What Is Magnetic Filtration

What Is Magnetic Filtration

Uploaded by

Anwar SadatCopyright:

Available Formats

What Is Magnetic Filtration

What Is Magnetic Filtration

Uploaded by

Anwar SadatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

What Is Magnetic Filtration

What Is Magnetic Filtration

Uploaded by

Anwar SadatCopyright:

Available Formats

What is Magnetic Filtration?

Magnetic filtration is a method that removes iron particles from products that are in liquid or slurry

form. It’s a method that can be used in nearly any environment where ferrous, para-magnetic, and

grinding medium contamination is an issue. Magnetic filters make this type of filtration easy and

effective. In fact, when the filters become full, they can simply be cleaned and reused.

How Do Magnetic Filters Work?

Magnetic filters work with the use of high-intensity filter magnets. The filter is installed in the desired

location along the path of the liquid or slurry. The flow is directed around the magnetic field created

by the high-intensity filter magnets and any ferrous particles are captured in a magnetic trap. The

filter can then be removed, the captured particles washed away from the filter, and the filter reused.

There are many configurations of magnetic filters for the use in process

industries. These filters may come in the form of a magnetic plug (such as with the use in Spears Y

strainers such as these) for quick flushing. Another common form of a magnetic filter is the flow-

through configuration, in which particles flow through specific slots that are magnetized so regular

flow is not interrupted. Our LOFPLEAT filter cartridges (here) use flow-through magnetic filtration. A

third common type of magnetic filtration is the rod magnet, which extends down into tanks and filter

canisters to remove metallic particles.

Advantages of Magnetic Filtration

Using magnetic filtration is an environmentally friendly, cost-effective, and efficient way for various

industries to ensure that ferrous particles are removed from important fluids. Let’s take a look at

some of the advantages that you’ll experience when using a magnetic filter.

Environmentally Friendly

Magnetic filters are not only effective at filtering out ferrous particles, but they do so while being good

for the environment. The contamination that is collected in the magnetic trap is easily recycled as a

single material. That means that none of the contaminated material will end up in a landfill. Further,

the liquid that is being filtered retains its essential properties providing a longer lasting fluid life.

No Disposal Costs

Once you have a magnetic filter installed, there are no other expenses to incur over the lifetime of

your filter. But not only will you save on future expenses, you will also save on disposal costs. The

collected contamination is completely recyclable.

Minimal Running Costs

Magnetic filters have minimal running costs. You have the option of using manually cleaned filters or

self-cleaning filters. If you choose the latter, there is no extra power required, and self-cleaning

magnetic filters only need a small amount of power for cleaning.

Doesn’t Hinder Productivity

Magnetic filters don’t hinder productivity in any way. In fact, because fluid doesn’t flow through any

filter media, the flow is never interrupted. That means that the flow rate isn’t affected by your filter,

rather it’s determined by the requirements of your process. Even if the magnetic filter becomes full of

contaminates, there isn’t a risk of back pressure drop or burst filters.

It is also important to mention that magnetic filters are able to remove particles that are smaller than

one micron in size. Barrier filters leave particles that are smaller than five microns in the fluid. Even

at that tiny size, those particles can negatively affect the performance of the fluid and lead to

bacterial buildup.

Uses of Magnetic Filters

Magnetic filters and filtration systems are used in many different industries and applications. You will

find magnetic filters in the following products and applications:

•Hydraulic oils

•Liquid chemicals

•Manual and CNC machinery

•Slurries

•Liquid pharmaceutical products

•Transmission

•Lubricants

•Liquid food products

•Lapping and milling operations

•Pump protection

•Laser cutting operations

•Coolants

•Ceramics

This isn’t an exhaustive list. Magnetic filtration is a method that can be used in nearly any

environment where ferrous is an issue.

Use Magnetic Filtration for Liquid-Based Systems

Filtration is an essential component of the above products and processes, as well as many other

liquid-based systems. The process of removing contaminants or impurities from your media is vital to

preventing negative consequences from occurring in your products or processes. For any system

where ferrous particles are a risk to your liquids or slurries, magnetic filtration is an ideal solution. It’s

low-cost, environmentally friendly, and efficient for industrial uses and processes.

You might also like

- Kalrez Semicon Selection GuideDocument4 pagesKalrez Semicon Selection GuideSofwat SanjayaNo ratings yet

- Separation and Classification of Solids (Module 3)Document17 pagesSeparation and Classification of Solids (Module 3)Mark Goldwyn Blando100% (2)

- Why Must We Maintain Distillation of Diesel 95Document1 pageWhy Must We Maintain Distillation of Diesel 95Anwar SadatNo ratings yet

- Filter Types For The Pharmaceutical Industry - Water Tech OnlineDocument6 pagesFilter Types For The Pharmaceutical Industry - Water Tech OnlineWONG TSNo ratings yet

- Advances Filters in Pharma IndDocument4 pagesAdvances Filters in Pharma IndJohn LeninNo ratings yet

- 2012 One Eye CatalogueDocument44 pages2012 One Eye CatalogueRavinder SinghNo ratings yet

- Automatic Waste Segregator and Monitoring System: January 2016Document8 pagesAutomatic Waste Segregator and Monitoring System: January 2016Deepak sutarNo ratings yet

- Automatic Waste Segregator and Monitoring System PDFDocument4 pagesAutomatic Waste Segregator and Monitoring System PDFAllen Kyle PrielaNo ratings yet

- Magnetic SeparatorsDocument18 pagesMagnetic SeparatorskarthicknlNo ratings yet

- Magnetic Drain Plug TwoDocument7 pagesMagnetic Drain Plug TwoahmadNo ratings yet

- Best Blackpowder2013Document24 pagesBest Blackpowder2013sohail1985No ratings yet

- 1 PBDocument7 pages1 PBanandhra2010No ratings yet

- Filtering and MicrostrainingDocument5 pagesFiltering and Microstrainingrandhie hakimNo ratings yet

- Multi-Purpose Shredder With A Mixer.Document7 pagesMulti-Purpose Shredder With A Mixer.Duff AlbaciteNo ratings yet

- Final ReviewDocument11 pagesFinal Reviewaddalanagendra111No ratings yet

- Frequently Asked Questions: GeneralDocument3 pagesFrequently Asked Questions: GeneralRahul MoottolikandyNo ratings yet

- Wa0026.Document22 pagesWa0026.Manal WehbaNo ratings yet

- Predictive Maintenance PDFDocument7 pagesPredictive Maintenance PDFAnonymous iQMKqMqqWNo ratings yet

- Magnetic Separation Belt For Spices Processing Industries - An Informative GuideDocument3 pagesMagnetic Separation Belt For Spices Processing Industries - An Informative GuideJay Krishna MagneticNo ratings yet

- Automatic Waste Segregator and Monitoring System: Journal of Microcontroller Engineering and ApplicationsDocument7 pagesAutomatic Waste Segregator and Monitoring System: Journal of Microcontroller Engineering and Applicationsaastree01No ratings yet

- Air Pollutants & Control TechnicquesDocument25 pagesAir Pollutants & Control TechnicquesStan MacapiliNo ratings yet

- Hydraulic Filters: Prof. Salvador Vargas Díaz Semestre 2020-IDocument15 pagesHydraulic Filters: Prof. Salvador Vargas Díaz Semestre 2020-ISalvador Vargas-DiazNo ratings yet

- Microsart Manifolds: The Filtration Stand That Adapts To Your NeedDocument8 pagesMicrosart Manifolds: The Filtration Stand That Adapts To Your NeedchiralicNo ratings yet

- Industrial Process Module No. 3Document17 pagesIndustrial Process Module No. 3Ismaeli Kiel100% (1)

- Microstructure and Chemical Property Investigation of Candle Type Water FilterDocument5 pagesMicrostructure and Chemical Property Investigation of Candle Type Water Filterahmed.mo.22555417No ratings yet

- MetalFin Nov08 UltrasonicsDocument5 pagesMetalFin Nov08 UltrasonicsJacques PretoriusNo ratings yet

- Magnetic Separators ManufacturesDocument41 pagesMagnetic Separators ManufacturesmagnatronixindiaNo ratings yet

- FiltrationDocument8 pagesFiltrationM A R k H O RNo ratings yet

- Microsart Manifold SartoriusDocument8 pagesMicrosart Manifold SartoriusPutri Tania ArianaNo ratings yet

- Department of Petrochemical Engineering: Summer Training Program (2019 - 2020)Document7 pagesDepartment of Petrochemical Engineering: Summer Training Program (2019 - 2020)soran najebNo ratings yet

- Stream Filters For Industrial UseDocument8 pagesStream Filters For Industrial UseVasudev Water SolutionNo ratings yet

- FiltrationDocument22 pagesFiltrationDennis DeusNo ratings yet

- DataSheet Microsart-Manifolds IDocument8 pagesDataSheet Microsart-Manifolds IlorenzoNo ratings yet

- Tube MagnetsDocument40 pagesTube MagnetsotrepaloNo ratings yet

- Wear Particle AnalysisDocument20 pagesWear Particle AnalysisAgus Qupink Luph AriaNo ratings yet

- Metal SegDocument4 pagesMetal Segvishnu.s.eee.2021No ratings yet

- Trinh Vu Nguyen Long HW2Document6 pagesTrinh Vu Nguyen Long HW2Long Trịnh vũ nguyênNo ratings yet

- Kelompok 1: 1. Maulana Satya 2310100002 2. Cahyaning Lestari 2308100009 3. Gunawan Hartanto 2308100048Document13 pagesKelompok 1: 1. Maulana Satya 2310100002 2. Cahyaning Lestari 2308100009 3. Gunawan Hartanto 2308100048kradsrevolcNo ratings yet

- Che 341 Group ThreeDocument24 pagesChe 341 Group ThreeKevwe Macaulay -GbogidiNo ratings yet

- Pre and Depth FilterationDocument13 pagesPre and Depth FilterationJohnveslin. RvNo ratings yet

- Wet Drum Magnetic Separator PDFDocument4 pagesWet Drum Magnetic Separator PDFevalenciaNo ratings yet

- Automated Waste Segregator Bin202020Document10 pagesAutomated Waste Segregator Bin202020MANOJ KNo ratings yet

- Sparkler Filter BrochureDocument4 pagesSparkler Filter BrochurekiranNo ratings yet

- Plasma EtchingDocument4 pagesPlasma EtchingnarendraNo ratings yet

- Unit 3 MUODocument22 pagesUnit 3 MUOSiddh Bhatt100% (1)

- Amiad Self-Cleaning Strainers For Water FiltrationDocument10 pagesAmiad Self-Cleaning Strainers For Water FiltrationHari Krishna.MNo ratings yet

- CE and ME TalkDocument2 pagesCE and ME TalkMelanieNo ratings yet

- The Basics of Hydraulic FiltrationDocument3 pagesThe Basics of Hydraulic Filtrationbee1406763181No ratings yet

- Unit 3 Wear Debris AnalysisDocument4 pagesUnit 3 Wear Debris AnalysisVenkadeshwaran KuthalingamNo ratings yet

- Ebook Ipal ComminutorDocument7 pagesEbook Ipal ComminutorPradana RonyeNo ratings yet

- Carotek Filtration Strainers Selection Guide 06042020Document3 pagesCarotek Filtration Strainers Selection Guide 06042020SaidFerdjallahNo ratings yet

- Unit 4 Mechanical SeparationDocument23 pagesUnit 4 Mechanical SeparationSk jahidul IslamNo ratings yet

- FItrLTERS PDFDocument4 pagesFItrLTERS PDFAriz Joelee ArthaNo ratings yet

- Sludge Dewatering Technologies PDFDocument9 pagesSludge Dewatering Technologies PDFTahaNo ratings yet

- IJPRAS-2015-4-2-19-21 Filtration Application in Production of Liquid SugarsDocument3 pagesIJPRAS-2015-4-2-19-21 Filtration Application in Production of Liquid SugarsArmando CastañedaNo ratings yet

- Ultrafiltration PlantDocument7 pagesUltrafiltration PlantgulfamNo ratings yet

- Wet Drum Magnetic Separator: Product BulletinDocument3 pagesWet Drum Magnetic Separator: Product Bulletinjm.hupontNo ratings yet

- Ultimate Guide To Bag Filter Types Function EfficiencyDocument9 pagesUltimate Guide To Bag Filter Types Function EfficiencyAmit SinghNo ratings yet

- Cartridge Filter Application NotesDocument5 pagesCartridge Filter Application NotesSamik MukherjeeNo ratings yet

- New Sensors and Processing ChainFrom EverandNew Sensors and Processing ChainJean-Hugh ThomasNo ratings yet

- Advanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingFrom EverandAdvanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingNo ratings yet

- W Series Multi-Round: Bag Filter HousingsDocument16 pagesW Series Multi-Round: Bag Filter HousingsAnwar SadatNo ratings yet

- HF Series: Cartridge Filter HousingsDocument2 pagesHF Series: Cartridge Filter HousingsAnwar SadatNo ratings yet

- Hydraulic Torque Wrench Working Condition SurveyDocument1 pageHydraulic Torque Wrench Working Condition SurveyAnwar SadatNo ratings yet

- The Cetane Index Is A Figure Which Denotes The Quality of A Diesel FuelDocument4 pagesThe Cetane Index Is A Figure Which Denotes The Quality of A Diesel FuelAnwar SadatNo ratings yet

- Outline of Diesel Hydrotreating Unit (DHT Unit)Document4 pagesOutline of Diesel Hydrotreating Unit (DHT Unit)Anwar SadatNo ratings yet

- General Arrangement Drawing 1200-E-4006: Document TitleDocument2 pagesGeneral Arrangement Drawing 1200-E-4006: Document TitleAnwar SadatNo ratings yet

- Part Detail Drawing 1200-E-4006: Document TitleDocument4 pagesPart Detail Drawing 1200-E-4006: Document TitleAnwar SadatNo ratings yet

- UzairsahmedDocument1 pageUzairsahmedAnwar SadatNo ratings yet

- Piping Work Contractor Bill-1Document21 pagesPiping Work Contractor Bill-1Anwar SadatNo ratings yet

- Tube Bundle Detail Drawing 1200-E-4006: Document TitleDocument2 pagesTube Bundle Detail Drawing 1200-E-4006: Document TitleAnwar SadatNo ratings yet

- Name Plate Drawing 1200-E-4006: Document TitleDocument2 pagesName Plate Drawing 1200-E-4006: Document TitleAnwar SadatNo ratings yet

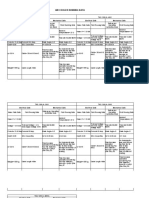

- Name Deposit Meals. Meals Rate Total Cost Balance (+)Document3 pagesName Deposit Meals. Meals Rate Total Cost Balance (+)Anwar SadatNo ratings yet

- Filters: CCR Platforming Process UnitDocument3 pagesFilters: CCR Platforming Process UnitAnwar SadatNo ratings yet

- Md. Hasmat Ali S.H. Plaza, 9091 Nazimuddin Road, 4 Floor F-2 Dhaka: 1100 Career AspirationDocument3 pagesMd. Hasmat Ali S.H. Plaza, 9091 Nazimuddin Road, 4 Floor F-2 Dhaka: 1100 Career AspirationAnwar SadatNo ratings yet

- Offer Sheet: Packing, Trucking and Other Charge in Korea Total (F.O.B Busan Port Terms) RemarkDocument1 pageOffer Sheet: Packing, Trucking and Other Charge in Korea Total (F.O.B Busan Port Terms) RemarkAnwar SadatNo ratings yet

- Air CoolerDocument5 pagesAir CoolerAnwar SadatNo ratings yet

- Avanti Process Pte LTDDocument3 pagesAvanti Process Pte LTDAnwar SadatNo ratings yet

- Ariel Corporation - Arielcorp - Com11Document1 pageAriel Corporation - Arielcorp - Com11Anwar SadatNo ratings yet

- Ariel Corporation - Arielcorp - Com7Document1 pageAriel Corporation - Arielcorp - Com7Anwar SadatNo ratings yet

- Junyet Al Habib-MergedDocument3 pagesJunyet Al Habib-MergedAnwar SadatNo ratings yet

- Name Deposit Meals. Meals Rate Total Cost Balance (+)Document3 pagesName Deposit Meals. Meals Rate Total Cost Balance (+)Anwar SadatNo ratings yet

- Name Deposit Meals. Meals Rate Total Cost Balance (+)Document3 pagesName Deposit Meals. Meals Rate Total Cost Balance (+)Anwar SadatNo ratings yet

- Deputy Project DirectorDocument2 pagesDeputy Project DirectorAnwar SadatNo ratings yet

- Ariel Corporation - Arielcorp - Com 4Document1 pageAriel Corporation - Arielcorp - Com 4Anwar Sadat100% (1)

- Ariel Corporation - Arielcorp - Com22Document1 pageAriel Corporation - Arielcorp - Com22Anwar SadatNo ratings yet

- Monarch Examiner 1000 - Vibration Meter - Electronic StethoscopeDocument4 pagesMonarch Examiner 1000 - Vibration Meter - Electronic StethoscopeAnwar SadatNo ratings yet

- Ariel Corporation - Arielcorp - Com15Document1 pageAriel Corporation - Arielcorp - Com15Anwar Sadat100% (1)

- Shim Stock Analysis TechniquesDocument2 pagesShim Stock Analysis TechniquesSathish KrishnanNo ratings yet

- Unit 4 - Week 2: Assignment 2Document3 pagesUnit 4 - Week 2: Assignment 2sai prakash sunkavalliNo ratings yet

- Waste Water Treatment Training Institute in ChennaiDocument1 pageWaste Water Treatment Training Institute in ChennaiKishore KumarNo ratings yet

- Cap (Acorn) Nuts: O P H C N, L CDocument1 pageCap (Acorn) Nuts: O P H C N, L CMAI_QualityNo ratings yet

- Design of SpindleDocument36 pagesDesign of SpindleAMIT SOLANKI50% (2)

- Welcome TO Lecture On Process For Nonprocess Engineers: K.P.Pradeep KumarDocument170 pagesWelcome TO Lecture On Process For Nonprocess Engineers: K.P.Pradeep Kumarpacoto livingstoneNo ratings yet

- Factsheet 24301Document1 pageFactsheet 24301GoBozicNo ratings yet

- Elmac Material SelectionDocument1 pageElmac Material SelectionAnil Krishna JangitiNo ratings yet

- Chapter 4 (Design of Permanent Joints)Document30 pagesChapter 4 (Design of Permanent Joints)wabdushukurNo ratings yet

- C E P S I: Joël RECHDocument12 pagesC E P S I: Joël RECHwitiabNo ratings yet

- DW-55LSR: 4G 2G 2F 3G UphillDocument1 pageDW-55LSR: 4G 2G 2F 3G Uphillamit singhNo ratings yet

- TF100 17D Rynglok Tube Repair SystemDocument8 pagesTF100 17D Rynglok Tube Repair SystemAnup DahalNo ratings yet

- BPI-Company ProfileDocument19 pagesBPI-Company Profilesunny vachhaniNo ratings yet

- Ch14 - Metal-Forging Processes and EquipmentDocument26 pagesCh14 - Metal-Forging Processes and Equipmentlam minhNo ratings yet

- Sotras FiltersDocument4 pagesSotras FiltersSami SupperiNo ratings yet

- Sertifikat Na Bezopasnuyu Poliuretanovuyu Smolu RFID BrelokiDocument6 pagesSertifikat Na Bezopasnuyu Poliuretanovuyu Smolu RFID BrelokiAzifahNo ratings yet

- Nioec SP 80 20Document42 pagesNioec SP 80 20Javad MonfaredNo ratings yet

- 3.0 Foam Drilling: 3.1 Make Up 3.2 Generation 3.3 Disposal 3.4 Drilling Practices 3.5 ProblemsDocument16 pages3.0 Foam Drilling: 3.1 Make Up 3.2 Generation 3.3 Disposal 3.4 Drilling Practices 3.5 ProblemsShahin KhanNo ratings yet

- HempelDocument2 pagesHempelAnuar SalehNo ratings yet

- PT Horiguchi Engineering Indonesia: General CatalogueDocument24 pagesPT Horiguchi Engineering Indonesia: General CatalogueAkhmad RamdaniNo ratings yet

- India Plastics ManufactureDocument12 pagesIndia Plastics Manufacture01 Financial100% (1)

- Hot-Dip Galvanizing of Cold-Formed Steel Hollow Sections - A State-Of-The-Art ReviewDocument17 pagesHot-Dip Galvanizing of Cold-Formed Steel Hollow Sections - A State-Of-The-Art ReviewJesús Ribera100% (1)

- Chapter 1 ShaftDocument21 pagesChapter 1 ShaftRayuth KEATNo ratings yet

- Wear Rate LoescheDocument8 pagesWear Rate LoescheEdson Ricardo Lima100% (2)

- Catalogo E60HDocument68 pagesCatalogo E60Hjorge alonsoNo ratings yet

- Tikidan Tds - Tiki Aquaseal Pu-She, r9Document3 pagesTikidan Tds - Tiki Aquaseal Pu-She, r9sandeepNo ratings yet

- 150OP2300006 SetupPlanDocument4 pages150OP2300006 SetupPlanAdonis Elme Yaya RodriguezNo ratings yet

- Hydrocracking SolverDocument10 pagesHydrocracking SolverkrishnaNo ratings yet

- Root Pass: Vertical-Up Method Root Pass: Vertical-Down MethodDocument7 pagesRoot Pass: Vertical-Up Method Root Pass: Vertical-Down MethodWilly UioNo ratings yet