Safety Procedure Rammer

Safety Procedure Rammer

Uploaded by

Aura SantosCopyright:

Available Formats

Safety Procedure Rammer

Safety Procedure Rammer

Uploaded by

Aura SantosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Safety Procedure Rammer

Safety Procedure Rammer

Uploaded by

Aura SantosCopyright:

Available Formats

Safe Operating Procedure

Rammer

The instructions recommended within this document apply to normal risk conditions. If the Rammer

is to be operated in a dangerous or hostile environment, the user/client is responsible for

conducting an appropriate risk analysis and applying suitable controls to mitigate those additional

risks.

This instruction should be read in conjunction with the Risk Assessment.

GENERAL SAFETY

• Wear safety footwear, safety gloves, hearing protection, eye protection and Hi-Vis jacket)

• The rammer can only be operated if it is a safe and sound operating condition and by a

competent operator.

• Work sites on roads must be separated from normal traffic flow

• Rammer activity must remain in a barricaded area at all times unless traffic flow is stopped

to allow access in or out of the work area.

• Avoid operating on slopes in excess of 25 degrees to avoid tipping and failure of lubrication

system

• Ensure adequate fresh air is available if operating in an enclosed area

• Extreme care to be taken when operating near trenches or pits

• Operate from the side when travelling backwards to avoid crushing between handle and

obstacles

• Operator must never stand in the direction of any descent

TRANSPORT OF RAMMER

• Ensure unit is firmly tied down on transport vehicle without damaging engine and fittings

• If transporting over long distances, drain fuel tank before leaving

OPERATING CONDITIONS

• Check fuel and oil levels

• Check for fuel and oil leaks. DO NOT OPERATE UNIT IF LEAKS ARE FOUND

• Ensure no slip/trip hazards are present in work area

• Avoid standing on loose ground

• Turn on fuel valve

• Turn choke on

• Pull cord to start

• Switch off choke

• Operate hand throttle

• Bring revs to operating speed

• Move throttle to RUN position

• USE BOTH HANDS AT ALL TIMES

• NEVER LEAVE RAMMER RUNNING WHILE UNATTENDED

SHUT DOWN PROCEDURE

• Move hand throttle back to start position

• Switch turned to off position

• Turn off fuel valve

INSPECTION AND MAINTENANCE

• Inspect fuel lines and tank for leaks.

• Ensure fuel valve, choke and throttle functioning.

The above instructions must be followed at all times If any of the instructions are not

possible, contact the site supervisor for an assessment of any safety requirements

SOP-0046 Version 1.0

Page 1 of 1 Approval Date August 2018

Rammer Risk Assessment

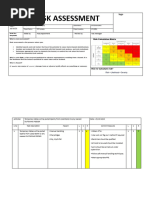

Likely Risk Who/ What What is the Rate What Risk Control Actions Needs to Be Taken? Time

Issue may be Level? (What needs to be considered so that the risks are identified and effectively Frame

harmed? (Rate risk as Low, controlled)

(Specific Persons) Medium or High)

Eye Damage Operator Severity of Risk (S)- 2 • Always wear safety glasses Every Hire

Load Noise ear Spectator Likelihood of Risk (L)- 2 • Always wear hearing protection

damage Overall Risk (S x L)= 4 • Warn bystanders prior to starting machine

MEDIUM

Foot Damage Operator Severity of Risk (S)- 2 • Wear appropriate footwear - steel cap boots Every Hire

Spectator Likelihood of Risk (L)- 2 • Make sure work area is clear of obstacles which may obstruct operation of plate

Overall Risk (S x L)= 4 • Be aware of bystanders and set up exclusion zone if necessary

MEDIUM • Nowhere your feet are in relation to the operation of the machine

Collision with Operator Severity of Risk (S)- 3 • Never leave unit running when unattended Every Hire

machine Spectator Likelihood of Risk (L)- 2 • Ensure work environment is well lit

Overall Risk (S x L)= 6 • Make sure work area is hazard free

MEDIUM

Trips, slips, fall Operator Severity of Risk (S)- 1 • Clear work area of potential obstacles prior to commencing work Every Hire

Spectator Likelihood of Risk (L)- 2 • Maintain proper footing at all times and avoid standing on uneven, rough, wet or

Overall Risk (S x L)= 2 slippery surfaces

LOW • Always keep both hands-on guide handle when using machine

• Never operate from dangerous areas such as ladders, walls etc

• If operating on roof ensure edge protection, safety lines and harnesses are used

Burns Operator Severity of Risk (S)- 2 • Always stop the unit prior to refueling Every Hire

Fire Spectator Likelihood of Risk (L)- 2 • Wear safety gloves to protect hands from hot parts

Explosions Overall Risk (S x L)= 4 • Allow machine time to cool down after use prior to moving

MEDIUM • Never smoke near machine

Exposure to Operator Severity of Risk (S)- 3 • Never use plate compactor in confined spaces Every Hire

Dangerous Spectator Likelihood of Risk (L)- 1 • Always ensure adequate ventilation prior to use

fumes Overall Risk (S x L)= 3

LOW

Calculation of Risk Evaluation

Severity of Risk (S) is judged by evaluating the effects of the hazard if the risk occurs. This is evaluated as Minor = 1, Major = 2, Serious = 3

Risk Likelihood (L) - The likelihood of the harm occurring is evaluated on the basis of: Unlikely =1, Possible = 2, Likely = 3

Overall Risk is calculated by multiplying the figure for Severity (S) and Likelihood (L).

The overall risk figure calculated is related to the Risk Level of either Low: 1 to 3; Medium: 4 to 6 or High: 7 to 9

NB This is a generic risk assessment only. It is advisable to carry out a site-specific assessment prior to using this equipment.

RA-0046 Version 1.0

Page 1 of 1 Approval Date July 2018

You might also like

- RA Confined Space PDFDocument10 pagesRA Confined Space PDFrodman823100% (2)

- Quantum HealingDocument2 pagesQuantum HealingCatrin Jacksties70% (20)

- Post Hole Borer Risk Assessment: September 2015 //1Document2 pagesPost Hole Borer Risk Assessment: September 2015 //1Rajendra0% (1)

- Work at Height TrainingDocument6 pagesWork at Height TrainingRaza Muhammad Soomro100% (1)

- Post Hole BorerDocument3 pagesPost Hole BorermuneebNo ratings yet

- Safe Operating Procedure Roller: General SafetyDocument4 pagesSafe Operating Procedure Roller: General SafetyRonald AranhaNo ratings yet

- Diesel GensetDocument2 pagesDiesel Gensetvega f ankaNo ratings yet

- Ladder Risk AssessmentDocument3 pagesLadder Risk Assessmentvasanth pugazhendhiNo ratings yet

- SOP SOP0007 Hitachi Electric Jack HammerDocument3 pagesSOP SOP0007 Hitachi Electric Jack HammerWidya BungaNo ratings yet

- Honda Petrol GensetDocument3 pagesHonda Petrol Gensetmanishadash009No ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- SOP SOP0001 Crane TruckDocument3 pagesSOP SOP0001 Crane TruckMmamoraka Christopher MakhafolaNo ratings yet

- Electric Submersible PumpDocument2 pagesElectric Submersible Pumpneyazy abdelmonemNo ratings yet

- Hitachi Electric Jack HammerDocument3 pagesHitachi Electric Jack Hammernidhibinitsingh2007No ratings yet

- Concrete Core DrillDocument3 pagesConcrete Core DrillrehmanNo ratings yet

- Oxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Document2 pagesOxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Alves EdattukaranNo ratings yet

- SOP SOP0003 Nail GunDocument2 pagesSOP SOP0003 Nail Gunjeevan georgeNo ratings yet

- Risk Assessment For Grinding Work: Classic Builders and DevelopersDocument3 pagesRisk Assessment For Grinding Work: Classic Builders and DevelopersradeepNo ratings yet

- Safe Operating Procedure Crane Truck: You Must Wear This Personal Protective Equipment When Doing This TaskDocument3 pagesSafe Operating Procedure Crane Truck: You Must Wear This Personal Protective Equipment When Doing This Taskr afriantoNo ratings yet

- Welding Robots Technology System Issues and Applications - J Norberto PiresDocument76 pagesWelding Robots Technology System Issues and Applications - J Norberto PireshetpinNo ratings yet

- Safe Work Method Statement Rafter Fallguard (0004) : Job DetailsDocument11 pagesSafe Work Method Statement Rafter Fallguard (0004) : Job DetailsThandabantu MagengeleleNo ratings yet

- Risk AssessmentDocument4 pagesRisk AssessmentThoufeer NETTERYNo ratings yet

- Risk AssesmentDocument3 pagesRisk Assesmentaliyev.eti1978No ratings yet

- Radf - G05 - Working Aloft and OverboardDocument4 pagesRadf - G05 - Working Aloft and OverboardSuryaprakash TiwariNo ratings yet

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Radf - g07 - Operating High Pressure Hydraulic ToolsDocument4 pagesRadf - g07 - Operating High Pressure Hydraulic ToolsSuryaprakash TiwariNo ratings yet

- Machine Guarding - Machine Safeguarding PresentationDocument46 pagesMachine Guarding - Machine Safeguarding PresentationIns TaNo ratings yet

- SP0904 - SDP Induction SP-CON-06-1 Safety Data Package - Basic Induction Information Rev 07 28-07-22Document9 pagesSP0904 - SDP Induction SP-CON-06-1 Safety Data Package - Basic Induction Information Rev 07 28-07-22Wajdi MansourNo ratings yet

- CTRA-23-STM-062-TK-95-001 - ManliftDocument3 pagesCTRA-23-STM-062-TK-95-001 - ManliftMohamed RizwanNo ratings yet

- Safe Jetting Manual HP1Document4 pagesSafe Jetting Manual HP1Sheik Abdullah BakrudeenNo ratings yet

- Aussie Safe Jetting Manual 2018 (Assassin Jetters)Document20 pagesAussie Safe Jetting Manual 2018 (Assassin Jetters)sathish15No ratings yet

- 01 Slides - Session 1 Health and Safety - A PerspectiveDocument54 pages01 Slides - Session 1 Health and Safety - A PerspectivemedepallyphanisaiNo ratings yet

- Earth WorksDocument4 pagesEarth WorksLawrence adeleke OmisakinNo ratings yet

- BOSHDocument5 pagesBOSHJeffrey RegondolaNo ratings yet

- Safe Work Method Statement Gangra Kilometre 8 Phase 2 ProjectDocument3 pagesSafe Work Method Statement Gangra Kilometre 8 Phase 2 ProjectMark GarmondehNo ratings yet

- Line of Fire TBTDocument4 pagesLine of Fire TBTumairgee00No ratings yet

- Basic Construction SafetyDocument41 pagesBasic Construction SafetyLei LopezNo ratings yet

- Radf - g05 - Working Aloft and OverboardDocument5 pagesRadf - g05 - Working Aloft and OverboardSuryaprakash TiwariNo ratings yet

- 02 Safety - MT2200 - enDocument28 pages02 Safety - MT2200 - enjackNo ratings yet

- Risk Generator Risk AssessmentDocument2 pagesRisk Generator Risk AssessmentBaher Mohamed100% (1)

- Risk RegisterDocument37 pagesRisk RegisterSufiyan Farooq100% (1)

- Booklet Cardinal Rules - EngDocument12 pagesBooklet Cardinal Rules - EngsaikatnaskarlntNo ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- Radf g10 PaintingDocument4 pagesRadf g10 PaintingSuryaprakash TiwariNo ratings yet

- Radf - g03 - Handling Heavy PartsDocument4 pagesRadf - g03 - Handling Heavy PartsSuryaprakash TiwariNo ratings yet

- Exhibitor RAMS Example - LDB 23Document11 pagesExhibitor RAMS Example - LDB 23BocirneaNo ratings yet

- Agmp Chapter - 3Document21 pagesAgmp Chapter - 3vijethaezhill13No ratings yet

- BSC Slides Construction Unit B Part 2Document23 pagesBSC Slides Construction Unit B Part 2james.rawcliffe123No ratings yet

- Risk AssesmentDocument2 pagesRisk AssesmentHamayon MushtaqNo ratings yet

- Scissor Lift Truck Safety and Operating ProcedureDocument7 pagesScissor Lift Truck Safety and Operating Procedurenatuan74No ratings yet

- METHOD-STATEMENT-FOR-WORKING-AT-HEIGHT-Rev-A0Document12 pagesMETHOD-STATEMENT-FOR-WORKING-AT-HEIGHT-Rev-A0shafiki.ehsNo ratings yet

- Fall Protection GRP 4Document9 pagesFall Protection GRP 4Ruben SibayanNo ratings yet

- List Pre-Requisites Here: Importance Ranking Satisfactory or Needs WorkDocument19 pagesList Pre-Requisites Here: Importance Ranking Satisfactory or Needs WorkiZnoGouDmuzicNo ratings yet

- Screening and Crushing Operations 2016 VersionDocument3 pagesScreening and Crushing Operations 2016 Versionmohamedkeita0880No ratings yet

- AHA - Bucket Truck OperationDocument2 pagesAHA - Bucket Truck OperationJon CarloNo ratings yet

- Risk Assessment ExerciseDocument10 pagesRisk Assessment ExerciseScribdTranslationsNo ratings yet

- TbT - Fall From HeightsDocument1 pageTbT - Fall From Heightsfazel1997No ratings yet

- SOP-22 AC Compressore Replacement WorkDocument4 pagesSOP-22 AC Compressore Replacement WorkNarendra SinghNo ratings yet

- Fall Protection & Working at Height: by - S. Meril PandithaDocument32 pagesFall Protection & Working at Height: by - S. Meril PandithaSamantha Meril PandithaNo ratings yet

- Risk Assessment - House and Office CleaningDocument6 pagesRisk Assessment - House and Office CleaningVimal ThomasNo ratings yet

- Sexual Response CycleDocument7 pagesSexual Response CycleHana-Lou TaquiquiNo ratings yet

- v2 Cad Base Zero 2024Document144 pagesv2 Cad Base Zero 2024Thifany SousaNo ratings yet

- SSM - Safe Ship ManagementDocument26 pagesSSM - Safe Ship Managementsai_balaji_8No ratings yet

- EML-Leading-Self-Reflections-WorksheetDocument9 pagesEML-Leading-Self-Reflections-WorksheettonyjesudasNo ratings yet

- BOOK The - Psychopath - A - True - Story - by - Mary - Turner - ThomsonDocument214 pagesBOOK The - Psychopath - A - True - Story - by - Mary - Turner - Thomsonarahrojas33No ratings yet

- Behavior TherapyDocument50 pagesBehavior TherapyRoberto VargasNo ratings yet

- REFERENCESDocument4 pagesREFERENCESSanhati Ghosh BanerjeeNo ratings yet

- TLD PDFDocument1 pageTLD PDFsayar_kyeeNo ratings yet

- Unit VDocument66 pagesUnit VardanielallenjosephNo ratings yet

- Clinical Trials Its Difficulties and The SolutionDocument8 pagesClinical Trials Its Difficulties and The SolutionSmartway PharmaceuticalsNo ratings yet

- Bond & Stipend Details for NEET PGDocument4 pagesBond & Stipend Details for NEET PGPriya SikdarNo ratings yet

- Addressing Domestic Violence Against Women - An Unfinished AgendaDocument5 pagesAddressing Domestic Violence Against Women - An Unfinished AgendaAkshata NetkeNo ratings yet

- Gaa 2023 Vol 1 BDocument1,070 pagesGaa 2023 Vol 1 BteenskeeNo ratings yet

- Nutrients in Marine FishesDocument5 pagesNutrients in Marine FishesAnasSuhaimiNo ratings yet

- 10 - All or Nothing PrincipleDocument11 pages10 - All or Nothing Principlebreinfout fotosNo ratings yet

- MSDS Antiseptic LiquidDocument17 pagesMSDS Antiseptic LiquidFebrianto DimazNo ratings yet

- Maslach ReferencesDocument2 pagesMaslach Referencesdr09abiNo ratings yet

- Provisional List of Firms Issued Form 7 ImportedDocument142 pagesProvisional List of Firms Issued Form 7 ImportedMuhammad Irfan100% (1)

- General Guidance in Inclement Wether Conditions-EngDocument12 pagesGeneral Guidance in Inclement Wether Conditions-EngkarvizNo ratings yet

- ABB TPL67-C36 Operation ManualDocument128 pagesABB TPL67-C36 Operation ManualWorld ServiceNo ratings yet

- Martin Humor 17 - 1Document20 pagesMartin Humor 17 - 1FernandoCedroNo ratings yet

- Fabros, DanielDocument28 pagesFabros, DanielSarah FabrosNo ratings yet

- Multimodal Transportation of Dangerous Goods in The Eastern DirectionDocument16 pagesMultimodal Transportation of Dangerous Goods in The Eastern DirectionAkhmadRifaniNo ratings yet

- Contoh JsaDocument8 pagesContoh JsaarnNo ratings yet

- Texas To Cut Planned Parenthood Out of MedicaidDocument5 pagesTexas To Cut Planned Parenthood Out of MedicaidBrian M. Rosenthal100% (1)

- Member Data Record: Tulang, Sharece Dale LapurgaDocument1 pageMember Data Record: Tulang, Sharece Dale LapurgaAd InfinitumNo ratings yet

- RPA Sir - OSH Labor Act RegulationsDocument13 pagesRPA Sir - OSH Labor Act RegulationsAmar Kaji JonchhenNo ratings yet

- 2023 Baptist Shining StarDocument5 pages2023 Baptist Shining StarBaptist Memorial Health CareNo ratings yet

- HealthPoint 6 Wendy (Lorraine)Document6 pagesHealthPoint 6 Wendy (Lorraine)maryhenderson2No ratings yet