total mobility of injection, is sim-

even at low mobility ratios. Thus, the applicability of these studies ply equal to Teff(1) as the only injection well.

to real systems is very limited, if not invalid, and the variety of

techniques used preclude a direct comparison of the flow capaci- Determining Effective Total Mobilities. The effective total mo-

ties of the patterns as a function of mobility characteristics. bility for a given well, Teff(1), is the single mobility value, kr/,

To the authors’ knowledge, the most rigorous analytical treat- that represents the pressure-drop equivalent mobility between the

ment of nonunit mobility pattern flow is given by Willhite.12 Un- wellbore and the average reservoir pressure contour. For any pat-

like previous works that discuss equations in nonunit mobility tern well, this definition satisfies the relationship given by

systems2,6,8 where only pistonlike displacement is assumed, Will-

hite also considers non-pistonlike displacement where there is two- 141.2

phase flow behind the flood front. To accomplish this, he intro- 关ppat − pwf共j兲兴Teff共1兲 = pD共j兲q共j兲 , . . . . . . . . . . . . . . . . . . . . . . . ( 5)

kh

duces a total mobility ratio, Mt, that is used to account for the

mobility gradient within the swept region. While rigorous, Willhite where pD(j) is the steady-state dimensionless pressure for a given

presents only the equations for the five-spot and line-drive pat- well that accounts for the flow geometry between pwf(j) and ppat.

terns, which are valid for times up to an areal sweep efficiency of Teff(1) can be estimated with the same approach outlined by Will-

50% (in practice, these equations should be adequate to estimate hite for calculating an “average apparent viscosity”, rf–1, for

rates up to breakthrough). Note also that Mt is defined only for a well12:

these patterns, where P/I⳱1.0, and it is not shown how Mt would rf

be defined for other patterns. Because only the five-spot and line-

drive patterns are considered, comprehensive flow-rate compari- 兰

rw

r

− 1

dr Ⲑ r

− 1

sons between all of the patterns with respect to total mobility ratio rf = . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 6)

are not possible. ln共rf Ⲑ rw兲

Other methods of predicting waterflooding behavior in nonunit This formula results from radial series averaging of total mobility

total mobility ratio, 2D systems include numerical finite-difference between the well and some radial distance rf. Radial flow around

simulation and analytical streamtube methods.13–18 These methods the wells is a good assumption for repeated patterns.2,21 In this

can account for the complete fractional flow behavior without full paper, the effective total mobility is similarly defined as

analytical treatment. The limitation of these methods is that they

do not provide the insight into the parameters governing the flow ln共rpavg Ⲑ rw兲

Teff = , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 7a)

process that a representative analytical equation can provide. We rpavg

dr Ⲑ r

believe this insight into pattern flow behavior is afforded by the

relationships presented in this paper.

兰 rw T共r兲

Theoretical Development where Teff is defined between the wellbore and the radial distance

The basis of the new pattern flow equations is a new equation for to average reservoir pressure contour, rpavg , and T(r) is the av-

the average reservoir pressure in isotropic, homogeneous patterns. erage total mobility at radius r, or

For the assumptions of incompressible fluids flowing at steady-

兰

state conditions in a horizontal, homogeneous, and isotropic res- 1

ervoir within a uniformly spaced, repeated pattern, the average T共r兲 = ⳯ r ⳯ d. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 7b)

r T

reservoir pressure within any element of symmetry is given by20 0

ppat =

兰p ⳯ dV = 共MT兲共pwfI兲 + 共P Ⲑ I兲共pwfP兲

, . . . . . . . . . . . . . . . ( 1)

兰dV MT + P Ⲑ I

where

TI

MT = , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 2)

TP

NI

兺f

j= 1

共j兲 ⳯ Teff共j兲

TI = NI

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 3a)

兺f

j= 1

共j兲

and

NP

兺f

j= 1

共j兲 ⳯ Teff共j兲

TP = NP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 3b)

兺f

j= 1

共j兲

Fig. 1—Inverted nine-spot quarter element of symmetry.

318 October 2003 SPE Reservoir Evaluation & Engineering

In calculating Teff for a given well, it may seem problematic that 141.2

for any pattern, the steady-state flow regime becomes increasingly and ppat − pwfP = pD( prod) qprod, . . . . . . . . . . . . . . . . . . . . . . ( 11b)

kh

nonradial away from the wells and that the location of the average

pressure contour is not known a priori before the calculation of Eq. 141.2

we can see that the term pD must be the same for both in-

1 is made. However, a study of Eq. 7 will reveal that the total kh

mobilities closer to the well have the greatest impact on the cal- jectors and producers in Eqs. 11a and 11b to satisfy Eq. 10 [i.e.,

culation of Teff, which is a well-known characteristic of radial pD(inj)⳱D(prod)]. Note that this is true only when the pressure drop

flow. As a result, the mobilities farther away from a well have an is defined relative to the average reservoir pressure, which is a

increasingly smaller impact on the calculation of Teff. Also for significant result derived from Eq. 1. Therefore, dimensionless

this reason, the flow regime away from the well, be it subradial to pressure for any pattern is defined in this paper according to Eq. 11

elliptical to linear, can be assumed radial. Thus, Teff can be as pD(pat), where pD(pat)⳱pD(inj)⳱pD(prod). Furthermore, we can

closely approximated by using Eq. 7 out to a sufficiently large solve for pD(pat) for any pattern if we equate the single-phase

radial distance. Hansen20 uses a numerical method to carry out the equations with the generalized form of Eq. 11. For example,

integration to a radial distance of 0.5d to estimate Teff and shows equating Muskat’s single-phase five-spot equation1 with Eq. 11a,

that the analytical and numerical results agree closely. Therefore, we have

knowing the exact location of the average reservoir pressure con-

tour or accounting for the shift away from a radial flow regime is 0.003541kh共⌬P兲 kh共⌬P兲 PⲐI

冉 冊

qinj = = ⳯ , . . . . . . ( 12)

not required to determine an accurate Teff for each well. d 141.2pD共pat) 1 + P Ⲑ I

With the definitions of TI, TP, and Teff given by Eqs. 3 and ln − 0.619

rw

5, and as approximated by Eq. 7, it can be seen that MT represents

the total mobility at every point in the reservoir and is defined for where a rearranged form of Eq. 1 has also been substituted for

all patterns at any stage of the flood. Thus, the mobility charac- pwfI–ppat in Eq. 11a:

teristics of the reservoir as these relate to flow rate are described PⲐI

fully by MT. Also, while the value of MT changes continuously pwfI − ppat = ⌬P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 13)

throughout the life of a flood because of changing saturations in 1 + PⲐI

the reservoir, its definition does not change. MT is similar to the The pD(pat) for each pattern determined in this way is shown in

definition of total mobility ratio Mt given by Willhite12; however, Eqs. 14 through 17. The determination of pD(pat) for the nine-spot

his definition applies only to the five-spot and line-drive patterns is somewhat more complicated, as discussed in Appendix A. Un-

up to an areal sweep of 50%. like the original equations for the nine-spot,2 the generalized

single-phase flow relationship (Eq. 11) using the dimensionless

Applicability of the Average Pressure Equation. Eq. 1 is appli- pressure given by Eq. 17 is now insensitive to the value of R, the

cable to uniformly spaced, repeated patterns. The precise meaning ratio of corner-to-side well flow rates, where pD(pat) varies <1%

of “uniformly spaced” is any pattern where an element of symme- when R<10. This is because in the equations presented by Deppe,2

try can be drawn in which the geometric relationship between the R indirectly accounts for the side and corner sandface pressures.

element area and all of the element wells is the same. This defi- These pressures are accounted for with the average pressure rela-

nition thus includes any square or rectangular patterns such as the tionship, and the dependency between pD(pat) and R now involves

five-spot, direct and staggered-line drives, the nine-spot, and the only effects of flow geometry. Thus, using R⳱1.0 in Eq. 17 should

hexagonal seven-spot pattern. This strict definition excludes the be adequate for most situations when calculating pD(pat) for

skewed four-spot; however, in practicality, Eq. 1 would closely the nine-spot.

approximate the average reservoir pressure for this pattern. Refs. Five-Spot:

12 and 19 show the geometry of the various patterns. Eq. 1 is also

derived assuming incompressible fluids; however, application to d

pD( pat) = ln− 0.619. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 14)

compressible fluids can be made with small errors (<2%) for typi- rw

cal oil and water compressibilities.20 Direct Line-Drive and Staggered Line-Drive:

a d

Generalized Flow Equation for pD共pat) = ln+ 1.571 − 1.838. . . . . . . . . . . . . . . . . . . . . . . . ( 15)

Two-Phase Patterns rw a

Seven-Spot:

The development of a general pattern flow equation will now be

outlined. Additional details can be found in Ref. 20. The average d

reservoir pressure equation (Eq. 1) can be rewritten for the single- pD共pat) = ln− 0.569. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 16)

rw

phase case, where MT⳱1.0, as Nine-Spot:

pwfI − ppat d 1 0.693

= P Ⲑ I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 8) pD( pat) = ln − 0.272 − ⳯ . . . . . . . . . . . . . . . . . . . . . . ( 17)

ppat − pwfP rw 2 2+ R

We also know that for steady-state flow (i.e., a succession of A confirmation of pD(pat) for the nine-spot (Eq. 17) can be shown

steady states for two-phase flow), using the limiting case in which the side well rates approach zero

and R→ ⬁. For this case, the nine-spot pD(pat) at well spacing d

qinj should be equal to the five-spot pD(pat) at well spacing d√ 2; that is,

PⲐI = . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 9)

qprod d 1 0.693 d公2

ln − 0.272 − ⳯ = ln − 0.619, . . . . . . . . . . . ( 18)

Combining Eqs. 8 and 9, we can write rw 2 2+ R rw

which the reader can verify is true for R→ ⬁.

pwfI − ppat qinj

= . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 10)

ppat − pwfP qprod Comparison of Pattern Dimensionless Pressures. Given that

pD(pat) represents the flow resistance caused by the geometry or

If we write general pattern flow equations for injectors and pro- composite flow path of a pattern, just as ln (re/rw) applies to pure

ducers relative to the average reservoir pressure, radial flow, and that the geometries of patterns are similar, the

dimensionless pressures also should be similar. Fig. 2 compares

141.2 pD(pat) for the various patterns at several well densities for a con-

pwfI − ppat = pD( inj) qinj . . . . . . . . . . . . . . . . . . . . . . . . . . ( 11a)

kh stant rw. At any given well density, the pD(pat) values are within 5%.

October 2003 SPE Reservoir Evaluation & Engineering 319

each injector is given by 1+P/I, we can define a normalized

throughput rate as the rate per pattern well:

qinj

q̃ = . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 22)

1 + PⲐI

Thus, we have the full, normalized reservoir flow rate equation by

combining Eq. 20 and Eq. 22:

PⲐI ⌬P kh

q̃ = TI ⳯ ⳯ . . . . . . . . . . . ( 23)

共MT + P I兲共1 + P I兲

Ⲑ Ⲑ pD( pat) 141.2

The total field rate, either production or injection, would then

equal Eq. 23 multiplied by the total number of wells in the field.

Furthermore, a reservoir conductivity ratio can be defined using

Eq. 23 as follows:

q̃共1兲 共TI兲1 共P Ⲑ I兲1 共MT + P Ⲑ I兲2 共1 + P Ⲑ I兲2

= , . . . . . . . . . . . . . . . ( 24)

q̃共2兲 共TI兲2 共P Ⲑ I兲2 共MT + P Ⲑ I兲1 共1 + P Ⲑ I兲1

Fig. 2—Dimensionless pressures of patterns at various well where subscripts 1 and 2 refer to two different patterns and/or two

densities (see Eqs. 14 through 17). points in time at a given well spacing within the same reservoir. If

the flow performance of two different patterns is being compared

Consequently, an expression for pD(pat) that can be used for any for the time period before water breakthrough, then Eq. 24 can be

pattern within 2.5% is given by Eq. 19: reduced further by setting (TI)1⳱(TI)2. This is because TI (and,

Any Pattern (within 2.5%): thus, MT) will be nearly identical, varying similarly with areal

sweep for any of the patterns within a given reservoir-fluid system,

d so that a single value for TI can be assumed. The assumption of

pD( pat) = ln − 0.443. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 19) TI being the same for any given pattern is especially good when

rw

M<1 and is quite acceptable when M>1. This is also shown later by

This is an important result for patterns without a single-phase- the correlation between M and MT. Thus, a more simplified form

flow equation (e.g., the skewed four-spot pattern) or for other of Eq. 24 for comparisons involving the same injection fluid where

hybrid patterns (an example of which is discussed in a later sec- (TI)1⳱(TI)2 is given by

tion of this paper). Eq. 19 can be used with excellent accuracy in

these cases. q̃共1兲 共P Ⲑ I兲1 共MT + P Ⲑ I兲2 共1 + P Ⲑ I兲2

= . . . . . . . . . . . . . . . . . . . . . ( 25)

q̃共2兲 共P Ⲑ I兲2 共MT + P Ⲑ I兲1 共1 + P Ⲑ I兲1

General Pattern Flow Equation. Based on the preceding discus-

sion, it can be shown in a straightforward manner that a general Conductivity Relationships

expression for the two-phase flow rate of any pattern is given Eq. 25 provides an easy method to quickly determine the relative

by Eq. 20: flow performance of the various patterns before water break-

PⲐI ⌬P kh through by comparing the P/Is of all the patterns [as (P/I)1] relative

qinj = TI ⳯ ⳯ . . . . . . . . . . . . . . . . . . . ( 20) to a base pattern [as (P/I)2]. Using Eq. 25, the comparison involves

MT + P Ⲑ I pD( pat) 141.2 only estimating the parameters TI and TP. As mentioned earlier,

In deriving Eq. 20, it was necessary to assume that all injection TI will be essentially the same among all the patterns in a given

well pressures and production well pressures are the same (i.e., ⌬P reservoir-fluid system before water breakthrough so that a single

is the same for any injector/producer pair). value for TI (and, thus, MT) can be used to compare all the pattern

Because pD(pat) is related strictly to pattern geometry, the P/Is during this period.

single-phase terms are applicable to two-phase flow, while the

effects of mobility are fully accounted for with the new total mo- Conductivity Relationship for MT=1.0. The reservoir conductiv-

bility ratio, MT. pD(pat) for the nine-spot can change slightly de- ity relationship for MT⳱1.0 is shown by Fig. 3, where the P/I of

pending on the relative corner-to-side well rates as given by R, but each pattern is compared with base pattern (P/I)2⳱1.0.

this dependency is small, as discussed previously. Fig. 3 shows that when MT⳱1.0, the maximum reservoir flow

Note also that in developing two-phase equations for the five- rate is achieved at P/I⳱1.0 (i.e., a five-spot or a line-drive pattern

spot and line-drive patterns,12 Willhite accounts for the effects of

geometry using combinations of radial and linear flow segments

that are coupled with mobility terms. By incorporating ppat, our

approach has enabled the flow relationship to be generalized for all

patterns by separating the effects of mobility and geometry

through MT and pD(pat).

Normalized Flow Rates and Conductivity Ratio. Referring to

Eq. 20, because the dimensionless pressures are within 5% for

equivalent well spacing, comparing the individual injection well

flow rates between the different patterns within a given reservoir

can be based solely on the comparison of the term

PⲐI

qinj ⬀ TI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 21)

MT + P Ⲑ I

because all other terms would be equal or nearly so. Eq. 21 is

proportional to the individual well flow rates and does not tell us

how the throughput rates of patterns would compare on a reservoir

or a rate per total well basis. We can compare reservoir throughput

rates as follows. Because the number of total wells associated with Fig. 3—Conductivity relationship for MT=1.0.

320 October 2003 SPE Reservoir Evaluation & Engineering

with d/a⳱1.0). The seven-spot and nine-spot patterns, either nor-

mal or inverted, provide 88% and 75% of the capacity of the

five-spot or line-drive, respectively. In actuality, the line-drive

pattern (d/a⳱1.0) will provide 95% of the flow capacity of the

five-spot because the pD(pat) for the line drive is approximately 5%

higher (see Fig. 2). Note that this conductivity relationship also

could have been generated with the single-phase flow equations,1,2

which are applicable when MT⳱1.0. Note also that the base P/I

used in Eq. 25, (P/I)2, also provides the maximum conductivity;

thus, (P/I)2 is denoted (P/I)max, as shown on the ordinate axis of

Fig. 3. This convention is also used for the following comparisons

of other total mobility ratios.

Conductivity Relationships for MT=0.5 and MT=2.0. The con-

ductivity relationships for MT=0.5 and MT=2.0 are shown in

Fig. 4. These total mobility ratios are plotted on the same graph to

illustrate a few of the important relationships of Eq. 25. Note how

the conductivity relationships are symmetrical around the P/I⳱1.0

axis for these total mobility ratios, which are reciprocals of one Fig. 4—Conductivity relationships for MT=0.5 and MT=2.0.

another. The P/Is corresponding to the maximum flow capacity,

(P/I)max, are also reciprocals; that is, when MT=0.5, (P/I)max⳱0.7, Pressure and Flow Relationships Including the

while for MT=2.0, (P/I)max⳱1.428, or 1/0.7. The producer/injector Skin Effect

ratios providing the minimum reservoir flow capacity, or (P/I)min,

The inclusion of skin effect can be handled as an adjustment to P/I.

only provide 62% of that provided by (P/I)max. The average reservoir pressure relationship (Eq. 1), including skin

Even though no repeatable pattern corresponds exactly to the effect, is rewritten as

values of (P/I)max for MT⳱0.5 and MT⳱2.0, they are sufficiently

close to an actual pattern. In this case, a hybrid pattern that fills the 共MT兲共pwfI兲 + 共P̃ Ⲑ Ĩ兲共pwfP兲

gap between a five-spot and a seven-spot will provide the highest ppat = , . . . . . . . . . . . . . . . . . . . . . . . . . . (26)

MT + P̃ Ⲑ Ĩ

flow capacity. This pattern is a combination five-spot, skewed

four-spot (or seven-spot in a square well arrangement), as shown where

in Fig. 5. The P/I of this pattern is either 1.67 (5:3) for an inverted

pattern or 0.60 (3:5) for a normal pattern. Even though a dimen- 关pD( pat) + s( inj) 兴

P̃ Ⲑ Ĩ = P Ⲑ I , . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 27)

sionless pressure has not been derived for this pattern, we know 关pD( pat) + s( prod) 兴

from Fig. 2 that pD(pat) is largely independent of pattern configu- NI

ration. Thus, for this pattern we can use pD(pat) given by Eq. 19.

兺f

j= 1

共j兲 ⳯ s共j兲 ⳯ q共j兲

Conductivity Relationships for MT=0.2 and MT=5.0. Fig. 6 s( inj) = NI

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 28)

shows the conductivity relationships for MT⳱0.2 and MT⳱5.0.

For MT⳱0.2, (P/I)max⳱0.45, and for MT⳱5.0, (P/I)max⳱1/0.45, 兺f

j= 1

共j兲 ⳯ q共j兲

or 2.22. Note from Fig. 4 and Fig. 6 that when MT>1.0, (P/

and

I)max>1.0, and when MT<1.0, (P/I)max<1.0. Also, as MT gets fur-

ther away from 1.0, the difference between the conductivity at NP

(P/I)max and (P/I)min gets larger. For MT⳱0.2 and MT⳱5.0,

the highest and lowest conductivity patterns differ by a factor

兺f

j= 1

共j兲 ⳯ s共j兲 ⳯ q共j兲

s共prod兲 = . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 29)

of approximately 2. NP

Discussion of Results. The preceding discussion shows that pat-

兺f

j= 1

共j兲 ⳯ q共j兲

tern selection can have a tremendous impact on the flow perfor- P̃/Ĩ is the effective P/I, s(j) is the skin factor for a given well within

mance and, thus, on the economics of a flood. With the relative the pattern element, and q(j) is the reservoir flow rate for the same

performance of the patterns now defined with respect to the total well, while all other parameters are as previously defined. Note

mobility ratio of the system, a rational, economically optimum

pattern selection can be made using this information along with

other pertinent economic variables. For example, when MT⳱0.2,

the optimum pattern probably will not be an inverted nine-spot

because this pattern would provide approximately one-half the rate

that could be achieved with a normal seven-spot. Even though it

provides maximum flow capacity, the normal seven-spot ulti-

mately may not be the optimum pattern for this system, depending

on the capital investment required to convert wells to injection,

install the necessary fluid handling facilities, etc. Conversely,

when MT⳱5.0, it would not be necessary to convert more injection

wells than required for an inverted nine-spot because this pattern

provides 98% of the maximum possible reservoir flow rate. Note

that when 0.2<MT<5.0, a five-spot will provide at least 87% of the

flow capacity of (P/I)max.

The conductivity relationship for any total mobility ratio can be

determined with the procedure outlined above. The relative cost/

benefit of implementing the various patterns can then be evaluated

easily in reservoirs that can be considered homogeneous and iso-

tropic, as well as in heterogeneous, isotropic reservoirs, as dis-

cussed later. Fig. 5—Hybrid pattern with P/I=5:3 or 3:5.

October 2003 SPE Reservoir Evaluation & Engineering 321

Fig. 7 shows the oil relative permeability curves calculated

with Eq. 31 for m⳱1, 2, 3, 4, and 5 and for ␣1⳱1.0, as also

presented in Ref. 12. The water relative permeability curve calcu-

lated from Eq. 33 for n⳱2.0 is also shown, where ␣2⳱0.10. Note

that only the exponents m and n (primarily m) are characteristic to

the correlation to be presented, while the endpoint relative perme-

abilities are simply scaling factors; thus, any endpoint relative

permeabilities can be used in the correlation. For the correlation to

be presented, only the oil exponent m was varied, while the water

exponent n was fixed at n⳱2.0.

The correlation shown below is based on the average rate be-

fore water breakthrough, where MT was back-calculated according

to a rearranged form of Eq. 20,

PⲐI

冋 册

MT = . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 34)

kh⌬P共P Ⲑ I兲TP

− 1

141.2pD( pat) qavg

Fig. 6—Conductivity relationships for MT=0.2 and MT=5.0.

Note that TI is calculated from the value of MT obtained from the

correlation and the specific endpoint value of TP for a given

that s(inj) and s(prod) are the average skin factors for the injectors reservoir, with TI⳱MTTP.

and producers, respectively. Even though the individual well skin Table 1 shows the correlation between MT and M for the oil

factors are constant, s(inj) and s(prod) can change if the relative flow relative permeability exponents shown in Fig. 7 (m=1, 2, 3, 4, and

rates of the element injectors or producers change according to 5 for the five-spot, the inverted nine-spot, and the normal nine-spot

Eqs. 28 and 29. Changes in s(inj) and s(prod) in turn result in changes patterns). Fig. 8 shows this information graphically for exponents

to P̃/Ĩ (Eq. 27). The average injection well flow-rate equation (Eq. m⳱1, 3, and 5, while Fig. 9 shows the relationships for exponents

20), including skin, becomes m⳱2 and 4.

When comparing patterns using a single value of MT in the

P̃ Ⲑ Ĩ ⌬P kh conductivity-ratio relationship (Eq. 25), the value for the inverted

qinj = TI ⳯ ⳯ . . . . . . . . . . . . ( 30) nine-spot in Table 1 should be used because patterns with higher

MT + P̃ Ⲑ Ĩ 关pD( pat) + s共inj兲兴 141.2

P/Is are more sensitive to any variations in MT.20

An interesting aspect of pattern flow behavior that can be in-

vestigated with Eqs. 26 through 30 is the incremental benefit of Determining MT After Water Breakthrough

stimulating the producers vs. the injectors, and how in some cases

The equations presented also apply after water breakthrough.

little benefit is obtained by stimulating one type of well relative to

However, after breakthrough the calculation of Teff for the pro-

the other, which depends on P/I and MT. Take, for example, a

ducing wells is further complicated by the fact that total mobility

system with MT⳱0.10 and pD(pat)⳱8.2. If the pattern is a five-spot

is not uniform at a given radial distance away from a producer

(P/I⳱1.0) with all wells initially having s⳱0, then the throughput

because of the nonradial advance, or cusping, of the flood front

rate can be increased 50% if the injectors are stimulated to a skin

toward the producers. This necessitates that the total mobilities at

of s⳱–3.0. However, only a 3.4% increase can be achieved if the

a given radial distance from a producer are first averaged accord-

same stimulation is done to the producers. There is a synergistic

ing to Eq. 7b before being incorporated into the calculation given

effect if both producers and injectors are stimulated—in this case,

by Eq. 7a. However, the equations presented are equally valid

a 58% increase. This case is a good example of a system that is

after breakthrough.

injection-capacity limited, in which an increase in production flow

capacity has a relatively minor effect.

Heterogeneous (Isotropic) Reservoirs

Correlation of M and MT for Prebreakthrough Period If the permeability is different around individual wells, as might be

A correlation for the total mobility ratio, MT, vs. the endpoint determined from well tests, then the permeability thickness of each

mobility ratio, M, is presented for a range of oil relative perme-

ability curve shapes. This correlation was developed from simu-

lation results and applies to the prebreakthrough period for a res-

ervoir that originally is at irreducible water saturation. The corre-

lation can be used to predict average reservoir flow rates and

pressures using the equations presented. The prebreakthrough per-

formance is treated because of its significance to the economics of

a project.

Correlation Methodology. Willhite12 shows how a range of oil

relative permeability curves can be obtained based on varying the

exponent m in the relative permeability relationship given by

kro = ␣1共1 − SwD兲m, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 31)

where

Sw − Siw

SwD = . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 32)

1 − Sor − Siw

The water relative permeability is given by the relationship Fig. 7—Oil relative permeability curves as calculated from Eq.

31 for different m exponents and water relative permeability as

krw = ␣2 SwDn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 33) calculated from Eq. 33 for n=2 (after Willhite12).

322 October 2003 SPE Reservoir Evaluation & Engineering

Fig. 8—Average MT before water breakthrough vs. M for oil rela-

tive permeability exponents m=1, m=3, and m=5.

NP

兺f

j= 1

共j兲 ⳯ Teff共j兲 ⳯ kh共j兲

and TP( abs) = NP

, . . . . . . . . . . . . . . . . . . . . ( 35b)

兺f

j= 1

共j兲

where kh has now been included with mobility. Then, these aver-

age absolute effective total mobilities are used in the equations in

the same way as those defined in Eqs. 3a and 3b. Eq. 20 then

becomes

PⲐI ⌬P

qinj = TI( abs) ⳯ , . . . . . . . . . . . . . . . . . . . ( 36)

MT + P Ⲑ I 141.2pD( pat兲

where total mobility ratio MT is also calculated with TI(abs) and

TP(abs) using Eq. 2.

Conductivity Relationships in Heterogeneous Reservoirs. If the

reservoir heterogeneity is limited to variable formation permeabil-

ity thickness, kh, and/or variable porosity thickness, h, and not

anisotropy, then the conductivity relationships presented for ho-

mogeneous systems can be used with good results if the following

condition applies:

NP

兺f

j= 1

共j兲 ⳯ kh共j兲

PⲐI = NI

; . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( 37)

兺f

j= 1

共j兲 ⳯ kh共j兲

pattern well can be incorporated into the average effective relative

total mobility calculation (Eq. 3) to result in an average effective

absolute total mobility for injection and production as

NI

兺f

j= 1

共j兲 ⳯ Teff共j兲 ⳯ kh共j兲

TI( abs) = NI

. . . . . . . . . . . . . . . . . . . . . . ( 35a)

兺f

j= 1

共j兲 Fig. 9—Average MT before water breakthrough vs. M for oil rela-

tive permeability exponents m=2 and m=4.

October 2003 SPE Reservoir Evaluation & Engineering 323

that is, the total permeability thickness of the producers to that of the correlation), as is the endpoint water relative permeability,

the injectors is approximately equal to P/I for any pattern that ␣2⳱0.10.

might be implemented in the reservoir. The probability of this Calculate Endpoint Mobility Ratio, M. The endpoint mobility

condition applying to a given reservoir should increase as the ratio M is calculated as follows:

number of wells increases.

krw Ⲑ w 0.1 Ⲑ 0.8

M= = = 0.30. . . . . . . . . . . . . . . . . . . . . . . . . . ( 38)

Correlation of M vs. MT Applied to Heterogeneous Reser- krow Ⲑ o 1.0 Ⲑ 2.4

voirs. The correlation of M vs. MT presented above can be applied Using Table 1, we see that there are no tabulated values for the

to heterogeneous, isotropic reservoirs if pore volume is homoge- mobility ratio M⳱0.3 at the exponent m⳱2.5. We can, however,

neous using the adjustments to the flow equations discussed pre- interpolate a value using these parameters for the inverted nine-

viously. However, the correlation becomes more approximate if spot (which can be used for all patterns, as discussed earlier) and

pore volume is heterogeneous, especially in systems in which arrive at MT⳱0.291. The conductivity relationship for MT⳱0.291

M>1.0. This is because the pore volume around each injector de- will be very similar to that for MT⳱0.2, shown in Fig. 6. There-

termines how quickly the flood front moves away from the well fore, we expect that (P/I)max is close to 0.5, or the normal seven-

(which in turn affects how the total mobility profile changes as a spot pattern, while (P/I)min is 3.0, or the inverted nine-spot pattern.

function of time), and the calculation of TI. Thus, the injection

mobility profile and the resulting calculation for MT can be some- Calculate Absolute Well and Reservoir Flow Rates for

what different depending on the degree of pore-volume heteroge- MT=0.291. The absolute flow rates that will be provided by the

neity. This is not as big of a concern when M<1.0 because the total various patterns for the reservoir system discussed earlier can be

mobility of the injection wells, or TI, is established at the endpoint calculated using Eq. 20 as follows, with MT⳱0.291. First, TP will

mobility of water more quickly than when M>1.0. be equal to the endpoint total mobility of the oil, assuming that the

reservoir is at Siw. Thus, TP is calculated as

Example Calculations

krow 1.0

The following example calculations will demonstrate the use of the TP = = = 0.417 cp− 1. . . . . . . . . . . . . . . . . . . . . . . . . . . ( 39)

equations and concepts presented in this paper, as well as the o 2.4

correlation for the total mobility ratio, MT, vs. the endpoint mo- TI can be calculated knowing MT and TP (Eq. 2) as

bility ratio, M, as presented in Table 1.

TI = MTTP = 0.291 ⳯ 0.417 = 0.121 cp− 1. . . . . . . . . . . . . . ( 40)

Determining Endpoint Mobility Ratio, M, and Prebreak-

pD(pat) for the inverted nine-spot can be calculated with Eq. 17,

through MT. Fig. 10 shows the two-phase water/oil relative per-

using R⳱1.0 as discussed in the text, as

meability curves using the correlation presented by Honarpour22

for a water-wet sandstone reservoir with the following reservoir pa- 933.4 1 0.693

rameters: Siw⳱0.31, Sor⳱0.325, k ⳱10.0 md, and =0.12. Addi- pD( pat) = ln − 0.272 − ⳯ = 7.55. . . . . . . . . . . ( 41)

0.33 2 2 + 1.0

tional reservoir information is as follows: ⌬P⳱4,190 psi; h⳱25 ft;

depth⳱5,300 ft; spacing⳱20 acres; d⳱933.4 ft for five-spot, nine- The pD(pat) can also be calculated using Eq. 19, which is within

spot, or direct line-drive with d/a⳱1.0; d⳱1.0745×933.4⳱1002.9 ft 2.5% for any pattern:

for hexagonal seven-spot; wellbore radius rw⳱0.33 ft; o⳱2.4 cp;

933.4

and w⳱0.80 cp. pD( pat) = ln − 0.443 = 7.50. . . . . . . . . . . . . . . . . . . . . . . . ( 42)

0.33

Fit Relative Permeability Data. The first step is to fit the relative Thus, using the parameters given above and pD(pat)⳱7.50, the

permeability data for the field using Eqs. 31 through 33. Fig. 10 injection well rate for the inverted nine-spot is calculated with

shows how the oil relative permeability data were curve fit using Eq. 20 as

an m exponent equal to 2.50 and an endpoint oil relative perme-

ability of ␣1⳱1.0. As also shown in Fig. 10, it is more important 3.0 4190 (10.0)(25)

to match the oil relative permeability values at higher water satu- qinj = 0.121 ⳯ ⳯ ⳱109 RB/D, . . ( 43)

0.291 + 3.0 7.50 141.2

rations than at lower because this region has a more significant

influence on the water relative permeability in the swept portion of which, according to the conditions of Table 1, is the average in-

the reservoir. The water relative permeability data fit using Eq. 33 jection well rate before water breakthrough. The reservoir through-

and an n exponent equal to 2.0 is also shown (n is fixed at 2.0 for put rate, as given by Eq. 23, is calculated as

qinj 109

q̃ = = = 27 RBⲐDⲐwell . . . . . . . . . . . . . . . . . . ( 44)

1 + P Ⲑ I 1 + 3.0

(i.e., the rate per pattern well). pD(pat) for the seven-spot is calcu-

lated according to Eq. 16. For the hexagonal seven-spot, the in-

terwell distance must be greater than that of the nine-spot by a

factor of 1.0745 for equal well density. Thus, pD(pat) for the seven-

spot is

共933.4兲共1.0745兲

pD( pat) = ln − 0.569 = 7.45. . . . . . . . . . . . . . . ( 45)

0.33

pD(pat) for the seven-spot in a square well arrangement (i.e., the

skewed four-spot) will be very close to that for the hexagonal

seven-spot. Once again, we can use this pD(pat) or simply use that

given by Eq. 19 as 7.50. The injection well rate for the normal

seven-spot (P/I⳱0.5) is likewise calculated according to Eq. 20 as

0.5 4190 共10.0兲共25兲

qinj = 0.121 ⳯ ⳯ = 76 RBⲐD.

0.291 + 0.5 7.50 141.2

. . . . . . . . . . . . . . . . . . . . . . . . . . (46)

Fig. 10—Oil and water relative permeability curves using Ho-

narpour’s correlation22 for a water-wet sandstone reservoir. The reservoir throughput rate is calculated as

324 October 2003 SPE Reservoir Evaluation & Engineering

qinj 76 Nomenclature

q̃ = = = 50 RBⲐDⲐwell. . . . . . . . . . . . . . . . . . . ( 47)

1 + P Ⲑ I 1 + 0.5 a ⳱ line-drive distance between wells within same row,

Thus, even though the individual injection well rate is lower for the ft

normal seven-spot as compared to the inverted nine-spot, the res- d ⳱ interwell distance, or distance between well rows for

ervoir throughput rate is 87% greater. It should be remembered line-drive patterns, ft

that these equations are for flow rates at reservoir conditions, and f ⳱ fraction of a well’s flow rate contributing to pattern

formation volume factors must be included to calculate surface element, dimensionless

production and injection rates. h ⳱ formation thickness, ft

Influence of Skin Effect. The relative benefit of stimulating the k ⳱ permeability, md

injectors vs. producers should also be evaluated. Using Eq. 30, it kro ⳱ relative permeability to oil in the presence of water,

can be seen that a conductivity ratio in the presence of skin effect dimensionless

can be defined similarly to Eq. 25 as krw ⳱ relative permeability to water, dimensionless

m ⳱ oil relative permeability equation exponent (see Eq.

q̃共1兲 共P̃ Ⲑ Ĩ兲1 共MT + P̃ Ⲑ Ĩ兲2 共1 + P Ⲑ I兲2 关pD( pat) + s( inj) 兴2 31)

= . . . . . . . . ( 48)

q̃共2兲 共P̃ Ⲑ Ĩ兲2 共MT + P̃ Ⲑ Ĩ兲1 共1 + P Ⲑ I兲1 关pD( pat) + s( inj) 兴1 M ⳱ mobility ratio based on relative permeability

endpoints, dimensionless

Note that Eq. 48 involves both the physical and effective producer/

injector ratios, P/I and P̃/P̃, respectively. If we consider stimulat- Mt ⳱ total mobility ratio, dimensionless (after Ref. 12)

ing only the producers to a –3.0 skin, then the effective P/I (Eq. 27) MT ⳱ total mobility ratio (Eq. 2), dimensionless

for any pattern is given by n ⳱ water relative permeability equation exponent (see

Eq. 33)

共7.5 + 0兲 NI ⳱ number of injectors in pattern element

P̃ Ⲑ Ĩ = P Ⲑ I ⳯ = P Ⲑ I ⳯ 1.67. . . . . . . . . . . . . . . . . . ( 49)

共7.5 − 3.0兲 NP ⳱ number of producers in pattern element

If it is determined from the preceding analysis that the optimum pD(pat) ⳱ steady-state pattern dimensionless pressure,

pattern is the five-spot, then P/I⳱1.0 and P̃/P̃⳱1.67. Then, the dimensionless

increase in throughput rate from stimulating only the producers pD(SS) ⳱ steady-state dimensionless pressure, dimensionless

(where p(2) is the zero skin reference case) according to Eq. 48 is ppat ⳱ volumetric average reservoir pressure of pattern, psi

pwfI ⳱ sandface pressure of injection wells, psi

q̃共1兲 共1.67兲1 共0.291 + 1.0兲2 共1 + 1.0兲2 共7.5 + 0兲2

= = 1.10, . . ( 50) pwfP ⳱ sandface pressure of production wells, psi

q̃共2兲 共1.0兲2 共0.291 + 1.67兲1 共1 + 1.0兲1 共7.5 + 0兲1 P/I ⳱ physical producer/injector ratio, dimensionless

or only a 10% increase will result. The benefit of stimulating only (P/I)max ⳱ producer/injector ratio of maximum conductivity,

the injectors to the same skin of –3.0 can be determined in the dimensionless

same way as (P/I)min ⳱ producer/injector ratio of minimum conductivity,

q̃共1兲 共0.60兲1 共0.291 + 1.0兲2 共1 + 1.0兲2 共7.5 + 0兲2 dimensionless

= = 1.45 . . . ( 51) P̃/Ĩ ⳱ effective producer/injector ratio in the presence of

q̃共2兲 共1.0兲2 共0.291 + 0.60兲1 共1 + 1.0兲1 共7.5 − 3.0兲1 skin effect, dimensionless

(i.e., a 45% increase in rate). Stimulating both producers and in- q̃ ⳱ normalized pattern reservoir, or throughput, rate,

jectors will result in RB/D/well

qavg ⳱ average flow rate before breakthrough, RB/D

q̃共1兲 共1.0兲1 共0.291 + 1.0兲2 共1 + 1.0兲2 共7.5 + 0兲2

= = 1.67 . . . . . ( 52) qinj ⳱ average rate of pattern injectors, RB/D

q̃共2兲 共1.0兲2 共0.291 + 1.0兲1 共1 + 1.0兲1 共7.5 − 3.0兲1 qprod ⳱ average rate of pattern producers, RB/D

(i.e., a 67% increase in throughput rate). As can be seen from Eq. R ⳱ ratio of corner to side-well flow rates for nine-spot,

27 and Eq. 48, when both types of wells have the same skin factor, dimensionless

the effective P/I is equal to the physical P/I, and therefore the same rw ⳱ wellbore radius, ft

improvement (67%) will be obtained regardless of the pattern. rf ⳱ flood-front radius, ft

However, the relative amount of improvement attributable to the s ⳱ well skin factor, dimensionless

injectors vs. the producers will be different depending on P/I s(inj) ⳱ average skin factor for injectors (Eq. 28),

and MT. dimensionless

s(prod) ⳱ average skin factor for producers (Eq. 29),

Conclusions

dimensionless

This paper presents new equations for steady-state pattern flow

Siw ⳱ irreducible water saturation, dimensionless

performance in isotropic reservoirs. The relationships reveal how

P/I and a newly defined total mobility ratio are key mechanisms Sor ⳱residual oil saturation, dimensionless

controlling pattern rates and pressures. SwD ⳱ dimensionless water saturation (Eq. 32)

A single, generalized pattern flow equation unifies previous ␣1 ⳱ endpoint oil relative permeability in presence of

works while greatly expanding the range of application to all pat- water, dimensionless

terns and mobility ratios. This equation makes comparing the rela- ␣2 ⳱ endpoint water relative permeability, dimensionless

tive flow performance of the various patterns before breakthrough ⌬P ⳱ interwell pressure drop from injector to producer,

possible when used in conjunction with the correlation presented psi

between endpoint mobility ratio and total mobility ratio. The eco- ⳱ included angle of well in pattern element, radians

nomically optimum pattern can be determined analytically using rf–1 ⳱ average reciprocal of total mobility (“apparent

these relationships and other pertinent economic variables.

visocity” in Ref. 12), cp

We also show how the new relationships can be modified to

include skin effect and reservoir heterogeneity. The relationships r–1 ⳱ reciprocal of total mobility at radial distance r

including skin effect are useful to determine the relative benefit (“apparent viscosity” in Ref. 12), cp

of stimulating the pattern producers vs. injectors, which can be T ⳱ total mobility, cp–1

dramatically different depending on the pattern and total mobil- Teff ⳱ effective well total mobility, cp–1

ity ratio. T(r) ⳱ average T at radius r, cp–1

October 2003 SPE Reservoir Evaluation & Engineering 325

TI ⳱ average effective total mobility of injection, cp–1 21. Dyes, A.B., Caudle, B.H., and Erickson, R.A.: “Oil Production After

TP(abs) ⳱ average absolute effective total mobility of injection, Breakthrough—As Influenced by Mobility Ratio,” Trans., AIME

md-ft-cp–1 (1954) 201, 81.

TP ⳱ average effective total mobility of production, cp–1 22. Honarpour, M., Koederitz, L., and Harvey, A.H.: Relative Permeability

TP(abs) ⳱ average absolute effective total mobility of of Petroleum Reservoirs, CRC Press, LLC (1986).

production, md-ft-cp–1

o ⳱ oil viscosity, cp Appendix A—Derivation of pD(pat) for the

Nine-Spot

w ⳱ water viscosity, cp

⳱ porosity, fraction The equations for the nine-spot using “ideal” flow assumptions

(see main text) were given by Deppe2 as follows. In terms of the

Acknowledgments corner well sandface pressure, pwfc, the equation is

The authors wish to thank Erdal Ozkan and Robert Thompson of

0.003541kh共⌬Pi,c兲

冉 冊

the Colorado School of Mines and Neil Humphreys of ExxonMo- q= . . . . . . . . . . . . . . . . . . . . . . . . . . . ( A-1)

bil for their helpful review and input into the content of this paper. 1+ R d

ln − 0.272

Also, thanks to Alda Behie (Aldanumerics Ltd., Calgary), Tony 2+ R rw

Settari (U. of Calgary, Taurus Reservoir Solutions), and Duke

Engineering & Services (Calgary) for use of their black-oil simu- In terms of the side well sandface pressure, pwfs, the equation is

lator to generate the numerical results presented in this paper.

0.007082kh共⌬Pi,s兲

冋 冉 冊 册

References q= . . . . . . . . . . . . . . . . ( A-2)

3+ R d 0.693

1. Muskat, M.: Flow of Homogeneous Fluids, IHRDC, Boston, Massa- ln − 0.272 −

2+ R rw 2+ R

chusetts (1982).

2. Deppe, J.C.: “Injection Rates—The Effect of Mobility Ratio, Area For the single-phase case, a more general form of Eq. 1 applies that

Swept, and Pattern,” SPEJ (June 1961) 81; Trans., AIME, 222. does not require that the sandface pressures of the side and corner

3. Aronofsky, J.S. and Ramey, H.J. Jr.: “Mobility Ratio—Its Influence on wells be the same, as was necessary in deriving Eq. 1 for two-

Injection and Production Histories in Five-Spot Water Flood,” Trans., phase conditions. For the single-phase case, a more general defi-

AIME (1956) 207, 205. nition of pwfI and pwfP applies20:

4. Caudle, B.H. and Witte, M.D.: “Production Potential Changes During

Sweep-Out in a Five-Spot System,” JPT (December 1959) 63; Trans., NI

AIME, 216.

5. Nobles, M.A. and Janzen, H.B.: “Application of a Resistance Network

兺f

j= 1

共j兲 ⳯ pwf共j兲

for Studying Mobility Ratio Effects,” Trans., AIME (1958) 213, 356.

pwfI = NI

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( A-3)

6. Prats, M. et al.: “Prediction of Injection Rate and Production History

for Multifluid Five-Spot Floods,” JPT (May 1959) 98; Trans., AIME,

兺f

j= 1

共j兲

216.

7. Caudle, B.H., Hickman, B.M., and Silberberg, I.H.: “Performance of and

the Skewed Four-Spot Injection Pattern,” JPT (November 1968) 1315; NP

Trans., AIME, 243.

8. Hauber, W.C.: “Prediction of Waterflood Performance for Arbitrary 兺f

j= 1

共j兲 ⳯ pwf共j兲

Well Patterns and Mobility Ratios,” JPT (January 1964) 95; Trans., pwfP = NP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( A-4)

兺f

AIME, 231.

9. Cotman, N.T., Still, G.R., and Crawford, P.B.: “Laboratory Compari- 共j兲

j= 1

son of Oil Recovery in Five-Spot and Nine-Spot Waterflood Patterns,”

Prod. Monthly (December 1962) 27, No. 12, 10. So, referring to the element of the inverted nine-spot in Fig. 1,

10. Watson, R.E., Silberberg, I.H., and Caudle, B.H.: “Model Studies of the application of Eq. A-4 will result in the following:

Inverted Nine-Spot Injection Pattern,” JPT (July 1964) 801; Trans.,

AIME, 231. pwfP = 2 Ⲑ 3pwfs + 1 Ⲑ 3pwfc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( A-5)

11. Muskat, M.: “The Theory of Nine-Spot Flooding Networks,” Prod.

Monthly (March 1948) 12, 14. Therefore, defining an interwell pressure drop, ⌬P, that is con-

12. Willhite, G.P.: Waterflooding, Textbook Series, Society of Petroleum sistent with the average reservoir pressure definition (Eq. 1) is

Engineers, Richardson, Texas (1986) 3. given as

13. Douglas, J. Jr., Peaceman, D.W., and Rachford, H.H. Jr.: “A Method

for Calculating Multi-Dimensional Immiscible Displacement,” Trans., ⌬P = pwfI − 共2 Ⲑ 3pwfs + 1 Ⲑ 3pwfc兲. . . . . . . . . . . . . . . . . . . . . . . . ( A-6)

AIME (1959) 216, 297.

14. Higgins, R.V. and Leighton, A.J.: “A Computer Method of Calculating

Note that Eq. A-6 also can be written as

Two-Phase Flow in Any Irregularly Bounded Porous Medium,” JPT

⌬P = 1 Ⲑ 3共pwfI − pwfc兲 + 2 Ⲑ 3共pwfI − pwfs兲. . . . . . . . . . . . . . . . . ( A-7)

(June 1962) 679; Trans., AIME, 225.

15. Fanchi, J.R.: Principles of Applied Reservoir Simulation, Butterworth- In terms of Eqs. A-1 and A-2,

Heinemann, Boston, Massachusetts (2001).

16. LeBlanc, J.L. and Caudle, B.H.: “A Streamline Model for Secondary

Recovery,” SPEJ (March 1971) 7.

17. Martin, J.C. and Wegner, R.E.: “Numerical Solution of Multiphase, pwfI − pwfc =

1+ R

2+ R

d

ln − 0.272 q

rw 冉 冊

. . . . . . . . . . . . . . . . . ( A-8)

Two-Dimensional Incompressible Flow Using Stream-Tube Relation- 0.003541kh

ships,” SPEJ (October 1979) 313; Trans., AIME, 267.

18. Datta-Gupta, A.: “Streamline Simulation: A Technology Update,” JPT and

冋 冉 冊 册

(December 2000) 68.

19. Craig, F.F. Jr.: The Reservoir Engineering Aspects of Waterflooding,

3+ R d 0.693

ln − 0.272 − q

Monograph Series, SPE, Richardson, Texas (1971) 3. 2+ R rw 2+ R

20. Hansen, C.E.: A General Pattern Flow Theory for Maximizing Water-

pwfI − pwfs = . . . . . . . ( A-9)

0.007082kh

flooding Rates, MS thesis, Colorado School of Mines, Golden, Colo-

rado (May 2001). Therefore, Eq. A-6 can be rewritten using Eqs. A-8 and A-9 as

326 October 2003 SPE Reservoir Evaluation & Engineering

⌬P = pwfI − pwfP

冋 冉 冊 册

SI Metric Conversion Factors

1+ R d

ln − 0.272 q acre × 4.046 873 E+03 ⳱ m2

2+ R rw

= 1Ⲑ3 bbl × 1.589 873 E–01 ⳱ m3

0.003541kh E–03 ⳱

再冋 冎

cp × 1.0* Pa⭈s

= 2Ⲑ3

3+ R

2+ R

d

冉

ln − 0.272 −

rw 冊

0.693

2+ R 册q

.

ft × 3.048*

psi × 6.894 757

E–01 ⳱

E+00 ⳱

m

kPa

0.007082kh * Conversion factor is exact.

. . . . . . . . . . . . . . . . . . . . . . . .(A-10)

We now have all the information necessary to solve for pD(pat) for Chris E. Hansen is a reservoir engineer at EOG Resources Inc. in

the nine-spot that is consistent with the definition of the general- Denver. e-mail: chris_hansen@eogresources.com. His current

ized flow equation given by Eq. 11. Using the inverted nine-spot responsibilities include reservoir studies and development op-

case, we apply the form shown by Eq. 12, which was derived using timization in oil and gas fields throughout the Rocky Mountains

Eq. 1 and Eq. 11a: and California. Previously, he has worked for other major and

independent oil and gas companies in Texas and New

kh共pwfI − pwfP兲 PⲐI Mexico. He holds BS and MS degrees in petroleum engineering

qinj = ⳯ . . . . . . . . . . . . . . . . . . . . . . ( A-11) from the Colorado School of Mines. John R. Fanchi is a profes-

141.2pD( pat) 1 + PⲐI

sor of petroleum engineering at the Colorado School of Mines.

Combining Eqs. A-10 and A-11 and substituting P/I⳱3.0 for the e-mail: jfanchi@mines.edu. He has worked at three major oil

inverted nine-spot, we solve for pD(pat) as shown in Eq. 17: companies and as a consultant. His publications include soft-

ware, numerous articles, and four books, including Principles of

d 1 0.693 Applied Reservoir Simulation and Integrated Flow Modeling.

pD( pat) = ln − 0.272 − ⳯ . . . . . . . . . . . . . . . . . . . ( A-12)

rw 2 2+ R He holds a PhD degree in physics from the U. of Houston.

October 2003 SPE Reservoir Evaluation & Engineering 327

Errata

“Producer/Injector Ratio: The Key to Understanding Pattern Flow Performance and Optimizing Waterflood Design,” by C.E. Hansen and

J.R. Fanchi, which appeared in the October 2003 issue of SPE Reservoir Evaluation & Engineering, contained several misprints in the

equations and text. The corrections are included here:

Page 318 Page 325

Page 326

Page 319

Page 327

366 December 2003 SPE Reservoir Evaluation & Engineering

You might also like

- PSD-S1 Load Cell - Zhengzhou Pushton Electronic Equipment Co.,LtdDocument11 pagesPSD-S1 Load Cell - Zhengzhou Pushton Electronic Equipment Co.,LtdrobyadNo ratings yet

- Garcia 2016Document18 pagesGarcia 2016husseinhshNo ratings yet

- Institute OF Hydrology On The Role of Physically - Based Distributed Ii (Odelling IN HydrologyDocument40 pagesInstitute OF Hydrology On The Role of Physically - Based Distributed Ii (Odelling IN HydrologySudharsananPRSNo ratings yet

- Yu Et Al. - 2019 - A Versatile Lattice Boltzmann Model For Immiscible Ternary Fluid FlowsDocument15 pagesYu Et Al. - 2019 - A Versatile Lattice Boltzmann Model For Immiscible Ternary Fluid Flowsdongwang12126No ratings yet

- Modeling Studies For The Determination of Completely Mixed Activated Sludge Reactor Volume: Steady-State, Empirical and Ann ApplicationsDocument32 pagesModeling Studies For The Determination of Completely Mixed Activated Sludge Reactor Volume: Steady-State, Empirical and Ann ApplicationsNedim HadžiaganovićNo ratings yet

- 10.1.1.870.7908 Conjunctive Interpretation of Core and Log Data Through Association of The Effective and Total Porosity ModelsDocument11 pages10.1.1.870.7908 Conjunctive Interpretation of Core and Log Data Through Association of The Effective and Total Porosity ModelsLorenzo SerraNo ratings yet

- Spe 113903 Pa PDFDocument7 pagesSpe 113903 Pa PDFPOOL SERVICES & SUPLLIESNo ratings yet

- Upgridding Under Multiphase Flow ConditionsDocument16 pagesUpgridding Under Multiphase Flow Conditionshosseindana40No ratings yet

- The Purpose: Areal Grid and LayeringDocument5 pagesThe Purpose: Areal Grid and LayeringAsit PadhiaryNo ratings yet

- Development of A Composite I.P.R. Model For Multi-Layered ReservoirsDocument11 pagesDevelopment of A Composite I.P.R. Model For Multi-Layered ReservoirsAli KiasariNo ratings yet

- Decline Curve Analysis Using Type CurvesDocument15 pagesDecline Curve Analysis Using Type Curvesdorian.axel.ptNo ratings yet

- SPE 71517 Decline Curve Analysis Using Type Curves - Evaluation of Well Performance Behavior in A Multiwell Reservoir SystemDocument15 pagesSPE 71517 Decline Curve Analysis Using Type Curves - Evaluation of Well Performance Behavior in A Multiwell Reservoir SystemGHIFFARI PARAMANTA ELBEESNo ratings yet

- SPE 25423 Transient Wellbore Pressure and Flow Rates in A Commingled System With Different Layer PressuresDocument10 pagesSPE 25423 Transient Wellbore Pressure and Flow Rates in A Commingled System With Different Layer Pressuresbladimir2010No ratings yet

- SPE-168965 Impact of Experimental Studies MRLDocument34 pagesSPE-168965 Impact of Experimental Studies MRLCristal ChávezNo ratings yet

- Spe 59370 TextDocument8 pagesSpe 59370 TextMarielis SifontesNo ratings yet

- Multi Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well FlowDocument9 pagesMulti Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well Flowpetar_damyanovNo ratings yet

- SPE-182704-MS - A Novel IPR Calculation Technique To Reduce Oscillations in Time-Lagged Network-Reservoir Coupled Modeling Using Analytical Scaling and Fast Marching Method PDFDocument12 pagesSPE-182704-MS - A Novel IPR Calculation Technique To Reduce Oscillations in Time-Lagged Network-Reservoir Coupled Modeling Using Analytical Scaling and Fast Marching Method PDFDenis GontarevNo ratings yet

- Modeling Aspects of Wellbore Stability IDocument8 pagesModeling Aspects of Wellbore Stability IAhmed GharbiNo ratings yet

- A multiphase compressible model for the simulation of multiphase flowsDocument11 pagesA multiphase compressible model for the simulation of multiphase flowsAime CHANNo ratings yet

- Bourdet 1985Document12 pagesBourdet 1985husseinhshNo ratings yet

- Dynamic Modeling Startegy For Flow Regime Transition in Gas-Liquid Two Phase FlowsDocument14 pagesDynamic Modeling Startegy For Flow Regime Transition in Gas-Liquid Two Phase FlowsVenkatesh KandalamNo ratings yet

- Chapter 00 - OverviewDocument7 pagesChapter 00 - OverviewLeonardo Octavio Olarte SánchezNo ratings yet

- Nwaokorie 2013Document11 pagesNwaokorie 2013Spica Z FadlyNo ratings yet

- Ijmet 06 10 018Document10 pagesIjmet 06 10 018IAEME PublicationNo ratings yet

- 2006 AIChEJ ARK Flow RegimesDocument19 pages2006 AIChEJ ARK Flow RegimesGopal KasatNo ratings yet

- Spe 79709 Pa P PDFDocument9 pagesSpe 79709 Pa P PDFtomk2220No ratings yet

- Applications of Partial Differential Equations in Reservoir SimulationDocument7 pagesApplications of Partial Differential Equations in Reservoir SimulationAbdul GhaffarNo ratings yet

- Integrated Reservoir Characterization and Modeling-Chapter5Document88 pagesIntegrated Reservoir Characterization and Modeling-Chapter5Bidyut MandalNo ratings yet

- SPE 30217 Well Test Analysis by Reservoir Simulation Coupled With A History Matching ProgramDocument2 pagesSPE 30217 Well Test Analysis by Reservoir Simulation Coupled With A History Matching ProgramNorberto Escobar MoralesNo ratings yet

- 2004 - JMS - Jain & GuptaDocument17 pages2004 - JMS - Jain & GuptasemantNo ratings yet

- A Multiscale Restriction-Smoothed Basis Method For Compressible Black-Oil ModelsDocument18 pagesA Multiscale Restriction-Smoothed Basis Method For Compressible Black-Oil ModelsfronghongNo ratings yet

- Water Resources Research - 2013 - Sheng - Dynamic Coupling of Pore Scale and Reservoir Scale Models For Multiphase FlowDocument16 pagesWater Resources Research - 2013 - Sheng - Dynamic Coupling of Pore Scale and Reservoir Scale Models For Multiphase Flowvcox4460No ratings yet

- 1 s2.0 S1385894708004300 Main PDFDocument7 pages1 s2.0 S1385894708004300 Main PDFashrafmchemNo ratings yet

- Simulation and Design Models For Adsorption ProcessDocument11 pagesSimulation and Design Models For Adsorption ProcessAlbert BittencourtNo ratings yet

- On The Modeling of Water Transport in Polymer Electrolyte Membrane Fuel Cells - Ref For User FunctionDocument15 pagesOn The Modeling of Water Transport in Polymer Electrolyte Membrane Fuel Cells - Ref For User Functionemonome2190No ratings yet

- Chapter 2Document72 pagesChapter 2Seun Sam AdetolaNo ratings yet

- (2012) (Smith) (Mechanistic Modeling of Interfacial Area Transport in Large Diameter Pipes)Document16 pages(2012) (Smith) (Mechanistic Modeling of Interfacial Area Transport in Large Diameter Pipes)Erol BicerNo ratings yet

- Enwald Et AlDocument46 pagesEnwald Et AlBucho Domingos Miguel CangundoNo ratings yet

- Upscaling of Flow Units For Reservoir Flow Incorporating Small-Scale HeterogeneitiesDocument19 pagesUpscaling of Flow Units For Reservoir Flow Incorporating Small-Scale HeterogeneitiessifatNo ratings yet

- Wiggins 2Document12 pagesWiggins 2Christian PradaNo ratings yet

- Xiao HaiDocument14 pagesXiao HaiLuis A G. C.No ratings yet

- SPE 99712 Generalized Horizontal Well Inflow Relationships For Liquid, Gas, or Two-Phase FlowDocument9 pagesSPE 99712 Generalized Horizontal Well Inflow Relationships For Liquid, Gas, or Two-Phase FlowraifelmbNo ratings yet

- 1 s2.0 S0920410521005842 MainDocument18 pages1 s2.0 S0920410521005842 MainFranciani GoedertNo ratings yet

- 30978Document10 pages30978reza_putra_11No ratings yet

- A Downward Structural Sensitivity Analysis of Hydrological Models To Improve Low Flow SimulationDocument11 pagesA Downward Structural Sensitivity Analysis of Hydrological Models To Improve Low Flow SimulationDanny Saavedra OreNo ratings yet

- Shape Relaxation of An Elongated Viscous Drop: K. Moran, A. Yeung, and J. MasliyahDocument11 pagesShape Relaxation of An Elongated Viscous Drop: K. Moran, A. Yeung, and J. MasliyahClaudio BiaginiNo ratings yet

- SPE 88761 - REE April 2006Document15 pagesSPE 88761 - REE April 2006rassunmonuNo ratings yet

- SPE 18565 PA - RelPermOvrvw PDFDocument5 pagesSPE 18565 PA - RelPermOvrvw PDFDavid OtálvaroNo ratings yet

- 5 Paperss Issue-9-2012-219 2 Final3 PDFDocument17 pages5 Paperss Issue-9-2012-219 2 Final3 PDFDr-Moamen Abd El RaoufNo ratings yet

- Vascoand MinkoffDocument20 pagesVascoand MinkoffilichgarNo ratings yet

- Analysis of Jet Flows With The Two-Fluid Particle Interaction MethodDocument11 pagesAnalysis of Jet Flows With The Two-Fluid Particle Interaction MethodWarrior sidNo ratings yet

- SPE 145808 Three-Phase Unsteady-State Relative Permeability Measurements in Consolidated Cores Using Three Immisicible LiquidsDocument12 pagesSPE 145808 Three-Phase Unsteady-State Relative Permeability Measurements in Consolidated Cores Using Three Immisicible LiquidsCristian TorresNo ratings yet

- Effects of Reservoir Heterogeneity On Performance: S F IETYDocument11 pagesEffects of Reservoir Heterogeneity On Performance: S F IETYmartin ferrerNo ratings yet

- CLASTICS How To Choose The Right Petrophysical Evaluation Method Using Standard LogsDocument10 pagesCLASTICS How To Choose The Right Petrophysical Evaluation Method Using Standard LogsRaulNo ratings yet

- Spe 26436 MS PDFDocument16 pagesSpe 26436 MS PDFDaniel Camilo BustosNo ratings yet

- HEM ModelDocument59 pagesHEM ModelPaolo MocellinNo ratings yet

- Ocean Dynamics and Modeling: HypopDocument3 pagesOcean Dynamics and Modeling: HypoppostscriptNo ratings yet

- Hess 28 1539 2024Document29 pagesHess 28 1539 2024Francis-marie colson BeniambieNo ratings yet

- Flujo5005spe 169426 MsDocument38 pagesFlujo5005spe 169426 MsJeanPierre BazanNo ratings yet

- A New Wellbore Position Calculation Method: C.R. Chia, SPE, W.J. Phillips, SPE, and D.L. Aklestad, SPE, SchlumbergerDocument5 pagesA New Wellbore Position Calculation Method: C.R. Chia, SPE, W.J. Phillips, SPE, and D.L. Aklestad, SPE, Schlumbergermohamadi42No ratings yet

- A New Comprehensive, MechanisticDocument10 pagesA New Comprehensive, Mechanisticmohamadi42No ratings yet

- Modeling of Transient Cuttings TransportDocument11 pagesModeling of Transient Cuttings Transportmohamadi42No ratings yet

- The Slug Suppression System in OperationDocument5 pagesThe Slug Suppression System in Operationmohamadi42No ratings yet

- Predicting Permeability From Well Logs inDocument11 pagesPredicting Permeability From Well Logs inmohamadi42No ratings yet

- Lateral Buckling of Pipe With ConnectorsDocument14 pagesLateral Buckling of Pipe With Connectorsmohamadi42No ratings yet

- Propagation of Chromium (III) AcetateDocument7 pagesPropagation of Chromium (III) Acetatemohamadi42No ratings yet

- Maximizing Yibal's Remaining ValueDocument9 pagesMaximizing Yibal's Remaining Valuemohamadi42No ratings yet

- Benchmarking The Formation Damage of Drilling FluidsDocument11 pagesBenchmarking The Formation Damage of Drilling Fluidsmohamadi42No ratings yet

- Gas-Lift Instability Resulted Production Loss and Its Remedy by Feedback ControlDocument9 pagesGas-Lift Instability Resulted Production Loss and Its Remedy by Feedback Controlmohamadi42No ratings yet

- IMPES Stability Selection ofDocument7 pagesIMPES Stability Selection ofmohamadi42No ratings yet

- Massive Hydraulic Fracturing - A Case History in Western Siberia, RussiaDocument12 pagesMassive Hydraulic Fracturing - A Case History in Western Siberia, Russiamohamadi42No ratings yet

- Waterflooding in Low NG Fluvial Environment - Thai Shell ExperienceDocument7 pagesWaterflooding in Low NG Fluvial Environment - Thai Shell Experiencemohamadi42No ratings yet

- Propellant Perforation Breakdown Technique Eastern Venezuela Field ApplicationsDocument15 pagesPropellant Perforation Breakdown Technique Eastern Venezuela Field Applicationsmohamadi42No ratings yet

- SPE 84842 Comparing Fracture Simulation Design To Radioactive Tracer Field Results: A Case HistoryDocument9 pagesSPE 84842 Comparing Fracture Simulation Design To Radioactive Tracer Field Results: A Case Historymohamadi42No ratings yet

- Pore Scale Network Modeling of Relative Permeability in Chemical FloodingDocument6 pagesPore Scale Network Modeling of Relative Permeability in Chemical Floodingmohamadi42No ratings yet

- Application of A New Class of Surfactants in Stimulation TreatmentsDocument10 pagesApplication of A New Class of Surfactants in Stimulation Treatmentsmohamadi42No ratings yet

- Robotics and Manipulators For Reactor Pressure Vessel Head InspectionDocument6 pagesRobotics and Manipulators For Reactor Pressure Vessel Head InspectionSEP-PublisherNo ratings yet

- # Python3 Program To Swap First and Last Element of A ListDocument25 pages# Python3 Program To Swap First and Last Element of A ListJomaina AhmedNo ratings yet

- CITEC - Genesis Catalogue 2008 FinalDocument12 pagesCITEC - Genesis Catalogue 2008 FinalDenny100% (3)

- Seabeacon 2Document27 pagesSeabeacon 2josecamposx24No ratings yet

- Predicative Complexes With The InfinitiveDocument3 pagesPredicative Complexes With The InfinitiveКарина КупрашNo ratings yet

- Chapter 6Document118 pagesChapter 6fanusNo ratings yet

- ELE447 Exp 4Document4 pagesELE447 Exp 4Fikret LockeNo ratings yet

- Bme Digital NotesDocument88 pagesBme Digital NotesAkshay KharmateNo ratings yet

- Math4 Quadrilaterals Semi Detailed Lesson Plan 2Document5 pagesMath4 Quadrilaterals Semi Detailed Lesson Plan 2Ellen CanjaNo ratings yet

- 1.1 Detailed Workload MatrixDocument2 pages1.1 Detailed Workload MatrixFaZe MoHANo ratings yet

- Electro-Motive Division General M O T O R S C0Rpof2AtlonDocument6 pagesElectro-Motive Division General M O T O R S C0Rpof2Atlonamir barekatiNo ratings yet

- Analysis of Flywheel Used in Petrol Engine Car IJERTV3IS051286Document5 pagesAnalysis of Flywheel Used in Petrol Engine Car IJERTV3IS051286sadman.me.20200208042No ratings yet

- Travelling Wave and Broadband Antennas / Frequency - Independent AntennaDocument66 pagesTravelling Wave and Broadband Antennas / Frequency - Independent Antennasurendraloya99No ratings yet

- Aspire TC-780 Desktop Computer Service GuideDocument138 pagesAspire TC-780 Desktop Computer Service GuideWarapot WongsiriNo ratings yet

- SBA #9 - Activity of Salivary AmylaseDocument5 pagesSBA #9 - Activity of Salivary AmylaselucyNo ratings yet

- The Time: TO PastDocument3 pagesThe Time: TO PastYeli GarcíaNo ratings yet

- Laterally Loaded Piles PDFDocument16 pagesLaterally Loaded Piles PDFriad10No ratings yet

- 03 Chapter 04 - Part 1 - 05Document41 pages03 Chapter 04 - Part 1 - 05MmmmohNo ratings yet

- Balancing of Reciprocating MassesDocument74 pagesBalancing of Reciprocating MassesPinky DeyNo ratings yet

- Physics Yearly Lesson Plan f4Document22 pagesPhysics Yearly Lesson Plan f4Rubiah BasriNo ratings yet

- Data Integration & TransformationDocument14 pagesData Integration & TransformationRupesh VNo ratings yet

- FC & ICC2 CMNDSDocument34 pagesFC & ICC2 CMNDSshagufta.mujeebNo ratings yet

- Bricks Notes For AL Tech by Hafeel SirDocument84 pagesBricks Notes For AL Tech by Hafeel SirIhthisam hamzaNo ratings yet

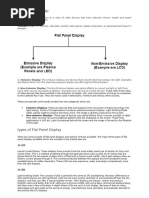

- Flat Panel DisplayDocument2 pagesFlat Panel DisplayAnchal SharmaNo ratings yet

- Name: - Section: - ScoreDocument2 pagesName: - Section: - ScoreJoenald Kent Ordoña100% (1)

- Passed H12Document13 pagesPassed H12Anonymous cs4BLczE0% (1)

- Year 11 Paper 3 Higher Autumn (A) 2021Document12 pagesYear 11 Paper 3 Higher Autumn (A) 2021zaara.kauserxNo ratings yet

- AcerDocument4 pagesAcerMrLaptop MYNo ratings yet

- Fema 310 CH-5Document3 pagesFema 310 CH-5Ibis GonzalezNo ratings yet