MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1

MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1

Uploaded by

sfd640Copyright:

Available Formats

MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1

MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1

Uploaded by

sfd640Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1

MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1

Uploaded by

sfd640Copyright:

Available Formats

PTTEP International Limited

Page 2/6

TABULATION OF REVISED PAGES

SHEET 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 REVISIONS A1 A2

X X X X X X

B1 B2

SHEET 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 1 2 3 4 5 6 7 8 9

REVISIONS A1 A2 B1 B2

ATTACHMENT \ APPENDIX

A B C D E F G H I

Zawtika Development Project, Phase 1A EPCIC of Zawtika Processing and Living Quarters Platform

Document : MM-ZTK-1A-ZPQ-QUA-TPN-8055 Revision Date : A1 : 31-August-12

PTTEP International Limited

Page 3/6

CONTENTS

1.0 SCOPE ........................................................................................................................ 4 2.0 OBJECTIVE ................................................................................................................. 4 3.0 REFERENCE DOCUMENTS....................................................................................... 4 4.0 ABBREVIATIONS ........................................................................................................ 5 5.0 RESPONSIBILITIES .................................................................................................... 5 6.0 LEVEL OF INSPECTION ............................................................................................. 6 7.0 ATTACHMENT............................................................................................................. 6

7.1 Attachment - A - ITP (ELECTRICAL, INSTRUMENTATION & TELECOM ) .......................... 6

Zawtika Development Project, Phase 1A EPCIC of Zawtika Processing and Living Quarters Platform

Document : MM-ZTK-1A-ZPQ-QUA-TPN-8055 Revision Date : A1 : 31-August-12

PTTEP International Limited

Page 4/6

1.0

SCOPE This Inspection and test plan shall be used to define the type and level of fabrication inspection requirements applicable to electrical, instrumentation and telecommunication installation in Zawtika Development Project, Phase 1A - EPCIC for Processing and Living Quarters Platform.

2.0

OBJECTIVE This Inspection and Test Plan shall be used to define the type and level of inspection requirements, which are to be performed during the electrical, instrumentation and telecommunication equipment installation of the project. It also identifies the procedure to be followed, reference to a specification, codes or standards for the acceptance criteria and verifying documents which are needed to provide the documentary evidence of the successful completion of the inspection activity and compliance with specified test requirements.

3.0

REFERENCE DOCUMENTS ZGS-TEL-101 Rev.0 ZGS-INS-101 Rev.0 ZGS-ELE-102 Rev.0 ZGS-PCC-101 Rev.0 ZGS-PCC-103 Rev.0 ZGS-COR-301 Rev.0 ZGS-ELE-402 Rev.0 ZGS-GEN-004 Rev.0 ZGS-GEN-006 Rev.0 Exhibit H MM-ZTK-1A-ZPQ-MAT-PRC-8009 MM-ZTK-1A-ZPQ-QUA-PRC-8055 MM-ZTK-1A-ZPQ-QUA-PRC-8056 MM-ZTK-1A-ZPQ-QUA-PRC-8058 Design, supply and Installation of Telecommunication systems. Instrumentation Engineering, supply and Construction general requirement. Electrical requirement for Mechanical package equipment. Precommissioning and Commissioning Specification. Commissioning Execution. Painting of Offshore and Coastal Structural and Facilities. Electrical Installation Specification. Material Traceability. QA/QC inspection and Testing. Quality Assurance and Quality Control. Material Management Plan. Welder Qualification Procedure. Welding consumable control procedure. Dimensional Control Procedure.

Document : MM-ZTK-1A-ZPQ-QUA-TPN-8055 Revision Date : A1 : 31-August-12

Zawtika Development Project, Phase 1A EPCIC of Zawtika Processing and Living Quarters Platform

PTTEP International Limited

Page 5/6

MM-ZTK-1A-ZPQ-QUA-PRC-8061 MM-ZTK-1A-ZPQ-QUA-PRC-8062 4.0 ABBREVIATIONS AWS COMPANY CONTRACTOR QA/QC ITP NDT PMT WPS PQR 5.0 5.1 5.2 5.3 RESPONSIBILITIES : : : : : : : : :

Material Traceability Procedure. Visual Inspection Procedure.

American Welding Society. PTTEP International Ltd (PTTEPI) SMOE Pte Ltd. Quality Assurance and Quality Control. Inspection and Test Plan. Non-destructive Testing Project Management Team. Welding Procedure Specification. Procedure Qualification Record.

Project QA/QC Manager, assisted by Construction QA/QC Manager, is responsible for establishing and monitoring the Inspection and Test Plans. Project Director is responsible for Implementation of the Inspection and Test Plans. Construction QA/QC Manager is responsible for ensuring Inspections are carried out, documented and all the relevant parties are informed in advance about inspection schedules. Discipline lead Engineers are responsible for liasing with the respective inspectors for all day to day activities. QC Inspector of the discipline shall be responsible for documenting the inspection at every stage with the approved format report. After completion of the inspection, QC Inspector of the discipline shall be responsible for generation of the relevant inspection and test reports. Inspection and test report shall be submitted to COMPANY for signature, as agreed upon elsewhere in this ITP, on regular basis. Welding Engineer is responsible for preparation of WPS, PQR ,WQT, maintain welder records and weld repair status of individual welder and welding operator. Dimensional Surveyor is responsible for executing dimensional control surveys at various stages of installation.

5.4 5.5

5.6 5.7

Zawtika Development Project, Phase 1A EPCIC of Zawtika Processing and Living Quarters Platform

Document : MM-ZTK-1A-ZPQ-QUA-TPN-8055 Revision Date : A1 : 31-August-12

PTTEP International Limited

Page 6/6

6.0 6.1

LEVEL OF INSPECTION There are three levels of inspections to be used in the Inspection and Test Plan. These three levels may be combined to form more than one inspection in any stage of inspection, which may be needed: (H) Hold Point Hold Points are defined as critical steps in construction and testing. At Hold Point, CONTRACTOR and its SUBCONTRACTOR (where applicable) will advise COMPANY Representative, an agreed time in advance of the operation, so that, it can be witnessed by COMPANYs Quality Representative. Work shall not proceed past the Hold Point without witness by COMPANYs Quality Representative, except by prior written agreement from COMPANY Representative.

(W) Witness Inspection Witness Points are defined as critical steps in construction and testing. At Witness Point, CONTRACTOR and its SUBCONTRACTOR (where applicable) will advise COMPANY Representative, an agreed time in advance of the operation, so that, it can be witnessed by COMPANYs Quality Representative. Work may proceed past the Witness Point, if COMPANYs Quality Representative has advised CONTRACTOR that he/she cannot attend. In the event of a Witness Point being deferred by COMPANYs Quality Representative, the next same operation will be witnessed. (R) Review Points Review Points are defined as steps in construction and testing, whereby COMPANYs Quality Representative, through the reviewing process, shall confirm that all quality records and documentation applicable to the inspection activity or test, are in compliance. COMPANYs Quality Representative shall endorse the records/documents.

(M) Monitoring Points Monitoring Points are defined as steps in construction and testing, whereby COMPANYs Quality Representative, through random examination and observations, shall identify that inspections, construction steps and testing activities are being fulfilled (generally used when a repetitious process or multiple similar activities are being carried out). The Inspection Notification (Request for Inspection) shall be issued to COMPANYs Quality Representative at least 24 hrs. in advance for inspection on normal working days. However, CONTRACTORs Quality Representative shall coordinate with COMPANYs Quality Representative to agree upon for performing urgent inspections activities. 7.0 7.1 ATTACHMENT Attachment - A - ITP (ELECTRICAL, INSTRUMENTATION & TELECOM )

Attachment - A - ITP E, I & T

Zawtika Development Project, Phase 1A EPCIC of Zawtika Processing and Living Quarters Platform

Document : MM-ZTK-1A-ZPQ-QUA-TPN-8055 Revision Date : A1 : 31-August-12

- 1 -Page 1 of 7

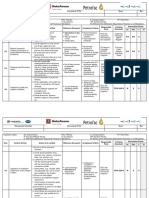

INSPECTION AND TEST PLAN (ELETRICAL, INSTRUMENTATION & TELECOMMUNICATION) ATTACHMENT - A Project : Zawtika Development Project, Phase 1A. - EPCIC of Zawtika Processing and Living Quarters Platform. Project Reference - MPG006 Item

A 1

Page 1 of 7 Date: 31-Aug-12 Revision : A1 SMOE COMPANY

Contract Number : IMO-EMP-CT-10-1015 Document Number : MM-ZTK-1A-ZPQ-GUA-TPN-8055 Acceptance Criteria Verifying Document

N/A

Process Description

REVIEWING CONSTRUCTION PACKAGES Review specification, standards, procedures and any other relevant information to ascertain its extent and complexity RECEIVING AND STORING OF EQUIPMENT (SMOE SUPPLY AND CLIENT FREE ISSUE) Receiving and checking of incoming equipment for correct quantity, physical damages, defects and discrepancy Prepare Incoming Material Verification Report (IMVR) Prepare overage, shortage and damage (OSD) report (if any)

QC Procedure Reference

Contract documents

N/A

B 1

(1) Material traceability procedure (MM-ZTK1A-ZPQ-MAT-PRC8061) (2) Electrical requirement for Mechanical package equipment (ZGS-ELE-102 rev.0)

(1) Purchase order specification (2) Delivery order (DO)

(1) Material Receiving Report (MRR) (2) Overage, Shortage and Damage Report (OSD)

C 1

TECHNICAL/COMPLIANCE INSPECTION (SMOE SUPPLY EQUIPMENT ONLY) Inspection of received equipment for compliance with specification, data sheet and/or RFQ. Any deviation shall be recorded as: Non-Conformance Report (NCR) or Punch-list

(1)

Non-conformance control procedure

(MM-ZTK-1A-ZPQMAT-PRC-8052)

(1) Request For Quotation / Data Sheet (2) Project specification (3) Certificate FAT Punch list

(1) Incoming Material Verification Report (IMVR), (2) NCR (3) Punch list Form

(2) Material traceability and identification procedure (MM-ZTK1A-ZPQ-MAT-PRC8061)

Note

H - HOLD POINT

W - WITNESS

R - REVIEW DOCUMENT

M MONITOR

- 2 -Page 2 of 7

INSPECTION AND TEST PLAN (ELETRICAL, INSTRUMENTATION & TELECOMMUNICATION) ATTACHMENT - A Project : Zawtika Development Project, Phase 1A. - EPCIC of Zawtika Processing and Living Quarters Platform. Project Reference - MPG006 Item

D 1

Page 2 of 7 Date: 31-Aug-12 Revision : A1 SMOE COMPANY

Contract Number : IMO-EMP-CT-10-1015 Document Number : MM-ZTK-1A-ZPQ-GUA-TPN-8055 Acceptance Criteria Verifying Document

Process Description

PERIODIC PRESERVATION INSPECTION Check for proper protective covers / corrosion preventive coating, physical and water/humidity damage 1)

QC Procedure Reference

Manufacturers and vendors document / recommendations. Preservation Procedure

(1) Manufacturers and vendors recommendation for preservation and maintenance. (2) PIMS preservation ITRs

Preservation Check List and records

2) E 1 WORKSHOP FABRICATION & INSPECTION OF SUPPORTS All supports and frameworks necessary for proper installation of equipment which are not supplied in prefabricated form shall be fabricated, blasted / painted and checked against mounting / installation details for dimension, quality and workmanship 1) 2)

Approved WPS Surface Preparation and Protective Coatings Procedure (MM-ZTK-1A-ZPQMAT-PRC-8070) Welding Control Procedure (MM-ZTK-1A-ZPQMAT-PRC-8052) Visual Inspection Procedure (MM-ZTK-1A-ZPQMAT-PRC-8062)

(1) AFC support typical detail drawing

1)Release note

3)

4)

Note

H - HOLD POINT

W - WITNESS

R - REVIEW DOCUMENT

M MONITOR

- 3 -Page 3 of 7

INSPECTION AND TEST PLAN (ELETRICAL, INSTRUMENTATION & TELECOMMUNICATION) ATTACHMENT - A Project : Zawtika Development Project, Phase 1A. - EPCIC of Zawtika Processing and Living Quarters Platform. Project Reference - MPG006 Item

F 1

Page 3 of 7 Date: 31-Aug-12 Revision : A1 SMOE COMPANY

Contract Number : IMO-EMP-CT-10-1015 Document Number : MM-ZTK-1A-ZPQ-GUA-TPN-8055 Acceptance Criteria Verifying Document

Process Description

FIELD ERECTION & INSPECTION OF SUPPORTS, EQUIPMENTS AND COMPONENT Weld supports, frames and brackets on module and inspect for workmanship / leveling in accordance with layout drawings, installation practices and procedure 1) 2)

QC Procedure Reference

Approved WPS Surface Preparation and Protective Coatings Procedure(MM-ZTK1A-ZPQ-MAT-PRC8070) Welding Control Procedure(MM-ZTK1A-ZPQ-MAT-PRC8052) Visual Inspection Procedure(MM-ZTK1A-ZPQ-MAT-PRC8062)

(1) AFC drawing

(1) NCR (2) Surveillance Report

3)

4)

Install equipment, MCT, cable tray / ladder and cables in accordance with drawing, specification and procedure

1)

E & I Installation Procedure.

(1) AFC drawing

(1) NCR (2) Surveillance Report

Note

H - HOLD POINT

W - WITNESS

R - REVIEW DOCUMENT

M MONITOR

- 4 -Page 4 of 7

INSPECTION AND TEST PLAN (ELETRICAL, INSTRUMENTATION & TELECOMMUNICATION) ATTACHMENT - A Project : Zawtika Development Project, Phase 1A. - EPCIC of Zawtika Processing and Living Quarters Platform. Project Reference - MPG006 Item

G 1

Page 4 of 7 Date: 31-Aug-12 Revision : A1 SMOE COMPANY

Contract Number : IMO-EMP-CT-10-1015 Document Number : MM-ZTK-1A-ZPQ-GUA-TPN-8055 Acceptance Criteria Verifying Document

Process Description

MECHANICAL COMPLETION Inspection of the system and its component (as follows) to ensure correct installation in accordance with project AFC drawing and specification. Inspection result to be recorded in the check sheet

(1)

QC Procedure Reference

E & I Installation Procedure

(1) AFC drawing (2) Project specification

Mechanical Completion (MC) ITRs

(2) Completion System Manual (3) Commissioning Philosophy

Check mechanical damage, alignment, mounting, mechanical operations and earthing of switch-gear, busduct and MCC

(1) E & I Installation Procedure

(1) Manufacturers recommendation (2) AFC drawing (3) Project Specification

Mechanical Completion (MC) ITRs

Check bus-bar connection bolts for switch-gear, bus-duct and MCC tighten to manufacturers recommendation torque setting and clearly marked with permanent marker

(1)

E & I Installation Procedure

(1) Manufacturers recommendation (2) AFC drawing (3) Project Specification)

Mechanical Completion (MC) ITRs

Perform ductor test on MCC and SWGR to confirm the integrity of bolted bus-bar joint

(1) E & I Installation Procedure

(1) Consistence reading on all joints (2) Project Specification

Mechanical Completion (MC) ITRs

Note

H - HOLD POINT

W - WITNESS

R - REVIEW DOCUMENT

M MONITOR

- 5 -Page 5 of 7

INSPECTION AND TEST PLAN (ELETRICAL, INSTRUMENTATION & TELECOMMUNICATION) ATTACHMENT - A Project : Zawtika Development Project, Phase 1A. - EPCIC of Zawtika Processing and Living Quarters Platform. Project Reference - MPG006 Item

d

Page 5 of 7 Date: 31-Aug-12 Revision : A1 SMOE

H

Contract Number : IMO-EMP-CT-10-1015 Document Number : MM-ZTK-1A-ZPQ-GUA-TPN-8055 Acceptance Criteria

(1) Commissioning Philosophy (2) Project Specification (3) ZGS-PCC-103

Process Description

Perform Hi-pot test on HV switch-gear bus-bar and HV cable

QC Procedure Reference

(1) Hi-pot Test Procedure

Verifying Document

Mechanical Completion (MC) ITRs

COMPANY

Precommissioning Execution

Commissioning Philosophy. Mechanical Completion (MC) ITRs W/R

Perform cable insulation resistance test

(1) E & I Installation Procedure

(1) (2)

ZGS-PCC-103 Precommissioning Execution

Commissioning Philosophy.

Check motor termination, earthing and measure insulation resistance of motor windings

(1) E & I Installation Procedure

(1) (2)

ZGS-PCC-103 Precommissioning Execution

Mechanical Completion (MC) ITRs

R/W

Check transformer for mechanical damage, alignment, mounting and earthing. Perform megger test between phases and phase to ground Check proper installation of heat trace cable prior to insulation / cladding works. Measure cable resistance value, continuity and megger before and after insulation

(1) E & I Installation Procedure

(1) Manufacturers recommendation (2) AFC drawing

Mechanical Completion (MC) ITRs

(1) E & I Installation Procedure (2) Electrical Heat Tracing Specification

(1) Approved detail installation drawing. (2) Manufacturers recommendation.

Mechanical Completion (MC) ITRs

R/W

Note

H - HOLD POINT

W - WITNESS

R - REVIEW DOCUMENT

M MONITOR

- 6 -Page 6 of 7

INSPECTION AND TEST PLAN (ELETRICAL, INSTRUMENTATION & TELECOMMUNICATION) ATTACHMENT - A Project : Zawtika Development Project, Phase 1A. - EPCIC of Zawtika Processing and Living Quarters Platform. Project Reference - MPG006 Item

I

Page 6 of 7 Date: 31-Aug-12 Revision : A1 SMOE

W

Contract Number : IMO-EMP-CT-10-1015 Document Number : MM-ZTK-1A-ZPQ-GUA-TPN-8055 Acceptance Criteria

(1) Approved detail installation drawing. (2) Manufacturers recommendation

Process Description

Check Neutral Ground Resistor (NGR) for mechanical damage, alignment, mounting and earthing. Measure and verify resistors resistance against nameplate data

QC Procedure Reference

(1) E & I Installation Procedure

Verifying Document

Mechanical Completion (MC) ITRs

COMPANY

Check installation of VFD, electrical control panel, control station, socket outlet, navigational aid system, UPS system, junction boxes and lighting circuit/fixture are as per approved drawing Check for proper installation of telecommunication equipment such as speaker, antenna, telephone etc

(1) E & I Installation

(1) AFC drawing. (2) Manufacturer recommendation

Mechanical Completion (MC) ITRs

(1)

E & I Installation Procedure

(1) AFC drawing. (2) Manufacturer recommendation

Mechanical Completion (MC) ITRs

(2) Telecommunications Philosophy Specification (3) Public Address and Alarm (PAA) System Specification l Check cable final dressing on ladder/tray, cable tag, MCT packing etc. during area inspection (1) E & I Installation Procedure

(1) AFC drawing. (2) Manufacturer recommendation (1) AFC drawing. (2) Project specification and data sheet

Mechanical Completion (MC) ITRs

Defects and poor workmanship to be rectified or recorded as punch-list before proceeding further

(1) Completion System Manual

Punch-list form

Note

H - HOLD POINT

W - WITNESS

R - REVIEW DOCUMENT

M MONITOR

- 7 -Page 7 of 7

INSPECTION AND TEST PLAN (ELETRICAL, INSTRUMENTATION & TELECOMMUNICATION) ATTACHMENT - A Project : Zawtika Development Project, Phase 1A. - EPCIC of Zawtika Processing and Living Quarters Platform. Project Reference - MPG006 Item

n

Page 7 of 7 Date: 31-Aug-12 Revision : A1 SMOE

R

Contract Number : IMO-EMP-CT-10-1015 Document Number : MM-ZTK-1A-ZPQ-GUA-TPN-8055 Acceptance Criteria

N/A N/A

Process Description

Red mark-up to be produced for any site changes

QC Procedure Reference

(1) As Built drawing Procedure (2) Document Numbering and Control Procedure

Verifying Document

COMPANY

As-built drawing to be produced based on site changes / red mark-up

(1) As Built drawing Procedure (2) Document Numbering and Control Procedure

Red Mark-up

As-built drawing

H 1

FINAL DOCUMENTATION Compilation of MC ITRs, red line mark-up, As-built drawing, MC dossier and outstanding work list etc. (1) Document Numbering and Control Procedure (2) Completion System Manual Contract document (1) Release note (2) MC Completion Certificates (3) Final Document Punch list R

Note

H - HOLD POINT

W - WITNESS

R - REVIEW DOCUMENT

M MONITOR

You might also like

- HW2 f17Document5 pagesHW2 f17aeviumNo ratings yet

- 62.120.002 - Preservation, Packing, Unpacking and Storage PRDocument6 pages62.120.002 - Preservation, Packing, Unpacking and Storage PRRizwan IqbalNo ratings yet

- 4.itp For Instrumentation & ControlDocument10 pages4.itp For Instrumentation & ControlJoel Alcantara75% (4)

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Document1 pageKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNo ratings yet

- 4.-QA-QC-Plan-job Desc Field PDFDocument12 pages4.-QA-QC-Plan-job Desc Field PDFAli HajirassoulihaNo ratings yet

- Attendance ListDocument2 pagesAttendance ListYusup MulyanaNo ratings yet

- 000 ZA E 09411 Punch List ProcedureDocument17 pages000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- Inspection Test Plan SampleDocument20 pagesInspection Test Plan SampleParviz Nasirov67% (3)

- 009 04 - Fy14 CH1Document10 pages009 04 - Fy14 CH1Brian Joseph MugrageNo ratings yet

- Dayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)Document2 pagesDayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)AmyNo ratings yet

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Document24 pagesED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- Attachment 6 - Technical Query FormDocument1 pageAttachment 6 - Technical Query FormLai HuynhNo ratings yet

- ITP's and ITR's A Necessary - Monster - PDFDocument5 pagesITP's and ITR's A Necessary - Monster - PDFshastri85No ratings yet

- Project: Samsun CCPP: Title: ITP of SwitchgearsDocument4 pagesProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- Itr-Pug (Ug Piping)Document12 pagesItr-Pug (Ug Piping)mahmoud100% (1)

- List Welder PT - InstrucomDocument4 pagesList Welder PT - InstrucomHerlan HutabaratNo ratings yet

- Electrical Junction Box ITP (Elektrik Bağlantı Kutusu Muayene Test Planı) PDFDocument1 pageElectrical Junction Box ITP (Elektrik Bağlantı Kutusu Muayene Test Planı) PDFUtku Can KılıçNo ratings yet

- Inspection and Test Plan (ITP) (Pressure Vessel)Document1 pageInspection and Test Plan (ITP) (Pressure Vessel)hannanNo ratings yet

- F01 Rev.1 Inspection Checklist 1Document1 pageF01 Rev.1 Inspection Checklist 1kamilNo ratings yet

- ITP Work DownDocument5 pagesITP Work DownMuralimohan Pandian100% (1)

- KP-00+++-CY712-BKM7109 Method Statment For Lightning Protection System Installation WorksDocument16 pagesKP-00+++-CY712-BKM7109 Method Statment For Lightning Protection System Installation WorksUtku Can KılıçNo ratings yet

- Inspection Test PlanDocument11 pagesInspection Test PlanJonathan PedreraNo ratings yet

- J910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.ADocument18 pagesJ910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.Arudi sarifudinNo ratings yet

- Cathodic Protection System MMO Grid of Tank Quality Control and Inspection Report FormDocument5 pagesCathodic Protection System MMO Grid of Tank Quality Control and Inspection Report Formjamal2877No ratings yet

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 pagesMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanNo ratings yet

- ITR For Electrical Instrument PDFDocument4 pagesITR For Electrical Instrument PDFCokro YudhaNo ratings yet

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- Instrumentation FormsDocument7 pagesInstrumentation FormsMark TrussellNo ratings yet

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocument1 pagePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNo ratings yet

- 14 Inspection and TestingDocument3 pages14 Inspection and TestingelmiraNo ratings yet

- Inspection and Test Plan Format: GeneralDocument4 pagesInspection and Test Plan Format: GeneralSABIR KHANNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYDocument2 pagesCommissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYtajudeenNo ratings yet

- Check List Pulling CableDocument2 pagesCheck List Pulling CableAldeline Sungahid100% (1)

- ITP Instrument-Cover EXAMPLEDocument6 pagesITP Instrument-Cover EXAMPLECharles RobiansyahNo ratings yet

- 13march2020 - Construction Completion Punch List MasterfileDocument143 pages13march2020 - Construction Completion Punch List MasterfileDangolNo ratings yet

- SAIC & SATR - InstrumentationDocument4 pagesSAIC & SATR - InstrumentationAdel KlkNo ratings yet

- KP-00+++-CQ712-B7510-Rev A-INSPECTION TEST PLAN FOR I C INSTRUMENT CONNECTION PART OF PIPING EQUIPMENTDocument17 pagesKP-00+++-CQ712-B7510-Rev A-INSPECTION TEST PLAN FOR I C INSTRUMENT CONNECTION PART OF PIPING EQUIPMENTUtku Can Kılıç100% (1)

- Fat ProcedureDocument50 pagesFat ProcedureDin AizuNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- ITR-B (Piping) Witness Joint1Document1 pageITR-B (Piping) Witness Joint1Momo ItachiNo ratings yet

- Pre Commissioning ProcedureDocument1 pagePre Commissioning ProcedurekapsarcNo ratings yet

- KP-00+++-CQ712-G0014 - Rev.A - ITP - Cable Tray Installation PDFDocument1 pageKP-00+++-CQ712-G0014 - Rev.A - ITP - Cable Tray Installation PDFUtku Can KılıçNo ratings yet

- NCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestDocument1 pageNCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestCharles KingNo ratings yet

- NPK 000 Q1 CP 6001 K Shop Inspection Procedure Rev.1 IFCDocument10 pagesNPK 000 Q1 CP 6001 K Shop Inspection Procedure Rev.1 IFCDangolNo ratings yet

- 02 MechanicalDocument44 pages02 MechanicalSigit Bintan100% (1)

- At SKTSZZ QA PRO 0008 000 C01 Quality Control InspectionDocument14 pagesAt SKTSZZ QA PRO 0008 000 C01 Quality Control InspectionAdil HasanovNo ratings yet

- TIMAS-PR-PI-001 - Hot Tapping ProcedureDocument11 pagesTIMAS-PR-PI-001 - Hot Tapping ProcedureMechanical Static WRKNo ratings yet

- Attachment 6 - Piping Test Package (Manifold 206) - A4A0Z9 PDFDocument13 pagesAttachment 6 - Piping Test Package (Manifold 206) - A4A0Z9 PDFMd asrar ali100% (1)

- Form No. 102 - Control ValveDocument2 pagesForm No. 102 - Control ValveVictor Nair100% (1)

- Main Inspection Test Plan SampleDocument2 pagesMain Inspection Test Plan SampleMuhd AfiqNo ratings yet

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- Itp - Rev eDocument36 pagesItp - Rev ezaki_saddarNo ratings yet

- X7Electrical Instrument Telecommmucation Test PlanDocument15 pagesX7Electrical Instrument Telecommmucation Test PlanNoor A QasimNo ratings yet

- Pre Energization Test ProceduresDocument6 pagesPre Energization Test Proceduressani priadiNo ratings yet

- PT BM 183 DC 00008 Preheat ProcedureDocument5 pagesPT BM 183 DC 00008 Preheat Procedureeldobie3No ratings yet

- Electrical Cable Installation Insp. ReportDocument1 pageElectrical Cable Installation Insp. ReportHendrick Peter MarthapangNo ratings yet

- Project Report On Threading Drill PipesDocument34 pagesProject Report On Threading Drill PipesVamshi KrishnaNo ratings yet

- Schedule Q - Attachment VIDocument8 pagesSchedule Q - Attachment VISIVANo ratings yet

- 3.0 Inspection & Test PlanDocument10 pages3.0 Inspection & Test PlanAbdul Hakam Mohamed Yusof83% (6)

- Dtex3f Man01 en v1r2 enDocument18 pagesDtex3f Man01 en v1r2 ennicolaunechitaNo ratings yet

- Vent. WorksheetDocument3 pagesVent. Worksheetjldriggers100% (1)

- SAIC-X-3003 Rev 3Document2 pagesSAIC-X-3003 Rev 3Imran khanNo ratings yet

- Basic Principles of GMP: PersonnelDocument22 pagesBasic Principles of GMP: Personnelzakx24x7bdNo ratings yet

- RC 16 Apr 2022Document7 pagesRC 16 Apr 2022Mary CharlesNo ratings yet

- BlowDocument2 pagesBlowDavid LambertNo ratings yet

- Comber DataDocument12 pagesComber DataSabbir Hossain ImranNo ratings yet

- Installing Dimensions Component Pack 3.5Document9 pagesInstalling Dimensions Component Pack 3.5Nakal19No ratings yet

- EWAC 600i-2Document2 pagesEWAC 600i-2K Narendar100% (1)

- Nuova Fima MGS18 - 100150mmDocument2 pagesNuova Fima MGS18 - 100150mmPaweł HejmowskiNo ratings yet

- 808 Recomendation On Performance Standards For Public Address Systems On Passenger Ships Including CDocument6 pages808 Recomendation On Performance Standards For Public Address Systems On Passenger Ships Including CTefin TefinNo ratings yet

- 2010.08.23-Quotation For Mogul Desktop ComputerDocument13 pages2010.08.23-Quotation For Mogul Desktop ComputerNyamzaya KhaynkhyrwaaNo ratings yet

- Electrical Power Distribution in ExperimentsDocument52 pagesElectrical Power Distribution in ExperimentsDevas ShuklaNo ratings yet

- Four Corners Book 1 Unit 5 PDFDocument10 pagesFour Corners Book 1 Unit 5 PDFAlejandro SánchezNo ratings yet

- Probacktest V10Document72 pagesProbacktest V10Javier del BarcoNo ratings yet

- Boiler Draught and Its TypesDocument4 pagesBoiler Draught and Its TypesHamza AbdullahNo ratings yet

- Managing Resources: Resources Can Be Easily Divided Into Two Sections: Renewable and Non-Renewable. TheseDocument7 pagesManaging Resources: Resources Can Be Easily Divided Into Two Sections: Renewable and Non-Renewable. Theseapi-25904890No ratings yet

- Change ManagementDocument20 pagesChange ManagementGoharNo ratings yet

- Wireless Networking ComponentsDocument4 pagesWireless Networking ComponentsPradeepCoolNo ratings yet

- English Hindi DictionaryDocument31 pagesEnglish Hindi DictionaryRajNo ratings yet

- Ist 220 A2 Ipconfig PingDocument4 pagesIst 220 A2 Ipconfig Pingmueller_gbNo ratings yet

- Myers Triplex Water Pump D35 D50 D60 D65 Data SheetDocument2 pagesMyers Triplex Water Pump D35 D50 D60 D65 Data Sheetsergio100% (1)

- M2584 Test Evaluation of The Honeywell GG 111 Single-Degree-Of-Freedom Isof) 00 Strapdown GyroscopeDocument35 pagesM2584 Test Evaluation of The Honeywell GG 111 Single-Degree-Of-Freedom Isof) 00 Strapdown Gyroscopeskr2010No ratings yet

- Here Be DragonsDocument28 pagesHere Be DragonsPete TaltonNo ratings yet

- How Does Internet WorksDocument12 pagesHow Does Internet WorksVinay J KatNo ratings yet

- Heat Recovery Analysis of A N Existing: C R U D E Distillation UnitDocument7 pagesHeat Recovery Analysis of A N Existing: C R U D E Distillation UnitPhilip ShihNo ratings yet

- User ManualDocument78 pagesUser ManualDora HunorNo ratings yet

- Types of Protection Schemes Part-2Document38 pagesTypes of Protection Schemes Part-2CHAITANYA KUMARNo ratings yet