67%(3)67% found this document useful (3 votes)

2K viewsInspection Checklist of Drill Machine: Project Name: Date: Time: Checked by

Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked by

Uploaded by

Raza Muhammad SoomroThis inspection checklist is used to check a drill machine for safety issues before use. It contains 21 items to check, including ensuring only authorized personnel operate the drill, it is properly grounded, cables are insulated and the right size, the material being drilled is secure, repairs are done by an electrician, and the operator removes loose jewelry. The inspector and reviewer sign off after completing the checklist.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked by

Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked by

Uploaded by

Raza Muhammad Soomro67%(3)67% found this document useful (3 votes)

2K views1 pageThis inspection checklist is used to check a drill machine for safety issues before use. It contains 21 items to check, including ensuring only authorized personnel operate the drill, it is properly grounded, cables are insulated and the right size, the material being drilled is secure, repairs are done by an electrician, and the operator removes loose jewelry. The inspector and reviewer sign off after completing the checklist.

Original Title

Drill Machine

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This inspection checklist is used to check a drill machine for safety issues before use. It contains 21 items to check, including ensuring only authorized personnel operate the drill, it is properly grounded, cables are insulated and the right size, the material being drilled is secure, repairs are done by an electrician, and the operator removes loose jewelry. The inspector and reviewer sign off after completing the checklist.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

67%(3)67% found this document useful (3 votes)

2K views1 pageInspection Checklist of Drill Machine: Project Name: Date: Time: Checked by

Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked by

Uploaded by

Raza Muhammad SoomroThis inspection checklist is used to check a drill machine for safety issues before use. It contains 21 items to check, including ensuring only authorized personnel operate the drill, it is properly grounded, cables are insulated and the right size, the material being drilled is secure, repairs are done by an electrician, and the operator removes loose jewelry. The inspector and reviewer sign off after completing the checklist.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

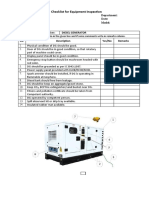

Company logo Company name with project name Project logo

INSPECTION CHECKLIST OF DRILL MACHINE

Project Name: Date:

Time: Checked by

S. STATUS REMARKS

ITEMS

N YES NO

1 Do you allow only authorized and trained personnel to use drill?

2 Provided with earthing or grounding properly.

Properly insulated and no exposed cables & Size of cable is suitable for

3

voltage supply.

4 Do not use the machine in flammable or potentially explosive environments.

5 Remove any adjusting keys or wrench before turning the power tool on.

6 Do not allow the connecting cable to hang over edges (danger of tripping).

7 Check that the tool is tightened securely before using.

Check the material/stock for any defects such as knots and foreign objects

8

such as nails, staples or screws

10 Inspect the work area for other possible hazards

Secure the material/stock to be drilled to prevent movement. Clamp small

11

pieces so they do not twist or spin

12 Repairs to the mains cable may only be carried out by a qualified electrician.

Hold the drill by the insulated gripping handle. Use an auxiliary handle for

13

larger work or continuous operation

14 Is the drill is free from defect?

15 Is the operator Removed the loose jewellery before start the work?

16 Is the dead man switch installed in drill machine?

17 Is the dead man switch is in working condition?

Is the cable of drill machine in ok condition means without cut or joint?

18 Is the Person who does the work is healthy and free from stress?

20 Locate and ensure you are familiar with all machine operations and controls.

21 Is the working area is clean and tidy?

Inspected by: _______________________ Reviewed By: ______________________

You might also like

- Compactor Daily Inspection ChecklistDocument1 pageCompactor Daily Inspection ChecklistThandabantu Magengelele50% (4)

- Welding Inspection Checklist..Document2 pagesWelding Inspection Checklist..Raza Muhammad Soomro93% (14)

- Checklist For Equipment Inspection EARTH COMPACTOR (ROLLER)Document1 pageChecklist For Equipment Inspection EARTH COMPACTOR (ROLLER)kami abdul33% (3)

- Bobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityDocument1 pageBobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityMuhammad Farooq Awan100% (5)

- Trowel Concrete Machine Pre-Use Inspection Checklist: ProjectDocument2 pagesTrowel Concrete Machine Pre-Use Inspection Checklist: ProjectImam Ali100% (1)

- Concrete Mixer ChecklistDocument1 pageConcrete Mixer ChecklistSafety Man Shop100% (2)

- Form 092 Excavator Safety ChecklistDocument2 pagesForm 092 Excavator Safety Checklistshamroz khan83% (6)

- Form 092 Excavator Safety Checklist 1Document2 pagesForm 092 Excavator Safety Checklist 1TANWIR AHEMADNo ratings yet

- 13 Checklist For Hammering Drill MachineDocument1 page13 Checklist For Hammering Drill Machinexiangjintao88% (8)

- Concrete Pump Safety ChecklistDocument15 pagesConcrete Pump Safety ChecklistHaleemUrRashidBangash50% (2)

- Inspection Checklist For HydraDocument1 pageInspection Checklist For HydraParthiban Venkatesan75% (4)

- L6.17 Mobile Welding Machine Inspection ChecklistDocument2 pagesL6.17 Mobile Welding Machine Inspection Checklistom prakash100% (6)

- Form-094-Loader Safety ChecklistDocument2 pagesForm-094-Loader Safety Checklistshamroz khan100% (7)

- C03.Safety Inspection Checklist For Backhoe Loader (JCB)Document1 pageC03.Safety Inspection Checklist For Backhoe Loader (JCB)SRR OHSE67% (6)

- Checklist For JCBDocument1 pageChecklist For JCBSafety Manager100% (1)

- Checklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleDocument1 pageChecklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleMarisabel Maidana100% (3)

- Inspection Sheet For Roller and ConveyorDocument2 pagesInspection Sheet For Roller and ConveyorPaintsil Bright0% (1)

- Inspection Checklist For BACKHOE LOADER (JCB)Document1 pageInspection Checklist For BACKHOE LOADER (JCB)Idada Ezekiel100% (1)

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 pageHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad Raza100% (1)

- Construction-Safety-Management-Plan For Hydro Power PlantDocument73 pagesConstruction-Safety-Management-Plan For Hydro Power PlantRaza Muhammad SoomroNo ratings yet

- Brush Cutter Pre Use ChecklistDocument1 pageBrush Cutter Pre Use ChecklistBruce Hove100% (2)

- FC 4.1.5 - Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist FormDocument2 pagesFC 4.1.5 - Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist FormJosef Demner Tiu Paspe100% (1)

- Grinding Machine ChecklistDocument1 pageGrinding Machine ChecklistPrashanth Jeer100% (2)

- DAILY CHECK LIST Crawler CraneDocument1 pageDAILY CHECK LIST Crawler CraneAditya Enterprise100% (1)

- Tower Crane Daily Inspection FormDocument1 pageTower Crane Daily Inspection FormZainul Hazwan88% (8)

- 19-F13 Vehicle Mounted Crane Inspection ChecklistDocument2 pages19-F13 Vehicle Mounted Crane Inspection ChecklistSn Ahsan100% (2)

- 05 Check List For Gas Cutting Set-1-1Document1 page05 Check List For Gas Cutting Set-1-1Eurico Seley Claúdio100% (1)

- Rammer/ Jumping Jack Compactor Inspection Checklist: Parameters Acceptable Yes/No RemarksDocument1 pageRammer/ Jumping Jack Compactor Inspection Checklist: Parameters Acceptable Yes/No RemarksJohn80% (5)

- Snake Bite SOPDocument5 pagesSnake Bite SOPRaza Muhammad SoomroNo ratings yet

- Work at Height TrainingDocument6 pagesWork at Height TrainingRaza Muhammad Soomro100% (1)

- 50 MW Nasda Wind Power Project: Snake Bite Risk Assesment WorksheetDocument4 pages50 MW Nasda Wind Power Project: Snake Bite Risk Assesment WorksheetRaza Muhammad SoomroNo ratings yet

- Jumping Compactor Inspection ChecklistDocument1 pageJumping Compactor Inspection Checklistarunjith rNo ratings yet

- Checklist For Equipment Inspection Bench Cutting MachineDocument2 pagesChecklist For Equipment Inspection Bench Cutting MachineHung Hoang100% (4)

- Bar Cutting Machine HSE ChecklistDocument2 pagesBar Cutting Machine HSE ChecklistMD Abdullah100% (4)

- Mobile Crane Monthly ChecklistDocument3 pagesMobile Crane Monthly ChecklistDAOUMY YOUNESSNo ratings yet

- Roller Compactor Monthly ChecklistDocument2 pagesRoller Compactor Monthly ChecklistDAOUMY YOUNESS100% (2)

- HSE-026.Pre-entry Hydra CraneDocument2 pagesHSE-026.Pre-entry Hydra CraneMithlesh Singh80% (5)

- Plate Compactor (Electric) Checklist Drafted For Shapar.Document3 pagesPlate Compactor (Electric) Checklist Drafted For Shapar.Alves Edattukaran100% (1)

- Checklist For Equipment Inspection BOOM PLACERDocument2 pagesChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (3)

- Plate Compactor Inspection ChecklistDocument1 pagePlate Compactor Inspection ChecklistNair R RakeshNo ratings yet

- Bar Cutting Machine Inspection ChecklistDocument1 pageBar Cutting Machine Inspection ChecklistRicardo Dalisay100% (6)

- 03 - Hydra Crane ChecklistDocument1 page03 - Hydra Crane ChecklistAfzal Akhtar100% (6)

- Form-162-Scissor Lift Daily Inspection ChecklistDocument1 pageForm-162-Scissor Lift Daily Inspection Checklistshamroz khan100% (2)

- Checklist For Equipment Inspection Diesel GeneratorDocument1 pageChecklist For Equipment Inspection Diesel GeneratorKaif SiddiqueNo ratings yet

- Boom Lift - Daily ChecklistDocument1 pageBoom Lift - Daily Checklistpawankumar100% (2)

- Checklist For Equipment Inspection Circular SawDocument1 pageChecklist For Equipment Inspection Circular SawKaif SiddiqueNo ratings yet

- Grinder Checklist2Document3 pagesGrinder Checklist2jovyNo ratings yet

- Form-093-Dump Truck Safety ChecklistDocument2 pagesForm-093-Dump Truck Safety Checklistshamroz khan100% (4)

- Checklist For Bar Bending and Bar CuttingDocument2 pagesChecklist For Bar Bending and Bar CuttingGyanendra SrivastavaNo ratings yet

- Form-069-Tower Crane Safety ChecklistDocument2 pagesForm-069-Tower Crane Safety ChecklistJishad Nalakath100% (6)

- 10.a. Welding Machine Inspection (Electric, Travo Type)Document1 page10.a. Welding Machine Inspection (Electric, Travo Type)Adhy DarmawanNo ratings yet

- Circular Saw Inspection Checklist MonthlyDocument1 pageCircular Saw Inspection Checklist Monthlymuhib.khattak0706No ratings yet

- Drill Machine - ChecklistDocument1 pageDrill Machine - ChecklistarkonamtfplNo ratings yet

- EHS VI 08 FaranaDocument2 pagesEHS VI 08 Faranashamshad ahamed100% (1)

- Checklist For Equipment Inspection TRANSIT MIXERDocument2 pagesChecklist For Equipment Inspection TRANSIT MIXERIdada EzekielNo ratings yet

- Checklist For Power Drill MachinDocument1 pageChecklist For Power Drill MachinLearn with Engr. Abdul Quyyaum ChaudharyNo ratings yet

- Bar Bending MachineDocument1 pageBar Bending MachineVinay PandeyNo ratings yet

- Checklist For Equipment Inspection - CONCRETE MIXERDocument1 pageChecklist For Equipment Inspection - CONCRETE MIXERabdulsalam sarooriNo ratings yet

- Earth Compactor Roller Inspection ChecklistDocument1 pageEarth Compactor Roller Inspection ChecklistPant NagarNo ratings yet

- Boom Placer Safety Inspection ChecklistDocument1 pageBoom Placer Safety Inspection ChecklistMyo LwinNo ratings yet

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- 30 Equipment Checklists in One Excel WorkbookDocument56 pages30 Equipment Checklists in One Excel WorkbookBorislav Vulić100% (2)

- (UG10) Builder Hoist PDFDocument2 pages(UG10) Builder Hoist PDFavinashNo ratings yet

- Site Equipment-Safety ChecklistDocument23 pagesSite Equipment-Safety ChecklistGoraksh BhakreNo ratings yet

- Safety Achievements - Tetra TechDocument2 pagesSafety Achievements - Tetra TechRaza Muhammad SoomroNo ratings yet

- Job Safety Analysis For Batching Plant Operation (Commissioning) - HSE DocumentsDocument4 pagesJob Safety Analysis For Batching Plant Operation (Commissioning) - HSE DocumentsRaza Muhammad SoomroNo ratings yet

- CV For HSE Manager - Environmental Health & Safety Associate at Gulf Oil & GasDocument3 pagesCV For HSE Manager - Environmental Health & Safety Associate at Gulf Oil & GasRaza Muhammad SoomroNo ratings yet

- EHS Supervisor ResponsibilitiesDocument1 pageEHS Supervisor ResponsibilitiesRaza Muhammad SoomroNo ratings yet

- HSE Manager Resume Samples - QwikResumeDocument14 pagesHSE Manager Resume Samples - QwikResumeRaza Muhammad SoomroNo ratings yet

- Safety Engineer ResponsibilitiesDocument3 pagesSafety Engineer ResponsibilitiesRaza Muhammad SoomroNo ratings yet

- EHS ManagerDocument1 pageEHS ManagerRaza Muhammad SoomroNo ratings yet

- HSE Engineer ResponsibilitiesDocument4 pagesHSE Engineer ResponsibilitiesRaza Muhammad SoomroNo ratings yet

- ESH Engineer ResponsbilitiesDocument3 pagesESH Engineer ResponsbilitiesRaza Muhammad SoomroNo ratings yet

- CCAA Environmental Guideline FinalDocument13 pagesCCAA Environmental Guideline FinalRaza Muhammad SoomroNo ratings yet

- Snakes Safety PrecautionsDocument5 pagesSnakes Safety PrecautionsRaza Muhammad SoomroNo ratings yet

- 013 Eia 03cDocument156 pages013 Eia 03cRaza Muhammad SoomroNo ratings yet

- Act02 50 MW Wind Power Plant: Checklist SummaryDocument54 pagesAct02 50 MW Wind Power Plant: Checklist SummaryRaza Muhammad SoomroNo ratings yet

- Safe Use of CranesDocument25 pagesSafe Use of CranesReda Mashal0% (1)

- Mhca - Redi Mix Concrete FacilitiesDocument14 pagesMhca - Redi Mix Concrete FacilitiesRaza Muhammad SoomroNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Weekly Report Requirements 27-03 To 02-04-2021Document2 pagesWeekly Report Requirements 27-03 To 02-04-2021Raza Muhammad SoomroNo ratings yet

- Revised-JSA On WTG InstallationDocument16 pagesRevised-JSA On WTG InstallationRaza Muhammad SoomroNo ratings yet

- Training Importance of PPEDocument7 pagesTraining Importance of PPERaza Muhammad SoomroNo ratings yet

- Lifting Plan RequirementsDocument1 pageLifting Plan RequirementsRaza Muhammad SoomroNo ratings yet

- Lifting Plan RequirementsDocument1 pageLifting Plan RequirementsRaza Muhammad SoomroNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- Construction Work Plan During Rains FallsDocument3 pagesConstruction Work Plan During Rains FallsRaza Muhammad SoomroNo ratings yet