Checklist For Const Building Supervisors PDF

Checklist For Const Building Supervisors PDF

Uploaded by

Miky TemaCopyright:

Available Formats

Checklist For Const Building Supervisors PDF

Checklist For Const Building Supervisors PDF

Uploaded by

Miky TemaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Checklist For Const Building Supervisors PDF

Checklist For Const Building Supervisors PDF

Uploaded by

Miky TemaCopyright:

Available Formats

Check List for use by Building Construction Supervisors 1

FEDERAL DEMOCRATIC REPUBLIC OF ETHIOPIA

MINISTRY OF WORKS AND URBAN DEVELOPMENT

CHECK – LIST

FOR USE BY BUILDING CONSTRUCTION SUPERVISORS

Ministry of Works and Urban Development

Addis Ababa, Ethiopia

2001

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 2

FOREWORD

The Proclamation to define the powers and duties of the Federal and Regional Executive

organs of the Federal Democratic republic of Ethiopia No. 4/1995 empowers the Ministry of

Works & Urban Development to prepare the Country's Building Code, issue Standards and

Guidelines for design and construction works, registration of professionals and consultants and

follow up and supervise the implementation of same.

In exercising these powers and in discharging of its responsibilities, the Ministry is issuing a

series of Building Code Standards, Manuals and Guidelines of general application.

The purpose of these documents is to serve as nationally recognized documents, the application

of which is deemed to ensure compliance of constructions with the minimum requirements for

design, procurement procedures, construction and quality of materials set down by the

Ministry.

The major benefits to be gained in applying these documents are the harmonization of

professional practice and the ensuring of appropriate levels of safety, health and economy with

due consideration of the objective conditions and needs of the country.

As the documents are technical documents which, by their very nature, require periodic

updating, revised editions will be issued by the Ministry from time to time as appropriate.

The Ministry welcomes comments and suggestions on all aspect of the documents. All

feedback received will be carefully reviewed by professional experts in the field with a view to

possible incorporation of amendments in the future editions.

Haile Assegide

Minister

Ministry of Works and

Urban Development

2001

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 3

PREFACE

This check-list for site supervisors is issued by the Ministry of Works and Urban Development for

use by Employers, Consultants and Contractors in order to ensure a uniform system of supervision

of building construction projects and as a result ensure a safe and durable construction. It is to be of

use mainly when construction works are carried out by contractors and can in some ways be of use

for construction carried out by direct labour. In this check-list the responsibilities, liabilities and

limitations of the supervisor are briefly mentioned. The steps to be followed in checking building

construction works are expressed in general terms. Details of construction are specified in the

drawings, technical specifications and in the general and special provisions of the contract. The duty

of the site supervisor is to ensure that the construction works are executed in accordance with the

contract requirements. Therefore in the application of this check-list the details specified in the

contract document always precede before the application and use of it. There are also tables and

forms in this check-list that help as records of the incidences affecting the work and as references. In

addition the standard technical specification is used as reference on the preparation of this check-

list.

ACKNOWLEDGEMENT

In July 2000, the Ministry of Works and Urban Development invited National

Consulting firms to compete for the preparation of codes and manuals. One of

these, is the present " ______________________"

Tessema Demisse Consulting Architects and Engineers was awarded the

contract for the preparation of this document, and prepared it in association with

professionals.

The working group of the document was:

Damtew Wolde, __________________,

who drafted the document; and

Beyene Wolde Gabriel, B.Sc. (Eng.),

who reviewed the document with comments and suggestions.

The document is based on " ________________________ " prepared by the

World Bank for use of its browses.

After presentation to the MoWUD, the document was commented on by

professionals of the Ministry and other invited institutions and individuals.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 4

MoWUD wishes to acknowledge the contributions made by the Consulting Office

and the associated professionals involved in its preparation and to thank all those

who made comments.

Our thanks also to ________________ for use of their document.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 5

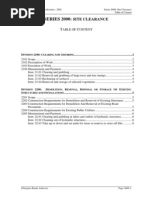

TABLE OF CONTENTS

PAGE

FORWARD ……………………………………………………………………… 1

PREFACE .............................................................................................................. 2

ACKNOWLEDGEMENT ...................................................................................... 3

1. INVESTIGATION & PREPARATION OF SITE ...................................................... 6

2. SETTING OUT .......................................................................................................... 6

3. EXCAVATION & EARTHWORK ............................................................................ 6

4. FOUNDATION TRENCH & PIT EXCAVATION .................................................... 7

5. FOUNDATION IN STONE MASONRY .................................................................. 8

6. BACK FILLING .......................................................................................................... 8

7. HARD CORE .............................................................................................................. 9

8. CONCRETE ................................................................................................................ 9

9. PRESTRESSED CONCRETE ................................................................................... 13

10. FORM WORK ............................................................................................................ 14

11. STEEL REINFORCEMENT ..................................................................................... 16

12. MORTAR .................................................................................................................. 17

13. STONE MASONRY .................................................................................................. 17

14. HOLLOW CONCRETE BLOCK WALL ................................................................. 18

15. WALLS WITH BRICKS ............................................................................................ 19

16. WOODEN WALLS .................................................................................................... 20

17. PLASTER AND POINTING ...................................................................................... 20

18. STRUCTURAL STEEL WORK ................................................................................ 20

19. PAVIOR (TILES PAVIOR) ........................................................................................ 22

20. WALL TILES ............................................................................................................. 22

21. P. V. C. TILES ............................................................................................................ 22

22. ROOFING AND CLADDING .................................................................................... 23

23. GUTTERS AND DOWN PIPES ................................................................................ 24

24. CARPENTRY AND JOINERY.................................................................................. 24

25. CEILING ..................................................................................................................... 25

26. PAINTING .................................................................................................................. 25

27. GLAZING ................................................................................................................... 26

28. WATER WELL .......................................................................................................... 26

29. WATER SUPPLY LINES .......................................................................................... 26

30. PLUMBING AND SANITARY INSTALLATIONS ................................................ 26

31 SEWER SYSTEM ..................................................................................................... 27

32. SEPTIC TANK & SOAK AWAY PIT ...................................................................... 28

33. ELECTRICAL INSTALLATIONS ........................................................................... 28

34. RETAINING WALLS ............................................................................................... 29

35. SITE WORK .............................................................................................................. 30

36. ROAD AND FOOTPATHS....................................................................................... 30

37. DRAIN CHANNELS & CULVERTS ....................................................................... 31

38. FENCING AND GATE ............................................................................................. 31

39. PREPARATION OF PAYMENT CERTIFICATES ................................................. 32

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 6

40. INFORMATION IN CONSTRUCTION PROCEDURES ........................................ 32

TABLE OF CONTENTS

TABLES & FORMS PAGE

1. TABLE 8.5.3a. STANDARD CONCRETE MIX …………………………….. 33

2. TABLE 8.5.3b. STANDARD CONCRETE MIX .................................................. 34

3. HANDING OVER THE CONSTRUCTION SITE ................................................. 35

4. ACQUISITION OF DOCUMENTS ......................................................................... 36

5. FOR MATERIAL TESTING .................................................................................. 37

6. EVALUATION OF TEST RESULTS....................................................................... 38

7. SOIL IDENTIFICATION AND ACCEPTANCE

OF EXCAVATION FOUNDATION DEPTHS ..................................................... 39

8. SITE DIARY .......................................................................................................... 40

9. MONTHLY REPORT ............................................................................................ 41

10. QUARTERLY REPORT ....................................................................................... 46

11. WORK ORDER ..................................................................................................... 51

12. PAYMENT CERTIFICATE ................................................................................... 52

13. SITE HANDOVER INSPECTION CERTIFICATE ............................................... 55

14. SITE PREPARATION INSPECTION CERTIFICATE ........................................... 56

15. FOUNDATION EXCAVATION INSPECTION ..................................................... 57

16. EARTHWORKS INSPECTION CERTIFICATE .................................................... 58

17. MATERIAL QUALITY EVALUATION CERTIFICATE ...................................... 59

18. CONCRETE WORK INSPECTION CERTIFICATE .............................................. 60

19. MASONRY WORK INSPECTION CERTIFICATE ............................................... 61

20. STRUCTURAL STEEL WORK INSPECTION ...................................................... 62

21. STRUCTURAL TIMBER WORK INSPECTION ................................................... 63

22. CARPENTRY & JOINERY WORK INSPECTION ................................................ 64

23. ROOFING & CLADDING WORK INSPECTION .................................................. 65

24. FINISHING WORK INSPECTION CERTIFICATE ............................................... 66

25 SITE WORK INSPECTION CERTIFICATE ......................................................... 68

26 MINUTES OF INSPECTION FOR TEMPORARY ACCEPTANCE ..................... 70

27. TEMPORARY ACCEPTANCE ............................................................................. 72

28. FINAL ACCEPTANCE ........................................................................................... 75

APPENDIX 1 : GUIDELINE ON CONTROL OF

CONSTRUCTION PROJECTS .............................................. 79

APPENDIX 2 : LIST OF MAJOR DUTIES AND

RESPONSIBILITIES OF A RESIDENT

ENGINEER (SUPERVISOR) ................................................ 84

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 7

1. INVESTIGATION AND PREPARATION OF SITE

CHECK:

1.1 The site visually if underground utilities cross it.

1.2 The site on maps showing the location of underground structures and utilities to avoid

breaking them during construction.

1.3 The site plan and layout of buildings and sewer system specially concerning levels and soil

condition. If changes are necessary submit a written report to the designer.

1.4 The area to be cleared off and take measurements.

1.5 The trees and bushes within the foundation to be cut and rooted up as given in the standard

technical specification.

1.6 Permission is obtained from local authorities to cut down trees outside the foundation areas.

1.7 Boarder lines are agreed with local municipality and corner stones placed.

1.8 The connection points for water and electricity are agreed upon with local authorities.

1.9 All necessary temporary drains are constructed to keep the site free of water.

2. SETTING OUT

CHECK:

2.1 The setting out is done correctly with proper measuring tape and accurate levelling

instrument.

2.2 All measurements to confirm the accuracy and correct locations of working areas are

properly stated out.

2.3 The elevation reference point in accordance with the survey map, and confirm.

2.4 All bottom of trenches and floor levels are according to the elevations shown on the

drawings.

3. EXCAVATION AND EARTHWORK

3.1 Check all top soil is excavated separately.

3.2 Decide the place to pile up the suitable excavated material and check it is 2 meters outside

the building perimeter.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 8

3.3 Decide the place for the cart away which is not necessary for backfilling or terracing.

CHECK:

3.4 For sites where blasting is proposed, the explosives are used in the quantities and manner

recommended by the manufacturers. Check a written consent is obtained on each occasion

the contractor wished to use explosives.

3.5 All excavations are carried out to the lines, levels, widths and depths shown on the

drawings.

3.6 Any discrepancies in levels, dispositions etc. are reported to the engineer prior to

proceeding with the works.

3.7 All necessary temporary drains and culverts are constructed to keep the site free of water.

3.8 Slopes to embankments, cuttings, shoulders, ditches etc.; are trimmed to the dimensions

and inclinations shown on drawings.

3.9 Cut for roads is carried out until a level of suitable material is allowed.

3.10 Excavations are suitably trimmed and levelled before any concrete or masonry work is

placed.

3.11 In locations where the soil is subject to softening during excavation, a bottom layer of soil

removed immediately before the placing of concrete, in accordance with the standard

technical specification.

4. FOUNDATION TRENCH AND PIT EXCAVATION

CHECK:

4.1 The foundation drawings to correspond with the conditions on the site, if not prepare a

written report and submit to the designer immediately.

4.2 The foundation depth, width, line and levels to correspond the drawings.

4.3 The excavation or foundation is executed 25cm. wider on each side than the thickness of

the foundation wall as given in the standard technical specification.

4.4 The trench and pits to be clean from grass, bushes and pieces of wood.

4.5 The trench and pits to be kept free of water by pumping or other means.

4.6 The foundation engineer has accepted the excavated foundation depths by filling form No.

005.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 9

4.7 The foundation excavation is suitably trimmed and levelled before concrete or masonry

work in placed.

4.8 In the event of over excavation, without approval the area to be filled with selected

excavation or borrowed material or class 5 concrete in accordance with the standard

technical specification.

4.9 The faces of excavation is retained with sheeting, tim-bearing, strutting and shoring to

protect workmen and prevent damage where necessary.

5. FOUNDATION IN STONE MASONRY

CHECK:

5.1 The trench to be clean from grass, bushes and pieces of wood.

5.2 The stone is of the type given on specifications.

5.3 The stone to be hard, sound, free from cracks and decay and not weathered.

5.4 The stone is freshly quarried from an approved quarry.

5.5 The stone not to be round surfaced.

5.6 The stone masonry execution is with specified mortar and with well filled joints.

5.7 The stone masonry during execution is kept free from solid and other kind of dirt.

5.8 The length of stone does not exceed three times its height.

5.9 The mix of lean concrete to correspond the specification.

5.10 The mix proportion of mortar is correct.

6. BACKFILLING

CHECK:

6.1 All internal back filling is done with approved material, if possible with material excavated

on the site.

6.2 All external backfilling around foundation walls and behind retaining walls shall be done

with approved selected materials, if possible with material excavated on the site which is

capable of being compacted and form a stable filling.

6.3 all organic materials, such as pieces of wood, roots, bushes and black cotton soil are

removed from all backfill material.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 10

6.4 All ground trenches and places where backfilling shall be executed are clean from grass,

bushes and pieces of wood.

6.5 Where pipes and electrical cables are in connection with the backfilling, the work shall be

executed very carefully, so they do not break or get damaged.

6.6 All backfilling to be in layers and compacted to 95% of maximum dry density in

accordance with the standard technical specification.

6.7 Each layer to be well rammed and consolidated with the addition of water as necessary to

achieve the required compaction.

6.8 The maximum layer of fill for one time compaction does not exceed 20cm. thickness in

accordance with the standard technical specification.

6.9 Depressions or voids that are crated during trimming of slopes to embankments, cuttings,

shoulders, ditches etc.; are filled with suitable material and to approved compaction.

6.10 Any material which after repeated compaction does not fulfil the requirements is removed

and replaced.

7. HARD CORE

CHECK:

7.1 Stone for hardcore is sound and approved quality.

7.2 All stones in the hardcore are of approximately equal and recommended size.

7.3 All hardcore is well rammed and consolidated with the top surface blinded with crushed

aggregate of 20mm. thickness in accordance with the standard technical specification.

7.4 The thickness of the hardcore satisfies the specification or design.

7.5 the placing of stones to result in minimum voids.

8. CONCRETE

CHECK:

8.1 All ingredients cement, aggregates and water are of the type and quality specified.

8.2 Cement is fresh, not older than six months and is delivered to the site in the manufacturer's

original sealed bags.

8.3 Cement is stored in a dry and well ventilated store, on a wooden floor raised minimum

20cm. above the ground.

8.4 Cement is stocked separately.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 11

8.5 The cement has markings showing the type and date of consignment pinned to it and check

it is used in the order of its arrival.

8.6 Cement more than six months old after production is tested to satisfy the specified

requirements.

8.7 Sand or fine aggregate to be clean river or pits sand of approved quality and consist of

hard, dense, durable uncoated rock fragments.

8.8 Sand to be clear of impurities like dust, mica and organic matter.

8.9 Rejected samples of aggregates are removed from the site within 24 hours.

8.10 Coarse aggregate to be crushed basaltic stone or gravel of approved quality.

8.11 Coarse aggregate to be hard, dense, durable non-porous and uncoated rock fragments.

8.12 Coarse aggregate to be free from impurities like clay, soft thin elongated or laminated

pieces and shall be free from alkali and organic matter.

8.13 The gradation of coarse aggregate to comply with the standard technical specification.

8.14 Before any coarse aggregate is delivered to the site, the quality is approved at the quarry by

the designer.

8.15 Aggregates are stored on clear hard surface to prevent contamination by soil.

8.16 Different grades are stocked independently.

8.17 Water used for mixing concrete is clean and free from injurious amounts of oil, acids,

alkalies, organic materials.

8.18 Water is not taken from sea or tidal rivers to be used for structural concrete. If possible

water shall be piped or otherwise stored in an enclosed container free from contamination.

8.19 If there are any doubts about the quality of the water a sample shall be sent to the designer

or engineer for testing.

8.20 If the temperature of the water exceeds 60°c it is first mixed with the aggregate before the

cement is added.

8.21 The concrete is mixed to a uniform colour and consistency prior to placing.

8.22 Hand mixing is not allowed but if unavoidable shall be used only for class II concrete and

shall under no circumstance be allowed for concrete of class C-200 and higher.

8.23 Concrete is mixed in an approved mechanical batch mixer machine, the mixer is

thoroughly cleaned from hardened concrete and other kind of dirt before use.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 12

8.24 Mixer which has been out of use for more than 20 minutes is thoroughly washed before any

fresh concrete is mixed as specified in the standard technical specification.

8.25 The mixer drum is tight to avoid loss of mortar. The values must not leak mixing water.

8.26 The specified mixing time is carefully adhere to but in no case shall the mixing discontinue

for less than 2 minutes after adding water as specified in the standard technical

specification.

8.27 The batch capacity. The contractor must not be allowed to exceed the rated capacity of the

mixer.

8.28 The materials enter the drum rapidly.

8.29 The whole of the mixed batch is removed before materials for fresh batch enter the mixer.

8.30 Mixed concrete is not modified by the addition of extra water or cement, in order to

facilitate handling or any other purpose.

8.31 Before any casting starts at the site, test cubes of side dimension 15x15x15 or cylinders of

diameter 15cm and length 30cm of wood or steel are made ready.

8.32 All reinforcement and form work are properly placed prior to any concreting and the mix

approved and also check from No. 004 is filled and approved by the designer.

8.33 For any one structure samples are made at the same time from the same batch and the date

clearly marked on each cube.

8.34 Test cubes are made when directed but not less than one set of nine cubes for each 100m3

of concrete placed, or if the rate of placing is less than 100m3 then each 10 days or every

floor for multi-storey structures in accordance with the standard technical specifications.

8.35 Three cubes of each set are tested at 3 and 7 or 7 and 14 days and the third at 28 days all in

accordance with the code of practice.

8.36 In the absence of approved design mix that the standard mixes in Tables 8.5.3a and table

8.5.3b or the mix design given in the standard technical specification are followed.

8.37 Before any casting starts the consistency of fresh concrete must be measured using the

slump test, from the same batch for test cubes.

8.38 Concrete is son transported as rapidly as practicable and placed such that contamination,

segregation or loss of constituent materials does not occur.

8.39 All placing of concrete starts from one end and continue in the same direction without any

break.

8.40 Concrete is deposited as near as practicable and no concrete is dropped from a height

exceeding 2 meters as specified on the standard technical specification.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 13

8.41 When chutings is used the inclination of the chute shall be such as to allow the concrete to

flow without the use of water in excess of the specified volume for mix and without

segregation or loss of the ingredients. Details of any proposed chuting plant must be

approved before the plant is delivered.

8.42 The vibration is carefully done, and continues until a dense homogeneous mass is produced

and surface is fairly smooth.

8.43 Concrete is not over vibrated so that the consistency of the concrete is maintained and

separation of materials is caused.

8.44 If construction joints are necessary they are approved by the designer.

8.45 When concrete casting continues on a construction joint, the joint is clean from foreign

matter.

8.46 When concrete casting continues on a construction joint, the surface of the joint is

roughened and aggregate is exposed without being damaged.

8.47 The roughened surface of the construction joint is wetted with thin layer of mortar prior to

concreting.

8.48 After casting is completed and for 7 days thereafter, that the concrete is kept damp (cured)

to minimize loss of moisture from the concrete.

8.49 Whenever testing of a material is required fill the requisition from No.005 and for the

evaluation of test result fill form No.006 and get the approval of the engineer or designer

when the result is submitted.

8.50 Inspection prior to concreting:

CHECK:

The rigidity of the scaffolding and shuttering

The leak-tightness of joints between form work elements

Conformity of the dimensions of the form work with the (drawings)

The cleanliness of the form work

The surface conditions of the reinforcement

The position and size of reinforcement

The rigidity of the reinforcement securing systems, and the quality of the joints between

bars.

Cover to reinforcement is correct.

Class of concrete, mix design and water cement ratio.

8.51 Pre cast concrete is cast under sheds and remain in the moulds for 3 days and further 7

days after removal from the moulds. Then removed from the sheds and stocked in the

open for at least 7 days to season.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 14

8.52 Random load testing is made on the pre cast units and the damaged ones immediately

replaced.

8.53 Pre cast units and boisted and placed in proper position in such a way as to avoid over

stressing or damaging the units nor causing damage to previously erected structure.

8.54 If any doubt about the quality of, aggregatem dement, reinforcement and water arises

sample are sent for testing.

9. PRESTRESSED CONCRETE

CHECK:

9.1 All pre stressing components are stored in clean dry conditions.

9.2 All pre stressing components are clean and free from loose rust at the time of fixing in

position and subsequent concreting.

9.3 All pre stressing tendons are not welded within the length to be tensioned.

9.4 All pre stressing tendons (cables) are not twisted and individual wires or strands are

identifiable at each member.

9.5 All ducts and tendons are respectively sealed and protected until the tendon is threaded

through and the stressing operations are commenced.

9.6 All anchor cones, blocks and plates are positioned and maintained during concreting such

that the center line of the duct passes axially through the anchorage assembly.

9.7 All bearing surface of the anchorages are clean prior to concreting and tensioning.

9.8 The tendons immediately and during stressing do not exceed the strength specified.

9.9 Stressing is from both ends unless required or agreed by the engineer.

9.10 The tendons are anchored only if the pre stressing is applied to the satisfaction of the

engineer.

9.11 The jack pressure is released in such a way as to avoid shock to the anchorage or

tendons.

9.12 If the pull-in of the tendons at completion of anchoring is greater than that agreed by the

engineer, the load shall be released slowly and tensioning carried out afresh.

9.13 Sufficient test cubes are taken and specified transfer strength is attained.

9.14 The tendons are not cropped or cut prior to 3 days after grouting.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 15

9.15 Full records of all tensioning operations including the measured extensions, pressure

guage or load all readings and the amount of pull-in at each anchorage, are kept.

9.16 All ducts are thoroughly cleaned by compressed air or method specified prior to

grouting.

9.17 all achorages are sealed before grouting.

9.18 The ducts are completely filled with grout.

9.19 The filled ducts are protected to the satisfaction of the engineer that they are not

subjected to shock or vibration for one day.

9.20 Full records of grouting including the date each duct was grouted is kept.

9.21 The grout mixer produces a grout of colloidal and uniform consistency.

9.22 The grout is mixed for a minimum of two minutes unless otherwise specified.

9.23 No admixtures like chloride or nitrates are used. But if other admixtures may be used a

written permission must be submitted from the engineer and check it is applied strictly

with the manufacturer's instructions.

9.24 The gout consists only of ordinary port land cement and water unless otherwise

specified.

9.25 Pre stressed members are lifted or supported only at the points specified and handled

and placed without impact.

9.26 Beams are prevented from moving laterally during the placing of the in situ concrete.

9.27 The engineer informed in advance of the date of commencement of manufacture and the

dates when tensioning of tendons, casting of members and transfer of stress will be

undertaken for the first time for each type of beam.

9.28 All pre stressed concrete construction comply the standard technical specification.

10. FORM WORK

CHECK:

10.1 Form work is so constructed that it can be stripped from the hardened concrete easily

without bammering or without such shock or vibration in order to protect the concrete

or reduce labour cost.

10.2 The bracing of the form work. The form work must be strong enough to carry the load

until the concrete is strong enough to carry itself and hardened sufficiently.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 16

10.3 The inside surface of form works shall, except for permanent form works, or unless

otherwise agreed by the engineer, are coated with a release agent.

10.4 Release agents do not come into contact with the reinforcement and anchorages, and

should not be visible on the finished works.

10.5 Wooden form works for unexposed concrete surface, are executed of sawed boards with

sharp edges and of the same thickness.

10.6 Wooden form works for exposed concrete surface are generally of tongued and grooved

boards of the same thickness and free from knots, holes, cracks and splits.

10.7 Form work lumber shall be kept under shed and in varying thickness and width and

shall be constantly aerated and under weight to prevent it from decay.

10.8 Before any concreting starts, the form work has the right dimensions and is level and

straight.

10.9 Before any concreting starts, all forms are thoroughly cleaned out and free from holes

and dirt.

10.10 The top level of the form work is at the same level as the top of the finished concrete.

10.11 All form work is removed without any damage to the concrete during the striking.

10.12 After removal of the form work remedial treatment to surfaces of the hardened concrete

is carried out immediately without delay and period of removal is as follows:

for vertical form work to columns, walls and beams - 16 hrs.

for soffit form work to slab - 21 days

for props to slabs - 14 days

for soffit form work to beams - 21 days

for props to beams - 14 days

in accordance with the standard technical specification.

10.13 Where intended to re-use form work it is thoroughly cleaned and made good to the

satisfaction of the engineer.

10.14 Stripping of form work not to be done until concrete is set i.e. should ring under a

hammer blow. In no circumstances shall form work be struck until the concrete attains a

cube strength of at least twice the stress to which it may be subjected at the time of

striking.

10.15 All form work construction and quality comply the standard technical specification.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 17

11. STEEL REINFORCEMENT

CHECK:

11.1 Steel reinforcement is stored in clean condition. It should be free from loose rust.

11.2 All reinforcement bars are of the specified quality and in accordance with the standard

technical specification.

11.3 Given in the design in cases where certificates for ultimate tensile strength, yield stress,

elongation and cold bend tests are not issued by the manufacturers.

11.4 The dimension, length and shape of the reinforcement bars is according to the drawings

and specifications.

11.5 Bending of reinforcement bars is done with adequate bending tools. But heat is strictly

not allowed for bending of reinforcement bars.

11.6 All bars with cracks or splits at the bend are not used for construction.

11.7 All mild steels have their ends booked, and the bending radius meets the specification.

11.8 All reinforcement bars are clean and free from loose rust, grease, oil, or tar and other kind

of dirt.

11.9 The reinforcement bars are placed in position according to the drawings, and firmly

bound together with mild steel wire, diameter 1.6mm in accordance with the standard

technical specification.

11.10 Before any casting of concrete starts, that pre cast concrete blocks or spacers or metal

chairs are prepared and all reinforcement bars are placed on them.

11.11 These blocks or spacers do not turn over when concrete is casted.

11.12 The thickness of concrete cover is according to the requirements of the drawings and

specifications.

11.13 And approve the placing of the reinforcement and form work condition before any

concrete is casted.

11.14 The reinforcement in structures are not welded unless permitted by the designer.

11.15 All reinforcement quality and work comply the standard technical specification.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 18

12. MORTAR

CHECK:

12.1 All mortar is if possible mixed in an approved mechanical batch miser. If not possible it

could be mixed by hand until its color and consistancy are uniform.

12.2 Lime for mortar is freshly burnt limestone. Lime shall be delivered to the site in large

lumps, slaked, run to putty and mature for not less than two weeks before use.

12.3 If hydraulic lime is used, it is stored in the same manner as described for cement.

12.4 Cement used in mortar is port land cement and of quality as described for concrete

works.

12.5 Sand for mortar is of quality as described for concrete works.

12.6 Water is of quality described for concrete works.

12.7 Cement mortar consists of cement and sand as specified. If not given in the

specification, check that cement mortar consists of one part cement to three parts of

sand (1:3) measured by volume.

12.8 Compo mortar consists of cement, lime and sand as specified. If not specified, check

that the compo mortar is composed of one part cement two parts of lime and nine parts

of sand (1:2:9) measured by volume.

12.9 Cement mortar is used within 30 minutes of the duration of cement.

13. STONE MASONARY WALL

CHECK:

13.1 Stone is of type given on specification.

13.2 The stone in hard, sound, free from cracks and decay and not weathered.

13.3 The stone is freshly quarried from an approved quarry.

13.4 The stone masonry execution is with specified mortar and with well finished joints.

13.5 All mortar for stone masonry bedding and jointing is 20mm thick.

13.6 Stone masonry during execution is kept free from solid and other kind of dirt.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 19

13.7 Stone walling is carried up with no portion more than 1000mm above adjacent wall at

any one time.

13.8 The wall is in plumb within 3m.

13.9 Sample panel of wall not less than 1m2 in area including joint pointing as specified is

prepared and approved.

13.10 The type size and pattern of laying is as detailed on drawing.

13.11 All stone masonry walling comply with the standard technical specification.

14. HOLLOW CONCRETE BLOCK WALL

CHECK:

14.1 The hollow concrete blocks are free from laminations, cracks and other defects that

would impair the proper setting, strength or permanence of the construction.

14.2 The hollow concrete blocks are well compacted, properly cured and uniform colour and

texture.

14.3 The hollow concrete blocks manufactured on the site above the quality of cement and

aggregate as described for concrete works.

14.4 All blocks are manufactured in an approved special hollow block machine and under

shed.

14.5 Before any manufacturing in big scale starts on the site, test samples are made, cured

and sent for testing and test results are approved by the designer.

14.6 For curing of hollow blocks, that they are kept moist, at least for seven days after

casting.

14.7 That the blocks are properly dried under shade for at least 14 days before they are used

for construction.

14.8 Damaged or blocks with defects in the walls are replaced with good ones at the

expenses of the contractor.

14.9 Hollow blocks and the walls are kept free from soil and other kind of dirt during

execution.

14.10 All joints vertical and horizontal are well filled with specified mortar.

14.11 Walling is carried up with no portion more than 1000mm. above adjacent wall at any

one time.

14.12 Partition walls are well bonded to elevations walls.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 20

14.13 That the joints and the walls are in plumb within 3m.

14.14 If the wall in designated as load bearing by the designer and special care in taken for the

execution of the work.

14.15 A minimum of 6 blocks per 1000 pcs. for site manufactured blocks are tested.

14.16 The thickness of the joints do not exceed 15mm.

14.17 The compo mortar is used only above ground level.

14.18 The drawings carefully before any wall construction if extra reinforcement or expansion

joints are prescribed.

14.19 The minimum compressive strength class A, class B and class C, hollow concrete

blocks in as follows according to the standard technical specification.

CLASS AVERAGE OF 6 BLOCKS INDIVIDUAL BLOCKS

Class A 48kg/cm2 38 kg/cm2

Class B 35kg/cm2 32 kg/cm2

Class C 20kg/cm2 18kg/cm2

14.20 All hollow concrete block walling comply with the standard technical specification.

15. WALLS WITH BRICKS

CHECK:

15.1 Bricks are not dumped on site but stocked in regular tires as they are unloaded.

15.2 Bricks to be used for different situations are stocked separately on a clean place.

15.3 Bricks are soaked in water for a minimum period of one hour before use.

15.4 Sample panels of not less than 1m2 for each type of brick.

15.5 All brick works are laid in good English bond even and true to line plumb within 3m,

level and all joints accurately kept.

15.6 All joints vertical and horizontal are well filled with specified mortar.

15.7 The thickness of the joints do not exceed 10mm.

15.8 All bricks of the same dimensions are only used in the same wall.

15.9 Brick samples are taken at random from the load approved also manufacturers test

certificate submitted.

15.10 All brick walling comply with the standard technical specification.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 21

16. WOODEN WALLS

CHECK:

16.1 The quality and dimensions of wood are according to specifications and drawings.

16.2 All wood for wall are well seasoned, fee from major knots, worms, splits and bends.

16.3 All wood for construction are stored free from the ground and well protected against

rain.

16.4 All wood if specified are treated with antitermite liquid.

16.5 Dimension, placing and number of nails in according to drawings. Unless indicated on

the drawing no wood structure shall be joined.

16.6 The wall is plumb and level.

17. PLASTER AND POINTING

CHECK:

17.1 The cement plaster and compo plaster quality mixture, thickness and type of surface are

according to the specification and drawing.

17.2 That cement plaster is used where water effect is expected such as in toilets, laundries

and external walls while compomortar is used in all cases unless otherwise specified.

17.3 Before any plaster is applied, the wall is thoroughly cleaned from dirt and dust.

17.4 all plaster in mixed in a mechanical mixer of approved type if possible.

17.5 The wall, depending on the material is kept wet for some time before any plaster

applied. It's not enough to sprinkle water just before plastering.

17.6 All pointing if prescribed in done with cement mortar.

17.7 All pointing in plumb and level.

17.8 All plastering and pointing comply with the standard technical specification.

18. STRUCTURAL STEEL WORK

CHECK:

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 22

18.1 The shape and size of structural steel members comply with the requirements of the

specification and the manufacturers standards.

18.2 Size location, elevation and plumbing of another bolts.

18.3 Condition and capacity of welding equipment.

18.4 Conformity of electrodes to specifications and correct usage.

18.5 Production and assembly of steel in carried out in accordance with the detail drawings

and specifications.

18.6 Steel before and after fabrication is straight and free from twist or other damages.

18.7 Cutting is done by shearing, cropping, sawing or machine flame cutting.

18.8 Cutting by hand operated flame in approved.

18.9 Sheared or cropped edges are dressed to a neat machine work and are prepared for

welding finish.

18.10 Welded sections are inspected and approved prior to priming.

18.11 The maximum gap for butt welded section in less that 3mm.

18.12 Each weld in continuous, sound and without interruption and free of creaters.

18.13 Slag in taken away immediately after welding and the weld cleared with metal brush.

18.14 All ends of rectangular, square and circular sections (DHS, CHS) are sealed by welding

to prevent ingress of moisture.

18.15 The steel structure is securely bolted to plates, channels or angle cleates during erection.

18.16 Direct bolting to sides of steel hollow sections in not carried on.

18.17 Holes for fixing electrical fittings, partitions etc. … are correctly positioned.

18.18 All structural steel is protected from chemical solutions.

18.19 All structural steel ready to erect is prevented from water or dirt accumulated against

any of the surfaces.

18.20 All steel which will have concrete cast against them are clean and free from loose rust at

the time of concreting.

18.21 all structural steel work comply with the standard technical specification.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 23

19. PAVIOR (TILES PAVIOR)

CHECK:

19.1 Before any paving starts, the mass concrete is completely free from standing water.

19.2 Cement tiles conform with the standards.

19.3 In the mass concrete surface immediately before the bedding is laid, a slurry of cement

and water is brushed, unless specified.

19.4 The bedding in of cement mortar, one part cement to four parts sand (1:4), and the slump

in 2-5cm and over.

19.5 the bedding thickness is 2-3cm.

19.6 The tiles are gently knocked down into the bedding so the mortar will be forced up in the

joints approximately 5mm.

19.7 When the bedding is hard enough usually after one day the joints which shall be 2-4mm

wide are filled with cement mortar.

19.8 Expansion joints are executed as indicated on drawings.

19.9 The complete floor under construction is protected for the first 14 days and kept wet and

is protected against damage.

20. WALL TILES

CHECK:-

20.1 Wall tiles are soaked in clean water before laying and taken out just before use.

20.2 Tiles are bedded with straight joints in cement and sand (1:3) and grouted in white

cement.

20.3 The work when completed is cleaned properly before approval.

20.4 Only tiles free from defects are used for the construction.

21. P.V.C. TILES

CHECK:

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 24

21.1 P.V.C. tiles are laid on floor screeds with approved glue and in accordance with

manufacturer's instruction.

21.2 Only tiles free from defects are used for the construction.

21.3 Damaged tiles are replaced with good ones at the contractor's expense.

22. ROOFING AND CLADDING

CHECK:

22.1 Asbestos cement sheets are free from visible defects.

22.2 The surface of asbestos cement sheet is of uniform texture and smooth on one side.

22.3 The edges of asbestos cement sheets are square, straight and clean.

22.4 Asbestos cement sheet unless otherwise specified is 6mm thick when used for roofing.

22.5 Asbestos cement accessories match the pitch of the sheets.

22.6 Galvanized plain and corrugated sheets comply the manufacturer's specifications.

22.7 Steel hock bolts and nuts are zinc coated, the size and use of which shall be as per

manufacturer's instruction.

22.8 Fixing of roofing and flashing is made fully water tight and performed to the standard of

best workmanship.

22.9 Chiseler diamond adges and convex bend nails made of mild steel round wires are used to

fix galvanized steel sheet roofing and flashing to timber members.

22.10 Steel hock bolts and nuts are used to fix galvanized steel sheets and asbestos roofing to

steel and wooden truss members and purlins.

22.11 Fixing holes are drilled in crown of corrugation of roofing sheets.

22.12 Holes are 5mm larger in diameter than bolts or screws.

22.13 Holes are 40mm far from edges of sheet.

22.14 Sheets are laid with laps not less than 150mm.

22.16 Upper laps of sheets are constructed away from prevailing wind.

22.17 No person other than workmen in roofing have access to roof area.

22.18 All roofing work comply with the standard technical specification.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 25

23. GUTTERS AND DOWN PIPES

CHECK:

23.1 Gutters and down pipes are formed with the specified guage galvanized mild steel flat

sheet from suitable lengths and to shapes shown on the drawings.

23.2 Gutter hangers and down pipe supports are 2.25mm anti-rust painted flat sheet spaced at 1

meter center maximum unless otherwise specified.

23.3 Joints of gutter are lapped 15cm and welded.

23.4 Jointer of gutter after welding treated with three coats of zinc paint.

24. CARPENTRY AND JOINERY

CHECK:

24.1 Timber for carpentry and joinery is as specified and of best quality.

24.2 Timber is reasonably straight grained and obtained from an approved sources.

24.3 And inspect the timber as it arrives, an timber not approved is removed forthwith.

24.4 Timber is open stacked for as long as possible before use.

24.5 Timber and assembled wood work are protected from rain and sun.

24.6 Timber and assembled wood work are stored in such away as to prevent attack by

termites, insects or decayed fungi.

24.7 Timber ready for use in free from live borer, beetle or other insect attack.

24.8 All measures to eradicate insect attack of timber are approved.

24.9 Timer in seasoned to moisture content of not more that 20% for Carpentary and 12% for

joinery.

24.10 All timber surface exposed by cutting are treated with three coats of approved

preservations.

24.11 All pressure impregnated timber is treated with preservative chemicals at a pressure of

not less than 10 atmospheres and in accordance with the chemical manufacturers

instruction.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 26

24.12 Fixed joinery is completely protected from damage until the completion of the

construction.

24.13 Profile of sections is not modified from those shown on drawings without approval.

24.14 Right type of door is fixed in the right place and that the doors awing in accordance to the

drawings.

24.15 Door frames and window frames are fixed straight and in plumb.

24.16 Hinges, locks, latches and handles are of approved type and properly fixed.

24.17 Window panels are of the right thickness and properly fixed.

24.18 All carpentry and joinery to comply with the standard technical specification.

25. CEILING

CHECK:

25.1 Material and dimensions are according to the specifications and the drawings.

25.2 Before any mounting, painting of parts in connection with the ceiling such as steel guides

and walls, is completed.

25.3 The ceiling in cleaned and well fixed when the work is completed.

26. PAINTING

CHECK:

26.1 The kind of paints in according to the specifications and designer's instructions.

26.2 The painting is done according to the manufacturer's instructions.

26.3 The paint is not diluted unless specified by the manufacturer.

26.4 All surface to be painted is clean from dust and dirt.

26.5 All surface to be painted is absolutely dry and free from defects before painting.

26.6 All brushes and tins used for painting are clean and free from old paint.

26.7 The room is closed until the paint dries.

26.8 All electrical appliances, iron and brass works are removed before painting and properly

refixed after painting.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 27

27. GLAZING

CHECK:

27.1 Frames are fixed straight and in plumb.

27.2 The type and thickness of glass is according to the specifications and drawings.

27.3 The application and properness of putty.

28. WATER WELL

CHECK:

28.1 The water well is dug according to the specifications and drawings, if possible dug during

the dry season.

28.2 If septic tanks, soak away pits and dry latrines are situated nearby and inform the designer

to change the position of the wall.

28.3 The water is tested and approved after the digging is completed.

28.4 The masonry work is not started before the test result is known and approved.

29. WATER SUPPLY LINES

CHECK:

29.1 The dimensions and types, tubes valves and water tower is according to the specifications

and drawings.

29.2 All valves, unless otherwise specified is buried in the ground to a minimum depth of

30cm.

29.3 All valves are placed according to the drawings.

29.4 Inspect and approve the supply line before any back filling starts.

30. PLUMBING AND SANITARY INSTALLATIONS

CHECK:

30.1 Dimensions and types of pipes, tubes, valves and sanitary ware is according to the

specification and drawings.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 28

30.2 All pipes and tubes to be installed in the floor are placed in position.

30.3 All joints before mass concrete in east.

30.4 Pipes and tubes are placed in the board core with minimum 10cm covering layer of sand

or in channels of floors as indicated on the drawings.

30.5 All sanitary ware is properly fixed in its correct position.

30.6 All connection between sanitary ware and sewer system is done with the prescribed

syphon.

30.7 All exposed pipes and tubes are well cleaned and painted as specified.

30.8 All sanitary work comply with the standard technical specification.

31. SEWER SYSTEM

CHECK:

31.1 Dimensions and types of pipes and inspection pits is according to the specifications and

the drawings.

31.2 The excavation measurements of the sewer lines is according to the drawings.

31.3 The excavation is done in straight lines between the manholes.

31.4 All trenches before pipes are laid.

31.5 Unless otherwise specified, the pipes are laid on a sand bed with a minimum thickness of

10cm and in an absolutely straight line with an even slope of minimum 1:100 and

covering soil layer is minimum 50cm.

31.6 The joining of concrete to pipes is always done with cement mortar, the joint completely

filled all around.

31.7 Joining of asbestos cement pipes is done according to the manufacturer's instruction.

31.8 Inspection pit is according to the drawing before back filling.

31.9 All pipes connected to the inspection pit come approximately on the same level and check

channel formed in concrete at the bottom of the pit.

31.10 Back fill soil is of good quality, free from stones and it is not top soil.

31.11 Back filling is in layers of minimum 20cm, if vibrating or roller machine is used the

thickness of the layer can be 40cm unless otherwise specified.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 29

31.12 Each layer of back fill is well rammed and consolidated with the addition of water if

necessary.

31.13 The correct position of the water and sewer systems and prepare a sketch on the site plan

to send to the designer for preparing drawings showing their correct positions as built on

site.

31.14 Measure the correct lengths of all trenches, of all tubes and pipes.

32. SEPTIC TANK AND SOAK AWAY PIT

CHECK:

32.1 Dimension and type of septic tank and soak away pit is according to the specifications

and drawings.

32.2 The position of septic tank and soak away pit if situated nearby water wells, and inform

the designer for the change of the positions.

32.3 Level of overflow pipes between different chambers and inlet and outlet pipes are

according to the drawings.

32.4 all plastering in and out, is with cement plaster with thickness and mixture according to

specifications and drawings.

32.5 All water proofing is done according to specifications and drawings.

33. ELECTRICAL INSTALLATIONS

CHECK:

33.1 The electrical installation is approved by EELPA or the designated professional.

33.2 Materials to be used for the installation strictly follow the specifications and the drawings.

33.3 The electrical subcontractor has a valid certificate issued by EELPA before he starts his

work and his foreman is competent.

33.4 The conduits are free from defects and cover the wires all the way.

33.5 All switches and outlets are properly fixed according to the drawings.

33.6 The connections of wires are always done in junction boxes.

33.7 All external cables are placed with a minimum 10cm depth in concrete or asbestos

cement pipes and 40cm depth in the ground, unless otherwise specified.

33.8 The excavation is in a straight line between the inspection pits.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 30

33.9 The inspection pits are constructed every 30cm unless otherwise specified.

33.10 All trenches before pipes are laid.

33.11 The pipes are laid on a minimum 10cm thick sand bed unless otherwise specified.

33.12 The joining of asbestos cement pipes is done with cement mortar, the joint completely

filled around.

33.13 The joining of asbestos cement pipes is done according to the manufacturer's instructions.

33.14 The inspection pits, pipes and joints before back filling.

33.15 The back fill soil is of good quality, free from stones and it is not top soil.

33.16 The back filling is in layers of minimum 20cm if vibrating or rolled machine is used the

thickness of the layer can be 40cm unless otherwise specified.

33.17 Each layer of back fill is well rammed and consolidated with the addition of water if

necessary.

33.18 All underground cable joining are done in special water-tight junction box approved by

EELPA or designated professional.

33.19 All junction boxes used are placed in the inspection pits.

33.20 Measure the correct lengths of all trenches and cables.

33.21 The correct position of external cables and pits and prepare a sketch on the site plan to

send to the designer for preparing drawings showing their correct positions as built on

site.

33.22 All electrical installation comply with the standard technical specification.

34. RETAINING WALLS

CHECK:

34.1 The trench to be free from loose soil, roots and pieces of wood before construction.

34.2 The depth and width of trench to correspond with the drawing.

34.3 All stones are of good and approved quality.

34.4 All stones and the wall are kept free from soil and other kind of dirt during execution.

34.5 No borrow pits are to be opened in the vicinity.

34.6 If expansion joints are executed as on the drawings.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 31

34.7 The mix propertion of mortar.

34.8 All retaining wall construction comply with the standard technical specification.

35. SITE WORK

CHECK:

35.1 The clearing of buildings is up to 2 meters from elevation walls on all sides, and check

thin limit is approved by the designer.

35.2 The clearing for roads, footpaths and parking areas is up to 1 meter from their boundaries

and check this limit is approved by the designer.

35.3 All roots are taken out within the building area, under roads footpaths and parking lots

and transported away from the site.

35.4 The place for the down trees and check they are within the building site.

35.5 All top soil is excavated separately.

35.6 And decide the place to pile up the excavated to soil and check it is 2 meters outside the

building perimeter.

35.7 And decide the place for the cart away which is not necessary for back filling or terracing.

35.8 All back filling and terracing is done in layers not exceeding 20cm and if vibrating or

roller machine is used the thickness must be 40cm.

35.9 Each layer of back filling and terracing is well rammed and consolidated.

35.10 Back filling and terracing is not with top soil.

35.11 All site work comply with the standard technical specification.

36. ROADS AND FOOTPATHS

CHECK:

36.1 Excavation for roads footpaths is executed to bottom of footpaths is executed to bottom

of hard core.

36.2 Back filling for roads and foot paths is done with non expansive selected material.

36.3 All back filling is done in layers not exceeding 20cm and if vibrating or roller machine is

used the thickness must be 40cm.

36.4 Each layer of back filling is well rammed and consolidated with addition of water if

necessary.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 32

36.5 Before back filling starts the ground is free from top soil, grass, bushes, roots and pieces

of wood.

36.6 Stone for hard core is of approved quality.

36.7 All stones in the hard core are of approximately equal size.

36.8 The hard core is well rammed, consolidated and the top tightened with crushed stones or

gravel.

36.9 The thickness of hard core is not less than specified.

36.10 The hard cores as well as the top surface is executed with a minimum slope of 1:100

towards the sides.

36.11 The top surface is executed with material on the specification or drawings.

37. DRAIN CHANNELS AND CULVERTS

CHECK:

37.1 Drain channels are according to the measurements on the drawings.

37.2 Drain channels to have a minimum slope of 1:200, unless otherwise specified.

37.3 Stone channels to be on a bed hard-core or well compacted gravel with joints and

pointing in cement mortar (1:3).

37.4 Channels of half-concrete pipes are on a well compacted layer of fine aggregate with a

thickness not less than 10cm.

37.5 Half-concrete pipes are laid in and joined with cement mortar (1:3).

37.6 Stone channels and culverts are constructed according to the drawings and specifications.

37.7 All pipes are laid so that each one is in contact with the bed throughout the length of its

38. FENCING AND GATE

CHECK:

38.1 The type of fence and gate are according to the specifications and drawings.

38.2 The foundations of fence and gate is according to the specifications and drawings.

39. PREPARATION OF PAYMENT CERTIFICATE

39.1 Payment certificate should be prepared on official formats.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 33

39.2 Payment certificates should be prepared in sufficient copies as needed.

39.3 Payment certificates should be signed by:

a. the supervisor

b. consultant, if there is contract provision for such supervision

c. the contractor

d. the investor

39.4 The supervisor shall check payment against:

a. arithmetic error

b. contract prices

c. contract quantities

d. contract time

e. actual measurement sheets

f. variation orders

g. supplementary agreements

h. validity of performance bond

i. progress reports

40. INFORMATION ON CONSTRUCTION PROCEDURES

40.1 Check a site book is kept for any construction work and the following information is

included:

dates on which excavation, concreting, stripping of form work, back filling, site work

has taken place.

acceptance of materials an components

results of tests and measurements

type of cement and aggregate

inspection and measurement reports of the positioning of reinforcement.

important instruction received.

description of any incidents.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 28

Table 8.5.3a Standard Mixes for Ordinary Structural Concrete per 50kg Bags of Cement

(ESCP 2 : Part 1: 1983)

Nominal max. size of

Concrete Aggregate (mm) 40 20 14 10

Work Workability Medium High Medium High Medium High Medium High

Limits to slump that may be expected

(mm) 30-60 60-120 20-50 50-100 10-30 30-60 10-25 25-50

C5 Total Aggregate (kg) 640 550 540 480

Fine Aggregate (%) 30-45 30-45 35-50 35-50 - - - -

Vol. of finished concrete (m3) 0.312 0.275 0.277 0.252

C15 Total Aggregate (kg) 370 330 320 280

Fine Aggregate (%) 30-45 30-45 35-50 35-50 - - - -

Vol. of finished concrete (m3) 0.200 0.183 0.178 0.160

C20 Total Aggregate (kg) 350 270 280 250 255 220 240 200

Fine Aggregate (%) 30-35 30-40 30-40 35-45 35-45 40-50 40-50 45-55

Vol. of finished concrete (m3) 0.165 0.155 0.156 0.143 0.146 0.130 0.137 0.121

C25 Total Aggregate (kg) 265 240 240 215 220 195 210 175

Fine Aggregate (%) 30-35 30-40 30-40 35-45 35-45 40-50 40-50 45-55

Vol. of finished concrete (m3) 0.147 0.137 0.137 0.127 0.130 0.118 0.124 0.110

C30 Total Aggregate (kg) 235 215 210 190 195 170 180 150

Fine Aggregate (%) 30-35 30-40 30-40 35-45 35-45 40-50 40-50 45-55

Vol. of finished concrete (m3) 0.134 0.127 0.124 0.115 0.115 0.106 0.109 0.097

NOTE: To get volumes of fine and coarse aggregates as follows:

1. Calculate the weights of fine and coarse aggregates by using percentages within the given ranges.

2. Calculate the volume of fine aggregate in it, by dividing the weight in kg.

3. Calculate the volume of coarse aggregates in it by dividing the weight in kg. By 1.25.

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 29

Table 8.5.3b Standard Concrete Per 50kg. Bag of Cement

(ESCP 2 : Part 1: 1983)

Nominal Max. Size of Agg. (mm) 40 20

Concrete Work Ability Medium High Medium High

Grade Limits to Slump that may be expected (mm) 30-60 60-100 20-50 50-100

C5 Sand 5A 6C 6C 4A

Coarse Agg. 7A 7C 7C 5

Water (Litres) 48 48 48 48

C15 Sand 3A 3B 3B 2B

Coarse Agg. 4A 4B 4B 4B

Water (Litres) 30 30 30 30

C20 Sand 3C 2A 2B 2C

Coarse Agg. 4C 3A 4b 4C

Water (Litres) 25 25 25 25

C25 Sand 2A 2B 2B 2C

Coarse Agg. 3A 3B 3B 3C

Water (Litres) 23 23 23 23

C50 Sand 2B 2C 2C 2B

Coarse Agg. 3B 3C 3C 2B

Water (Litres) 20 20 20 20

Standard Box Sizes

(Sizes in cms)

A - 40x50x20

B - 40x50x18

C - 40x50x16

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 30

MINISTRY OF WORKS AND URBAN DEVELOPMENT

HANDING OVER THE CONSTRUCTION SITE

This _________________________________ date of ___________ 19____ the work for the

construction of the _______________________________________________ has been officially

handed over to the contractor:

MR/ATO ____________________________________________________________________

The Contractor, therefore, acknowledges the taking over of the site and immediately the work with

all its explanation clearly defined in the specification and drawings (sketches).

The Contractor, hereinafter, shall be responsible for the damages that occur as a result of his fault,

carelessness or negligence in connection with untimely commencement of the work.

The Contractor, in addition, acknowledges the completion of the said work shall count as from the

date mentioned above and comply with the terms and conditions of the Contract to the Contract to

the satisfaction of the Client.

IN WITNESS HEREOF THIS DOCUMENT HAS BEEN SIGNED BY ALL PRESENCE IN SIX

COPIES OF WHICH THE CLIENT HAS ONE, THE SUPERVISOR ONE, THE

CONTRACTOR ONE, AND THE BUILDING DESIGN ENTERPRISE THREE.

_____________________________ ___________________________

FOR THE CLIENT (EMPLOYER) THE CONTRACTOR

WITNESS

1. _____________________ 1. ___________________

2. _____________________ 2. ___________________

3. _____________________ 3. ___________________

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 31

MINISTRY OF WORKS AND URBAN DEVELOPMENT

ACQUISITION OF DOCUMENTS

PROJECT : ___________________________________________________

SITE : ___________________________________________________

EMPLOYER : ___________________________________________________

CONTRACTOR : ___________________________________________________

SUPERVISOR : ___________________________________________________

This is to acknowledge that I have received the following set of documents concerning the

project.

1. CONTRACT DOCUMENT NO. ________________________________________

2. ARCHITECT DRAWINGS NO. ________________________________________

3. STRUCTURAL DRAWINGS NO. ________________________________________

4. ELECTRICAL DRAWINGS NO. ________________________________________

5. SANITARY DRAWINGS NO. _________________________________________

6. BILL OF QUANTITIES _________________________________________

7. OTHERS NO. _________________________________________

DOCUMENT HANDED OVER BY DOCUMENT RECEIVED BY

______________________________ ___________________________

DATE: ______________________________

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 32

MINISTRY OF WORKS AND URBAN DEVELOPMENT

REQUISITION FOR MATERIAL TESTING

PROJECT : ____________________________________________________

SITE : ____________________________________________________

EMPLOYER : ____________________________________________________

CONTRACTOR : ____________________________________________________

SUPERVISOR : ____________________________________________________

REQUIRED TEST

TEST REQUESTED BY _____________________________________________________

SUPERVISOR

APPROVED BY _____________________________________________________

CONSULTANT OR DESIGNER

DATE _____________________

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 33

MINISTRY OF WORKS AND URBAN DEVELOPMENT

EVALUATION OF TEST RESULT

Contract No. ________________

PROJECT : ___________________________________________________

SITE : ___________________________________________________

EMPLOYER : ___________________________________________________

CONTRACTOR : ___________________________________________________

SUPERVISOR : ___________________________________________________

TESTING LAB ________________________________ TEST NO. ___________________

DATE OF TESTING __________________________________________________________

KIND OF MATERIAL TESTED _________________________________________________

____________________________________________________________________________

SPECIFIED QUALITY ________________________________________________________

____________________________________________________________________________

TEST RESULT _______________________________________________________________

____________________________________________________________________________

RECOMMENDATION OF DESIGNER ___________________________________________

____________________________________________________________________________

____________________________________________________________________________

MATERIAL ACCEPTED MATERIAL REJECTED

APPROVED BY : _____________________________________________

CONSULTANT OR DESIGNER

C.C To Site Supervisor

To Contractor

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 34

To Employer

MINISTRY OF WORKS AND URBAN DEVELOPMENT

SOIL IDENTIFICATION AND ACCEPTANCE OF EXCAVATED

FOUNDATION DEPTHS

PROJECT : _____________________________________________________

SITE : _____________________________________________________

EMPLOYER : _____________________________________________________

CONTRACTOR : _____________________________________________________

SUPERVISOR : _____________________________________________________

SOIL TEST REPORT NO. ___________________________ DATE _____________________

Specified Soil Recommended

Type Test Actual Soil Specified Depth in Foundation Remark

Report Condition Test Report Depth

RECOMMENDATION OF

FOUNDATION ENGINEER ___________________________________________________

____________________________________________________________________________

INSTRUCTION PASSED TO

THE CONTRACTOR ____________________________________________________

_____________________________________________________________________________

ACKNOWLEDGEMENT OF SUPERVISOR _______________________________________

_____________________________________________________________________________

Ministry of Works and Urban Development

Check List for use by Building Construction Supervisors 35

MINISTRY OF WORKS AND URBAN DEVELOPMENT

SITE DIARY

Report No. _____

Date __________

Project : ____________________________________________________________

Site : ____________________________________________________________

Employer : ____________________________________________________________

Contractor : ____________________________________________________________

Consultant : ____________________________________________________________

Site Supervisor : ____________________________________________________________

1. Weather Conditions : Fine _________ Good ________ Bad _______ Lost Hrs. _______

2. Staff on Site :

Project Eng. ________________ Secretary ______________ Driver ____________

Civ. Eng. _______________ Clerk _________________ Guard ____________

Bld. Eng. _______________ Purchaser ______________ Messenger _________

Technician _______________ Cashier ________________ Cleaner ___________

Eng. Aide _______________ Dresser ________________ Others ____________

3. Labour Force

Gen. Forman _______________ Mason ________________ Plasterer __________

Gen. Operator _______________ Carpenter ______________ Painter __________

Forman ____________________ Barbender ______________ Chiselled __________

Operator ___________________ Plumber ________________ Glazier ___________

Mechanic __________________ Electrician ______________ Labourer _________

Welder ____________________ Helper _________________ Others ____________

4. Work in progress: __________________________________________________________

________________________________________________________________________

5. Materials on Site : _________________________________________________________

________________________________________________________________________

6. Equipment on Site : ________________________________________________________

________________________________________________________________________

7. Given Instruction __________________________________________________________