ITR For Electrical Instrument PDF

ITR For Electrical Instrument PDF

Uploaded by

Cokro YudhaCopyright:

Available Formats

ITR For Electrical Instrument PDF

ITR For Electrical Instrument PDF

Uploaded by

Cokro YudhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ITR For Electrical Instrument PDF

ITR For Electrical Instrument PDF

Uploaded by

Cokro YudhaCopyright:

Available Formats

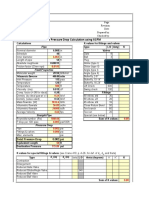

CHECK AND TEST INSTRUMENT AIR SUPPLY PIPING/TUBING

Project Title :

Company : Date :

Contractor : Report No :

Sub-Contractor : Page of

RESULT INSPECTED BY

INSPECTION

No. TAG No. VISUAL INSPECTION SUB- REMARKS

BLOW TEST LEAK TEST DATE KPMOG

CONTRACTOR

REMARKS :

Prepared by, Witnessed/Reviewed by, Witnessed/Reviewed by

Print name Date Print name Date Print name Date

CHECK AND TEST CABLING AND WIRING

Project Title :

Company : Date :

Contractor : Report No :

Sub-Contractor : Page of

VISUAL INSULATION RESISTANCE TEST (MΩ) INSPECTED BY

INSPECTION

No. TAG NO. CONTINUITY REMARKS

INSPECTION DATE

CORE TO CORE TO SUB-

RESULT KPMOG

CORE EARTH CONTRACTOR

REMARKS :

Prepared by, Witnessed/Reviewed by, Witnessed/Reviewed by

Print name Date Print name Date Print name Date

CHECK AND TEST ELECTRICAL MOTORS

Project Title :

Company : Date :

Contractor : Report No :

Sub-Contractor : Page of

REFERENCES

Drawing No. Location

Revision Equipment ID

Sheet System No.

Approval

No. Description of Checks Remarks

Sub-Con KPMOG CPGL

Verify that the name plate date included area clarification is correct as

1 per drawings

2 Verify that installation location and orientation is as per drawings

Verify that the motor rotor turns easily by hand and there is no friction or

3 binding

Verify that the bolting and weatherproofing of the terminal box are

completed and

4 tight. the terminal connections and control cable connections are correct

and tight.

5 Check that the enclosure seals and gaskets of terminal boxes are intact.

6 Verify that the glands and plugs are complete and tight with accessory.

7 Verify the continuity of equipment earthing connection.

Verify that the local control station included control wire is properly

8 installed with

Perform the insulation resistance test of motor winding with cable

9

RYB – E: _______________MΩ

Perform the insulation resistance test of space heater with cable

10

L – E: _______________MΩ

11

Perform the polarization index test of motor (Applicable for MV Motor

Only)

Applicable / Not Applicable

RST — E: Min (10 minutes test)

RST-E:

COMMENT

Prepared by, Witnessed/Reviewed by, Witnessed/Reviewed by

Print name Date Print name Date Print name Date

CHECK AND TEST FOR PANEL

Project Title :

Company : Date :

Contractor : Report No :

Sub-Contractor : Page of

REFERENCES

Drawing No. Location

Revision Equipment ID

Sheet System No.

Approval

No. Description of Checks Remarks

Sub-Con KPMOG CPGL

1 Check that the control panel has no mechanical damage.

2 Check that the board assembly, bolting, orientation, alignment and

leveling are satisfactory.

3 Check the safety features are satisfactory.

4 Check the nameplate details.

5 Check the components of panel are correct.

6 Check the close and open operation of mcb’s by hand.

7 Check and continuity test of earthing connection to main grid

system.

8 Verify the equipment has been thoroughly cleaned.

9 Perform the insulation resistance test

(Applied voltage is 500 V Line to earth : MOhm

(Acceptance criteria is above 1.0 mohm)

COMMENT :

Prepared by, Witnessed/Reviewed by, Witnessed/Reviewed by

Print name Date Print name Date Print name Date

You might also like

- F4ae0481a 681aDocument190 pagesF4ae0481a 681ajvega_534120No ratings yet

- Urbanization and IndustrializationDocument6 pagesUrbanization and Industrializationshahriar sNo ratings yet

- MS - Installation - of - Containments - QC - REV - 2Document7 pagesMS - Installation - of - Containments - QC - REV - 2irfan vpNo ratings yet

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Document1 pageKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmy100% (1)

- Saudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 ElectDocument7 pagesSaudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 Electkarthi51289No ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Recommended Practice - Davey PumpDocument32 pagesRecommended Practice - Davey PumpAlghazee Abo-jlalNo ratings yet

- Practice Problems DesignDocument5 pagesPractice Problems DesignEric Ibarra100% (2)

- SATR-J-6505-Rev 0 PDFDocument5 pagesSATR-J-6505-Rev 0 PDFAdel KlkNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYDocument2 pagesCommissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYtajudeenNo ratings yet

- Itp For Commissioning Procedure For LV Switchgear SystemDocument4 pagesItp For Commissioning Procedure For LV Switchgear SystemSuliman100% (1)

- MHI Electrical 1st Comment RSAE-MTS-QA-EL-009 MTS For MotorsDocument17 pagesMHI Electrical 1st Comment RSAE-MTS-QA-EL-009 MTS For MotorskamilNo ratings yet

- Itp - Electrical Second FixDocument4 pagesItp - Electrical Second Fixirfan vpNo ratings yet

- Inspection Test Plan For ElectricalDocument39 pagesInspection Test Plan For Electricalpire.resiNo ratings yet

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNo ratings yet

- For Information For Review For Approval For Construction As-BuiltDocument35 pagesFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNo ratings yet

- ELECT-TIC-8.2 (Diesel-Generator Installation & Identification Visual Inspection)Document2 pagesELECT-TIC-8.2 (Diesel-Generator Installation & Identification Visual Inspection)Muhammad IrfanNo ratings yet

- KP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationDocument1 pageKP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationUtku Can KılıçNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Document4 pagesFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- 13.11.2023 SKD - DEC - QAC - ITP - 054 - ITP - of Cable Installation and TerminationDocument20 pages13.11.2023 SKD - DEC - QAC - ITP - 054 - ITP - of Cable Installation and Terminationsokhib.salimov1992No ratings yet

- Cable Laying ItpDocument6 pagesCable Laying ItpPetra SehsanyotoNo ratings yet

- Method Statement For Cable Laying & TerminationDocument18 pagesMethod Statement For Cable Laying & TerminationVikramNo ratings yet

- Doha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalDocument1 pageDoha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalmeeNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Multi Core Cable Test SheetDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Multi Core Cable Test SheetmeeNo ratings yet

- Checklist CablesDocument2 pagesChecklist CablesSourav RanaNo ratings yet

- Transformer 1 MosDocument5 pagesTransformer 1 MosMohamedAhmedFawzyNo ratings yet

- Motor Electric Test RecordDocument1 pageMotor Electric Test RecordArka HatiNo ratings yet

- QDR-GCS-ESJ-REP-1000 RevADocument31 pagesQDR-GCS-ESJ-REP-1000 RevAshaheen iqbal100% (2)

- MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1Document13 pagesMM ZTK 1a ZPQ Qua TPN 8055 Rev.a1sfd640No ratings yet

- ChecklistDocument14 pagesChecklistInstrument SCINo ratings yet

- Hopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistDocument2 pagesHopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistRajuNo ratings yet

- Itr Ew 03b HV MV SwitchboardDocument6 pagesItr Ew 03b HV MV Switchboardmatreng100% (1)

- Installation of Ac Ups: Project: Construction of Rail Fed Depot at Village Swaipura/Chotila, Dist-Pali, RajasthanDocument8 pagesInstallation of Ac Ups: Project: Construction of Rail Fed Depot at Village Swaipura/Chotila, Dist-Pali, RajasthansidharthNo ratings yet

- Cable Tray Erection ProcedureDocument3 pagesCable Tray Erection ProcedureAnmohieyNo ratings yet

- Inspection Checklist: Light Installation Check ListDocument2 pagesInspection Checklist: Light Installation Check ListanilNo ratings yet

- E&I QAP's - Submitted To Contractor HZADocument33 pagesE&I QAP's - Submitted To Contractor HZASuraj Shetty100% (1)

- MCCB Replacement in Switch Rack S-SB-115 and Verification of Voltage Testing.Document11 pagesMCCB Replacement in Switch Rack S-SB-115 and Verification of Voltage Testing.hse quizNo ratings yet

- Check List Pulling CableDocument2 pagesCheck List Pulling CableAldeline Sungahid100% (1)

- KP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSDocument22 pagesKP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSUtku Can KılıçNo ratings yet

- Instrument J.BOX ITP 01.09.2020Document2 pagesInstrument J.BOX ITP 01.09.2020Ahmad DagamsehNo ratings yet

- Cable GlandingDocument5 pagesCable GlandingSourav RanaNo ratings yet

- H.T. Motor Operating Checking ListDocument3 pagesH.T. Motor Operating Checking ListsuperthambiNo ratings yet

- Field Quality Plan of EHV Power CablesDocument10 pagesField Quality Plan of EHV Power CablesMohammed TauseefNo ratings yet

- Installation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListDocument1 pageInstallation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListZulfequar R. Ali KhanNo ratings yet

- SSE-QC-ELE-525-Cable LayingDocument3 pagesSSE-QC-ELE-525-Cable LayingBhalsingh JangraNo ratings yet

- Rev02-Work Method Statement For LV and MV Motor InstallationDocument14 pagesRev02-Work Method Statement For LV and MV Motor InstallationMahaboob PashaNo ratings yet

- OCP - 06 LT Panel (SWGR)Document10 pagesOCP - 06 LT Panel (SWGR)NaveedNo ratings yet

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- Certificate of Motor Solo RunDocument1 pageCertificate of Motor Solo RuntalhaNo ratings yet

- Inspected by QCP Approval 1-APC 1-Employer APC 2 - DAR 2-Engineer DAR 3 - Contractor NEGEMCO 4 - Vendor 5 - Third PartyDocument2 pagesInspected by QCP Approval 1-APC 1-Employer APC 2 - DAR 2-Engineer DAR 3 - Contractor NEGEMCO 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- IQ347-300-EL-CHL-00007 LV Cable Drum Test Report SheetDocument1 pageIQ347-300-EL-CHL-00007 LV Cable Drum Test Report SheetkamilNo ratings yet

- 21 - Low Voltages Electl. Power Conductors and CablesDocument6 pages21 - Low Voltages Electl. Power Conductors and CablesWalid MarhabaNo ratings yet

- Qap (T183-E-Qp-003) For LT PanelDocument14 pagesQap (T183-E-Qp-003) For LT PanelTejendra TambeNo ratings yet

- Instrument Calibration ChecklistDocument11 pagesInstrument Calibration ChecklistMohd A IshakNo ratings yet

- 00 MSCL Sec I&c Itp 001 Rev.bDocument17 pages00 MSCL Sec I&c Itp 001 Rev.bMohd Sami UddinNo ratings yet

- ITP (Electrical)Document6 pagesITP (Electrical)petroniko8880% (5)

- Method Statement For Installation of Light Fittings Luminary's Exterior InteriorDocument7 pagesMethod Statement For Installation of Light Fittings Luminary's Exterior InteriorCSD shakthiNo ratings yet

- Old LT Panel 400 AmpDocument5 pagesOld LT Panel 400 AmpAbhinav TewariNo ratings yet

- Blk-2 Fiber MSDDocument26 pagesBlk-2 Fiber MSDanbarasusivaprakasamNo ratings yet

- Method Statement - Bus DuctDocument2 pagesMethod Statement - Bus Ductsoubhagya100% (1)

- Tightening BoltDocument10 pagesTightening Boltdoan gunawan100% (1)

- Record of Oil Flush - KPMOG PDFDocument1 pageRecord of Oil Flush - KPMOG PDFCokro YudhaNo ratings yet

- Reading Sheet - Inspection Form (Comp - Engine) PDFDocument5 pagesReading Sheet - Inspection Form (Comp - Engine) PDFCokro YudhaNo ratings yet

- Cylinder Liner Compressor Inspection: Unit: MMDocument1 pageCylinder Liner Compressor Inspection: Unit: MMCokro YudhaNo ratings yet

- Crankshaft Engine & Compr FormDocument1 pageCrankshaft Engine & Compr FormCokro YudhaNo ratings yet

- Connecting Rod FormDocument1 pageConnecting Rod FormCokro YudhaNo ratings yet

- Compressor Start-Up Check ListDocument6 pagesCompressor Start-Up Check ListCokro YudhaNo ratings yet

- Ariel Compressor Bolting Tightening Torque-Reciprocating CompDocument8 pagesAriel Compressor Bolting Tightening Torque-Reciprocating CompCokro Yudha100% (1)

- Fiba Guide To Basketball Facilities - Air DistributionDocument2 pagesFiba Guide To Basketball Facilities - Air DistributionMustafa Onur SarıkayaNo ratings yet

- Chapter 4 Single-Phase SystemDocument38 pagesChapter 4 Single-Phase SystemRenu SekaranNo ratings yet

- BMCT NotesDocument22 pagesBMCT NotesPrakriti GoelNo ratings yet

- ErectionDocument16 pagesErectionÞÜšhpendra JAñgidNo ratings yet

- Mass Flow MeterDocument158 pagesMass Flow MeterMuhammad Furqan JavedNo ratings yet

- UDRS01 - 01GBMaintenance DRS LastDocument460 pagesUDRS01 - 01GBMaintenance DRS LastRachid Smaili100% (10)

- Approved Water Product As of 06092019 FittingsDocument6 pagesApproved Water Product As of 06092019 FittingsHazel Liow HYNo ratings yet

- XXI Paper HAZOP ErrorsDocument6 pagesXXI Paper HAZOP ErrorsravisankarNo ratings yet

- A Folded PlateDocument10 pagesA Folded PlatePradnya ChavanNo ratings yet

- Star Plastic EbrochureDocument8 pagesStar Plastic EbrochureManan ShahNo ratings yet

- New in JlinproDocument3 pagesNew in JlinproVedran StojanovićNo ratings yet

- Predicting Weld Structure Using Modified Schaeffler Constitution DiagramDocument6 pagesPredicting Weld Structure Using Modified Schaeffler Constitution DiagramzoranNo ratings yet

- Pages From ASME B31.3 2018 PDFDocument6 pagesPages From ASME B31.3 2018 PDFAli AdnanNo ratings yet

- Is Copper Really The Only Option For ADocument13 pagesIs Copper Really The Only Option For AtermomontazaNo ratings yet

- SILCOSVS Rev02 BrochureDocument64 pagesSILCOSVS Rev02 BrochuremadanielabgNo ratings yet

- CC FS Concast Long-Life-Tundish 150604Document2 pagesCC FS Concast Long-Life-Tundish 150604Partha AdhikaryNo ratings yet

- Grinding Machine: Navigation Search List of References External Links ImproveDocument13 pagesGrinding Machine: Navigation Search List of References External Links ImprovePruthviKashiNo ratings yet

- Esd201306en S2danny1 20150615174338539Document36 pagesEsd201306en S2danny1 20150615174338539BogieGunturNo ratings yet

- Slurry Infiltrated Fiber Concrete SIFCON With Waste Tire Rubber..Document17 pagesSlurry Infiltrated Fiber Concrete SIFCON With Waste Tire Rubber..علي مظفرNo ratings yet

- States of MatterDocument28 pagesStates of Matterapi-261462856No ratings yet

- MTC DetailsDocument2 pagesMTC DetailsHarisul IslamNo ratings yet

- General Method For Cable Sizing - Electrical Installation GuideDocument10 pagesGeneral Method For Cable Sizing - Electrical Installation Guidebhaskar_dandapathakNo ratings yet

- Capacitive Proximity Sensors Osisense XT: CatalogueDocument22 pagesCapacitive Proximity Sensors Osisense XT: CataloguetorrieistegNo ratings yet

- 20 HP Three Phase Ac Induction Motor PDFDocument32 pages20 HP Three Phase Ac Induction Motor PDFDhruba Jyoti BuragohainNo ratings yet

- Gas Pressure Drop Calculation Using SCFM: Pipe ValvesDocument3 pagesGas Pressure Drop Calculation Using SCFM: Pipe ValvesDavid Muñoz CastroNo ratings yet

- Use of L27 Orthogonal Array With Grey Taguchi Technique To Optimize MRR and SR in EDM Machining For Al - 6082, Al - 6061, Al - 2014 and Mild SteelDocument11 pagesUse of L27 Orthogonal Array With Grey Taguchi Technique To Optimize MRR and SR in EDM Machining For Al - 6082, Al - 6061, Al - 2014 and Mild SteelAneesh Kumaar IyyapphanNo ratings yet