Instruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015

Instruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015

Uploaded by

supendra phuyalCopyright:

Available Formats

Instruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015

Instruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015

Uploaded by

supendra phuyalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Instruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015

Instruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015

Uploaded by

supendra phuyalCopyright:

Available Formats

INSTRUCTION .

Burner Pipe Refractory Installation

Created by : CREP

Approved by : GRC

Approved date : 22. December 2015

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 2

Table of contents:

Page No:

1. General information .................................................................3

2. Refractory Castables ................................................................3

3. Storage .................................................................................3

4. Site of Working .......................................................................4

5. Mixing ...................................................................................4

6. Placement of templates and formwork ........................................6

7. Installation .............................................................................6

8. Curing ...................................................................................10

9. Preheating .............................................................................11

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 3

NOTE!

The present instruction manual is concerned with the situations, which,

according to the experience of FLSmidth, are the most likely to occur. An

exhaustive enumeration of all conceivable situations, which may occur during

the installation, operation and maintenance of the refractory castables, cannot

be provided.

Consequently, if a situation should arise, the occurrence of which is not foreseen in

the instruction manual, and which the operator is/or feels unable to handle, it is

recommended that FLSmidth is contacted without undue delay for advice on

appropriate action.

Warning!

If this is shown in the instruction manual specific attention and caution is needed.

1. General information

This manual gives a detailed description and overall guidelines for placement of low

cement refractory castables on the burner pipe. In instances where specific

instructions have been provided by the refractory supplier for the application of burner

castable, it is imperative that such instructions be strictly followed.

2. Refractory Castables

A Refractory castable is a dry, powdery material which solidifies into a hard mass after

mixing with water. When heated, the hardened castable gives off water and at high

temperatures it sinters into a ceramic refractory material.

Refractory castable are often used for lining complex areas in which it is difficult to

use lining bricks.

The castable is fixed to the steel casing by anchors which must be fitted as indicated

on the lining drawing and/or as directed by the supplier.

3. Storage

Castables are packed in moisture resistant bags; however, they must be stored in a

frost proof and dry place free from excess dampness. The bags are to be checked for

the expiry date before the usage and bags without the expiry date should not be used.

Important!

If the castable contains solid lumps, this would indicate that the castable sustained

severe damage, rendering it unfit for use.

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 4

4. Site of Working

Working operation is to be conducted under a roof, in a dry and frost-free place,

preferably at temperatures within the range 10 - 25ºC.

At temperatures near or below the freezing point, the operation must be carried out in

a closed, heated room or the necessary arrangements must be made for localized

heating of the working site to ensure that the castable has a temperature of more

than 10ºC up to the stage where the setting process of castable is completed. Where

the temperatures is above 25ºC, ice cold water should be used to maintain the

castable temperature below 25ºC.

5. Mixing

Prior to use, the mixer and all other implements must be cleaned very carefully. Any

remnants, however small, of castables or mortar may bring a drastic change in the

properties of the castable.

Castables are to be mixed in a horizontal forced-flow paddle-type mixer as this gives

us a rapid mix (avoid excessive mixing times), results in a uniform mix.

Important!

Use tools and equipment which are as clean as possible and free from all old

mortar, Portland cement, lime and dirt. Clean water suitable for drinking must be

used.

Mix only as much castable as can be placed immediately. Under ideal conditions, 20

minutes is the maximum placement time. For the initial batch, first determine the

minimum recommended water level for the product being mixed. The castable must

be mixed in the dry state for a few minutes and then with water addition for 4 to 6

minutes. If a mix appears too dry after the 4 to 6 minutes of mixing, water can be

added in 0.1% increments, making sure to stay within the recommended water range

for the specific product. Allow 1 to 2 minutes of additional mixing time between water

additions. Once an acceptable water level is reached, use that amount as the starting

point for the next batch.

Important!

The correct water addition can be determined by forming a hand sized ball of the

ready mixed castable. The ball should be able to retain its shape, when the ball is

thrown in the air a couple of times and caught in the hand, it should start to flow by

itself.

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 5

Ball in hand consistency test-castable mixed with excess water

Ball in hand consistency test-castable mixed with insufficient water

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 6

Ball in hand consistency test-castable mixed with right amount of water.

6. Placement of templates and formwork

All templates and framework must be plane and free from rust or any other

impurities. The length/height of the frame work should be approx. 1000mm. Apply a

thin coat of oil or wax to the inner sides of templates and forms to avoid adhesion of

the castable. The templates and forms must be trial-assembled before the placement

procedure is started. Ensure uniform gap between form work and burner pipe before

casting.

7. Installation

Figure Showing the Casting Arrangement

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 7

The burner pipe could be placed in horizontal or vertical position and supported

properly for the casting. Anchor irons to be tag/lock welded to anchor iron support on

the burner pipe as shown in the drawing below. Plastic caps to be used on the tips of

the welded anchors and use of wax or bitumen on the anchors are recommended.

Burner pipe with ceramic felt

Ceramic fiber, 6 mm thick, is to be wrapped around the burner pipe to take care of

radial expansion. The ceramic felt must be fixed to the burner pipe shell by means of

glue or binding wire between the anchors. The fibre felt is to be made water-proof to

avoid absorbing water from the castable before starting castable installation. For this

purpose, plastic foil, diffusion-proof paint, paraffin wax or bitumen may be used.

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 8

Burner pipe partly casted

Pour well-mixed castable material into the firmly fixed mould on the burner pipe and

vibrate it all the way from the bottom until all air has been expelled from the mixture,

eliminating voids and ensuring proper consolidation of castable. For vibrating one

could e.g. use a vibrator with a poker diameter of 25mm (1 inch) with frequency of

approx 17500 vibrations/minute or a vibration device erected directly on the mould.

Time for vibrating depends on the refractory material used.

Burner pipe with front and top mould

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 9

The castable around the burner pipe may be casted in two halves radially, at 3 o'clock

and 9 o'clock, with 6 mm fibre felt expansion between each. The height/length of the

mould must not exceed 1000 mm. Ceramic fibre, 6 mm thick, is to be placed between

every cast panels as axial expansion joints.

Important!

Be careful not to over vibrate the castables, as the finer particles tend to float to the

surface. Excess castable should be disposed of and not to be remixed.

Further, do not overwork or excessively trowel the surface. A smooth surface

inhibits moisture removal during curing and drying by bringing fines to the surface.

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 10

Exampel of casting the burner pipe in vertical position.

8. Curing

Cover all air exposed surfaces with a polyethylene film, or spray with a commercial

curing compound. This will prevent water evaporation and the moisture is necessary

in the castables to hydrate the cement and thus, develop proper strength. On

completion of hardening (this could take from 12 to 24 hours, depending of the

ambient temperature, but the suppliers instructions must always be followed), the

templates can be removed and the lining must be dried out at an ambient

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 11

temperature of 16 – 25ºC for 24 hours. Improved strength characteristics can be

obtained by extending the period to 48 hours or more.

9. Preheating

A hardened and air dried castable will still contain a certain amount of water and this

is to be driven off. To drive off this water, the castable lining should be preheated

according to the manufacturer's instruction. If these instructions are not available, the

following instructions are to be followed.

Preheating should be carried out as slowly as possible and with a good control over

the temperature. Refractory castables usually have a dense structure which does not

allow the water to escape easily.

Important!

Small Furnace with auxiliary burners can be used for preheating the casted burner

pipe. Alternatively electrical heating system may also be used.

A too rapidly increased temperature may create steam formation in the structure of

the castable, thus causing spalling of the layers from the surface and/or cracks.

Raise the temperature from ambient to 150oC at the rate of ~15oC per hour and the

temperature is to be maintained at 150oC for a period of 12 hours. The temperature of

lining is then increased to 350oC at the rate of ~25oC per hour and maintained at

350oC for a period of 12 hours. The temperature of lining is then increased to 550oC at

the rate of ~25oC per hour and maintained at 550oC for a period of 6 hours, then cool

down to ambient temperature at the rate of 50OC per hour.

Doc. No.:70024908 - 2.0

Burner Pipe Refractory Installation 12

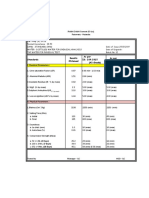

Heat up Curve

600

500

400

Temperature

300

200

100

0

1 6 11 16 21 26 31 36 41 46 51 56 61 66 71

Time in hours

Important!

During preheating sufficient ventilation should be provided so that the water vapour

can escape. Temperatures should be measured on the surface of the lining.

Doc. No.:70024908 - 2.0

You might also like

- Kiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DDocument1 pageKiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DMohamed SelimNo ratings yet

- Sop Sap Outgoing Payment 0.1Document12 pagesSop Sap Outgoing Payment 0.1supendra phuyal100% (1)

- Quality Manual ReportDocument21 pagesQuality Manual ReportRinku BalwadaNo ratings yet

- Sata Faulty Spray PatternDocument1 pageSata Faulty Spray PatternAnkur PanwarNo ratings yet

- Basic Plant Data Pyro Section: PurposeDocument5 pagesBasic Plant Data Pyro Section: PurposeDilnesa EjiguNo ratings yet

- Mercury in Cement Clinker ProductionDocument38 pagesMercury in Cement Clinker ProductionzementheadNo ratings yet

- Compatibility Report For Ball Charge Design Mill 2Document3 pagesCompatibility Report For Ball Charge Design Mill 2herwinNo ratings yet

- S.No. Particulars Units FLS: Performance Guarantees Pyro-Processing PlantDocument2 pagesS.No. Particulars Units FLS: Performance Guarantees Pyro-Processing Plantrashmiranjan1110No ratings yet

- Process Control IEEE Eml RDocument40 pagesProcess Control IEEE Eml RFran JimenezNo ratings yet

- PH Fan Flow CalculationDocument2 pagesPH Fan Flow CalculationVisnu Sankar100% (1)

- Ceramic Ball in Cement IndustryDocument6 pagesCeramic Ball in Cement IndustryMauricio PortillaNo ratings yet

- Instrumental Beer's Law Deviations: Linear Least-Squares Fit To Calibration CurveDocument11 pagesInstrumental Beer's Law Deviations: Linear Least-Squares Fit To Calibration CurveBùi Hắc Hải100% (1)

- Operational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionDocument6 pagesOperational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionJoshua JordanNo ratings yet

- How To Remove Scrap Materials From A Ball Mill CircuitDocument5 pagesHow To Remove Scrap Materials From A Ball Mill Circuitsafwat hassanNo ratings yet

- Bag-Filter Cleaning Fly-Ash Recirculation SiloDocument2 pagesBag-Filter Cleaning Fly-Ash Recirculation SiloPRTHA SARATHI PATRANo ratings yet

- Fuel & Energy Comparison Between B/E & Air LiftDocument1 pageFuel & Energy Comparison Between B/E & Air LiftAbul Qasim QasimNo ratings yet

- Comparison of Bricks SpecificationsDocument1 pageComparison of Bricks SpecificationsSaji KumarNo ratings yet

- Textbook 3 Cementproduction v31Document8 pagesTextbook 3 Cementproduction v31Mohammad Awais NazirNo ratings yet

- V6 EngineeringDocument252 pagesV6 Engineeringcrengifo1726No ratings yet

- Presentación Claudius Peters-EnfriadorDocument24 pagesPresentación Claudius Peters-EnfriadoremadsabriNo ratings yet

- Sieve Analysis GraphDocument6 pagesSieve Analysis GraphRoa Mae JulatonNo ratings yet

- Manual Testo-510Document7 pagesManual Testo-510roberto saenzNo ratings yet

- Kiln Eval Line IDocument1 pageKiln Eval Line IRaji SuriNo ratings yet

- Refrateck SolutionsDocument8 pagesRefrateck SolutionsMagesh Kumar0% (1)

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- Bybass Data SheetDocument5 pagesBybass Data SheetSatish KumarNo ratings yet

- Volume 3 Burning WorkshopDocument59 pagesVolume 3 Burning WorkshopmkpqNo ratings yet

- 2 - Polytrack Cooler HydDocument168 pages2 - Polytrack Cooler Hydruchikaporwal2018No ratings yet

- AFR Material Quality 18-Jul-2012Document2 pagesAFR Material Quality 18-Jul-2012Safrin SangiaNo ratings yet

- Overtaking CapacityDocument6 pagesOvertaking CapacityIrfan Ahmed100% (1)

- S I L I C O N: Save The Energy Save The WorldDocument23 pagesS I L I C O N: Save The Energy Save The WorldSmit ShahNo ratings yet

- Chapter 6 Final A5 EditDocument16 pagesChapter 6 Final A5 EditkINGNo ratings yet

- Grinding Media ConsumptionDocument9 pagesGrinding Media ConsumptionMuhammadNo ratings yet

- Date Who Comments: File: Tromp Curve - Eng v3 DateDocument14 pagesDate Who Comments: File: Tromp Curve - Eng v3 DateThaigroup CementNo ratings yet

- NM3 To ACTUAL M3Document3 pagesNM3 To ACTUAL M3Vipan Kumar DograNo ratings yet

- Description Kiln Size Project Doc - No DateDocument2 pagesDescription Kiln Size Project Doc - No DateRaji SuriNo ratings yet

- CM2 AXIAL TEST Aug2014Document1 pageCM2 AXIAL TEST Aug2014Junaid Mazhar100% (1)

- Raw Mill - Kiln Mass FlowDocument19 pagesRaw Mill - Kiln Mass FlowAndalia Ayu PutryNo ratings yet

- PR RFR P10-25 v1-0 How To Ensure Safety Under Refractory RoofsDocument7 pagesPR RFR P10-25 v1-0 How To Ensure Safety Under Refractory RoofsJuan Nacimba NacimbaNo ratings yet

- Measurements of The Quality of Cement Produced From Looped LimestoneDocument30 pagesMeasurements of The Quality of Cement Produced From Looped LimestoneCharlie Dean100% (1)

- Cpb-Sem2011-P11-Axial Sampling and Tromp CurveDocument54 pagesCpb-Sem2011-P11-Axial Sampling and Tromp Curvechibssa alemayehu100% (1)

- Dry Feed: Feed Entered SP H2O Content in SP H2O Content in SPDocument20 pagesDry Feed: Feed Entered SP H2O Content in SP H2O Content in SPIrfan Ahmed100% (2)

- Condition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Document6 pagesCondition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Shandi Hasnul FarizalNo ratings yet

- Refractory Stock SheetDocument9 pagesRefractory Stock SheetJunaid MazharNo ratings yet

- Fan Build Up ControlDocument2 pagesFan Build Up ControlSafrin SangiaNo ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Kiln Audit - Required Measurement ToolsDocument1 pageKiln Audit - Required Measurement ToolsVijay BhanNo ratings yet

- CID FanDocument2 pagesCID FanIrfan AhmedNo ratings yet

- Pneumat Silo Cleaning APAC RFA FactPackDocument4 pagesPneumat Silo Cleaning APAC RFA FactPackTin NguyenNo ratings yet

- Fuels 1 SlidesDocument19 pagesFuels 1 Slidesengr_saifNo ratings yet

- EAU-1,19000 CFM at 75 MM StaticDocument1 pageEAU-1,19000 CFM at 75 MM StaticdesignhvacNo ratings yet

- Pyro 2. Kiln Feeding SystemsDocument4 pagesPyro 2. Kiln Feeding SystemstesfamariamNo ratings yet

- AFR TT 2013 - Preliminary Program Rev 2Document1 pageAFR TT 2013 - Preliminary Program Rev 2Safrin SangiaNo ratings yet

- L-2 Fans 21.11.11Document5 pagesL-2 Fans 21.11.11Aaron HortonNo ratings yet

- Combustion Interlocks and Process SafetiesDocument2 pagesCombustion Interlocks and Process SafetiesclauNo ratings yet

- Main Burner: OperationDocument8 pagesMain Burner: OperationDIAGNENo ratings yet

- Mercury in CementDocument87 pagesMercury in Cementirvan Chaerul SNo ratings yet

- Pyro System - Control Loops V0.0Document2 pagesPyro System - Control Loops V0.0Junaid MazharNo ratings yet

- Dust - and - Meal Presentation PDFDocument27 pagesDust - and - Meal Presentation PDFawwadNo ratings yet

- Raw Mix Oxide Calculation: Coke Need For 100 KG Clinker LS Need For 100 KG Clinker LOI Clay Need For 100 KG ClinkerDocument2 pagesRaw Mix Oxide Calculation: Coke Need For 100 KG Clinker LS Need For 100 KG Clinker LOI Clay Need For 100 KG ClinkerMahla Raj KumarNo ratings yet

- Mcr-T1: Raw Material BasisDocument1 pageMcr-T1: Raw Material Basismahreza189No ratings yet

- Processing Instructions V 3.3 REFRAJET® ClaybondDocument3 pagesProcessing Instructions V 3.3 REFRAJET® ClaybondMohammed AbdoNo ratings yet

- Application Procedure For Dense Conventional Castable MAXHEAT KDocument6 pagesApplication Procedure For Dense Conventional Castable MAXHEAT Kumakant.electricianNo ratings yet

- Now Free Download Here Download Ebook: (Ilruk - Ebook) A Glimpse of Eternal Snows PDF FreeDocument2 pagesNow Free Download Here Download Ebook: (Ilruk - Ebook) A Glimpse of Eternal Snows PDF Freesupendra phuyalNo ratings yet

- SOP SAP Landed Cost 0.1Document9 pagesSOP SAP Landed Cost 0.1supendra phuyalNo ratings yet

- Recieved Limestone BhumichuliDocument1 pageRecieved Limestone Bhumichulisupendra phuyalNo ratings yet

- J. Biol. Chem.-1972-Colman-215-23Document10 pagesJ. Biol. Chem.-1972-Colman-215-23supendra phuyalNo ratings yet

- s3350 06 Dfu EngDocument16 pagess3350 06 Dfu Engsupendra phuyalNo ratings yet

- Report Titlbibid Author Title Pub Date Group Location Mfhdid Call Numbeenum/ChroDocument123 pagesReport Titlbibid Author Title Pub Date Group Location Mfhdid Call Numbeenum/Chrosupendra phuyalNo ratings yet

- NMB Sulav Application PDFDocument2 pagesNMB Sulav Application PDFsupendra phuyalNo ratings yet

- Product Description: Digital XENSIV Barometric Pressure SensorDocument44 pagesProduct Description: Digital XENSIV Barometric Pressure Sensorsupendra phuyalNo ratings yet

- Lgif) K B:O / Lxtu - FXL Jolqm JF +:yf Alrsf) Demf) TFDocument1 pageLgif) K B:O / Lxtu - FXL Jolqm JF +:yf Alrsf) Demf) TFsupendra phuyalNo ratings yet

- Test Certificate - OPC - RSCPLDocument2 pagesTest Certificate - OPC - RSCPLsupendra phuyalNo ratings yet

- HOMOGENIZATION OF BULK MATERIAL IN Chevron PileDocument7 pagesHOMOGENIZATION OF BULK MATERIAL IN Chevron Pilesupendra phuyal100% (2)

- SZP MG and MN RemovalDocument12 pagesSZP MG and MN RemovalBruce WillisNo ratings yet

- Flange Insulation SetsDocument2 pagesFlange Insulation SetspeeteesNo ratings yet

- Waste PaperDocument4 pagesWaste PapertisaNo ratings yet

- Curtain WallDocument20 pagesCurtain WallAkshay Borati50% (2)

- TDS POLYREX SP 30-4 D1 (١) -1Document1 pageTDS POLYREX SP 30-4 D1 (١) -1albaz666666No ratings yet

- 15281456Document15 pages15281456Manar KamelNo ratings yet

- Oxyfuel Brazing PrimerDocument5 pagesOxyfuel Brazing Primeralfian leoanakNo ratings yet

- Coro CleanDocument18 pagesCoro Cleanlaminar ersNo ratings yet

- Esacote Pu 73: Technical Data SheetDocument2 pagesEsacote Pu 73: Technical Data SheetShambhatiaNo ratings yet

- Sorting Materials Into Groups: Bjects Round USDocument9 pagesSorting Materials Into Groups: Bjects Round USSipra PaulNo ratings yet

- Petrographic Examination of Hardened Concrete: Standard Practice ForDocument17 pagesPetrographic Examination of Hardened Concrete: Standard Practice ForChavier ManguanaNo ratings yet

- 3PBO-M: Oil-Lubricated Rotary Vane Vacuum PumpDocument2 pages3PBO-M: Oil-Lubricated Rotary Vane Vacuum PumpAir-center CompresoresNo ratings yet

- A Review On Design and Development of Semi-Automated Colour Painitng Machine PDFDocument4 pagesA Review On Design and Development of Semi-Automated Colour Painitng Machine PDFHussain MuslimNo ratings yet

- Qatif Method Statement GroutingDocument13 pagesQatif Method Statement GroutingelbaraniNo ratings yet

- Brosure Sika Membran SystemDocument8 pagesBrosure Sika Membran SystemProyek ATCNo ratings yet

- Unit 1 Water and Its Treatment 2022Document27 pagesUnit 1 Water and Its Treatment 2022ABISHEIK sNo ratings yet

- Product Catalog: Bavaria SchweisstechnikDocument152 pagesProduct Catalog: Bavaria SchweisstechnikFilipe CordeiroNo ratings yet

- Pottery - WikipediaDocument43 pagesPottery - WikipediaAndy ToNo ratings yet

- Super Concrete - TibayMix AdmixturesDocument2 pagesSuper Concrete - TibayMix AdmixturesJulie Anne CastroNo ratings yet

- ColaTeric 2CMDocument1 pageColaTeric 2CMmndmattNo ratings yet

- Abdulkadir Beshir PDFDocument120 pagesAbdulkadir Beshir PDFkibromgidey12No ratings yet

- Amphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingDocument3 pagesAmphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingOsamaAliBangashNo ratings yet

- Marriage Hall - DesignDocument85 pagesMarriage Hall - DesignMuhammad Shahid Hussain89% (9)

- Dyeing of Turquiose PDFDocument31 pagesDyeing of Turquiose PDFrahul trivedi100% (1)

- 17709-Article Text-58507-1-10-20211219Document18 pages17709-Article Text-58507-1-10-20211219criajoynnajosseyNo ratings yet

- Application Guide Penguard Topcoat: Other Conditions That Can Affect Drying / Curing / Over CoatingDocument1 pageApplication Guide Penguard Topcoat: Other Conditions That Can Affect Drying / Curing / Over CoatingTamerTamerNo ratings yet

- Effect of Amine Groups in The Synthesis of Ag NanoDocument6 pagesEffect of Amine Groups in The Synthesis of Ag NanoNaveen KumarNo ratings yet

- Projeto Mini AnagamaDocument5 pagesProjeto Mini AnagamaAntonio José Fernandes Fernandes100% (1)