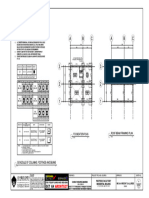

DETAIL-'1': SECTION '6-6' (Showing Reinf.) SECTION '5-5' (Showing Reinf) Typical Detail of Hand Rail at Fob

DETAIL-'1': SECTION '6-6' (Showing Reinf.) SECTION '5-5' (Showing Reinf) Typical Detail of Hand Rail at Fob

Uploaded by

Shivam SharmaCopyright:

Available Formats

DETAIL-'1': SECTION '6-6' (Showing Reinf.) SECTION '5-5' (Showing Reinf) Typical Detail of Hand Rail at Fob

DETAIL-'1': SECTION '6-6' (Showing Reinf.) SECTION '5-5' (Showing Reinf) Typical Detail of Hand Rail at Fob

Uploaded by

Shivam SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DETAIL-'1': SECTION '6-6' (Showing Reinf.) SECTION '5-5' (Showing Reinf) Typical Detail of Hand Rail at Fob

DETAIL-'1': SECTION '6-6' (Showing Reinf.) SECTION '5-5' (Showing Reinf) Typical Detail of Hand Rail at Fob

Uploaded by

Shivam SharmaCopyright:

Available Formats

℄OF BEARING NB 40 PIPE

2-10T (TYP.)

50 50

DETAIL-'1'

3-16T

24

131

4-10T

83

6 THK

COLUMN REINF PLATE

24

100

SECTION '6-6' SECTION '5-5'

(SHOWING REINF.) (SHOWING REINF) TYPICAL DETAIL OF

HAND RAIL AT FOB

DETAIL-'1'

NOTES:

GENERAL

1. ALL DIMENSIONS ARE IN MILLIMETER AND LEVELS ARE IN METER UNLESS OTHERWISE SPECIFIED.

2. DIMENSIONS SHALL NOT BE SCALED, ONLY WRITTEN DIMENSIONS SHOULD BE FOLLOWED.

6 3. GRADE OF CONCRETE= M30

℄OF BEARING ℄OF BEARING 4. GRADE OF REINFORCEMENT= FE500

300 400 250 300 5. SBC= 15t/m2 AT 2000mm FROM N.G.L.

6. CLEAR COVER TO ALL REINFORCEMENT BARS INCLUDING STIRRUPS SHALL BE ASFOLLOWS:

a. FOOTING 50 mm

215 215 b. CONCRETE PEDESTAL 40 mm

c. STAIR CASE 20 mm

335

335

7. STRUCTURAL STEEL SHALL CONFORM TO GRADE E250 QUALITY (BR) OF IS.2062-2011.

8. STEEL MEMBERS S HALL BE FREE FROM IMPERFECTION (MILL SCALES. SLAG INTRUSIONS,

LAMINATION, PITTINGS,RUSTS ETC.) THAT MAY IMPAIR STRENGTH, DURABILITY AND APPEARANCE.

ALL MATERIALS SHALL BE OF TESTED QUALITY.

9. ALL STRUCTURAL STEEL FABRICATION WORK SHALL BE CARRIED OUT AS PER RELEVANT INDIAN

STANDARDS AND MORT&H SPECIFICATIONS.

10. ALL BUTT WELDS ARE TO BE EXAMINED RADIOGRAPHICALL Y OR ANY EQUALLY EFFECTIVE NON

275 DESTRUCTIVE TEST METHOD.

11. ALL WELDS TO BE MADE BY APPROVED WELDERS USING APPROVED WELDING PROCEDURES.

12. CRITERIA FOR WELD TEST AND ACCEPTANCE SHALL BE STRICTLY AS PER THE MORT&H

SPECIFICATIONS.

6 13. FILLET WELDS ARE OF LEG SIZE 8mm MINIMUM UNLESS SPECIFIED OTHERWISE.

SECTION '6-6' SECTION '5-5' 14. ALL WELDS SHALL BE IN ONE GO (CONTINUOUS) UNLESS SPECIFIED OTHERWISE.

15. MEMBER SHALL BE RIGIDLY SECURED IN JIGS & FIXTURES WITH TEMPORARY BOLTS DURING

WELDING TO AVOID DISTORTION.

16. DURING WELDING POSITION OF MEMBERS AND ASSEMBLY SHOULD BE SUCH THAT OVERHEAD

SHALL BE AVOIDED/ MINIMIZED.

17. ALL THE MEMBERS MEETING AT A JOINTS SHOULD BE WELDED ALL AROUND.

REFER SEPERATE 18. ALL OBTUSE ANGLE CUTTING SHOULD BE DONE IN PROPER SHAPE & WITHOUT DAMAGE.

19. OVERHANGING MEMBER TO BE SUITABLY SUPPORTED TO AVOID DISTORTION DURING

DRAWING FOR TRANSPORTATION.

BEARING DETAIL 20. BREAKUP OF DIMENSION SHOULD TALLY WITH OVERALL DIMENSION FOR ALL THE MEMBER.

21. SCHEME OF ERECTION SHALL BE FINALIZED BY THE CONTRACTOR RESPONSIBLE FOR EXECUTION.

THE ERECTION SCHEME SHALL BE GOT APPROVED FROM THE ENGINEER

300 400

300 400

22. PRIOR TO COMMENCEMENT OF WORK SAFETY OF THE BRIDGE DURING ERECTION SHALL BE THE

SOLE RESPONSIBLY OF THE CONTRACTOR ALL BOLTS SHALL BE OF HSFG 8.8 GRADE CONFORMING

700

700

TO IS:4000-1992.

23. STIFFENERS SHALL BE FIT CLOSE IN BETWEEN FLANGE. NOTCHING OF STIFFENERS (MINIMUM) IF

5 5 REQUIRED MAY BE DONE TO ACCOMMODATE WELDS BETWEEN WEB & FLANGES.

24. ALL OPEN HOLES SHALL BE PLUGGED FULLY AFTER SUCCESSFUL COMPLETION OF ERECTION

WORK.

250 300 2600 300 250 25. MINOR MODIFICATION MAY BE DONE AT SITE WITH PRIOR APPROVAL OF ENGINEER-IN-CHARGE.

26. ACTUAL LENGTH OF MEMBERS SHALL BE VERIFIED AT SITE BEFORE FABRICATION.

575 575 27. THE CONSTRUCTION AGENCY SHOULD ENSURE THAT THE NECESSARY PERMISSIONS HAS BEEN

OBTAINED FROM CONCERNING AUTHORITY.

PLAN OF DETAIL-'4' 28. IF ANY AMBIGUITY FOUND IN DRAWINGS OR AT SITE BRING IT TO DESIGNER'S NOTICE BEFORE

EXECUTION.

29. THIS DRAWING SHALL BE READ IN CONJUCTION WITH SHEET 1 OF 2 THIS DRAWING.

You might also like

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- Section of Cable Trench: Y.L Y.LDocument1 pageSection of Cable Trench: Y.L Y.LKunal ChhatlaniNo ratings yet

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- TR121 0R TR221 - 8112W00077Document1 pageTR121 0R TR221 - 8112W00077Dave ChaudhuryNo ratings yet

- Slab Culvert 2m ModelDocument1 pageSlab Culvert 2m ModelMonjit Gogoi100% (1)

- Field Assembly Manual: Dump TruckDocument370 pagesField Assembly Manual: Dump TruckTiago Rodrigues100% (1)

- D8.1M 2007PV PDFDocument5 pagesD8.1M 2007PV PDFkhadtarpNo ratings yet

- KS-304 Kiosk Substation Plinth Details Enclosure Type 4-15Document1 pageKS-304 Kiosk Substation Plinth Details Enclosure Type 4-15RickNo ratings yet

- RCC Design & DetailsDocument1 pageRCC Design & DetailsKanhaiya PanwarNo ratings yet

- ART500 HorizontalDocument1 pageART500 HorizontalPuji PawokoNo ratings yet

- Beam PDFDocument1 pageBeam PDFPaschal MazikuNo ratings yet

- BeamDocument1 pageBeamPaschal MazikuNo ratings yet

- Final Structural DWG of Public ToiletDocument5 pagesFinal Structural DWG of Public ToiletSalin ShresthaNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-10.LINTEL DETAILSDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-10.LINTEL DETAILSMr. SinghNo ratings yet

- Mezzanine FloorDocument1 pageMezzanine FloorHarshit KesarwaniNo ratings yet

- 10m-300dan Concrete PoleDocument1 page10m-300dan Concrete Polenigerluv100% (3)

- Section A-A Scale 1: 1: Exterieur PoigneeDocument4 pagesSection A-A Scale 1: 1: Exterieur PoigneezizouhicheNo ratings yet

- Trolley RefugeDocument1 pageTrolley RefugesidhaksinghbhattiNo ratings yet

- Planos LTM 1100Document166 pagesPlanos LTM 1100Milagros Herrera100% (3)

- Mark Up Holding Ss WWTP 2Document1 pageMark Up Holding Ss WWTP 2rhynaka23No ratings yet

- Fence 8 M (2-2)Document1 pageFence 8 M (2-2)s.nanaahNo ratings yet

- Allorde - S1Document1 pageAllorde - S1flor johnNo ratings yet

- GARLOCKSPIRALWOUNDDocument4 pagesGARLOCKSPIRALWOUNDjose manuel perez gomezNo ratings yet

- Ign Rfa Mep CSD 010.3Document1 pageIgn Rfa Mep CSD 010.3Abdul KarimNo ratings yet

- HCL Coil 12 MT Megatherm-ModelDocument1 pageHCL Coil 12 MT Megatherm-ModelSAIKAT KARMAKARNo ratings yet

- Ormo Engneers: India Limited A Manhole With DavitDocument2 pagesOrmo Engneers: India Limited A Manhole With DavitsahilNo ratings yet

- This Site: Going TO Digos City ProperDocument14 pagesThis Site: Going TO Digos City ProperJude Darwin EmanoNo ratings yet

- R0 - All Structural Details - Foundation 15.11.22-A2-ANCHOR BOLT DETAILS (02 OF 02)Document1 pageR0 - All Structural Details - Foundation 15.11.22-A2-ANCHOR BOLT DETAILS (02 OF 02)Farhan DanishNo ratings yet

- Curtain Wall & Crash Barrier DrawingDocument1 pageCurtain Wall & Crash Barrier DrawingSharun ShajiNo ratings yet

- Drrdock Repair Jobs (Excluding DD Routines) No 1Document15 pagesDrrdock Repair Jobs (Excluding DD Routines) No 1Amit Raj AnandNo ratings yet

- ClariflocculatorDocument1 pageClariflocculatorPabitra Kumar PuhanNo ratings yet

- Les PDFDocument196 pagesLes PDFNeeraj Singh0% (1)

- HYD007-URC-A1-TF-SD-S-0006 - Rev 01Document1 pageHYD007-URC-A1-TF-SD-S-0006 - Rev 01Nithya priyaNo ratings yet

- RB 624590 007Document1 pageRB 624590 007Er Md AamirNo ratings yet

- Mir Ou: Phenol' With R Fly Proof Ventilat Top Dome 125mm ThickDocument1 pageMir Ou: Phenol' With R Fly Proof Ventilat Top Dome 125mm ThickanilNo ratings yet

- Slab 3 BDocument1 pageSlab 3 BPrakash GunasekaranNo ratings yet

- Structural Detailing of (G+2) Residential Apartment: Notes and SpecificationDocument1 pageStructural Detailing of (G+2) Residential Apartment: Notes and SpecificationSUBHADIP KARANNo ratings yet

- Brace DetailDocument1 pageBrace DetailAnonymous YW5mvpNo ratings yet

- 12M-LP-DESIGN-STRL+FDN RevDocument9 pages12M-LP-DESIGN-STRL+FDN RevSANJeEVNo ratings yet

- 1 ST - Generral NotesDocument1 page1 ST - Generral Notesmandeep gautamNo ratings yet

- A B C 4850 4850 9700 A1: Revision No. byDocument1 pageA B C 4850 4850 9700 A1: Revision No. byPaschal MazikuNo ratings yet

- Quantity L15A L15B: Saudi Basic Industries CorporationDocument1 pageQuantity L15A L15B: Saudi Basic Industries CorporationDessouki SamakNo ratings yet

- Quantity L15A L15B: Saudi Basic Industries CorporationDocument1 pageQuantity L15A L15B: Saudi Basic Industries CorporationDessouki SamakNo ratings yet

- Soil Machine Dynamics LTD: SCALE: 1: 15Document1 pageSoil Machine Dynamics LTD: SCALE: 1: 15jsNo ratings yet

- Detail - A Typical Plan For Module Mounting Structure: Section 1-1Document1 pageDetail - A Typical Plan For Module Mounting Structure: Section 1-1Spandan MurthyNo ratings yet

- Working Drawings Riprap-A2Document1 pageWorking Drawings Riprap-A2minchin talanganNo ratings yet

- B1 PDFDocument1 pageB1 PDFSuman RoyNo ratings yet

- Capacidad de 300 KG A 2000 KG: Células de CargaDocument2 pagesCapacidad de 300 KG A 2000 KG: Células de CargaMetano TanoNo ratings yet

- 2124 V5014 DRG 004 - 0 - CFDocument1 page2124 V5014 DRG 004 - 0 - CFSilver PhiriNo ratings yet

- GA Stang Fire MonitorDocument1 pageGA Stang Fire MonitorDAN DANINo ratings yet

- Zahroof Valves Inc 8535-N Jackrabbit Road, Houston 77095, TX, USADocument2 pagesZahroof Valves Inc 8535-N Jackrabbit Road, Houston 77095, TX, USAMohamed Ashraf SolimanNo ratings yet

- Foundation Plan Column Footing DetailDocument1 pageFoundation Plan Column Footing Detailparkrocky0No ratings yet

- Propshafts & Couplings: B E A R M A C HDocument31 pagesPropshafts & Couplings: B E A R M A C HJoao Espada100% (3)

- ORISSA SCHOOL (STR-ARCH) - Model - pdf73Document1 pageORISSA SCHOOL (STR-ARCH) - Model - pdf73NISHIKANTA MONDALNo ratings yet

- 8M LP Design STRL+FDNDocument9 pages8M LP Design STRL+FDNSANJeEVNo ratings yet

- Section B-B: Foundation Details For Gas Driven Engine CompressorDocument1 pageSection B-B: Foundation Details For Gas Driven Engine CompressorChandrakant GiddeNo ratings yet

- General NotesDocument1 pageGeneral NotesKishor GavaliNo ratings yet

- Pressure Relief Valve-NewDocument4 pagesPressure Relief Valve-Newnikaro1989No ratings yet

- ModelDocument1 pageModelShady RainNo ratings yet

- Cylindrical Pins Is-2393Document2 pagesCylindrical Pins Is-2393Rajasekaran MuruganNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- July-2020 CDRDocument3 pagesJuly-2020 CDRShivam SharmaNo ratings yet

- No. G47A2: Scale 1:50,000Document1 pageNo. G47A2: Scale 1:50,000Shivam SharmaNo ratings yet

- May - 2021.cdrDocument24 pagesMay - 2021.cdrShivam SharmaNo ratings yet

- Toilet Plan MorthDocument1 pageToilet Plan MorthShivam SharmaNo ratings yet

- Amendments 2017 (IRC-6, 22,83 'Spherical and Cylindrical Bearing' &112)Document24 pagesAmendments 2017 (IRC-6, 22,83 'Spherical and Cylindrical Bearing' &112)Shivam SharmaNo ratings yet

- UntitledDocument1 pageUntitledShivam SharmaNo ratings yet

- Reinforcement Detail of SlabDocument1 pageReinforcement Detail of SlabShivam SharmaNo ratings yet

- Pedestrain Guard RailDocument1 pagePedestrain Guard RailShivam SharmaNo ratings yet

- No. G47A5: Scale 1:50,000Document1 pageNo. G47A5: Scale 1:50,000Shivam SharmaNo ratings yet

- 2 Row HPC For BC SoilDocument1 page2 Row HPC For BC SoilShivam SharmaNo ratings yet

- Detail of Abutment and PierDocument1 pageDetail of Abutment and PierShivam SharmaNo ratings yet

- Detail of RCC SlabDocument1 pageDetail of RCC SlabShivam SharmaNo ratings yet

- No. G47A1: Scale 1:50,000Document1 pageNo. G47A1: Scale 1:50,000Shivam SharmaNo ratings yet

- HPC at VUP TransitionDocument1 pageHPC at VUP TransitionShivam SharmaNo ratings yet

- Gad (PCC Sub Structure) 3X10.0Document1 pageGad (PCC Sub Structure) 3X10.0Shivam SharmaNo ratings yet

- 1X12X5.5 Vup PDFDocument55 pages1X12X5.5 Vup PDFShivam SharmaNo ratings yet

- Reinforcement Details of End DiaphragmDocument1 pageReinforcement Details of End DiaphragmShivam SharmaNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- Lower GodavariDocument10 pagesLower GodavariShivam SharmaNo ratings yet

- Compendium On National Highway, CRF EtcDocument427 pagesCompendium On National Highway, CRF EtcShivam SharmaNo ratings yet

- Plan (Showing RCC Pedestal and Elastomeric BearingDocument1 pagePlan (Showing RCC Pedestal and Elastomeric BearingShivam SharmaNo ratings yet

- Introduction To Mellin Transforms Part - 01Document5 pagesIntroduction To Mellin Transforms Part - 01Shivam SharmaNo ratings yet

- (Near Mid Span) (Near Support) X-Section of Precast RCC Girder Detail-1Document1 page(Near Mid Span) (Near Support) X-Section of Precast RCC Girder Detail-1Shivam SharmaNo ratings yet

- Deletion of Provision For IMS - DT 27-01-22Document2 pagesDeletion of Provision For IMS - DT 27-01-22Shivam SharmaNo ratings yet

- Design of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMDocument24 pagesDesign of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMShivam SharmaNo ratings yet

- Effect of Earthquake in BuildingDocument20 pagesEffect of Earthquake in BuildingShivam SharmaNo ratings yet

- Mvse-101 PdeDocument123 pagesMvse-101 PdeShivam SharmaNo ratings yet

- Calculus of VariationDocument21 pagesCalculus of VariationShivam SharmaNo ratings yet

- Introduction To Hankel Transforms Part 1Document6 pagesIntroduction To Hankel Transforms Part 1Shivam SharmaNo ratings yet

- Job Hazard Analysis Site InspectionDocument12 pagesJob Hazard Analysis Site InspectionNonsoufo eze100% (1)

- Ad-90.0-E-02057-Pdf Lighting Protection Details 1Document1 pageAd-90.0-E-02057-Pdf Lighting Protection Details 1mcaslamNo ratings yet

- Steel Quiz: Manual (Document2 pagesSteel Quiz: Manual (Seismotec EngineersNo ratings yet

- RR250 - C30 OmmDocument16 pagesRR250 - C30 OmmturboshaftNo ratings yet

- Cold Facts 2011-FallDocument52 pagesCold Facts 2011-Fallchandushar1604No ratings yet

- Index of Revisions Description And/Or Revised Sheets: ENG-E&P / Ieuep-Ii / IecoDocument43 pagesIndex of Revisions Description And/Or Revised Sheets: ENG-E&P / Ieuep-Ii / IecoMatheus Pires PereiraNo ratings yet

- Spec Sheet - AirForce 500iDocument4 pagesSpec Sheet - AirForce 500iHobart Welding ProductsNo ratings yet

- 1 s2.0 0308016196000117 MainDocument61 pages1 s2.0 0308016196000117 MainHimanshu ChaudhariNo ratings yet

- RQ 10 Rev. 4 (Maio-2011) - InglêsDocument43 pagesRQ 10 Rev. 4 (Maio-2011) - InglêsMoacir Ramos JuniorNo ratings yet

- Weld TechnicsDocument208 pagesWeld TechnicsSiraj Ahamed ShaikNo ratings yet

- Heatcorrection of KilnDocument4 pagesHeatcorrection of KilnMohamed Shehata100% (2)

- RE EstimateDocument56 pagesRE EstimateAssistant EngineerNo ratings yet

- Copper Staves For Blast Furnaces 2016 PDFDocument18 pagesCopper Staves For Blast Furnaces 2016 PDFkalaiNo ratings yet

- BS 1449-1-11 - 1991Document11 pagesBS 1449-1-11 - 1991ماقوريNo ratings yet

- John Deere Dubuque Factory Specifications I: SteelDocument3 pagesJohn Deere Dubuque Factory Specifications I: SteelGANESH GNo ratings yet

- EN 1993-1-12-2007 Eurocode 3  " Design of Steel Structures  " Part 1-12 Additional Rules For The Extension of EN 1993 Up To Steel Grades S 700Document12 pagesEN 1993-1-12-2007 Eurocode 3  " Design of Steel Structures  " Part 1-12 Additional Rules For The Extension of EN 1993 Up To Steel Grades S 700Gökhan Çiçek100% (1)

- Apron FeederDocument10 pagesApron FeederKenny Ruiz100% (1)

- Filipe Giesteira ResumeDocument2 pagesFilipe Giesteira ResumeFilipe GiesteiraNo ratings yet

- Welding Program Summative Assessment: Technical Skill Attainment Assessment SummaryDocument7 pagesWelding Program Summative Assessment: Technical Skill Attainment Assessment Summaryairbuk doeing100% (1)

- Oferaustria25abril WeldersDocument8 pagesOferaustria25abril WeldersTimeaNo ratings yet

- Poster Welding P VoxXa PDFDocument1 pagePoster Welding P VoxXa PDFඅාරච්චි අයියාNo ratings yet

- Lexique Anglais FrançaisDocument222 pagesLexique Anglais FrançaislordofwarNo ratings yet

- Experience With Lined and Clad PipelinesDocument17 pagesExperience With Lined and Clad Pipelinesjoni Mart Sitio100% (2)

- ELX 321 MODULE 1 Introduction To RoboticsDocument13 pagesELX 321 MODULE 1 Introduction To RoboticsButs ButitoyNo ratings yet

- Fcaw Welding Guide PDFDocument2 pagesFcaw Welding Guide PDFElizabethNo ratings yet

- General Specification Offshore Platforms Offshore Structures ConstructionDocument89 pagesGeneral Specification Offshore Platforms Offshore Structures Constructionhazopman50% (2)

- Y-7 Yoke: AC/DC Electromagnetic YokeDocument2 pagesY-7 Yoke: AC/DC Electromagnetic YokeImmanuel RajNo ratings yet