0 ratings0% found this document useful (0 votes)

531 viewsCrayamid 115X - 70%

Crayamid 115X - 70%

Uploaded by

WALTER KLISSMANCRAYAMID 115X is a liquid amino polyamide resin supplied at 70% solid content in xylene. It is used in conjunction with epoxy resins to produce top coats and primers with excellent resistance properties and adhesion to metallic substrates. A recommended mixing ratio for CRAYAMID 115X and epoxy resins is 65:35 on a solid resin basis. This ratio provides flexibility, adhesion and solvent resistance for various coating applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Crayamid 115X - 70%

Crayamid 115X - 70%

Uploaded by

WALTER KLISSMAN0 ratings0% found this document useful (0 votes)

531 views2 pagesCRAYAMID 115X is a liquid amino polyamide resin supplied at 70% solid content in xylene. It is used in conjunction with epoxy resins to produce top coats and primers with excellent resistance properties and adhesion to metallic substrates. A recommended mixing ratio for CRAYAMID 115X and epoxy resins is 65:35 on a solid resin basis. This ratio provides flexibility, adhesion and solvent resistance for various coating applications.

Original Title

CRAYAMID 115X_70%_

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

CRAYAMID 115X is a liquid amino polyamide resin supplied at 70% solid content in xylene. It is used in conjunction with epoxy resins to produce top coats and primers with excellent resistance properties and adhesion to metallic substrates. A recommended mixing ratio for CRAYAMID 115X and epoxy resins is 65:35 on a solid resin basis. This ratio provides flexibility, adhesion and solvent resistance for various coating applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

531 views2 pagesCrayamid 115X - 70%

Crayamid 115X - 70%

Uploaded by

WALTER KLISSMANCRAYAMID 115X is a liquid amino polyamide resin supplied at 70% solid content in xylene. It is used in conjunction with epoxy resins to produce top coats and primers with excellent resistance properties and adhesion to metallic substrates. A recommended mixing ratio for CRAYAMID 115X and epoxy resins is 65:35 on a solid resin basis. This ratio provides flexibility, adhesion and solvent resistance for various coating applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

COATING RESINS

TECHNICAL DATA CRAYAMID 115X(70%)

SALES SPECIFICATION OTHER PROPERTIES

Non-volatile content, % @ 150°C 68 - 72 Volatile Xylene

(ISO 3251)

Viscosity in CPS at 40°C 1200 - 1800 Flash point, °c (Iso3679 ) 24 ( Typical)

Colour, Gardner scale ≤ 11

(ISO 4630)

Density at 20°c 0.97

Acid value, mg KOH/g NA

(ISO 3682)

Typical hydrogen Equivalent Weight 240

Amine value, mg KOH/g 205 – 220

( HCL Method)

Note: Amine Value relative to solid resin

65:35 based on solid resin. Excess polyamide in a coating will

PRODUCT INFORMATION :

Impart flexibility and adhesion at the expense of solvent

resistance.

CRAYAMID 115X is a general purpose liquid amino polyamide

resin supplied at 70% solid content in xylene.It is used in

CURE RATE:

conjuction with suitable epoxy resins to produce both top coats

A 65:35 epoxy resin :CRAYAMID115X blend on solid resin will

and primers for wide variety of substrates. The main

reach a tack free time in 30 mins. At 25°c. Film will obviously dry

characteristics are it’s excellent resistance properties and

more rapidly if higher molecular weight epoxy resins are used. An

adhesion to metallic substrates. It is compatible with many

induction period to ensure complete compatibility is recommended.

synthetic resins, varnishes , oils and other media.

Cure of epoxy::polyamide can be accelerated by the addition of

catalysts and in particularly Tris ( dimethylaminomethyl) phenol types

RECOMMENDATIONS FOR USE :

which are recommended for use at a level of 1 – 5 % ( calculated by

The selection of a particular grade of epoxy will depend upon the

weight on total resin). It should be noted, that when catalysts are

end use of the product.It is recommended that for high build

employed pot life will be reduced and there may be an adverse effect

coating it is always recommended to use low molecular weight

on flexibility and colour.

epoxy. In solvent based coatings medium molecular weight and

unmodified liquid epoxy resins may be used , while for adhesive

POTLIFE :

applications either the unmodified or modified liquid epoxy resins

Reaction between the epoxy resin and CRAYMID 115X will

are recommended. While the mixing ratio using CRAYAMID

commence as soon as the reactants are mixed . A65:35 epoxy:

polyamides is not critical, optimum performance of the coating is

CRAYAMID115X mixture on solid resin will have a limited pot life.

achieved by stoichiometric mixing of the epoxy resin and

Solvents will have a considerable effect on pot life e.g. alcohols tend

CRAYAMID 115X. The mix ratio is calculated on the basis of one

to reduce it’s pot life where as esters and ketones tend to extend it.

Active Hydrogen Equivalent weight of the polyamide resin, will

Since ketones and esters form complexes with amino polyamides on

react with each epoxy group in the base resin. The AHEW of the

storage , these solvents should only be incorporated into the epoxy

polyamide resin CRAYAMID115X is typically 240 on solid resin.

resin component.

Considering that each epoxy reacts with one active hydrogen the

mix ratio of CRAYAMID115X and an epoxy resin with epoxide ADHESIVES:

equivalent approx. 500 is calculated as follows;

CRAYAMID 115X : epoxy resin systems demonstrate excellent

adhesion to a wide variety of surfaces , such as glass , wood ,

Resin Mass of solid Mass of Resin ceramics, masonry, leather and plastic substrates. The pot life of a

Resin Solution CRAYAMID 115X : epoxy resin adhesives will cure at ambient

CRAYAMID115X 240g 343g temperature but cure time can be reduced by heating to elevated

75% Epoxy resin 1 500g 667g temperature.

November 2001 Page 1 of 1 UPC 99686

The information contained in this document is based on trials carried out by our Technical centres and data selected from literature, but shall in no event be help to constitute or

imply any warranty, undertaking, expressed or implied commitment from our part. Our formal specifications define the limit of our commitment. No liability whatsoever can be

accepted by CRAY VALLEY with regard to the handling, processing or use of the product or products concerned which must in all cases be employed in accordance with all

relevant laws and/or regulations in force in the country or countries concerned.

CRAY VALLEY (I) PVT. LTD

D-43(1) MIDC Industrial AREA Navi Mumbai - 400706

TELEPHONE: 55907102-08

COATING RESINS

TECHNICAL DATA CRAYAMID 115X(70%)

The resulting epoxy:polyamide mix ratio in this case is approx. NOTES:

1. Epoxy resins epoxide equivalent approx. 500

Araldite 6100 - Cieba Geigy limited.

2. Unmodified epoxy resin epoxide equivalent 200

Epikote 828 - shell Chemicals.

3. Modified epoxy resins epoxide equivalent approx. 200

Epikote 915 - Shell Chemicals

November 2001 Page 2 of 1 UPC 99686

The information contained in this document is based on trials carried out by our Technical centres and data selected from literature, but shall in no event be help to constitute or

imply any warranty, undertaking, expressed or implied commitment from our part. Our formal specifications define the limit of our commitment. No liability whatsoever can be

accepted by CRAY VALLEY with regard to the handling, processing or use of the product or products concerned which must in all cases be employed in accordance with all

relevant laws and/or regulations in force in the country or countries concerned.

CRAY VALLEY (I) PVT. LTD

D-43(1) MIDC Industrial AREA Navi Mumbai - 400706

TELEPHONE: 55907102-08

You might also like

- Epoxy Resin Arts and Crafts for BeginnersFrom EverandEpoxy Resin Arts and Crafts for BeginnersRating: 3 out of 5 stars3/5 (5)

- Emulsion Polymers and Emulsion Polymerization (PDFDrive)Document596 pagesEmulsion Polymers and Emulsion Polymerization (PDFDrive)WALTER KLISSMANNo ratings yet

- Handbook For Code of Practice For Structural Use of Steel 2011Document154 pagesHandbook For Code of Practice For Structural Use of Steel 2011hui123kitNo ratings yet

- The Role of Thickeners in Optimizing Coatings FormulationDocument13 pagesThe Role of Thickeners in Optimizing Coatings FormulationArturo Antonio Matencio ArroyoNo ratings yet

- CompEx GuideDocument22 pagesCompEx GuideFederico MaggiNo ratings yet

- The Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesFrom EverandThe Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesRating: 5 out of 5 stars5/5 (1)

- Crayamid 115Document1 pageCrayamid 115ashfaq afzalNo ratings yet

- Versamid 125: Technical Data SheetDocument3 pagesVersamid 125: Technical Data SheetAMIT HALDERNo ratings yet

- CYMEL-342_EN_A4(1)Document1 pageCYMEL-342_EN_A4(1)林宗穎No ratings yet

- High-Solids Epoxy Systems For Protective and Marine CoatingsDocument6 pagesHigh-Solids Epoxy Systems For Protective and Marine CoatingsJuan Carlos Contreras CherresNo ratings yet

- Zepoxy Technical GuideDocument24 pagesZepoxy Technical Guideagomo18No ratings yet

- EC TDS EL160 High Temperature Laminating ResinDocument2 pagesEC TDS EL160 High Temperature Laminating ResinDILIGENT AM11No ratings yet

- Cymel-1158 en A4Document1 pageCymel-1158 en A4vikram.iitkgpNo ratings yet

- Anquamine® 401 Curing Agent: DescriptionDocument5 pagesAnquamine® 401 Curing Agent: DescriptionrosarioNo ratings yet

- Cymel 1158Document2 pagesCymel 1158sidneidecarvalho100% (1)

- Rrrrrnaa EF PDFDocument1 pageRrrrrnaa EF PDFHYDRAGUARDPLUS ANTIMICROBIAL NANO COATINGNo ratings yet

- Evonik-Ancamide 261A EUDocument7 pagesEvonik-Ancamide 261A EUNimerksNo ratings yet

- ANCAMINE® 2422 Curing Agent: DescriptionDocument7 pagesANCAMINE® 2422 Curing Agent: DescriptionSastra MahachemNo ratings yet

- ACRYSOL RM 2020Document4 pagesACRYSOL RM 2020oguz.ferroNo ratings yet

- Laropal A 81 June 2014 R2 ICDocument3 pagesLaropal A 81 June 2014 R2 ICOswaldo Manuel Ramirez MarinNo ratings yet

- TDS Acronal 7079 PDFDocument3 pagesTDS Acronal 7079 PDFWahid Karol100% (1)

- High Build Epoxy Coating Epigen 1311: Potable Water SuitabilityDocument2 pagesHigh Build Epoxy Coating Epigen 1311: Potable Water Suitabilityjulius hasan33No ratings yet

- Aerosol A-102 Pds 2014Document2 pagesAerosol A-102 Pds 2014Permata Adinda100% (2)

- Acronal 7079 PI EDADocument3 pagesAcronal 7079 PI EDAGokul Basker100% (2)

- Ancarez AR555 e TDS EN EN TDS PV 52042207 en GB EMEADocument13 pagesAncarez AR555 e TDS EN EN TDS PV 52042207 en GB EMEAmanojNo ratings yet

- Laropal A81: Industrial CoatingsDocument3 pagesLaropal A81: Industrial CoatingsMOEEN KHAN ASLAM KHAN RISALDARNo ratings yet

- General Properties Rheological Properties: PVC Paste Resin (Copolymer)Document2 pagesGeneral Properties Rheological Properties: PVC Paste Resin (Copolymer)AminulIslamNo ratings yet

- Additol XL 6557 TdsDocument2 pagesAdditol XL 6557 TdsDean HidayatNo ratings yet

- Tds Acronaleco702ap enDocument3 pagesTds Acronaleco702ap enShreyashi MukhopadhayNo ratings yet

- Cymel-Nf-2000a en A4Document2 pagesCymel-Nf-2000a en A4DidarNo ratings yet

- Adipic Acid Dihydrazide - A Unique Crosslinking Agent and CurativeDocument4 pagesAdipic Acid Dihydrazide - A Unique Crosslinking Agent and CurativeSuharti RifaiNo ratings yet

- Ecrylic KDA 790 - Die Ecronova Polymer GMBHDocument8 pagesEcrylic KDA 790 - Die Ecronova Polymer GMBHLong An ĐỗNo ratings yet

- TDS - Synocure 862 X60 HVDocument2 pagesTDS - Synocure 862 X60 HVfalcon falconpaintNo ratings yet

- Airflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideDocument2 pagesAirflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents - Americas PDFDocument74 pagesEpoxy Curing Agents - Americas PDFMuhammad FahadNo ratings yet

- Cryol 912 60 - TDSDocument2 pagesCryol 912 60 - TDSShafiq LatifNo ratings yet

- The Role of Thickeners in Optimizing Coatings Formulation PDFDocument13 pagesThe Role of Thickeners in Optimizing Coatings Formulation PDFArturo Antonio Matencio Arroyo100% (1)

- TDS Acronal 18 DDocument3 pagesTDS Acronal 18 DNguyễn Thị Ngọc Lan100% (1)

- Alkyphoenix S 63 - 70Document1 pageAlkyphoenix S 63 - 70Lê TiếnNo ratings yet

- RelyX Ultimate TDS USDocument16 pagesRelyX Ultimate TDS USTiến Hưng Lê ĐặngNo ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- DSM Chemical Guide 2007 03.qDocument17 pagesDSM Chemical Guide 2007 03.qABHISEK BHATTACHARYANo ratings yet

- Synocure 9279 S 70 TDSDocument2 pagesSynocure 9279 S 70 TDSCao LongNo ratings yet

- APAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFDocument10 pagesAPAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFraahul_nNo ratings yet

- APAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFDocument10 pagesAPAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFSumanta RoyNo ratings yet

- NX 795Document6 pagesNX 795محمد عزتNo ratings yet

- TDS Ac-Eagle (Oh138-30m60) 60%Document2 pagesTDS Ac-Eagle (Oh138-30m60) 60%Joseph FayekNo ratings yet

- Additol XL 6557 en Letter 2Document2 pagesAdditol XL 6557 en Letter 2Dean HidayatNo ratings yet

- Rhoplex Ei-3500Document5 pagesRhoplex Ei-3500Chirag PatelNo ratings yet

- Acronal ECO 702 AP TI EDA Nov 07Document3 pagesAcronal ECO 702 AP TI EDA Nov 07nanoNo ratings yet

- RelyX Ultimate Clicker TDS INT PDFDocument18 pagesRelyX Ultimate Clicker TDS INT PDFdrg. Rifqie Al HarisNo ratings yet

- ACRYSOL™ RM-825: Rheology ModifierDocument6 pagesACRYSOL™ RM-825: Rheology ModifierNam BùiNo ratings yet

- 2015 - ConstructionProduct - NA BASFDocument34 pages2015 - ConstructionProduct - NA BASFSantosh RajNo ratings yet

- BECKOPOX VEH 2188w 55WA - EN - A4Document2 pagesBECKOPOX VEH 2188w 55WA - EN - A4NganNo ratings yet

- Product Guide: Energising Possibilities Stimulating GrowthDocument20 pagesProduct Guide: Energising Possibilities Stimulating GrowthWahid Karol100% (1)

- DK2131 CH37Document7 pagesDK2131 CH37azzaassNo ratings yet

- p190035 en Versalink-Brochure NR RZ WebDocument4 pagesp190035 en Versalink-Brochure NR RZ Webyilong luoNo ratings yet

- Resinas de AdhesionDocument8 pagesResinas de AdhesionsupermamenNo ratings yet

- TDS AlKyd ResinDocument2 pagesTDS AlKyd ResinAji Pradah100% (1)

- Rheolate 185 1Document2 pagesRheolate 185 1NaraNo ratings yet

- IJETR041163Document5 pagesIJETR041163erpublicationNo ratings yet

- 2015 Synfluid BroDocument8 pages2015 Synfluid BromarcelhidajatNo ratings yet

- Listado Materias PrimasDocument18 pagesListado Materias PrimasWALTER KLISSMANNo ratings yet

- Anticorrosive PaintsDocument197 pagesAnticorrosive PaintsWALTER KLISSMANNo ratings yet

- Effects of Epoxy Resin and Hardener Type OnDocument135 pagesEffects of Epoxy Resin and Hardener Type OnWALTER KLISSMANNo ratings yet

- Air Products Formulation No SCR 650 4Document2 pagesAir Products Formulation No SCR 650 4WALTER KLISSMANNo ratings yet

- Derakane Epoxi Vinil EsterDocument59 pagesDerakane Epoxi Vinil EsterWALTER KLISSMANNo ratings yet

- Listado Materias Primas 2Document20 pagesListado Materias Primas 2WALTER KLISSMANNo ratings yet

- Appendix 1 Epon Resin - Curing Agent Systems: Ã Resolution Performance ProductsDocument59 pagesAppendix 1 Epon Resin - Curing Agent Systems: Ã Resolution Performance ProductsWALTER KLISSMANNo ratings yet

- Atlas All Scales Track and Accesory Catalogue PDFDocument138 pagesAtlas All Scales Track and Accesory Catalogue PDFWALTER KLISSMANNo ratings yet

- MRC Prodigy Express User's Manual: More About Programming Locomotive Address On The Program Track or Main TrackDocument10 pagesMRC Prodigy Express User's Manual: More About Programming Locomotive Address On The Program Track or Main TrackWALTER KLISSMANNo ratings yet

- Atlas All Scale Track and Accesory CatalogueDocument143 pagesAtlas All Scale Track and Accesory CatalogueWALTER KLISSMANNo ratings yet

- Swo003283 Indercolor Sas4Document2 pagesSwo003283 Indercolor Sas4WALTER KLISSMANNo ratings yet

- 2013 SirE SENEPOL PDFDocument44 pages2013 SirE SENEPOL PDFWALTER KLISSMANNo ratings yet

- Ebay - Order DetailsDocument1 pageEbay - Order DetailsWALTER KLISSMANNo ratings yet

- Service Quote SWQ000441Document1 pageService Quote SWQ000441WALTER KLISSMANNo ratings yet

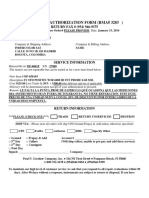

- Customer Authorization Form (Rma# 3283) : RETURN FAX # (954) 946-9375 Contact Person: DAVID RENDONDocument1 pageCustomer Authorization Form (Rma# 3283) : RETURN FAX # (954) 946-9375 Contact Person: DAVID RENDONWALTER KLISSMANNo ratings yet

- Formulation and Assessment Off A Wash - Removed - pdf-PDFADocument18 pagesFormulation and Assessment Off A Wash - Removed - pdf-PDFAWALTER KLISSMANNo ratings yet

- Delivery Package 1 of 1: Shipping AddressDocument2 pagesDelivery Package 1 of 1: Shipping AddressWALTER KLISSMANNo ratings yet

- Listado Materias Primas 3Document20 pagesListado Materias Primas 3WALTER KLISSMANNo ratings yet

- Mock Exam PLU 2017 - 11152017Document1 pageMock Exam PLU 2017 - 11152017KatsMendozaNo ratings yet

- Features:: Transport DimensionsDocument2 pagesFeatures:: Transport DimensionsshawnNo ratings yet

- Origin of LifeDocument14 pagesOrigin of Liferjpusung420No ratings yet

- STP Levamisole Hydrochloride BPDocument7 pagesSTP Levamisole Hydrochloride BPbejoykarim2022No ratings yet

- Comparing The Alkali Metals and The HalogensDocument2 pagesComparing The Alkali Metals and The Halogensapi-237448150No ratings yet

- Biochem Lab ManualDocument5 pagesBiochem Lab ManualshaneskiranrajaNo ratings yet

- Ground Improvement Techniques ME 3rd SemDocument57 pagesGround Improvement Techniques ME 3rd SemSojil Jain86% (7)

- Principal of DPTDocument5 pagesPrincipal of DPTAkshith SulliaNo ratings yet

- 16 Foundry Resins: 16.1 Mold-And Core-Making ProcessesDocument13 pages16 Foundry Resins: 16.1 Mold-And Core-Making ProcessesJoão Victor VieiraNo ratings yet

- HPLC EucaliptoDocument6 pagesHPLC EucaliptoMárcia SilvaNo ratings yet

- Chapter 2 Material and Energy BalancesDocument15 pagesChapter 2 Material and Energy Balancesaa0809No ratings yet

- KleenRite Edge 100-3Document21 pagesKleenRite Edge 100-3Nestor Marquez-Diaz100% (1)

- Intradialytic ComplicationsDocument5 pagesIntradialytic Complicationskane1978100% (1)

- Onion Paste LWT PaperDocument4 pagesOnion Paste LWT PaperYasir ArfatNo ratings yet

- Plastmix WPDocument2 pagesPlastmix WPmohab hakimNo ratings yet

- Journal of Liquid Chromatography & Related TechnologiesDocument12 pagesJournal of Liquid Chromatography & Related TechnologiesAni KushwahaNo ratings yet

- Gulf SDMO 20W-40Document6 pagesGulf SDMO 20W-40Om Prakash RajNo ratings yet

- DNA Extraction From Human BloodDocument41 pagesDNA Extraction From Human BloodhadymatrixNo ratings yet

- Energy Conservation in Domestic Rice CookingDocument11 pagesEnergy Conservation in Domestic Rice CookingAnonymous MVHQ97KEoPNo ratings yet

- SCIENCE 8 Q3 - WEEK 3 - LAS 1 Phase ChangeDocument2 pagesSCIENCE 8 Q3 - WEEK 3 - LAS 1 Phase ChangeGlin BarrientosNo ratings yet

- Bending Stress: by Jos IstiyantoDocument12 pagesBending Stress: by Jos IstiyantoMekro Permana PinemNo ratings yet

- Corrosion Under Insulation in Process IndustryDocument30 pagesCorrosion Under Insulation in Process IndustryWILLIAM100% (1)

- Combined TutorialDocument2 pagesCombined Tutorialcarleston thurgoodNo ratings yet

- PROJECTDocument21 pagesPROJECTHARI HARA RAO GUJJARNo ratings yet

- Selection of Cutting Tool Materials: CBN & PCDDocument24 pagesSelection of Cutting Tool Materials: CBN & PCDKarthick NNo ratings yet

- ASEAN TMHS GMP Training Chapter 4 Sanitation and Hygiene FDDocument48 pagesASEAN TMHS GMP Training Chapter 4 Sanitation and Hygiene FDRajib SarkarNo ratings yet

- Safety-Tools Product CatatalogueDocument16 pagesSafety-Tools Product CatatalogueYoga Sukma SaktiNo ratings yet

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document9 pagesEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)8612106535No ratings yet