Hazard Assessment and Control Form

Hazard Assessment and Control Form

Uploaded by

Rajalakshmi GajapathyCopyright:

Available Formats

Hazard Assessment and Control Form

Hazard Assessment and Control Form

Uploaded by

Rajalakshmi GajapathyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Hazard Assessment and Control Form

Hazard Assessment and Control Form

Uploaded by

Rajalakshmi GajapathyCopyright:

Available Formats

Hazard Assessment and Control Form

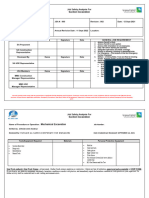

Job Class Job title: Assessment Performed By: Date:

Temporary - Light Industrial Material Handler, Shipper/Receiver, February 6 2013

Warehouse Worker, General Labor, Name: Nicky Muir

Picker/Packer (all jobs that fall into our Light

industrial Service Lines) Title: Service Operations Manager Western Canada

Job Title: Manager, Regulatory Compliance,

Reviewed By: Corey Burt Job Title: Safety, Health, Environmental & Approved By: Kim Myles-Barclay Canada

WCB Specialist

Prepared Date: February 6 2013 Revised By: Felicia Gow, Dean Bergen, Shannon Baradoy, Leona Ferguson, Valerie Revision Date: February 22 Revision #2

McDonald 2013

Risk Rating Potential Hazard Preventative/Control Measure

Recommended

Hazard/Task L,M,H Engineering, Administrative, PPE (E.A.P.)

Controls/PPE

S P F

Material Handling Musculoskeletal injuries, Familiarization with the material handling safe work practice. E: Step stools should be

lifting, carrying Repetitive strain injuries Use proper lifting techniques made available to access

Slips, trips, falls Frequent breaks, weight limits, rotations and realistic materials on higher

Oversized/awkward quotas. shelves.

objects Get assistance when necessary, another worker, forklift, E: Use of dolly etc to

pallet jack etc transport heavy items

Follow safe work practices, ie guidelines for material when possible

handling E: Not placing heavy items

3 2 3 H

Use PPE ie, safety footwear, gloves, vests, hard hats etc on high shelves.

A: Development of Safe

Work Procedures for lifting

and training on the risk

factors and symptoms of

musculoskeletal injury –

perhaps provide during

orientation.

Severity: 1=low, 2=moderate, 3=high Probability: 1=not likely , 2=likely, 3= very likely Frequency: 1= rarely done, 2=not common task, 3=do this task frequently

© 2013 Kelly Services (Canada), Ltd. R8/13

Hazard Assessment and Control Form

Risk Rating Potential Hazard Preventative/Control Measure

Recommended

Hazard/Task L,M,H Engineering, Administrative, PPE (E.A.P.)

Controls/PPE

S P F

Operating Forklifts, Forklift turnovers Obtain copy of forklift certification & document in employee E: Stack lighter items

Powered Industrial Trucks file. Check forklift references and have employee complete higher;

Falling product forklift evaluation. Ensure customer will provide machine

A: Properly maintain

specific orientation/training to employees. Have customer

equipment, including tires.

Foot injuries sign the Powered Motor Vehicle Release prior to the

assignment starting. A: Follow safe work

Crush injuries procedures for picking up,

Ensure housekeeping and safety programs are in place and putting down and stacking

“Run away” equipment clear areas of safe walk zones are marked and forklift loads.

training programs are in place & reviewed. Sound horn A: Training and

Inexperienced operator, when approaching pedestrians. certification for forklift

unsafe handling of operation.

vehicle, losing load Drive with due care and attention and obey all traffic A: Drive safely and slowly

regulations including plant speed limits. Look behind when never exceeding 5 km/h.

Environment - Weather reversing. If leaving forklift unattended, ensure it is in A: Lock out/ tag out

3 2 3 H conditions. Working in neutral, brakes are set and it is turned off with the key program to prevent

and outside may pose the removed. Ensure the forks are fully lowered. equipment from

risk of heat stress, cold or accidentally becoming

freezing temps and slips Drive slowly on wet or uneven surfaces. If noise level is energized.

and falls due to slippery over the legislative requirements, PPE will be required.

work conditions. Can be P: Wear toe caps when

a noisy environment. Operators are responsible for wearing the seatbelt or operating forklifts and

operator restraining device. Keep all body parts inside the transporting heavy items.

Pedestrians running lines of the forklift.

Other vehicles Ensure loads are safely arranged and stable according to

machines limitations. Caution must be taken when handling

off centre loads.

Do not have loads that exceed the trucks weighted

capability.

Severity: 1=low, 2=moderate, 3=high Probability: 1=not likely , 2=likely, 3= very likely Frequency: 1= rarely done, 2=not common task, 3=do this task frequently

© 2013 Kelly Services (Canada), Ltd. R8/13

Hazard Assessment and Control Form

Risk Rating Potential Hazard Preventative/Control Measure

Recommended

Hazard/Task L,M,H Engineering, Administrative, PPE (E.A.P.)

Controls/PPE

S P F

Working on/near Docks - Forklifts run off docs Ascend and descend ramps/grades slowly when driving A: Drive forklifts slowly on

- Products fall on forklift. Drive slowly on wet or slippery surfaces. Load docks and dock plates.

employees should always be uphill when climbing or descending

A: Secure the dock plates

inclines. Place heavy, odd shaped objects with the weight

- Equipment strikes a and check to see if the

as low as possible

person plate can safely support

- Falling off dock the load.

Wear/use PPE

3 2 3 H - Slips, trips falls A: Keep clear of dock

- Environment Ensure housekeeping and safety programs are in place. No edges and never back up

dock jumping. forklifts to the dock’s edge.

A: Provide visual warning

signs near dock edges.

A: Prohibit “dock jumping”

by employees.

Dealing with Co-Workers, Workplace Violence Avoid working alone A: Violence Policy

Clients and General Public Ensure employees are trained on what to do in an A: Safe Work Procedure

2 2 3 M

emergency, ie call security & know how to call from location A: Training on Workplace

where they are working. Violence

Working Alone Becoming injured Ensure regular check-in procedures are in place for any E: Effective means of

Workplace Violence employees working alone. communication

Ensure there is an effective means of communication in A: Safe Work

place, ie 2 way radio, cell phone etc Procedure/Policy for

2 2 1 M First aid kit on site Working Alone

Familiarization with Safety Policies/Programs A: All workers should be

trained in the Safe Work

Procedure for working

alone, cover in orientation

Severity: 1=low, 2=moderate, 3=high Probability: 1=not likely , 2=likely, 3= very likely Frequency: 1= rarely done, 2=not common task, 3=do this task frequently

© 2013 Kelly Services (Canada), Ltd. R8/13

Hazard Assessment and Control Form

Risk Rating Potential Hazard Preventative/Control Measure

Recommended

Hazard/Task L,M,H Engineering, Administrative, PPE (E.A.P.)

Controls/PPE

S P F

Working With and Near - Chemical Burns if WHMIS orientation & evaluation for all employees. Client E: Provide spill cleanup

Chemicals spills occur site specific WHMIS training, familiarization with MSDS and kits in areas where

know where they are kept at work site. chemicals are stored.

- - Exposure

- Inhalation A: Follow instructions on

Clean up any spills immediately (refer to MSDS for handling

the MSDS.

- Skin Absorption instructions)

A: Train employees on the

- Fire

If there is no label on the container STOP. Get your risks of each chemical

- Explosion being stored.

supervisor. Do not dispense/handle the produce until you

are certain you know what you are dealing with. A: Train employees to

clean up spills, protect

Familiarize yourself with the sites emergency themselves and properly

response/evacuation procedures. dispose of the used

materials.

3 2 2 M Wear PPE, ensuring that you have the correct PPE for the A: Store all chemicals

materials you are handling – refer to the MSDS sheets for safely and securely.

confirmation. A: Store chemicals away

from forklift traffic areas.

A: Flammable and

combustible materials

must be identified and

stored properly.

A: Fire equipment should

remain unobstructed.

A: Fire extinguishers and

alarms should be

conspicuously placed and

accessible.

Severity: 1=low, 2=moderate, 3=high Probability: 1=not likely , 2=likely, 3= very likely Frequency: 1= rarely done, 2=not common task, 3=do this task frequently

© 2013 Kelly Services (Canada), Ltd. R8/13

Hazard Assessment and Control Form

Risk Rating Potential Hazard Preventative/Control Measure

Recommended

Hazard/Task L,M,H Engineering, Administrative, PPE (E.A.P.)

Controls/PPE

S P F

Working at Heights Injuries from falling Wear appropriate fall arrest equipment, safety harness, E: Lifts

lanyard etc A: Maintain 3 points of

Inspect safety harnesses daily before use and report and contact when working on

replace any damaged components immediately ladders.

Identify anchor points to be used and configuration of A: Do not work from the

lifelines or other systems top 2 rungs, steps or

Familiarization with customer policies for working at heights. treads of a step ladder.

3 1 1 M

Part 9 – Fall Protection of the OHS Code. Work within the A: Center of balance at the

guidelines of the code. centre of the ladder is

maintained at all times.

If working over 3m fall protection must be used.

P: Fall protection and fall

Training on using fall protection and maintenance of fall

arrest when working 3

protection equipment.

meters or higher.

Ensure guard rails are in place as outlined in the OHS code

– over 1.2 m but less than 3m

General Housekeeping Slips, Trips and Falls Ensure housekeeping and safety programs are in place and A: Floors and aisles are

Injuries from falling clear areas of safe walk zones are marked. clear of clutter, electrical

objects Remove any tripping hazards cords, hoses, spills and

Clean up any spills immediately other hazards that could

Conduct regular work site inspections cause employees to slip,

2 2 3 M trip or fall.

A: Loose/unboxed

materials which might fall

from a pile are properly

stacked and secured.

Severity: 1=low, 2=moderate, 3=high Probability: 1=not likely , 2=likely, 3= very likely Frequency: 1= rarely done, 2=not common task, 3=do this task frequently

© 2013 Kelly Services (Canada), Ltd. R8/13

Hazard Assessment and Control Form

Risk Rating Potential Hazard Preventative/Control Measure

Recommended

Hazard/Task L,M,H Engineering, Administrative, PPE (E.A.P.)

Controls/PPE

S P F

Working with Electrocution Working with tools are risky as they may cause cuts, E: Equipment guards.

Equipment/Machinery repetitive strain type injuries, impact injuries and eye injuries

E: Equipment must be

Contact with moving parts if improperly used.

properly grounded.

(lacerations, abrasions,

fractures Ensure employees have received training and/or are E: Sufficient amount of

supervised on the appropriate equipment they are operating electrical outlet to prevent

circuit overloading.

Follow manufacturers operating instructions A: Check cords for frays.

2 2 3 M A: Electrical equipment

Stop using faulty equipment/machinery immediately. should be maintained.

A: Machines should be

Familiarization with lock out/tag out program and ensure disconnected before

you are following these instructions completely. cleaning or adjusting.

Generally machines and

equipment should be

locked or tagged out

during maintenance.

Computer work or Musculoskeletal injuries Ensure sufficient lighting E: Adjustable Chair &

handwritten inventory Repetitive strain injuries Take frequent breaks away from computer workstation

documents Stretch hands/wrists/forearms frequently

1 1 2 L P: Antistatic guards,

Ensure workstation is set up correctly

keyboard trays, wrist

Do a different task

guards.

Use available PPE, ie wrist guards, keyboard trays etc

Severity: 1=low, 2=moderate, 3=high Probability: 1=not likely , 2=likely, 3= very likely Frequency: 1= rarely done, 2=not common task, 3=do this task frequently

© 2013 Kelly Services (Canada), Ltd. R8/13

Hazard Assessment and Control Form

Risk Rating Potential Hazard Preventative/Control Measure

Recommended

Hazard/Task L,M,H Engineering, Administrative, PPE (E.A.P.)

Controls/PPE

S P F

Travel Working alone Familiarization with emergency procedures for hotel A: Violence Policy

Violence accommodation. Keep hotel room door locked at all times.

A: Safe Work Procedure -

other work sites, Environmental – weather Be aware of your surroundings

working alone, driving etc

overnight stays, other conditions Familiarization/training with Kelly’s policies for working

Transportation alone, violence prevention. A: Training on Workplace

countries 1 1 2 L Violence

Ensure branch have itinerary and arrange regular check in

times.

Global Mobility engaged for foreign travel to ensure all

documentation is correct and that a 24 hr number is

provided for emergencies.

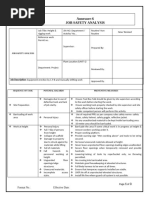

Sign-Off

I, ________________________________________________________ (please print) have read and understand Kelly Services’ Hazard Assessment and Control Form.

Signature:

Date:

Severity: 1=low, 2=moderate, 3=high Probability: 1=not likely , 2=likely, 3= very likely Frequency: 1= rarely done, 2=not common task, 3=do this task frequently

© 2013 Kelly Services (Canada), Ltd. R8/13

You might also like

- Risk Assessment For Installation of A New Air Conditioning SystemNo ratings yetRisk Assessment For Installation of A New Air Conditioning System5 pages

- Contractor Monthly HSE Progress Report Form100% (1)Contractor Monthly HSE Progress Report Form2 pages

- Tenses - Ready Reckoner: Tense Affirmative/Negative/Question Use Signal Words100% (2)Tenses - Ready Reckoner: Tense Affirmative/Negative/Question Use Signal Words7 pages

- Job Environmental Safety Analysis: Elimination/Substitution Engineering Administrative PPENo ratings yetJob Environmental Safety Analysis: Elimination/Substitution Engineering Administrative PPE7 pages

- Hazard Identification, Risk Assessment & Risk Control100% (1)Hazard Identification, Risk Assessment & Risk Control3 pages

- Environmental, Health and Safety Risks Analysis100% (2)Environmental, Health and Safety Risks Analysis2 pages

- Risk Assessment: Corresponding Permit To Work NoNo ratings yetRisk Assessment: Corresponding Permit To Work No4 pages

- Suction Excavation - JSA September 12 2021 NewNo ratings yetSuction Excavation - JSA September 12 2021 New10 pages

- Risk Assessment For Scaffolding Erection and Dismantling100% (1)Risk Assessment For Scaffolding Erection and Dismantling6 pages

- IOSH Risk Assessment Project - AJEET KUMAR SINGH100% (1)IOSH Risk Assessment Project - AJEET KUMAR SINGH2 pages

- Hse Management Plan: TIMIMOUN Field Development ProjectNo ratings yetHse Management Plan: TIMIMOUN Field Development Project37 pages

- Risk Assessment For Lifting Operation With CraneNo ratings yetRisk Assessment For Lifting Operation With Crane12 pages

- 000-00-Risk Assessment For Road Embankment WorksNo ratings yet000-00-Risk Assessment For Road Embankment Works7 pages

- NIS-HSE-F00-16 (r.1) HSE NEW EMPLOYEE INDUCTIONNo ratings yetNIS-HSE-F00-16 (r.1) HSE NEW EMPLOYEE INDUCTION1 page

- RISK ASSESSMENT (Backfilling of Excavated Area)No ratings yetRISK ASSESSMENT (Backfilling of Excavated Area)2 pages

- Job Safety Analysis (JSA) - Painting DateNo ratings yetJob Safety Analysis (JSA) - Painting Date2 pages

- JSA - Unloading and Storage of DAHU and EF Unit - Romp 05.No ratings yetJSA - Unloading and Storage of DAHU and EF Unit - Romp 05.4 pages

- CRISP-SUT2-SY2-MSRA-017 - RC - MSRA Hydrotest & Water Flushing of PipelinesNo ratings yetCRISP-SUT2-SY2-MSRA-017 - RC - MSRA Hydrotest & Water Flushing of Pipelines25 pages

- OSHA Hazardous Chemical Exposure Checklist - SafetyCulture PDFNo ratings yetOSHA Hazardous Chemical Exposure Checklist - SafetyCulture PDF5 pages

- JSA For Abqaiq Chiller Plant Demolition Rev-00No ratings yetJSA For Abqaiq Chiller Plant Demolition Rev-0010 pages

- 09 Tail Lift Pallet Truck Risk AssessmentNo ratings yet09 Tail Lift Pallet Truck Risk Assessment6 pages

- 2412-2413-JSA-001 - RAK Yard ActivitiesNo ratings yet2412-2413-JSA-001 - RAK Yard Activities19 pages

- Lock Out Tag Out Machinery Safety Risk Assessment ChecklistNo ratings yetLock Out Tag Out Machinery Safety Risk Assessment Checklist13 pages

- Expolink TBT # 86 - Excavation Protruding Steel Bar and Venomous Reptiles ManagementNo ratings yetExpolink TBT # 86 - Excavation Protruding Steel Bar and Venomous Reptiles Management1 page

- GESTS - Industrial Risk & Environment Management - October 2020 PDFNo ratings yetGESTS - Industrial Risk & Environment Management - October 2020 PDF2 pages

- SWMS - Material Delivery, Unloading and Stacking - JLL FormatNo ratings yetSWMS - Material Delivery, Unloading and Stacking - JLL Format11 pages

- Guidance On Selection of Anti-Entrapment Devices For MEWPsNo ratings yetGuidance On Selection of Anti-Entrapment Devices For MEWPs4 pages

- OHS-PR-09-03-F02 HIRA - 025 Fabrication and Installation of Equipment Steel Support Rev. 2021No ratings yetOHS-PR-09-03-F02 HIRA - 025 Fabrication and Installation of Equipment Steel Support Rev. 202110 pages

- Units Sold 96 Price Per Unit $5.00 Materials Per Unit $4.75 Labour $75.00No ratings yetUnits Sold 96 Price Per Unit $5.00 Materials Per Unit $4.75 Labour $75.001 page

- Imported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Packaged Goods Produce TotalNo ratings yetImported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Packaged Goods Produce Total1 page

- 1st Quarter Location Income Inventory Rent Supplies Wages Total ExpensesNo ratings yet1st Quarter Location Income Inventory Rent Supplies Wages Total Expenses2 pages

- Units Sold (Sunglasses) Per Day Hours of Sunny Weather Per DayNo ratings yetUnits Sold (Sunglasses) Per Day Hours of Sunny Weather Per Day1 page

- Imported Foods Company: Consolidated ReportNo ratings yetImported Foods Company: Consolidated Report5 pages

- Imported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Beverages Produce Packaged Goods Seafood TotalNo ratings yetImported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Beverages Produce Packaged Goods Seafood Total3 pages

- SAT Vs ACT: Everything You Need To Know: What Do The Tests Measure? Which Test Is Easier?No ratings yetSAT Vs ACT: Everything You Need To Know: What Do The Tests Measure? Which Test Is Easier?6 pages

- Present Simple: How Do We MAKE The Present Simple Tense?No ratings yetPresent Simple: How Do We MAKE The Present Simple Tense?29 pages

- 14 Punctuation Marks Everyone Needs To Master: 1. The Semi-ColonNo ratings yet14 Punctuation Marks Everyone Needs To Master: 1. The Semi-Colon27 pages

- 0xyz. EN - Handbook On Land Mobile 2021No ratings yet0xyz. EN - Handbook On Land Mobile 2021114 pages

- 310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 01No ratings yet310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 015 pages

- Troy Marine Fire Safety Product SolutionsNo ratings yetTroy Marine Fire Safety Product Solutions312 pages

- Helicopter and Equipment: Iogp Report 690-5No ratings yetHelicopter and Equipment: Iogp Report 690-523 pages

- SHC 631 Submission of Revised Method Statement of Double Surface Dressing and Apply For Trial Section of Double Surface Dressing100% (2)SHC 631 Submission of Revised Method Statement of Double Surface Dressing and Apply For Trial Section of Double Surface Dressing9 pages

- Research Article: COVID-19 Outbreak in Colombia: An Analysis of Its Impacts On Transport SystemsNo ratings yetResearch Article: COVID-19 Outbreak in Colombia: An Analysis of Its Impacts On Transport Systems16 pages

- (Shore) CV Indra Hendriyana 2020 Assisten Port Captain PT. Sillo Maritime PerdanaNo ratings yet(Shore) CV Indra Hendriyana 2020 Assisten Port Captain PT. Sillo Maritime Perdana9 pages

- R0120 Ed2.1 Vessel Traffic Services in Inland Waters V 120 December 2013No ratings yetR0120 Ed2.1 Vessel Traffic Services in Inland Waters V 120 December 201315 pages

- FM 90-8 - Counterguerilla Operations - Chapter 7 - Combat Service Support PDFNo ratings yetFM 90-8 - Counterguerilla Operations - Chapter 7 - Combat Service Support PDF6 pages

- Acfroga4rm06ykp06awgadfswpje4flprcub7fopu2hakjwero57h9fz D Gycmbb68wqtlgafwxk Iikz8xglfep Xjcli5kywtrvearkctixbxoqv6jhrctzkhzq4No ratings yetAcfroga4rm06ykp06awgadfswpje4flprcub7fopu2hakjwero57h9fz D Gycmbb68wqtlgafwxk Iikz8xglfep Xjcli5kywtrvearkctixbxoqv6jhrctzkhzq41 page

- Traffic Jam of Dhaka City and It's Environmental ConcernsNo ratings yetTraffic Jam of Dhaka City and It's Environmental Concerns3 pages

- Risk Assessment For Installation of A New Air Conditioning SystemRisk Assessment For Installation of A New Air Conditioning System

- Tenses - Ready Reckoner: Tense Affirmative/Negative/Question Use Signal WordsTenses - Ready Reckoner: Tense Affirmative/Negative/Question Use Signal Words

- Job Environmental Safety Analysis: Elimination/Substitution Engineering Administrative PPEJob Environmental Safety Analysis: Elimination/Substitution Engineering Administrative PPE

- Hazard Identification, Risk Assessment & Risk ControlHazard Identification, Risk Assessment & Risk Control

- Risk Assessment For Scaffolding Erection and DismantlingRisk Assessment For Scaffolding Erection and Dismantling

- Hse Management Plan: TIMIMOUN Field Development ProjectHse Management Plan: TIMIMOUN Field Development Project

- JSA - Unloading and Storage of DAHU and EF Unit - Romp 05.JSA - Unloading and Storage of DAHU and EF Unit - Romp 05.

- CRISP-SUT2-SY2-MSRA-017 - RC - MSRA Hydrotest & Water Flushing of PipelinesCRISP-SUT2-SY2-MSRA-017 - RC - MSRA Hydrotest & Water Flushing of Pipelines

- OSHA Hazardous Chemical Exposure Checklist - SafetyCulture PDFOSHA Hazardous Chemical Exposure Checklist - SafetyCulture PDF

- Lock Out Tag Out Machinery Safety Risk Assessment ChecklistLock Out Tag Out Machinery Safety Risk Assessment Checklist

- Expolink TBT # 86 - Excavation Protruding Steel Bar and Venomous Reptiles ManagementExpolink TBT # 86 - Excavation Protruding Steel Bar and Venomous Reptiles Management

- GESTS - Industrial Risk & Environment Management - October 2020 PDFGESTS - Industrial Risk & Environment Management - October 2020 PDF

- SWMS - Material Delivery, Unloading and Stacking - JLL FormatSWMS - Material Delivery, Unloading and Stacking - JLL Format

- Guidance On Selection of Anti-Entrapment Devices For MEWPsGuidance On Selection of Anti-Entrapment Devices For MEWPs

- OHS-PR-09-03-F02 HIRA - 025 Fabrication and Installation of Equipment Steel Support Rev. 2021OHS-PR-09-03-F02 HIRA - 025 Fabrication and Installation of Equipment Steel Support Rev. 2021

- Units Sold 96 Price Per Unit $5.00 Materials Per Unit $4.75 Labour $75.00Units Sold 96 Price Per Unit $5.00 Materials Per Unit $4.75 Labour $75.00

- Imported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Packaged Goods Produce TotalImported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Packaged Goods Produce Total

- 1st Quarter Location Income Inventory Rent Supplies Wages Total Expenses1st Quarter Location Income Inventory Rent Supplies Wages Total Expenses

- Units Sold (Sunglasses) Per Day Hours of Sunny Weather Per DayUnits Sold (Sunglasses) Per Day Hours of Sunny Weather Per Day

- Imported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Beverages Produce Packaged Goods Seafood TotalImported Foods Company: Qtr1 Qtr2 Qtr3 Qtr4 Total Beverages Produce Packaged Goods Seafood Total

- SAT Vs ACT: Everything You Need To Know: What Do The Tests Measure? Which Test Is Easier?SAT Vs ACT: Everything You Need To Know: What Do The Tests Measure? Which Test Is Easier?

- Present Simple: How Do We MAKE The Present Simple Tense?Present Simple: How Do We MAKE The Present Simple Tense?

- 14 Punctuation Marks Everyone Needs To Master: 1. The Semi-Colon14 Punctuation Marks Everyone Needs To Master: 1. The Semi-Colon

- 310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 01310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 01

- SHC 631 Submission of Revised Method Statement of Double Surface Dressing and Apply For Trial Section of Double Surface DressingSHC 631 Submission of Revised Method Statement of Double Surface Dressing and Apply For Trial Section of Double Surface Dressing

- Research Article: COVID-19 Outbreak in Colombia: An Analysis of Its Impacts On Transport SystemsResearch Article: COVID-19 Outbreak in Colombia: An Analysis of Its Impacts On Transport Systems

- (Shore) CV Indra Hendriyana 2020 Assisten Port Captain PT. Sillo Maritime Perdana(Shore) CV Indra Hendriyana 2020 Assisten Port Captain PT. Sillo Maritime Perdana

- R0120 Ed2.1 Vessel Traffic Services in Inland Waters V 120 December 2013R0120 Ed2.1 Vessel Traffic Services in Inland Waters V 120 December 2013

- FM 90-8 - Counterguerilla Operations - Chapter 7 - Combat Service Support PDFFM 90-8 - Counterguerilla Operations - Chapter 7 - Combat Service Support PDF

- Acfroga4rm06ykp06awgadfswpje4flprcub7fopu2hakjwero57h9fz D Gycmbb68wqtlgafwxk Iikz8xglfep Xjcli5kywtrvearkctixbxoqv6jhrctzkhzq4Acfroga4rm06ykp06awgadfswpje4flprcub7fopu2hakjwero57h9fz D Gycmbb68wqtlgafwxk Iikz8xglfep Xjcli5kywtrvearkctixbxoqv6jhrctzkhzq4

- Traffic Jam of Dhaka City and It's Environmental ConcernsTraffic Jam of Dhaka City and It's Environmental Concerns