ITP Work Down

ITP Work Down

Uploaded by

Muralimohan PandianCopyright:

Available Formats

ITP Work Down

ITP Work Down

Uploaded by

Muralimohan PandianOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ITP Work Down

ITP Work Down

Uploaded by

Muralimohan PandianCopyright:

Available Formats

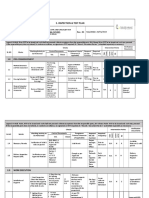

Document Number Document Title Item Rev

Inspection Codes: SC: Subcontractor PEC: Petrofac C: Company/Client TP: Third Party

R: Document/Report Review S: Surveillance RR: Random Review

H: Hold Point (Notification Required & Presence is Mandatory) W: Witness Point (Notification Required but Presence is not Mandatory)

Responsible Verifying Intervention Points

Item Control Activity Action to be verified Reference Document Acceptance Criteria

Party Document SC PEC C TP

a. Review & verify validity of Manufacturer’s data Good mechanical

PEC Site Calibration

calibration certificates, sheet and electrical

Control of Inspection Test Supervisor Certificate/

1.0 Identification Number/Sticker PEC-QU-GDE-X- condition R/S R/S S

& Measuring Equipment SC Electrical IM&TE

b. Verify condition of the test 11152 Valid calibration

QC Inspector Register

equipment Project Spec. certificate

a. Visual inspection to verify correct

size & type, appearance etc. No damage

Purchase Order/ SC Material Purchase

Material Inspection b. Ensure no damage to galvanization Conform to

Delivery Note/Data Controller Order/

(subject to provisions of and free from physical damages specifications

2.0 Sheet SC/PEC Delivery R/S R/S S

project Material Receiving c. All accessories are of correct Confirms to storage

Project Material Electrical QC Note/Data

procedure) type/material and preservation

Receiving Procedure Inspector Sheet

requirements

d. Storage and preservation (e.g. long

term outdoor storage at site)

a. Review of applicable

Complies with AFC

drawings/documents and ensure

List of latest revision document register PEC Site

that latest revision is available at

of applicable Complies with AFC Supervisor S

Drawings and Documents site (e.g.: Cable routing layout,

3.0 drawings drawings, C/PEC NIL R R R

status cable schedule, Review of work

AFC drawings and applicable Electrical QC

procedures, Method Statements,

Specifications standards and Inspector

QC Procedures and other related

Specifications

documents etc.)

a. Ensure fabrication is as per the

drawing

Correct routing

b. Where applicable, verify cable tray Adequate supports

route is in accordance with layout are provided

PEC Site

drawings Lay out drawings/ Support span is not

Inspection of cable tray Supervisor

c. Ensure adequate supports are installation details greater than ITR-E-0201X W S S

4.0 support installation SC E&I QC

provided as per Project Spec. straight section

Inspector

installation drawings length or as

recommended by

d. Check dimensions, distance

manufacturer

between supports, fixing method

etc.

Document Number Document Title Item Rev

Inspection Codes: SC: Subcontractor PEC: Petrofac C: Company/Client TP: Third Party

R: Document/Report Review S: Surveillance RR: Random Review

H: Hold Point (Notification Required & Presence is Mandatory) W: Witness Point (Notification Required but Presence is not Mandatory)

Responsible Verifying Intervention Points

Item Control Activity Action to be verified Reference Document Acceptance Criteria

Party Document SC PEC C TP

e. No cut or drill on structural

members

a. Check spacing between trays,

elevation, size, clamps, connectors,

bolts, nuts, washers, etc.

b. Ladder/tray are internally smooth

with the fastening bolts installed

Installation is

with the head inside and the complete in

nut/washer outside accordance with

c. Splice plates, (e.g.: straight, offset Layout drawings PEC Site

Inspection of installation applicable

Manufacturer’s Supervisor

5.0 Cable trays /racks (straight and adjustable etc.) are of correct drawings ITR-E-0201X W S S

instructions SC E&I QC

Length) type suitable for the location No more than one

Project Spec. Inspector

d. Ensure no sharp edges splice plate is

located between

e. Check for any additional support

supports

requirement

f. Verify location of expansion guide

and support for the same

g. Ensure touch up paint for cut edges

and drilled holes

a. Verify fittings and connectors are of

correct size, type suitable for the

location

b. Visual inspection against Installation details PEC Site

Clamps, fittings,

applicable drawing Manufacturer’s Complies with Supervisor

6.0 connectors, hanger ITR-E-0201X W S S

c. Satisfactory bending radius instructions Installation details SC E&I QC

clamps

d. Check supports at bends and route Project Spec. Inspector

changes

e. Each joints are properly tightened

with the fastening bolts installed

Document Number Document Title Item Rev

Inspection Codes: SC: Subcontractor PEC: Petrofac C: Company/Client TP: Third Party

R: Document/Report Review S: Surveillance RR: Random Review

H: Hold Point (Notification Required & Presence is Mandatory) W: Witness Point (Notification Required but Presence is not Mandatory)

Responsible Verifying Intervention Points

Item Control Activity Action to be verified Reference Document Acceptance Criteria

Party Document SC PEC C TP

with the head inside and the

nut/washer outside

a. Verify Expansion guides are fitted

at specified intervals

b. Verify gap setting is correct

Installation of Expansion c. Verify nut/bolt/washers are suitable Installation PEC Site

Splice Plates (Thermal

for the purpose details/Layout Complies with Supervisor

7.0 expansion and contraction ITR-E-0201X W S S

d. Check clamping method drawing installation detail SC E&I QC

of cable tray at long

e. Ensure no restriction for proper Project Spec. Inspector

straight run)

movement

f. Verify installation of supports at

both sides of expansion guide

a. Inspect cable route and ensure all All works

areas are free of debris, sharp completed, PEC Site

edges etc. which may damage Layout drawing adequately Supervisor

8.0 Release for cable laying Project Spec. ITR-E-0201X W W S

cables during installation supported, route SC E&I QC

b. Tray should never be used as a clean and no Inspector

debris

walk way

a. Ensure to maintain electrical

continuity of cable tray system

b. Verify bonding jumpers are

Complies with PEC Site

Cable tray system bonding provided at specified locations Installation details

installation details Supervisor

9.0 and connection to the (e.g.: Expansion splice plates, Layout drawings ITR-E-0203X W S S

and layout SC E&I QC

main earthing system adjustable splice plates, Project Spec.

drawings Inspector

discontinuous routes etc.)

c. Verify connection to main grid at

specified locations

Cable tray system Layout drawing Cable dressing,

a. Verify cable dressing/segregation SC/PEC E&I

10.0 released for installation of Cable Schedule segregation and ITR-E-0203X W W S

b. Verify, Tagging, clamping etc. QC Inspector

covers Project Spec. testing completed

Document Number Document Title Item Rev

Inspection Codes: SC: Subcontractor PEC: Petrofac C: Company/Client TP: Third Party

R: Document/Report Review S: Surveillance RR: Random Review

H: Hold Point (Notification Required & Presence is Mandatory) W: Witness Point (Notification Required but Presence is not Mandatory)

Responsible Verifying Intervention Points

Item Control Activity Action to be verified Reference Document Acceptance Criteria

Party Document SC PEC C TP

(if applicable)- Post c. Ensure all required tests are

cabling inspection performed and acceptable

a. Check clamps are of correct type,

size and material as per installation

details

Complies with PEC Site

Cable tray covers installed b. Check proper fixing of the covers Installation details

installation details Supervisor

11.0 as per requirement c. Check distance between clamps Layout drawing ITR-E-0204X W W S

and layout SC E&I QC

d. Check clamps are suitable for the Project Spec.

drawings Inspector

location (indoor/outdoor)

e. Correct type of nut/bolt/washers

used and properly tightened

a. Check trench depth, sand bedding Complies with PEC Site

Layout Drawing and

Inspect trench for b. Verify route is as per layout installation details Supervisor

12.0 installation details ITR-E-0202X W S S

underground conduit drawing and layout SC E&I QC

Project Spec.

c. Ensure no obstructions drawings Inspector

Check installation of

a. Check conduit routing is correct as

conduit, fittings, Complies with PEC Site

per drawing, cut edges are Layout Drawing and

identification labels if installation details Supervisor

13.0 deburred, correct size, correct installation details ITR-E-0202X W S S

required, before backfilling and layout SC E&I QC

bending radius, soft sand filling, Project Spec.

and compaction drawings Inspector

warning tape, identification, etc.

(Underground)

Check preparation of Layout Drawing and Draw rope PEC Site

a. Check for no obstructions, draw

14.0 conduit prior to cable installation details provided and NO Supervisor ITR-E-0202X S S S

ropes installed

pulling (Underground) Project Spec. obstructions SC E&I QC

Inspector

Complies with

Layout Drawing and

Check sealing after a. Check material used for sealing installation details

15.0 installation details PEC Site ITR-E-0202X S S S

installation(Underground) and sealed properly and layout

Project Spec. Supervisor

drawings

Document Number Document Title Item Rev

Inspection Codes: SC: Subcontractor PEC: Petrofac C: Company/Client TP: Third Party

R: Document/Report Review S: Surveillance RR: Random Review

H: Hold Point (Notification Required & Presence is Mandatory) W: Witness Point (Notification Required but Presence is not Mandatory)

Responsible Verifying Intervention Points

Item Control Activity Action to be verified Reference Document Acceptance Criteria

Party Document SC PEC C TP

SC E&I QC

Inspector

a. Verify location, routing, no

obstructions, cut edges are

deburred, correct bending radius,

Check installation of expansion joints fitted (if required),

Complies with PEC Site

conduit and fittings, workmanship, and identification Layout Drawing and

installation details Supervisor

16.0 Junction boxes, pull boxes, b. Ensure to avoid unnecessary installation details ITR-E-0202X W S S

and layout SC E&I QC

identification labels if bends Project Spec.

drawings Inspector

required (Above ground) c. Verify Junction boxes/pull boxes

are accessible and not obstructed

by conduit, cable tray, duct or any

other utilities

Adequate supports

provided PEC Site

a. Ensure adequate supports Layout Drawing and

Conduit supports structure Complies with Supervisor

17.0 provided at specified intervals installation details ITR-E-0202X W S S

secure (Above ground) installation details SC E&I QC

b. Correct fasteners and hangers Project Spec.

and layout Inspector

drawings

a. Ensure to maintain electrical

Conduit system bonding Complies with PEC Site

continuity steel conduit Layout Drawing and

and connection to the main installation details Supervisor

18.0 b. Check bonding jumpers are installation details ITR-E-0203X W S S

earthing system and layout SC E&I QC

provided and connection to main Project Spec.

drawings Inspector

grid at specified locations

a. Verify tags are provided as per

Complies with

project requirement Layout Drawing and

Post cabling inspection of installation details SC/PEC E&I

19.0 b. Verify sealing of conduits with installation details ITR-E-0203X W W S

conduits and layout QC Inspector

approved material Project Spec.

drawings

c. Verify clamps and fixing is secure

You might also like

- Actual Board Profed 2022Document242 pagesActual Board Profed 2022Eunice Grace Galvez90% (10)

- IKEA Catalogue 2012Document189 pagesIKEA Catalogue 2012nguyễn thăng vănNo ratings yet

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Document1 pageKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNo ratings yet

- German Panzer Group Von Kleist 10 May 1940Document4 pagesGerman Panzer Group Von Kleist 10 May 1940Paul McHughNo ratings yet

- ITP For Static Equipment Installation Code-ADocument28 pagesITP For Static Equipment Installation Code-Aميثم الخرسانيNo ratings yet

- Inspection & Test Plan For Earthworks Excavation and Backfill For Underground FacilitiesDocument7 pagesInspection & Test Plan For Earthworks Excavation and Backfill For Underground FacilitiesMouayed ZeadanNo ratings yet

- ITP - Distribution TransformerDocument6 pagesITP - Distribution TransformerOsman Abdout100% (2)

- KP-00+++-CQ712-G0014 - Rev.A - ITP - Cable Tray Installation PDFDocument1 pageKP-00+++-CQ712-G0014 - Rev.A - ITP - Cable Tray Installation PDFUtku Can KılıçNo ratings yet

- Tdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)Document1 pageTdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)mNo ratings yet

- SATIP-P-104-07 Rev 7 FinalDocument4 pagesSATIP-P-104-07 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Inspection Test Plan For Fabrication PDF FreeDocument4 pagesInspection Test Plan For Fabrication PDF Freesam paulNo ratings yet

- QMIS RFI RaisedDocument2 pagesQMIS RFI RaisedSulman YounasNo ratings yet

- ELECT-TIC-8.1 (Diesel-Generator MaterialReceiving)Document2 pagesELECT-TIC-8.1 (Diesel-Generator MaterialReceiving)Muhammad IrfanNo ratings yet

- KP-00+++-CQ712-G0006 - Rev.1 - ITP For Electrical Works (UnderGround Earthing Works)Document3 pagesKP-00+++-CQ712-G0006 - Rev.1 - ITP For Electrical Works (UnderGround Earthing Works)Utku Can KılıçNo ratings yet

- Itp WeldingDocument2 pagesItp WeldingAnoop ChandranNo ratings yet

- Annex 2 Scope of WorkDocument37 pagesAnnex 2 Scope of WorkWilliam PENGNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- X7Electrical Instrument Telecommmucation Test PlanDocument15 pagesX7Electrical Instrument Telecommmucation Test PlanNoor A QasimNo ratings yet

- QM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01Document11 pagesQM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01GaneshNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Document37 pagesIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNo ratings yet

- 835a) Method Statement For Ceramic Tile Marble Works - R0-SignedDocument23 pages835a) Method Statement For Ceramic Tile Marble Works - R0-Signedwaseq911No ratings yet

- 33 Weekly Quality Report Augist 10 To 15Document6 pages33 Weekly Quality Report Augist 10 To 15Noman Awan100% (1)

- EXternal ITP PDFDocument8 pagesEXternal ITP PDFjaineranaNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- NCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestDocument1 pageNCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestCharles KingNo ratings yet

- Instrumentation FormsDocument7 pagesInstrumentation FormsMark TrussellNo ratings yet

- PMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Document3 pagesPMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Emmanuel TamayoNo ratings yet

- Itp - Electrical Second FixDocument4 pagesItp - Electrical Second Fixirfan vpNo ratings yet

- ITP ProcedureDocument35 pagesITP ProcedureArif Sameer KhanNo ratings yet

- Testing & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsDocument12 pagesTesting & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsPKNo ratings yet

- ITP - Latticed Steel Tower - Sample TestDocument4 pagesITP - Latticed Steel Tower - Sample TestPrabhakar SvNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Itp For Equipment Erection - RotaryDocument5 pagesItp For Equipment Erection - Rotarycrm 2No ratings yet

- NG-018-XX-PNL-431203 - Rev07 NDT MatricesDocument20 pagesNG-018-XX-PNL-431203 - Rev07 NDT MatricesFolarin Ayodeji100% (1)

- Inspection Test Plan For ElectricalDocument39 pagesInspection Test Plan For Electricalpire.resiNo ratings yet

- PQP - Kilaraipur PDFDocument53 pagesPQP - Kilaraipur PDFVijendra SharmaNo ratings yet

- Method Statement - Fittings & Valves InstallationDocument48 pagesMethod Statement - Fittings & Valves InstallationmodshakNo ratings yet

- Itp For Fence & Gate Works: Provision of EPCC For Security Defence & Check Points For Block9 Phase-1Document17 pagesItp For Fence & Gate Works: Provision of EPCC For Security Defence & Check Points For Block9 Phase-1Berry UmpolaNo ratings yet

- Project Internal Audit Procedure: SheetalkumarDocument4 pagesProject Internal Audit Procedure: SheetalkumarTwin BullsNo ratings yet

- KP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Document3 pagesKP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Utku Can KılıçNo ratings yet

- KBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewDocument2 pagesKBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewkamlNo ratings yet

- Dokumen - Tips - Project Packing and Preservation ProcedureDocument27 pagesDokumen - Tips - Project Packing and Preservation ProceduremohdfaridabubakarNo ratings yet

- IRN-8108577716-432-01-RIL-Audco-17 Jan 2014Document1 pageIRN-8108577716-432-01-RIL-Audco-17 Jan 2014MuralitclNo ratings yet

- Inspection and Test Plan Format: GeneralDocument4 pagesInspection and Test Plan Format: GeneralSABIR KHANNo ratings yet

- Draft QPADocument3 pagesDraft QPASams Romantiz S'bontothlzNo ratings yet

- Instrumentation and ControlsDocument2 pagesInstrumentation and ControlsTrí NguyễnNo ratings yet

- Material Receiving Inspection Report: Project TitleDocument2 pagesMaterial Receiving Inspection Report: Project TitleGomathyselviNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument4 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- J910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.ADocument18 pagesJ910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.Arudi sarifudinNo ratings yet

- TJGP WTIP MR RFQ E004 RevDocument49 pagesTJGP WTIP MR RFQ E004 RevulinnuhaNo ratings yet

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- 23 05 93 Testing Adjusting and BalancingDocument7 pages23 05 93 Testing Adjusting and BalancingLangzkie NalipaNo ratings yet

- Inspected by QCP Approval 1-APC 1-Employer APC 2 - DAR 2-Engineer DAR 3 - Contractor NEGEMCO 4 - Vendor 5 - Third PartyDocument2 pagesInspected by QCP Approval 1-APC 1-Employer APC 2 - DAR 2-Engineer DAR 3 - Contractor NEGEMCO 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Quality Inspection FormDocument3 pagesQuality Inspection FormTesfuNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- Ims Manual 2019 ImportantlDocument59 pagesIms Manual 2019 ImportantlSAMYNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- RFI For 18.03.2014 Piping, Welding at SESA FabDocument4 pagesRFI For 18.03.2014 Piping, Welding at SESA Fabmuhammedemraan100% (1)

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs 4943Document1 pageMtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs Mtrs 4943Muralimohan PandianNo ratings yet

- Date Jsa Team (Name List) Name Position & SignatureDocument8 pagesDate Jsa Team (Name List) Name Position & SignatureMuralimohan PandianNo ratings yet

- PEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Document7 pagesPEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Muralimohan PandianNo ratings yet

- Quality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Document9 pagesQuality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Muralimohan PandianNo ratings yet

- Cable TrayDocument6 pagesCable TrayMuralimohan Pandian100% (2)

- Cable Drum IR ValueDocument2 pagesCable Drum IR ValueMuralimohan PandianNo ratings yet

- R272pfci30 RDG e Pro 0001 Rev A2Document11 pagesR272pfci30 RDG e Pro 0001 Rev A2Muralimohan PandianNo ratings yet

- George Darte Funeral Chapel Inc. Price ListDocument20 pagesGeorge Darte Funeral Chapel Inc. Price ListrobNo ratings yet

- Conjug4 Conjugacoes PortugueseDocument5 pagesConjug4 Conjugacoes PortugueseKareyNo ratings yet

- PresentationsDocument1 pagePresentationsMadina SaparbaevaNo ratings yet

- RCD AssignmentDocument3 pagesRCD AssignmentArj AsisNo ratings yet

- Wepik Revolutionizing Road Infrastructure A Comprehensive Overview of Road Civil Engineering 20231029040210dc0iDocument10 pagesWepik Revolutionizing Road Infrastructure A Comprehensive Overview of Road Civil Engineering 20231029040210dc0isameerkant089No ratings yet

- WEEK 12b - Berk DeMarzo-Chp 8Document81 pagesWEEK 12b - Berk DeMarzo-Chp 8Suzan BekçiNo ratings yet

- Case Analysis On Jayanta Kumar Das Vs State of OdishaDocument13 pagesCase Analysis On Jayanta Kumar Das Vs State of OdishaAditya DwivediNo ratings yet

- Electromagnetic Compatibility by Felicito S Caluyo PDFDocument40 pagesElectromagnetic Compatibility by Felicito S Caluyo PDFmjpadz100% (2)

- x50 M3u Links Tested Fnx20Document32 pagesx50 M3u Links Tested Fnx20Maverick ChukwuNo ratings yet

- 136 Yos Online Yabanci Uyruklu Ogrenci Sinavi TR YosDocument5 pages136 Yos Online Yabanci Uyruklu Ogrenci Sinavi TR Yosusmanmughal127790No ratings yet

- DvdavkjkDocument82 pagesDvdavkjkNajeebuddin AhmedNo ratings yet

- Vaginal ItchingDocument2 pagesVaginal ItchingHervis Francisco FantiniNo ratings yet

- Results 2022 World Triathlon Cup HuatulcoDocument2 pagesResults 2022 World Triathlon Cup HuatulcoBernewsAdminNo ratings yet

- Indian Institute of Technology Kharagpur: Academic Calendar For The Session 2018-2019Document8 pagesIndian Institute of Technology Kharagpur: Academic Calendar For The Session 2018-2019Gin ManNo ratings yet

- 2010 - Investigation of Wind Energy Potential of Muradiye in Manisa, TurkeyDocument5 pages2010 - Investigation of Wind Energy Potential of Muradiye in Manisa, TurkeygxydisNo ratings yet

- Unit 3 - Multiterminal DC SystemDocument21 pagesUnit 3 - Multiterminal DC Systemkarthik83% (6)

- Project Report of Seat Suspension by Vaibah Galave GroupDocument32 pagesProject Report of Seat Suspension by Vaibah Galave GroupSantosh BansodeNo ratings yet

- Chemistry Mole Concept....Document242 pagesChemistry Mole Concept....ojilongNo ratings yet

- Porter Ch01Document40 pagesPorter Ch01navin9849No ratings yet

- Share KhanDocument10 pagesShare KhangautammandalNo ratings yet

- Fire Safety Easy Quiz - BrainPOP JRDocument1 pageFire Safety Easy Quiz - BrainPOP JRleduylamNo ratings yet

- Sterner Infranor 872 & 876 Series Brochure 2005Document6 pagesSterner Infranor 872 & 876 Series Brochure 2005Alan MastersNo ratings yet

- 100 ThoughtsDocument3 pages100 Thoughtsraju_pnNo ratings yet

- Pass Leader DumpsDocument30 pagesPass Leader DumpsHyder BasetNo ratings yet

- Have Mercy On Us AutosavedDocument11 pagesHave Mercy On Us AutosavedMyrel Cedron TucioNo ratings yet

- Mission Green Sept 2017Document1 pageMission Green Sept 2017Robert OkandaNo ratings yet

- Distant View From Outside To Inside The Squence of Spaces Edges, Nodes & Termination of The Paths Corridors, Halls, Staircases, Lifts, EtcDocument1 pageDistant View From Outside To Inside The Squence of Spaces Edges, Nodes & Termination of The Paths Corridors, Halls, Staircases, Lifts, EtcChopra ShubhamNo ratings yet