0 ratings0% found this document useful (0 votes)

59 viewsAnnually Check List For Rig

Annually Check List For Rig

Uploaded by

ayman akrabThis document appears to be an annual inspection checklist for an oil rig. It contains over 50 inspection items divided among different systems of the rig including the engine, crown, draw work, travelling block, rotary, hydraulic system, swivel, carrier, air system, transmission, and others. The checklist includes inspection items like changing filters and fluids, checking for leaks, wear and cracks, lubricating parts, and evaluating the condition of sensors, cylinders, brakes, tires and other components. Upon completion of the inspection, mechanical and tool pusher signatures are required to sign off.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Annually Check List For Rig

Annually Check List For Rig

Uploaded by

ayman akrab0 ratings0% found this document useful (0 votes)

59 views2 pagesThis document appears to be an annual inspection checklist for an oil rig. It contains over 50 inspection items divided among different systems of the rig including the engine, crown, draw work, travelling block, rotary, hydraulic system, swivel, carrier, air system, transmission, and others. The checklist includes inspection items like changing filters and fluids, checking for leaks, wear and cracks, lubricating parts, and evaluating the condition of sensors, cylinders, brakes, tires and other components. Upon completion of the inspection, mechanical and tool pusher signatures are required to sign off.

Original Title

Annually Check List for rig

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document appears to be an annual inspection checklist for an oil rig. It contains over 50 inspection items divided among different systems of the rig including the engine, crown, draw work, travelling block, rotary, hydraulic system, swivel, carrier, air system, transmission, and others. The checklist includes inspection items like changing filters and fluids, checking for leaks, wear and cracks, lubricating parts, and evaluating the condition of sensors, cylinders, brakes, tires and other components. Upon completion of the inspection, mechanical and tool pusher signatures are required to sign off.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

59 views2 pagesAnnually Check List For Rig

Annually Check List For Rig

Uploaded by

ayman akrabThis document appears to be an annual inspection checklist for an oil rig. It contains over 50 inspection items divided among different systems of the rig including the engine, crown, draw work, travelling block, rotary, hydraulic system, swivel, carrier, air system, transmission, and others. The checklist includes inspection items like changing filters and fluids, checking for leaks, wear and cracks, lubricating parts, and evaluating the condition of sensors, cylinders, brakes, tires and other components. Upon completion of the inspection, mechanical and tool pusher signatures are required to sign off.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Technical office

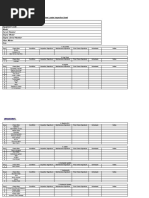

Annually Inspection for rig

Date .PN .SN Model Type Location

Engine

No Description Yes No Remarks

1 Change Oil Filter

2 Change Fuel Filter

3 Change Air Filter

4 Change The Belts

5 Check The Injectors by using CAT ET

6 Check Any Leakage

7 Change Cooling Water

8 Cleaning the Radiator

9 Check All Sensors By Using CAT ET

The Crown

No Description Yes No Remarks

1 Check the Sheaves

2 Check Sheaves Grove

3 Check and Greasing the Sheaves Bearing

4 Check the Oil seal

The Draw Work

No Description Yes No Remarks

1 Check Brake Rim

2 Change Brake Bands

3 Check Drilling Control Keys

4 Check Bands Spring

5 Check Bands Crack

6 Check Drive Chain

7 Check the Sprocket

8 Check the Auxiliary Brake Disc

9 Check the drum cooling connections

10 Check O-Matic Brakes Condition

11 Check Cooling Water Tank

The Travelling Block

No Description Yes No Remarks

1 Check Sheaves Grove

2 Check Sheaves Crack

3 Check and Greasing the Sheaves Bearing

The Rotary

No Description Yes No Remarks

1 Check The Gears

L F (02 – 05) Issue Date 24/8/2017 effective Date: 31/8/2017

2 Check The Bearing

3 Check Coupling between table and

transmission

The Hydraulic System

No Description Yes No Remarks

1 Change Hydraulic Filter

2 Change the Hydraulic oil

3 Check any leakage in Hoses of Hydraulic

system

4 Check the Cylinders for any leakage

5 Check the hydraulic Winch condition

Swivel

No Description Yes No Remarks

1 Check The Bearing

2 Greasing the Bearing

Carrier

No Description Yes No Remarks

1 Check Chassis crack

2 Check External Tires Conditions

3 Check Air Tires Pressure

4 Check the Axles of carrier

5 Check the Light

6 Check the battery condition

7 Check the battery charger system

8 Check the running start system and

protection departments

Air System

No Description Yes No Remarks

1 Check the any air leaks

2 Check the Air hoist condition

3 Check the air filters lubricators

4 Check the compressors and valves condition

The Transmission

No Description Yes No Remarks

1 Change transmission oil Filters

2 Change the transmission oil

3 Check the gear boxes

4 Check the gear boxes oil level

5 Check the spindle couplings

6 Check the clutch interlock

7 Check the spindle bearings

:Mechanical Signature: Tool Pusher Signature

L F (02 – 05) Issue Date 24/8/2017 effective Date: 31/8/2017

You might also like

- Suburban RV FURNACES SERVICE MANUALDocument40 pagesSuburban RV FURNACES SERVICE MANUALCheryl Ray95% (42)

- Marine Diesel Engines: Maintenance, Troubleshooting, and RepairFrom EverandMarine Diesel Engines: Maintenance, Troubleshooting, and RepairRating: 4.5 out of 5 stars4.5/5 (15)

- Mobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncDocument5 pagesMobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncCarwill TesdaNo ratings yet

- Detroit Diesel 50 Engine Tech ManualDocument2 pagesDetroit Diesel 50 Engine Tech Manualayman akrab100% (1)

- Sistem Low Pressure System - SD22Document19 pagesSistem Low Pressure System - SD22Wawan Jamesbon100% (4)

- Service Manual: Tennant A80Document33 pagesService Manual: Tennant A80Павел КорчагинNo ratings yet

- بنود الفحص اليومى الحفارة او كل 12 ساعةDocument1 pageبنود الفحص اليومى الحفارة او كل 12 ساعةayman akrabNo ratings yet

- Plan Maintenance System TongkangDocument2 pagesPlan Maintenance System TongkangBambang HermantoNo ratings yet

- Linde ChecklistDocument47 pagesLinde ChecklistVicente TanNo ratings yet

- Preventive Maintenance Check ListDocument23 pagesPreventive Maintenance Check Listindrabhansingh22443No ratings yet

- VEC2 - Prev-Maintenance-Checklist-scaled (1) copySSDocument1 pageVEC2 - Prev-Maintenance-Checklist-scaled (1) copySSdacunosddNo ratings yet

- Placing Boom Inspection ReportDocument3 pagesPlacing Boom Inspection ReportBishoo ShenoudaNo ratings yet

- Spider Crane Inspection ReportDocument6 pagesSpider Crane Inspection ReportBishoo Shenouda0% (1)

- بنود فحص الحفارة كل 2500 ساعةDocument1 pageبنود فحص الحفارة كل 2500 ساعةayman akrabNo ratings yet

- WO Number: - Date: - Op. CodeDocument2 pagesWO Number: - Date: - Op. CoderudiNo ratings yet

- PML 087a - PMS - EngineDocument70 pagesPML 087a - PMS - EngineFidriNo ratings yet

- GT Pre Startup Checks: S.no Work Description Status RemarkDocument2 pagesGT Pre Startup Checks: S.no Work Description Status RemarkBv RaoNo ratings yet

- Inspection Unit PC 200Lc - 8moDocument28 pagesInspection Unit PC 200Lc - 8moBima AditamaNo ratings yet

- Weekly Check List RS-1Document12 pagesWeekly Check List RS-1Pinki SahayNo ratings yet

- Fixed Crusher Plant FormDocument4 pagesFixed Crusher Plant FormPadmanava SupinNo ratings yet

- PV776 TSP154867Document5 pagesPV776 TSP154867Jesús Jaguer MeisterNo ratings yet

- Hitachi Zx870: Schedule Service 250 / 750 HoursDocument5 pagesHitachi Zx870: Schedule Service 250 / 750 HourspojokbioNo ratings yet

- 07 IOT - Form - Inspection Generator Set 1Document2 pages07 IOT - Form - Inspection Generator Set 1Oneesa Chandra0% (1)

- Checklist Fuel TruckDocument4 pagesChecklist Fuel Trucklaurdesfatima999No ratings yet

- Skid Steer Loader Inspection Report (OUT)Document4 pagesSkid Steer Loader Inspection Report (OUT)Bishoo ShenoudaNo ratings yet

- HH220i SERVICE MATRIXDocument3 pagesHH220i SERVICE MATRIXbakhtiar tiarNo ratings yet

- dd15 Coolant LossDocument2 pagesdd15 Coolant Lossmanpreetsabi88No ratings yet

- DAILY CHECK LIST - ExcavatorDocument2 pagesDAILY CHECK LIST - Excavatorsubhu kumarNo ratings yet

- Annual Vehicle ChecklistDocument2 pagesAnnual Vehicle ChecklistabdouNo ratings yet

- بنود الفحص اليومى للاوناشDocument1 pageبنود الفحص اليومى للاوناشayman akrabNo ratings yet

- New Microsoft Office Excel WorksheetDocument4 pagesNew Microsoft Office Excel Worksheetsanjeet giriNo ratings yet

- Group 2Document10 pagesGroup 2Ganapathi SankarNo ratings yet

- Conveyor Check ListDocument2 pagesConveyor Check Listh1549697100% (1)

- AIP-Aug-PM - Inspection ReopertDocument16 pagesAIP-Aug-PM - Inspection Reopertyibelta abebeNo ratings yet

- TM 120 Daily and Weekly Inspection and Maintenance TasksDocument23 pagesTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Transit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksDocument1 pageTransit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksRísês ÃfrözNo ratings yet

- Pre-Mob Function Test Certificate W 590 COMP-034 FP-030Document15 pagesPre-Mob Function Test Certificate W 590 COMP-034 FP-030Mohamed ShafeeqNo ratings yet

- Preventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForDocument2 pagesPreventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForAndrewNo ratings yet

- Checklist. For Dredging Equipment SurveysDocument7 pagesChecklist. For Dredging Equipment SurveysBambang Setyo UtomoNo ratings yet

- Inspection Report Week 1 AprilDocument5 pagesInspection Report Week 1 Aprilyibelta abebeNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- Motors Preventive Mentinance SheetDocument5 pagesMotors Preventive Mentinance SheetEngr. Talat KhanNo ratings yet

- NO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsDocument3 pagesNO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsrandyNo ratings yet

- TM 80 Daily and Weekly Inspection and Maintenance TasksDocument25 pagesTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Check Sheet Equipment Pre CommDocument23 pagesCheck Sheet Equipment Pre CommHANIF AKBARNo ratings yet

- PV776 TSP154716Document4 pagesPV776 TSP154716Jesús Jaguer MeisterNo ratings yet

- Grand Cherokee 2008 5.7LDocument254 pagesGrand Cherokee 2008 5.7Llefont100% (1)

- PDI AdtDocument3 pagesPDI AdtSigit SugionoNo ratings yet

- AAF QA GF 014 Plant Preventive MaintenanceDocument3 pagesAAF QA GF 014 Plant Preventive Maintenanceabdulahad.snmNo ratings yet

- DP 3 CompactorDocument4 pagesDP 3 Compactoripw.hrdNo ratings yet

- dd15 Coolant LoseDocument2 pagesdd15 Coolant Losemanpreetsabi88No ratings yet

- SLS-SP-2021-405 Service Sheet Dozer 4000 HoursDocument5 pagesSLS-SP-2021-405 Service Sheet Dozer 4000 HoursYUSRO BAHRUL HADI KUSUMANo ratings yet

- Maintenance Check ListDocument2 pagesMaintenance Check ListRagil PamungkasNo ratings yet

- 5 - Maintenance Servicing ChecklistDocument2 pages5 - Maintenance Servicing ChecklistAdriant WidayatNo ratings yet

- Heavy Vehicle Inspection Report: Excavator - Excavator Pre-Use Inspection ChecklistDocument4 pagesHeavy Vehicle Inspection Report: Excavator - Excavator Pre-Use Inspection ChecklistMark VillafloresNo ratings yet

- JSW Jaigarh Port LTD.: Sap Order NoDocument9 pagesJSW Jaigarh Port LTD.: Sap Order NoGajanan ChavhanNo ratings yet

- IX. Pengecekan Dan PerawatanDocument10 pagesIX. Pengecekan Dan Perawatanrandifradana83No ratings yet

- 1823 Chapter VDocument10 pages1823 Chapter VberkahharianNo ratings yet

- Eue-Lab Final See2Document29 pagesEue-Lab Final See2Harsha Samagara100% (1)

- Service Package KOM PC800 2000 HoursDocument5 pagesService Package KOM PC800 2000 HourspojokbioNo ratings yet

- Form Inspeksi CompressorDocument1 pageForm Inspeksi CompressorekoimampNo ratings yet

- SD46Document1 pageSD46ayman akrabNo ratings yet

- Nomac 247 - 900 Series Mobile Drilling RigDocument20 pagesNomac 247 - 900 Series Mobile Drilling Rigayman akrabNo ratings yet

- Transmission Xs Fe 75W-80: Very High Performance Lubricant For Heavy Duty Manual and Automated TransmissionsDocument2 pagesTransmission Xs Fe 75W-80: Very High Performance Lubricant For Heavy Duty Manual and Automated Transmissionsayman akrabNo ratings yet

- Auction: Odessa TexasDocument8 pagesAuction: Odessa Texasayman akrabNo ratings yet

- Ultrasonic-Cutter YPQ-40: Technical InformationDocument1 pageUltrasonic-Cutter YPQ-40: Technical Informationayman akrabNo ratings yet

- Di400 Ca Product Sheet 2018 Re 1519056320Document2 pagesDi400 Ca Product Sheet 2018 Re 1519056320ayman akrabNo ratings yet

- J1939-0 - Engine #1 Angular SpeedDocument7 pagesJ1939-0 - Engine #1 Angular Speedayman akrabNo ratings yet

- Model HC (Dry) : Pneumatically or Hydraulically Actuated ClutchesDocument4 pagesModel HC (Dry) : Pneumatically or Hydraulically Actuated Clutchesayman akrabNo ratings yet

- Caterpillar Power SystemsDocument92 pagesCaterpillar Power Systemsayman akrab100% (1)

- Drawworks: Stewart & Stevenson Product SpecificationsDocument4 pagesDrawworks: Stewart & Stevenson Product Specificationsayman akrabNo ratings yet

- V7ug bk1Document218 pagesV7ug bk1ayman akrabNo ratings yet

- 3508 SS 8769325 18377766 017 470kW 1200rpm PDFDocument6 pages3508 SS 8769325 18377766 017 470kW 1200rpm PDFayman akrabNo ratings yet

- MaintenanceDocument1 pageMaintenanceayman akrabNo ratings yet

- بنود الفحص اليومى لكمبيوسور الهواءDocument1 pageبنود الفحص اليومى لكمبيوسور الهواءayman akrabNo ratings yet

- بنود فحص الحفارة كل 2500 ساعةDocument1 pageبنود فحص الحفارة كل 2500 ساعةayman akrabNo ratings yet

- Lister Petter T Series Workshop Manual Edition 12 May 2005 Lister Ts1and Ts2Document0 pagesLister Petter T Series Workshop Manual Edition 12 May 2005 Lister Ts1and Ts2Katu2010100% (1)

- Advanced Level Lecture # 2Document23 pagesAdvanced Level Lecture # 2Vivian VijayNo ratings yet

- Types of Beams in Engineering MechanicsDocument7 pagesTypes of Beams in Engineering Mechanicsmarvellousokezie6No ratings yet

- List Persamaan Part Geely Persamaan Part mk1mk2mk Cross Ket Pandacross Ket - CompressDocument4 pagesList Persamaan Part Geely Persamaan Part mk1mk2mk Cross Ket Pandacross Ket - CompressRandy BellamyNo ratings yet

- Frint Back: An ISO 9001: 2008 Certified CompanyDocument4 pagesFrint Back: An ISO 9001: 2008 Certified CompanyVishal SharmaNo ratings yet

- Thin-Walled Cylinders Stress TheoryDocument67 pagesThin-Walled Cylinders Stress TheoryMaurizio FalconieriNo ratings yet

- Honda Crf250x Manual Do Proprietario InglesDocument174 pagesHonda Crf250x Manual Do Proprietario InglesDenissonPagliaNo ratings yet

- Kenr5125kenr5125-02 SisDocument13 pagesKenr5125kenr5125-02 Sisygor valdezNo ratings yet

- Metric Fasteners For Use in Structural Applications: ASME B18.2.6M-2012Document20 pagesMetric Fasteners For Use in Structural Applications: ASME B18.2.6M-2012Ganesh YadavNo ratings yet

- Jishu HozenDocument85 pagesJishu HozenRakesh Tigadi100% (2)

- Ultra-High-Purity Regulators: For Corrosive ServiceDocument1 pageUltra-High-Purity Regulators: For Corrosive ServiceOmar Iván Rozas GuzmánNo ratings yet

- 2012 ModelS LHD ReleaseDocument112 pages2012 ModelS LHD ReleaseBilly Hagler100% (2)

- 1 Input Data: Hilti PROFIS Engineering 3.0.64Document10 pages1 Input Data: Hilti PROFIS Engineering 3.0.64maheshbandhamNo ratings yet

- EN - MRI Curs1 PDFDocument70 pagesEN - MRI Curs1 PDFChirila AndreiNo ratings yet

- Types of Air Brake System:: Direct Release System: in Direct Release System The Brake Cylinder PressureDocument4 pagesTypes of Air Brake System:: Direct Release System: in Direct Release System The Brake Cylinder Pressuremanoj kumarNo ratings yet

- Goa Shipyard Limited Recruitment NotificationDocument20 pagesGoa Shipyard Limited Recruitment NotificationKshitijaNo ratings yet

- Ced 506 Hydraulics Assignment TwoDocument6 pagesCed 506 Hydraulics Assignment TwoCula Nauman TamaniiNo ratings yet

- Steam Turbine Inspection Bhel PDFDocument26 pagesSteam Turbine Inspection Bhel PDFReda Nari100% (1)

- 2 - One Sphere in Stokes FlowDocument46 pages2 - One Sphere in Stokes FlowqoberifNo ratings yet

- Connector Selector PDFDocument64 pagesConnector Selector PDFEduardo David100% (1)

- Catalogue: Flow Control EquipmentDocument19 pagesCatalogue: Flow Control EquipmentFranklin NavarroNo ratings yet

- Structural Analysis6Document18 pagesStructural Analysis6GrantHermanNo ratings yet

- Hydroshield: Conical and Cylindrical (H) Epa E10-E12Document2 pagesHydroshield: Conical and Cylindrical (H) Epa E10-E12HANIF AKBARNo ratings yet

- Johnson EvinrudegearcasecomponentsDocument71 pagesJohnson Evinrudegearcasecomponentswguenon100% (2)

- CONFERENCE Direct Shear Strength Properties of Limestone-Blended PDFDocument6 pagesCONFERENCE Direct Shear Strength Properties of Limestone-Blended PDFbagus yosan setiawanNo ratings yet

- Technical Note 37 - Pickup Truck Impacting Against Rigid WallDocument11 pagesTechnical Note 37 - Pickup Truck Impacting Against Rigid WallengrmudasarNo ratings yet

- Data Sheet Mini-Striker Dist PDFDocument4 pagesData Sheet Mini-Striker Dist PDFAnto Banyu Biru100% (1)

- Reference Standards PDFDocument1 pageReference Standards PDFChandrashekhar ThiramdasuNo ratings yet

- Steel-Hardness Conversion-Table PDFDocument2 pagesSteel-Hardness Conversion-Table PDFEngineering ProductionNo ratings yet