Professional Documents

Culture Documents

1100 SERIES Level Eye® BULLETIN 1100-SB16-01 Service Bulletin

1100 SERIES Level Eye® BULLETIN 1100-SB16-01 Service Bulletin

Uploaded by

Jose Antonio Andrade CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1100 SERIES Level Eye® BULLETIN 1100-SB16-01 Service Bulletin

1100 SERIES Level Eye® BULLETIN 1100-SB16-01 Service Bulletin

Uploaded by

Jose Antonio Andrade CruzCopyright:

Available Formats

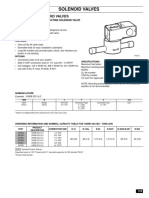

1100 SERIES

LEVEL EYE®

BULLETIN 1100-SB16-01

SERVICE BULLETIN

VALVES • VESSELS • SYSTEMS • CONTROLS

System drawings shown in this bulletin are for illustration purposes only. Refrigeration systems should only be serviced by a qualified technician. Always

observe proper safety procedures when servicing a refrigeration system. For more information see the latest revision of Phillips Safety Bulletin SGRV.

GENERAL INFORMATION

Pressure Rating: 1000 psig/69 bar

Temperature Rating: -60°F to 250°F

(-51°C to 121°C)

The H.A. Phillips Level Eye is a reliable, industrial type sight

glass; and comes in a large variety of housing styles and viewing

options.

The standard reflex lens indicates the true level of the liquid

present without requiring a second lens. The reflex lens appears

dark in the presence of liquid and clear otherwise as shown in

Figure 1. The reflex lens is ideal for determining the liquid level in

a vessel or column and shows up to 1-1/2” of liquid. An optional

clear lens is available when it is desirable to view into a vessel;

and can be used in pairs by shining a light into the vessel through

one while looking into the other.

The optional standard length frost shield allows clear vision

with refrigerant temperatures down to -20°F/-29°C, and a 1” long-

er frost shield is available for refrigerant temperatures below -20°

F/-29°C.

H.A. Phillips offers a wide variety of Level Eye configurations to

accommodate most refrigerant viewing situations. Some of the

common configurations are summarized in Table 1 and all the

available options are illustrated in Figure 5.

W !

NE

1 1/2”

See Last Page for New Level Eye Tools!

Standard Reflex Lens Optional Clear Lens LEVEL EYE APPLICATIONS

Shown Without Optional Frost Shield Shown Without Optional Frost Shield

Figure 1: Lens Options and Optical View Length The Level Eye assemblies are suitable for ASME code vessels

such as receivers, intercoolers, suction accumulators, oil separa-

Table 1: Common Level Eye Configuration Information tors, surge drums and oil pots.

Housing Style/Material

Assembly Connection Weight The 1100 Series Level Eyes can also be used in refrigeration col-

Number * Geometry (lbs.) umns or liquid line indicators, and other non-code applications.

1100 Square End 1.5

1100A Square End 2.0 The Level Eye assemblies are suitable for R717 (ammonia), R-22,

R-134a, R-404a, R-410a, R-507a and many other common refrig-

Weld SA36 1100C Saddle Milled 1.5 erants.

1100L Square End 3.0

1100LC Saddle Milled 3.0 GASKET MATERIAL COMPATIBILITY

1100S Square End 1.5

Weld 304SS The standard Neoprene gasket (1103) is compatible with most

1100LS Square End 3.0

1100AT 1-1/2” MPT 2.0 common refrigerants. Buna-N gasket material (1103B) is recom-

Threaded SA36 mended for use with Propane (R-290) and CO2 (R-744); Teflon

1100T 1-1/2” MPT 3.0

gasket material (1103T) is recommended for use with R-22.

Threaded Steel

1100V 2” MPT 1.5

Forging

For more information on gasket material compatibility with refriger-

Threaded 304SS 1100SL 1-1/2” MPT 3.0 ants and refrigerant oils please contact H.A. Phillips & Co.

* See Page 3 for more info on assembly part numbers

Visit us at: www.haphillips.com or e-mail us at: info@haphillip.com

INSTALLATION INSTRUCTIONS SERVICE AND MAINTENANCE

WELDED In service, do a periodic monthly visual inspection of the

OVER 19/16” glass; and a yearly retainer torque test. Re-torque to the prop-

DIAMETER er level if necessary. Replace glass and both gaskets immedi-

HOLE ately if any discoloration or physical damage is found.

If refrigerant leakage is found, check torque on retainer; If

torqued to the proper level and still leaking, then replace lens

LEVEL EYE and gaskets.

HOUSING Do not reuse gaskets; whenever the glass is replaced, re-

place both gaskets**.

2-4” PIPE

WELDED

When replacing the lens, look for any signs of damage. If the

INTO 2”

new lens is damaged, do not use. If the lens is dropped, do

DIAMETER

SADDLE MILLED not reuse even if there no visual damage.

HOLE

HOUSING Do not use any type of metal or sharp object to remove ice

from the sight glass. Always use low heat to slowly melt the

Chamfer Made by User Expansion Gap frost.

1-1/2”

Schedule Lens replacement kits and instructions:

80 pipe Please see Table 2 for lens replacement kits and spare parts**.

The two available kits come with the standard Neoprene (1103)

LEVEL EYE gasket, either a standard reflex lens (1101R) or a clear lens

HOUSING (1101R) and a fiber gasket (1104).

Weld Neck (AKA Butt

Weld) Connection Socket Weld Connection 1. Use only qualified and experienced persons to perform pre-

ventative maintenance work.

Neoprene, Buna-N, or Teflon Gasket 2. Read the latest PHILLIPS safety bulletin (available on our

Housing website or upon request) prior to performing any maintenance

and service work.

O-Ring 3. Follow all procedures for pumping out and discharging refrig-

Lens erant as described in the safety bulletin mentioned above and

Frost as required by good practice, local codes, ordinances and

Shield

regulations.

4. DO NOT begin disassembly of any valve or accessory com-

Retainer ponent until its internal pressure is confirmed to be equalized

Fiber Gasket to atmospheric pressure.

Figure 2: Installation Methods and Assembly Order 5. If a frost shield is installed remove it by twisting/pulling it out

by hand. Loosen and remove the 1102SH retainer. Next re-

1. To weld: Housing can be welded into a 2” opening, over a 1- move both gaskets and lens.

9

/16” opening, or treated as a 1-1/2 sch. 80 pipe as shown 6. Install the lens replacement kit** by following the installation

above. Remove the retainer, glass, and gaskets before weld- instructions steps 2 through 5.

ing. Anti spatter or a clean damp cloth applied/inserted over 7. When the time comes, after all installations are complete,

the threads will help protect the threads from weld spatter. evacuate and recharge the system as recommended/required

Weld the housing into place employing good welding practic- per good practice standards, local codes, ordinances, and

es paying special attention to heat input into the work piece regulations.

as an excessive amount of heat input can distort the housing.

2. Once the work piece has cooled, clean the threads with a

**Please order a custom lens replacement kit if using propane

cloth or non-abrasive nylon brush. Install the lens and gaskets (R-290), CO2 (R-744), or R-22: The kits contain the standard

in the order as shown above. Make sure the lens is installed Neoprene gasket (1103) which is compatible with most common

flat against the gaskets and all parts are clean and free of refrigerants. Buna-N gasket material (1103B) is recommended for

debris. Next insert the retainer, by engaging the threads by use with Propane (R-290) and CO2 (R-744); Teflon gasket materi-

hand, being careful to avoid crossing and mutilation of the al (1103T) is recommended for use with R-22. When needing a

threads. If retainer will not thread in properly please read replacement lens kit for a system operating with any of these

about the thread tap on page 4. three refrigerants please order the appropriate gasket, the desired

3. Tighten 1102SH retainer to 40-50 ft-lbs torque for a Neoprene lens, and the 1104 fiber gasket separately.

(1103) or Buna-N (1103B) gasket. For a Teflon gasket

(1103T), torque to 60-70 ft-lbs. See socket tool on page 4. 1103 or 1103B or 1103T

4. Important: Upon pressurizing the system (and before instal-

lation of a frost shield), and periodically thereafter, check for a 1104

proper seal by applying a dish soap/drinking water solution to

the Level Eye; keeping an eye out for any bubbles that may 1106

form from a leak. 1100

Housing 1105/

5. If applicable, insert the frost shield using a light coating of

1105L

Neoprene safe oil on the O-ring; push the frost shield into the 1101 or 1101R

1102SH by hand.

A VERY THIN WIRE (AROUND 27 GAUGE) HELD OVER THE O-RING, AL-

LOWING AIR TO ESCAPE WHILE INSERTING, WILL AID INSTALLATION OF 1102SH

A FROST SHIELD. WITHDRAW THE THIN MATERIAL AFTER INSTALLA-

TION. Figure 3: Lens Replacement Kits (includes parts in dark text)

Visit us at: www.haphillips.com or e-mail us at: info@haphillip.com

LEVEL EYE HOUSINGS AND PARTS

ALL DIMENSIONS ARE IN INCHES

Table 2: Level Eye Parts and Descriptions

Part Type Part No. Description 1100LH

or

1100H 2” long housing, square end 1100AH

1100LSH

1100AH 3” long housing, square end 1100H

Housings or

Weld 1100CH 2” long housing, saddle milled 1100SH

SA36 1100LH 4” long housing, square end

1100LCH 4” long housing, saddle milled 2.48

Housings 1100SH 2” long housing, square end

Weld 304SS 1100LSH 4” long housing, square end

Housings 1100ATH 3” long housing, 1-1/2” MPT 3

Threaded 1 4

1105L

SA36 1100TH 4” long housing, 1-1/2” MPT 1100LCH

Housing 1100CH

Threaded 1100VH 1-1/2” long housing, 2” MPT

Steel Forging 1105

Housing

Threaded 1100LSTH 4” long housing, 1-1/2” MPT

304SS

3

1101 clear lens, borosilicate glass 4

Lenses 1100TH

1101R reflex lens, borosilicate glass

or

Retainer 1102SH retainer, forged 416SS hex 1100ATH

1100LSTH

1103 ** gasket standard, neoprene **

1100VH

Gaskets ** 1103B ** gasket, Buna-N **

& 1103T ** gasket, Teflon (PTFE) ** 2” MPT 1-1/2” MPT 1-1/2” MPT

O-Rings 1104 gasket, vulcanized fiber

1106 O-ring, Neoprene

Figure 5: Level Eye Housings and Dimensions

frost shield, Lucite, standard

1105

length (1-1/2”)

Frost Shields frost shield, Lucite, extended ASSEMBLY PART NUMBER NOMENCLATURE

1105L length (2-1/2”); use for refriger- *When ordering please specify the assembly configuration num-

ant temps. below -20°F/-29°C.

ber using the assembly configuration number Identifier table be-

includes 1101 clear lens, 1103 neath:

K1100** Neoprene gasket** and 1104 Assembly Configuration Number Examples:

Lens fiber gasket 4” stainless steel Level Eye® (housing part number

Replacement 1100LSH) with reflex lens, extended frost shield and Teflon

Kits includes 1101R reflex lens,

K1100R** 1103 Neoprene gasket** and gasket is: 1100LS-RNXT

1104 fiber gasket

If the exploded assembly (Figure 4; shown with a 1100H

** See GASKET MATERIAL COMPATIBILITY section and custom lens

housing) had a Neoprene gasket (1103), a reflex lens

replacement instructions under the Service and Maintenance section.

(1101R, as pictured) and a standard length frost shield

(1105), then its configuration part number would be:

1100-RN.

1103/1103B/1103T assembly Configuration number Identifier

1100 -R NX T

1104 Housing Style (less ‘H’)

See assembly parts table above

1106 Please note that you do not list

the ‘H’ that is part of the housing

part number.

1100 Series

Housing 1105/ LENS

1105L (Blank) = Clear Lens

R = Reflex Lens

1101/1101R

FROST SHIELD

(Blank) = No Frost Shield

1102SH N = Standard Length (1-1/2”)

NX = Extended Length (2-1/2”)

Figure 4: Level Eye Exploded Assembly View GASKET MATERIAL

(Blank) = Standard Neoprene

B = Buna-N

T = PTFE

Visit us at: www.haphillips.com or e-mail us at: info@haphillip.com

LEVEL EYE TOOLS

Housing Thread Tap and Blanking Plug: Retainer Socket Tool:

ead Do not need

g thr 304 SS material

h o usin e as

sen’

s e sa m will to remove

Han ype is th his tap frost shield

t

l ip s ’. T both!

l

Phi ork fo r

to use Backing prevents

w

Tool! tool from slipping

past retainer

Normal Reflex lens Fits All Three!

Metal Blanking Plug Socket designed to

fit Phillips, R/S, and

ug fits Hansen retainers!

Blanking pl , and

/S

Phillips, R t glass

Hansen sighgs! Phillips’ recommended torque values

housin

½” drive permanently marked right on the tool!

The back-side of the tool has a slightly larger socket for use with retainers that

Part No. Description do not fit the main side (for example, this could be due to teeth marks in retainer

Level Eye Tap Level Eye Thread Tap (for sale only) from previously using a pipe wrench to tighten). This back-side can also be used

more easily if your insulation runs all the way up to the lip of the retainer.

Level Eye Tap -

Level Eye Thread Tap (for lease only)

Leased Part No. Description

1101B Level Eye Glass Blanking Plug, Plated Steel Level Eye sight glass retainer socket tool; 304

SS material; 1/2” drive socket; for use with

LevelEyeTool

Instructions for using tap to chase housing threads: Phillips, Hansen, and R/S’s bulls eye style

sight glasses.

If the retainer threads (male threads) are damaged please re-

place the existing retainer with a new 1102SH retainer. If your Instructions for setting torque wrench

existing retainer is an

Due to the additional length of the

older style retainer, has

socket tool, the true amount of

slots in the face of the

torque that you apply to the retain-

retainer (see image be-

er may be more that what you are

neath), you can use our

reading/have your torque wrench θ

newer style retainer to L wrench

set to. This will be dependent on the

replace the older style

angle of the wrench relative to the tool (θ)

retainer (current design is

backwards compatible). Old Style Retainer New Style Retainer as well as the length of your wrench (Lwrench). Center of

Whenever the tool is held perpendicular torque

If the housing threads (female threads) are stripped out, with to the socket (θ = 90°) , then the amount wrench

handle

insufficient thread material for the reforming process, or if the of torque applied will be true. If you cannot

thread contact area is insufficient (due to a severely warped hous- hold the wrench perpendicular to the tool

ing resultant from excess heat input during the welding process) then use the beneath graph to determine a correction factor to

then do not attempt to reuse the housing! If this is the case please account for the additional amount of torque being applied.

contact Phillips to discuss your options.

Example: To tighten a retainer to a true value of 45 ft-lbs, with

1. Prior to using the tap to chase your female housing threads, θ = 0° & Lwrench = 1 ft., we should set our torque wrench to click at

first clean the existing threads by removing any dirt, rust 36.5 ft-lbs: (0.81 correction multiplier times 45 ft-lbs = 36.5 ft-lbs)

scale, grease or other contaminants to the best of your ability.

A small bristle brush and refrigerant oil can assist in this pro-

cess.

2. Apply a generous amount of refrigerant oil to the housing

threads and to the tap.

3. Hold the tap in line with the hole and carefully insert the

thread chaser into the hole. It is designed to have undersized

tap heads that enable it to start in the hole with much accura-

cy. Initially hand tighten the thread chaser whenever possible.

4. Use an adjustable wrench (needs to open up to about 1.35”)

to turn the thread chaser clockwise through the hole a little bit

at a time. Counter rotate the thread chaser to lift grime and

debris off the surface. Pull out and clean tap with a rag or

brush. Repeat steps one through four until threads are com-

pletely chased.

H. A. Phillips & Co. Remit to:

770 Enterprise Avenue Department 20-8043

DeKalb, IL 60115 U.S.A. P. O. Box 5998

Phone: (630) 377-0050 Carol Stream, IL 60197-599

Fax: (630) 377-2706 U.S.A.

You might also like

- EOTech 520 Manual PDFDocument2 pagesEOTech 520 Manual PDFErikNo ratings yet

- Panasonic PT-LS26Document2 pagesPanasonic PT-LS26variNo ratings yet

- 1100 SB20 01Document4 pages1100 SB20 01sonj61915No ratings yet

- Henry 001Document1 pageHenry 001pdmsNo ratings yet

- HENRYDocument28 pagesHENRYpdmsNo ratings yet

- Refrig Alco Solenoid 2004Document10 pagesRefrig Alco Solenoid 2004Luis alberto Garcia villanuevaNo ratings yet

- Inbal DG04C Deluge Valve Electric Actuation PDFDocument4 pagesInbal DG04C Deluge Valve Electric Actuation PDFjakkol11No ratings yet

- Ty 5131Document4 pagesTy 5131Mohamed El-AyouttiNo ratings yet

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- A41 High Performance Butterfly Valve Instruction Manual PDFDocument36 pagesA41 High Performance Butterfly Valve Instruction Manual PDFtxlucky80No ratings yet

- Inbal Deluge ValveDocument4 pagesInbal Deluge ValveNelson Eduardo Zárate SalazarNo ratings yet

- Fisher Snoppy N511 ESVDocument2 pagesFisher Snoppy N511 ESVWynn ChoNo ratings yet

- Ae 1302 R4Document12 pagesAe 1302 R4last730No ratings yet

- TF100-53B 3900 Series QD CouplingsDocument6 pagesTF100-53B 3900 Series QD CouplingsrrrrNo ratings yet

- Model G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersDocument4 pagesModel G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersAchraf BoudayaNo ratings yet

- Brooks Kynar, Low FlowmeterDocument8 pagesBrooks Kynar, Low FlowmeterRangga TaufiqurahmanNo ratings yet

- TM 10 4310 392 13 and PDocument43 pagesTM 10 4310 392 13 and PVitor FreitasNo ratings yet

- Eclips Orfice ValveDocument4 pagesEclips Orfice Valveاحمد الجزار2007No ratings yet

- Type Ea-1 Protectospray Directional Spray Nozzles, Automatic, Medium Velocity General DescriptionDocument6 pagesType Ea-1 Protectospray Directional Spray Nozzles, Automatic, Medium Velocity General Descriptiono7934941No ratings yet

- Pistolet Devilbiss FLG 5 G Instrukcja SB E 2 790 ENGLISH POLISHDocument16 pagesPistolet Devilbiss FLG 5 G Instrukcja SB E 2 790 ENGLISH POLISHBrak BrakNo ratings yet

- Operational Manualhcr-Fls Valve - 2 116 10K PDFDocument14 pagesOperational Manualhcr-Fls Valve - 2 116 10K PDFParag PadoleNo ratings yet

- Product Bulletin Fisher 8560 High Performance Butterfly Control Valve en 123828Document8 pagesProduct Bulletin Fisher 8560 High Performance Butterfly Control Valve en 123828Rachmat MaulanaNo ratings yet

- Catálogo Conectores PDFDocument16 pagesCatálogo Conectores PDFJulioNo ratings yet

- Ansulite 1x1 AR-AFFF CONCENTRATEDocument2 pagesAnsulite 1x1 AR-AFFF CONCENTRATETechnical SupportNo ratings yet

- Tech Manual: Tech-5.12 10K Eh Dual Combi InvDocument22 pagesTech Manual: Tech-5.12 10K Eh Dual Combi InvRiski KurniawanNo ratings yet

- Glynn Johnson Price BookDocument36 pagesGlynn Johnson Price BookSecurity Lock DistributorsNo ratings yet

- Instalación y Montaje Acoplamiento WrapflexDocument8 pagesInstalación y Montaje Acoplamiento Wrapflexedwin nolbertoNo ratings yet

- IS 10605 (Steel Globe Valves (Flanged and Butt Welded Ends) For Petroleum, Petrochemical and AlliDocument17 pagesIS 10605 (Steel Globe Valves (Flanged and Butt Welded Ends) For Petroleum, Petrochemical and AlliRajan SteeveNo ratings yet

- Jamesbury Ball Valves PDFDocument20 pagesJamesbury Ball Valves PDFGabriel Andrés Barcha Angulo100% (1)

- Fisher POSI SEAL A11 High Performance Butterfly ValveDocument20 pagesFisher POSI SEAL A11 High Performance Butterfly ValveJan Richardo GultomNo ratings yet

- Level SwichgageDocument2 pagesLevel SwichgagekylegazeNo ratings yet

- Fpe 1 2 Válvula TermostáticaDocument6 pagesFpe 1 2 Válvula TermostáticamarbbanNo ratings yet

- PacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFDocument28 pagesPacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFGoutham KSNo ratings yet

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- Caleffi: Valvole Di BilanciamentoDocument16 pagesCaleffi: Valvole Di BilanciamentoThomas GregantiNo ratings yet

- Instruction Manual Fisher 9500 Butterfly Control Valve en 127086Document20 pagesInstruction Manual Fisher 9500 Butterfly Control Valve en 127086Jan Richardo GultomNo ratings yet

- 1 - Mounting Hubs: How To Use This ManualDocument8 pages1 - Mounting Hubs: How To Use This ManualriinNo ratings yet

- 04 Rociador Tyco K11.2 SRDocument6 pages04 Rociador Tyco K11.2 SRRuben Saucedo JacomeNo ratings yet

- Kennedy - Fire Protection Product BrochureDocument12 pagesKennedy - Fire Protection Product BrochureRobbinson JamesNo ratings yet

- Mooney Flowgrid Manual PDFDocument16 pagesMooney Flowgrid Manual PDFFernando FernandezNo ratings yet

- Instruction Manual Fisher 8560 Eccentric Disc Butterfly Control Valve en 137996Document36 pagesInstruction Manual Fisher 8560 Eccentric Disc Butterfly Control Valve en 137996Gani PrayudaNo ratings yet

- TFP 3153Document6 pagesTFP 3153Diego PinedaNo ratings yet

- 10.1 Equipment DocumentationDocument644 pages10.1 Equipment Documentationcristian rodriguezNo ratings yet

- Butterfly Valve (SD-BV W-300)Document1 pageButterfly Valve (SD-BV W-300)Abdullah NomanNo ratings yet

- 8510 and 8510B Eccentric Disc Rotary Valve BuletinDocument20 pages8510 and 8510B Eccentric Disc Rotary Valve BuletinRizalfariz HasbiNo ratings yet

- 8510 and 8510B Eccentric Disc Rotary Valve BuletinDocument20 pages8510 and 8510B Eccentric Disc Rotary Valve BuletinRizalfariz HasbiNo ratings yet

- Data Sheet Hydrant Air Isolation Valve v1 2Document3 pagesData Sheet Hydrant Air Isolation Valve v1 2iandegs2010No ratings yet

- DSHG - Válvula DirecionalDocument33 pagesDSHG - Válvula DirecionalAlessandro OliveiraNo ratings yet

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- ASCO Valve 8003 8202gh Solenoid ImDocument6 pagesASCO Valve 8003 8202gh Solenoid ImLeonardNo ratings yet

- Fisherr Posi-Sealt A31A High-Performance Butterfly ValveDocument12 pagesFisherr Posi-Sealt A31A High-Performance Butterfly ValveThanapaet RittirutNo ratings yet

- Catalog Series 551 553 Ss Namur 1 4 Et 1 2 3 2 5 2 Asco en 6316858Document9 pagesCatalog Series 551 553 Ss Namur 1 4 Et 1 2 3 2 5 2 Asco en 6316858Jeyson BueraNo ratings yet

- FLG-G5 DevilbissDocument8 pagesFLG-G5 DevilbissLuís GuerreiroNo ratings yet

- Acd Cooler Catalog Hy10-1700 2013-12 OawDocument7 pagesAcd Cooler Catalog Hy10-1700 2013-12 OawHECTOR IBARRANo ratings yet

- Catalogo Iso 5599 PDF 5e5e840e30943Document11 pagesCatalogo Iso 5599 PDF 5e5e840e30943andre.guedesNo ratings yet

- Service Manual Alpha Series - Rev1Document116 pagesService Manual Alpha Series - Rev1sh msNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Normally Closed Solenoid Valves PDFDocument55 pagesNormally Closed Solenoid Valves PDFrahulNo ratings yet

- WR22G o - 400 P 121120 e 00Document4 pagesWR22G o - 400 P 121120 e 00Eng-Mohammed SalemNo ratings yet

- Maintenance Chiksan FMC LLS - OM - STDDocument6 pagesMaintenance Chiksan FMC LLS - OM - STDDoni Kurniawan100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Hikvision IP Price Jan 2020Document4 pagesHikvision IP Price Jan 2020ravi jaganiNo ratings yet

- Basic Photography ConceptsDocument8 pagesBasic Photography Conceptssonia mae bandolaNo ratings yet

- Hikvision Network Camera Installation ManualDocument95 pagesHikvision Network Camera Installation ManualChristian LimNo ratings yet

- Canon LeakDocument2 pagesCanon LeakNikonRumorsNo ratings yet

- SmartDocument11 pagesSmartaaronclaux2014No ratings yet

- Multiple Target Detection and Tracking in A Multiple Camera NetworkDocument59 pagesMultiple Target Detection and Tracking in A Multiple Camera NetworkRazvanHaragNo ratings yet

- Instructions For Flashlight: High Powered Tactical FlashlightDocument1 pageInstructions For Flashlight: High Powered Tactical FlashlightMarkNo ratings yet

- (Đề thi gồm có 7 trang) Học sinh làm bài vào đề thi nàyDocument17 pages(Đề thi gồm có 7 trang) Học sinh làm bài vào đề thi nàyĐỗ Mỹ Diệu LinhNo ratings yet

- One Minute Academy Student Handbook (English)Document29 pagesOne Minute Academy Student Handbook (English)ayudwinyNo ratings yet

- The 7 Types of PhotographyDocument15 pagesThe 7 Types of PhotographyJoellito M TorreNo ratings yet

- 1.1 Purpose: Software Requirement Specification For Virtual TourDocument10 pages1.1 Purpose: Software Requirement Specification For Virtual TourChewang Phuntsok BhutiaNo ratings yet

- A Real-Time Embedded Image Identification and Access Control System Using E-MailDocument4 pagesA Real-Time Embedded Image Identification and Access Control System Using E-MailAbdul RazzakNo ratings yet

- HOMEWORKDocument9 pagesHOMEWORKAnii KvirkveliaNo ratings yet

- Take Stunning Natural Light PortraitsDocument7 pagesTake Stunning Natural Light Portraitsjeffreygovender5745100% (1)

- Datasheet IFP8670Document2 pagesDatasheet IFP8670Maaeglobal ResourcesNo ratings yet

- Working of Human Eye LensDocument18 pagesWorking of Human Eye LensNupur LolgeNo ratings yet

- Evaluation Worksheet l2 Blair Witch 2023Document3 pagesEvaluation Worksheet l2 Blair Witch 2023api-647724237No ratings yet

- Smart Glass SynopsisDocument6 pagesSmart Glass Synopsisdinkchak poojaNo ratings yet

- KODAK Instamatic M55-lDocument19 pagesKODAK Instamatic M55-lPablooskiNo ratings yet

- Nikon Z5 Mirrorless Digital Camera Overview (MegaGear Store)Document5 pagesNikon Z5 Mirrorless Digital Camera Overview (MegaGear Store)LelosPinelos123No ratings yet

- 2.fake PhotosDocument25 pages2.fake PhotosCarolNo ratings yet

- Full Download World Trade and Payments An Introduction 10th Edition Caves Solutions ManualDocument36 pagesFull Download World Trade and Payments An Introduction 10th Edition Caves Solutions Manualschietolicos100% (33)

- GR Ramma Ar and D Voca Abulary y Unit: Gra AmmarDocument10 pagesGR Ramma Ar and D Voca Abulary y Unit: Gra AmmarBEATRIZ MARÍN LÓPEZNo ratings yet

- Lightsphere Digital Photography: (Client To Cover Expenses For Out-Of-Town Shoot)Document2 pagesLightsphere Digital Photography: (Client To Cover Expenses For Out-Of-Town Shoot)Darwin Dionisio ClementeNo ratings yet

- Sony HVR-Z1U Sales BrochureDocument12 pagesSony HVR-Z1U Sales BrochureBit ScrollNo ratings yet

- Anh-9-26 7 23Document9 pagesAnh-9-26 7 23Thảo PhươngNo ratings yet

- CatalogoDocument56 pagesCatalogoMuhammad awaludin syahNo ratings yet

- Aligning CCD Sensor TiltDocument6 pagesAligning CCD Sensor TiltLuis G. RBNo ratings yet