Stc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The World

Stc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The World

Uploaded by

ryo asg3Copyright:

Available Formats

Stc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The World

Stc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The World

Uploaded by

ryo asg3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Stc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The World

Stc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The World

Uploaded by

ryo asg3Copyright:

Available Formats

STC550

STC550 TRUCK CRANE

55 TONS LIFTING CAPACITY

Quality Changes the World

STC550 Truck Crane STC550 Truck Crane

2 COMPANY BRIFE INTRODUCTION COMPANY BRIFE INTRODUCTION 3

SANY Automobile Hoisting Machinery is one of the core business unit of Sany Heavy

Industry, mainly engaged in the research and development of high end, mid to large

tonnage crane series, including mobile crane, crawler crane, tower crane and loader crane.

It has two industrial parks in Ningxiang and Huzhou, since entering the market, the products

of Sany Automobile Hoisting Machinery have received worldwide recognition with advanced

technology, lean manufacturing, high reliability and excellent service.

Quality Changes the World Quality Changes the World

STC550 Truck Crane STC550 Truck Crane

4 ICON Selling points 5

SANY TRUCK Crane

content

04 Icon

05 Selling points

06 Introduction

09 Dimension

10 Technical Parameter

11 Operation Condition

12 Load Chart

14 Wheel Crane Family Map

Excellent and stable chassis performance / Ultra long, super strong and highly sensitive

chassis system load lifting capacity

Double-axle drive is used, providing good trafficability and Five-section boom of high strength steel structure and optimized

comfortableness under complex road condition with reliable U-shaped cross section reduces weight significantly with higher

traveling performance. safety rates. Jib mounting angles are 0°, 15° and 30°, which

Cab Carrier frame Suspension system

Engine has the multimode power output function, which reduces ensures fast and convenient change-over between different

power consumption. The use of tipping over early-warning operating conditions so as to improving working efficiency of the

technology provides high stability and safety of the overall machine.

operation.

Hydraulic system Outriggers Telescopic boom

Control system Engine Lattice jibs

Telescopic system Transmission system Superlift devices

Luffing system Drive/Steer Tower boom

Slewing Axles winch mechanism:

Highly efficient, stable, energy-saving and Safe, stable, advanced and intelligent

adjustable hydraulic system electric control system

Hydraulic system load feedback and constant power control Self-developed controller SYMC specially for engineering

Counterweight Tyres is applied to provide strong lifting capacity and good micro- machinery is configured. The adoption of CAN-bus full-digital

mobility. Unique steering buffer design is adopted to ensure network control technology ensures stable control signal, simple

stable braking operation. harness and high reliability. Timely feedback of data information

can achieve the monitoring of the overall working status in real-

Safety system Brakes system time. The load moment limiter equipped with the comprehensive

intelligent protection system is used with accuracy within 3%

to provide a comprehensive logic and interlock control, thus

ensuring more safe and reliable operation.

Hoist system Electrical system

Quality Changes the World Quality Changes the World

STC550 TruCk Crane STC550 TruCk Crane

6 INTRODUCTION INTRODUCTION 7

Superstructure Superstructure

Cab ■ It is made of safety glass and anti-corrosion steel plate with ergonomic design such as Hoisting system ■ The adoption of pump and motor double variable speed control ensures high efficiency

full-coverage soften interior, panoramic sunroof and adjustable seats etc., and humanized and excellent energy saving functionality. With perfect combination of winch balance valve

design providing more comfortable and relaxing operation experience. The display of load and unique anti-slip technology, heavy load can be lifted and lowered smoothly. Closed

moment limiter integrates main console and operation display system, which clearly show winch brake and winch balance valve effectively prevent imbalance of the hook.

the data of all operating superstructure conditions for lifting operation. ■ One main hook: 610Kg, one auxiliary hook: 90Kg, and the max. lifting height are 55t and

5t.Wire rope of main winch: left-handed wire rope 18-35W×7-1960USZ 220m. Wire rope of

■ High-quality key hydraulic components such as main oil pump, rotary pump, main valve, auxiliary winch: left-handed wire rope 18-35W×7-1960USZ 130m.

Hydraulic system

winch motor and balancing parts etc. are adopted to achieve stable and reliable operation

of the hydraulic system. Superior operation performance is guaranteed by accurate Safety system ■ Load moment limiter: Load moment limiter calculation system based on lifting load

parameter matching. mechanical model is established using an analytical mechanics method with rated lifting

■ Through the adoption of load sensitive variable displacement piston pump, pump accuracy up to ±3% through on-line non-load calibration, providing full protection to lifting

displacement can be adjusted in real-time, achieving high-precision flow control with no operation. In case of overload operation, system will automatically issue an alarm to provide

energy loss during operation. safety protection for manipulation.

■ Main valve has flow compensation and load feedback control function, enabling stable ■ Hydraulic system is configured with the balance valve, overflow valve, and two-way

and convenient control of single action and combined action under different operation hydraulic lock etc. components, thus achieving stable and reliable operation of the

conditions . hydraulic system.

■ Winch adopts the electronically controlled variable motor to ensure high operation ■ Main and auxiliary winches are equipped with over roll-out limiter to prevent over rolling-out

efficiency. Max. single line speeds of main and auxiliary winches is up to 130m/min; of wire rope.

■ Slewing system is equipped with the integrated slewing buffer valve with free slipping ■ Boom and jib ends are equipped with height limiters respectively to prevent over-hoisting of

function to ensure more stable starting and control of the slewing operation and excellent wire rope.

micro-mobility. ■ Boom head is equipped with anemometer and press sensor to indicate the working

■ Hydraulic oil tank capacity: 840L. condition of whole crane in real-time, giving an alarm and cutting off the dangerous action

automatically.

Control system ■ CAN-bus instrument: CAN-bus instrument with a combined intelligent control electrical

system is used for easy reading of the traveling parameters at any time. The engine fault Counterweight ■ Counterweight is 3500kg, no flexible counterweight.

warning function is applied to ensure convenient and fast troubleshooting.

■ With fully security protection system, main and auxiliary winches are equipped with over-

roll out limiter and height limiters to prevent over-rolling out and over-hoisting of steel rope,

including tip-over and limit angle protection.

■ Load moment limiter: The adoption of high intelligent load moment limiter system can Chassis

comprehensively protect lifting operation, ensuring accurate, stable and comfort operation.

Cab ■ Cab is made of new steel structure self-developed by SANY, featuring excellent shock

■ The fault diagnosis system can detect superstructure electricity, hydraulic action, chassis

absorption and tightness, which is configured with swing-out doors at both sides,

(for major safety failure), engine and gearbox for fault to ensure reliable operation of the

pneumatically suspended driver’s seat and passenger’s seat, adjustable steering wheel,

crane.

large rearview mirror, comfortable driver’s chair with a headrest, anti-fog fan, air conditioner,

stereo radio and complete control instruments and meters, providing more comfortable,

Luffing system ■ Dead-weight luffing provides more stable luffing operation at low energy loss. safe and humanized operation experience.

■ Luffing angle:-2°~ 80°.

Carrier frame ■ Designed and manufactured by SANY, anti-torsion box structure is welded by fine-grain

Telescopic system ■ Five-section boom is applied with basic boom length of 11.5m, full-extended boom length high-strength steel plate to provide strong load bearing capacity.

of 43m, jib length of 16m and fully extended boom lifting height of 43.2m respectively.

Max. lifting height is 59.2m including jib. It is made of fine grain high-strength steel with

Axles ■ Axles 3 and 4 are drive axles and axles 1 and 2 are steering axles. The use of welding

U-shaped cross section and with telescopic operation controlled independently by dual-

process for axle housing provides stronger load bearing capacity.

cylinder rope.

Engine ■ Type: Inline six-cylinder, water cooled, supercharged and inter-cooling diesel engine

Slewing system ■ 360° rotation can be achieved with Max. slewing speed of 2r/min., providing stable and

■ Rated power: 250kw/2100r/min

reliable operation of the system. Unique rotary buffer design ensures more stable braking.

■ Environment-protection: Emission complies with EuroⅢ standard

■ Capacity of fuel tank: 350L

Quality Changes the World Quality Changes the World

STC550 TruCk Crane STC550 TruCk Crane

8 INTRODUCTION DIMENSION 9

Chassis

Transmission system ■ Gearbox: Manual gearbox is adopted with 9-gear and large speed ratio range applied,

which meets the requirements of low gradeability speed and traveling at high speed.

■ Transmission shaft: With optimized arrangement of the transmission shaft, the transmission

is stable and reliable. For most optimized transmission, face-tooth coupling transmission

shaft is used with large transmission torque. 13750

11500~43000

Brakes system ■ Air servo brakes are used for all wheels with dual-circuit brake system applied, engine is

equipped with an exhaust brake.

■ Brakes system includes traveling brake, parking brake, emergency brake and auxiliary

brake.

■ Traveling brake: All wheels use the air servo brakes and dual-circuit brake system.

■ Parking brake: Force driven by accumulator is applied on the third to fourth axle.

3650

■ For emergency brake, accumulator is used not only for cutting-off brake but also for

emergency brake.

■ Auxiliary brake is exhaust brake with brake safety ensured while travelling downhill.

18° 12°

Suspension system ■ All axles adopt the plate spring suspension systems with plate spring passed 100,000

fatigue tests and with optimization of performance parameters of the front and rear plate 1395 2750 1450 4000 1350 2250

springs applied to ensure strength and also to provide comfort ridding. 11800

Steering system ■ Hydraulic power mechanical steering systems are applied for axles 1 and 2 with unloading

valve installed in the steering gear.

Drive/Steer ■ 8x4 6000

2850 3150

Outriggers ■ Four-point supporting of the H-shaped outriggers ensures easy operation and strong

stability with Max. span up to 6×7.2m. They are made of fine-grain high-strength steel sheet Ø450

with full hydraulic transverse telescopic outriggers adopted for first and second outriggers

.Vertical cylinder of outrigger adopts bi-directional hydraulic locks to improve safety.

Tyres ■ 12.00R20-20PR×12

Electrical system ■ With 2*12V maintenance-free batteries, the crane power can be cut off manually via

a mechanical master power switch. The use of CAN-bus control system can achieve

information interaction between superstructure and undercarriage.

2730

7200

R14500 R12000

3150 2850

6000

Quality Changes the World Quality Changes the World

STC550 Truck Crane STC550 Truck Crane

10 TECHNICAL PARAMETER OPERATION CONDITION 11

STC550 Working Ranges

Type Item Parameter

Capacity Max. lifting capacity 55 t

Overall length 13750 mm

Overall width 2750 mm 43+16m

60(m)

Overall height 3650 mm 2.4

Dimensions

Axle-1,2 1450 mm 2.0

1.4 70 ~

Axle distance Axle-2,3 4000 mm 1.5

43+9.2 1.2

Axle-3,4 1350 mm m

55

1.0 1.1

Overall weight 42000 kg 0.851.0

3.2 60 ~

2.3

Axle load-1,2 16000 kg 2.7

Axle load 0.85 0.65

Weight Axle load-3,4 26000 kg 1.9 2.2 0.8

2.0

50

Rated power 250 kW/ 2100 rpm 0° 1.8 0.72 0.6

15° 1.7 1.7

30°

Rated torque 1425 N.m/ 1200-1500 rpm

1.4 1.1

Max.traveling speed 85 km/h 43m 1.4 50 ~

0.7 0.55

45

Min.turning radius 12 m 1.1

Turning radius 0.95 0.65

Min.turning radius of boom head 14.5 m

9.0 8.1

Lifting height (m)

Wheel formula 8×4 7.0 6.0 0.75

0.55

Traveling Min.ground clearance 310 mm 5.2

40

4.2

Approach angle 18 ° 35.15m 3.3

Departure angle 12 °

2.6

Max.gradeability 40% 14.0 2.0

35

Fuel consumption per 100km ≤ 45 L 11.7

9.4 1.5

Temperature range – 20 ℃ ~ +40 ℃ 6.6

Min.rated range 3m 5.0 1.15

27.25m

Tail slewing radius of swingtable 4m

30

4.0 0.9

Boom section 5 38 ~

21.0 3.1

0.6

Boom shape U-shaped 18.0 14.0

Main Performance Base boom 1774 kN·m 12.0 2.2

25

9.0

Data Max.lifting moment Full-extend boom 840.8 kN·m 1.7

19.38m 6.3

Full-extend boom+jib 318 kN·m

Base boom 11.5 m 4.7

1.2

Boom length Full-extend boom 43 m

20

15.44m 32.0 29.0 3.5

25.7

Full-extend boom+jib 59 m 21.5

17.0 25 ~

13.7

Outrigger span (Longitudinal×Transversal) 6 × 7.2 m 10.9 2.5 0.8

11.5m 40.0 33.2

Jib offset 0 °,15 °,30 ° 9.0

15

27.5 8.0

Max.single rope lifting speed of main winch (no load) 130 m/min 19.3 1.9

15.0

Max.single rope lifting speed of auxiliary winch (no load) 130 m/min 5.3

15 ~

55.0

Working speed 44.6 11.7 0.5

Full extension/retraction time of boom 120 / 100 s 36.2

10

28.0 9.6

Full lifting/descending time of boom 80 / 80 s 3.5

23.5 1.3

Slewing speed 0~2.0 r/min 19.5

Aircondition in up cab Heating/Cooling

Aircondition

80°

Aircondition in low cab Heating/Cooling

5

0 5 10 15 20 25 30 35(m)

Radius (m)

Quality Changes the World Quality Changes the World

STC550 Truck Crane STC550 Truck Crane

12 LOAD CHART LOAD CHART 13

Unit:Kg Unit:Kg

Prerequisites: Prerequisites:

① Boom operating conditions(fully extended boom length),min. length is 11.5m and max.length is 43m ① Boom operating conditions(fully extended boom length +jib length),max.length is 43m+16m

② The span of outriggers is 6m×7.2m ② The span of outriggers is 6m×7.2m

③ 360°rotation is applied ③ 360°rotation is applied

④ Counterweight is 3.5T ④ Counterweight is 3.5T

Main boom Main boom+Jib

Working range(m) Working range(m) Main boom angle

11.5 15.44 19.38 19.38 27.25 27.25 35.15 35.15 39 39 43 0° 15° 30°

3 55000 40000 32000 21500 3 78° 2400 1450 1000

3.5 50000 40000 32000 21500 3.5 77° 2400 1400 1000

4 44600 40000 32000 21500 4 75° 2300 1300 950

4.5 40000 36000 31000 21500 21000 15000 4.5 73° 2000 1200 850

5 36200 33200 29000 20000 21000 15000 5 71° 1800 1100 850

5.5 32000 30000 27500 19000 21000 14500 5.5 68° 1500 1000 800

6 28000 27500 25700 18100 21000 13700 14000 9000 6 66° 1300 950 760

6.5 25800 25500 23900 17500 19500 12800 14000 9000 6.5 63° 1100 850 720

7 23500 23200 21500 17000 18000 12100 14000 9000 11500 9000 7 61° 950 750 650

7.5 21400 21200 18600 16200 16800 11500 13500 8500 11500 9000 7.5 58° 650 600 550

8 19500 19300 17000 15600 15800 11000 12700 8500 11000 9000 9000 8 56° 500

9 15300 15000 13700 13800 14000 10000 11700 7800 10500 8500 8500 9 Min.elevation angle 55º

10 11700 10900 12000 12000 9000 10700 7100 10000 8000 8100 10

11 9600 9000 10600 9900 8200 9400 6400 9000 7500 7800 11

12 8000 8000 8700 9000 7500 8500 5800 8000 7000 7000 12

Unit:Kg

14 5300 6400 6300 6100 6600 5000 6300 5900 6000 14

16 3500 4600 4700 5000 5000 4400 5000 5000 5200 16 Prerequisites:

18 3500 4100 4000 3800 4000 4000 4200 18 ① Boom operating conditions(fully extended boom length +jib length),max.length is 43m+9.2m

② The span of outriggers is 6m×7.2m

20 2500 3000 3100 3200 3200 3500 3300 20 ③ 360°rotation is applied

22 1900 2300 2200 2700 2400 2800 2600 22 ④ Counterweight is 3.5T

24 1300 1800 1700 2400 1800 2100 2000 24

Main boom+Jib

26 1200 1900 1300 1650 1500 26 Main boom angle

0° 15° 30°

28 800 1500 900 1300 1150 28

78° 3500 2400 2000

30 500 1000 600 900 900 30

77° 3200 2300 1900

32 800 600 600 32

75° 3000 2200 1800

34 400 34

73° 2700 2000 1700

Number of lines 12 10 8 8 6 6 4 4 4 4 3 Number of lines

71° 2500 1800 1600

Telescoping condition(%)

68° 2200 1700 1400

Modes Ⅰ,Ⅱ Ⅰ Ⅰ Ⅱ Ⅰ Ⅱ Ⅰ Ⅱ Ⅰ Ⅱ Ⅰ,Ⅱ Modes

66° 2000 1500 1300

2nd boom 0 50 100 0 100 0 100 0 100 50 100 2nd boom

63° 1800 1400 1100

3rd boom 0 0 0 33 33 66 66 100 83.3 100 100 3rd boom

61° 1500 1200 950

4th boom 0 0 0 33 33 66 66 100 83.3 100 100 4th boom

58° 1100 950 750

Top boom 0 0 0 33 33 66 66 100 83.3 100 100 Top boom

56° 700 650 550

Min.elevation angle 55°

1. Values listed in the table refer to rated lifting capacity measured at flat and solid gound under the lever state of the crane.

2. Value above heavy line shall be determined by strength of the crane and under this line shall be determined by stability of the crane.

3. Rated load values determined by stability shall comply with ISO 4305.

4. Rated lifting capacity listed in the table includes weights of lifting hooks (610kg of main hook and 90kg of auxiliary hook)and hangers.

5. Rated lifting capacity with pulley at boom tip shall not exceed 4000kg and then substracts(230kg)to gain rated lifting capacity if the boom is

used to lift after the installation of jib.

6. If actual boom length and range are between two values specified in the table, larger value will determine the lifting capacity.

Quality Changes the World Quality Changes the World

STC550 Truck Crane

14 WHEEL CRANE FAMILY MAP

Quality Changes the World

Quality Changes the World

SANY AUTOMOBILE HOISTING MACHINERY

address: SanY Industrial Park, Jinzhou Development Zone, Distributed By:

Changsha, Hunan, China.

Service Hotline: 4006098318

email: crd@sany.com.cn

For more information, please visit: www.sanygroup.com

For our consistent improvement in techonology, specifications may change without notice.

The machines illustrated may show optional equipment which can be supplied at additional cost.

You might also like

- ITP ForkliftDocument6 pagesITP ForkliftAdven Tius Surya SurbaktiNo ratings yet

- Bosch Vp37 PumpsDocument32 pagesBosch Vp37 PumpsLuís Fidalgo92% (13)

- ZYC120Document10 pagesZYC120Bagus KorneliusNo ratings yet

- FORMULA 1 Cars - Albo Motori F1Document116 pagesFORMULA 1 Cars - Albo Motori F1Alex BearcatNo ratings yet

- Material PropertiesDocument2 pagesMaterial PropertiesSyahri MaryadiNo ratings yet

- 25 Ton Load ChartDocument1 page25 Ton Load ChartTaufik Singgih100% (5)

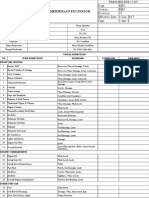

- F-MNASRG-EHS-17-072 - Form Pemeriksaan Inspeksi Excavator Rev.01Document2 pagesF-MNASRG-EHS-17-072 - Form Pemeriksaan Inspeksi Excavator Rev.01Leo FirstsonNo ratings yet

- Lifting Plan Pipa (25 Ton)Document3 pagesLifting Plan Pipa (25 Ton)Ryan Burnang Purba0% (1)

- Sertifikat SanyDocument7 pagesSertifikat Sanyryo asg3No ratings yet

- SPO2812 Eng 03 306420309Document3 pagesSPO2812 Eng 03 306420309Shane LinNo ratings yet

- Berdikari - Jsa Dismantle CraneDocument12 pagesBerdikari - Jsa Dismantle CraneHSE PT BPPNo ratings yet

- Contoh LIfting Plan #3Document2 pagesContoh LIfting Plan #3jonser gultom100% (3)

- Format Monitoring CuacaDocument21 pagesFormat Monitoring CuacaBistok SimbolonNo ratings yet

- Contoh Jsa Mobile CraneDocument7 pagesContoh Jsa Mobile CraneEry FosilNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.004Document7 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.004Yosua SitumorangNo ratings yet

- Tower Crane Daily Inspection Form PDFDocument1 pageTower Crane Daily Inspection Form PDFMd Imteyaz AnsariNo ratings yet

- Lifting Plan Mobilisasi TMCDocument9 pagesLifting Plan Mobilisasi TMCbobby100% (1)

- Inspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice BoomDocument4 pagesInspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice Boomrizal mubarokNo ratings yet

- Daily Crane Inspection Report Laporan Pemeriksaan Crane HarianDocument1 pageDaily Crane Inspection Report Laporan Pemeriksaan Crane HarianIan Mardiansyah100% (1)

- D85ess P2uDocument1 pageD85ess P2uTyler GoodwinNo ratings yet

- Load Charts 17Document53 pagesLoad Charts 17Doddy IndrawanNo ratings yet

- Catalogue SWRK55.Document10 pagesCatalogue SWRK55.daryonoNo ratings yet

- A. SOP Lifting & Handling KontainerDocument9 pagesA. SOP Lifting & Handling KontainerMuhammad Ali FahrudinNo ratings yet

- Form Inspeksi Tower CraneDocument2 pagesForm Inspeksi Tower CraneAnnisa Agustina100% (1)

- Form Check List Inspeksi CompactorDocument1 pageForm Check List Inspeksi CompactorAndro KTechNo ratings yet

- PS Checklist Motor GraderDocument1 pagePS Checklist Motor Graderyogi ganda pratamaNo ratings yet

- Standard Lifting Plan: Doc. Number (No. Dokumen) Rev. Number (No. Revisi) Date (Tanggal) Sheet (Lembar)Document2 pagesStandard Lifting Plan: Doc. Number (No. Dokumen) Rev. Number (No. Revisi) Date (Tanggal) Sheet (Lembar)rasinandamrizal 14100% (1)

- JSA Insulation OKI 18-07-2016Document9 pagesJSA Insulation OKI 18-07-2016FerdyCodetzNo ratings yet

- Cheklist SOP Drilling Rig Bore PileDocument1 pageCheklist SOP Drilling Rig Bore PileHaidar AliNo ratings yet

- Daily Checklist TMC R.001Document2 pagesDaily Checklist TMC R.001Maulana Yusuf100% (1)

- JSA - 017# PengecoranDocument6 pagesJSA - 017# PengecoranGoldwin Ricky AritonangNo ratings yet

- Struktur Organisasi QHSE PMME 1Document1 pageStruktur Organisasi QHSE PMME 1Abdee Prinzen WidyaNo ratings yet

- (HSE-ForM-A.05) Form Inspection Rough Terrain CraneDocument6 pages(HSE-ForM-A.05) Form Inspection Rough Terrain CraneIvansyah Sastrowardoyo100% (2)

- Op11 k3 Form Hse Performance ReportDocument83 pagesOp11 k3 Form Hse Performance ReportBambangNo ratings yet

- JSA - Installation Mini Platform CPP AreaDocument9 pagesJSA - Installation Mini Platform CPP AreaBayu SetiawanNo ratings yet

- LIFTING PLAN Crane 7tonDocument1 pageLIFTING PLAN Crane 7tonSeftian Muhardy100% (1)

- Form Hazard Report by NadaDocument1 pageForm Hazard Report by NadaNada SantikaNo ratings yet

- 4 - JSA Installation HDPE PIPE UG 311019Document10 pages4 - JSA Installation HDPE PIPE UG 311019RezkyNo ratings yet

- Laporan Progress Minggu Ke 2Document2 pagesLaporan Progress Minggu Ke 2Cak NhassNo ratings yet

- Load Chart FT 5 TonDocument1 pageLoad Chart FT 5 TonHerman HutabaratNo ratings yet

- Klasifikasi Pesawat Angkat Dan Pesawat Angkut: Oleh: Arief SuponoDocument80 pagesKlasifikasi Pesawat Angkat Dan Pesawat Angkut: Oleh: Arief SuponoAhmad MultidasaNo ratings yet

- JSA Install Pipe SupportDocument6 pagesJSA Install Pipe Supportem_we19No ratings yet

- SDS - Flobas NF-15Document3 pagesSDS - Flobas NF-15reginaulfahNo ratings yet

- HIRADC UNLOADING STEEL STRUCTURE Rev 1Document36 pagesHIRADC UNLOADING STEEL STRUCTURE Rev 1Herman SyahNo ratings yet

- Itp (Inspection Test Plan) - Kel 2 - Tower CraneDocument4 pagesItp (Inspection Test Plan) - Kel 2 - Tower Craneجحفر نیرومندNo ratings yet

- JSA NEW FORM - Penarikan Kabel FO 37Document6 pagesJSA NEW FORM - Penarikan Kabel FO 37Muchamad SalafudinNo ratings yet

- FC 4.1.31 - Crawler Crane Checklist FormDocument2 pagesFC 4.1.31 - Crawler Crane Checklist Formkhrayzie bhoneNo ratings yet

- Technical Specifications: Zoomlion Ztc550R Truck CraneDocument28 pagesTechnical Specifications: Zoomlion Ztc550R Truck CraneShahar QureshiNo ratings yet

- PDF Form Inspeksi Crane PancangDocument2 pagesPDF Form Inspeksi Crane PancangQadriani BaharuddinNo ratings yet

- Brochure Specification Zoomlion ZCC550H (55 Ton)Document12 pagesBrochure Specification Zoomlion ZCC550H (55 Ton)apray aprayNo ratings yet

- Air Instrument System Utilities Pertamina Ru Iv Project Pt. Wijaya Karya Industri & Konstruksi Form Inspeksi Peralatan KerjaDocument1 pageAir Instrument System Utilities Pertamina Ru Iv Project Pt. Wijaya Karya Industri & Konstruksi Form Inspeksi Peralatan KerjaDeny Prasetya100% (1)

- Karmand K - 404 CGDocument5 pagesKarmand K - 404 CGNokus itsmeNo ratings yet

- JSA-010-Road & PavingDocument7 pagesJSA-010-Road & PavingRendra ArNo ratings yet

- Form InspeksiDocument102 pagesForm InspeksiEkoleksonoNo ratings yet

- Form Inspeksi ScissorsDocument4 pagesForm Inspeksi ScissorsSafety Duta KaryaNo ratings yet

- Job Safety Analysis - Soil Test Investigation / SONDIR: Pt. Makmur Sejahtera Wisesa Pt. Graha Usaha TeknikDocument3 pagesJob Safety Analysis - Soil Test Investigation / SONDIR: Pt. Makmur Sejahtera Wisesa Pt. Graha Usaha TeknikAry ManNo ratings yet

- SL6000 Load ChartDocument12 pagesSL6000 Load ChartkinskiNo ratings yet

- Unloading, Lifting and Install Panel r1Document18 pagesUnloading, Lifting and Install Panel r1Nurdin Sudrajat SasrabahuNo ratings yet

- Lamp 11 - Form Tailgate Meeting OkDocument1 pageLamp 11 - Form Tailgate Meeting OkMuly AdiNo ratings yet

- Sertifikat Fire Fighting PDFDocument1 pageSertifikat Fire Fighting PDFSyamsuddin DidinNo ratings yet

- Industrial Valves: 150/300UTDZ (M) (G-150UTDZ (M) ) 150/300UTAZM 300UTDZ (M) (G-300UTDZ (M) ) 150/300UTDRZ (M)Document2 pagesIndustrial Valves: 150/300UTDZ (M) (G-150UTDZ (M) ) 150/300UTAZM 300UTDZ (M) (G-300UTDZ (M) ) 150/300UTDRZ (M)EnyNo ratings yet

- ITP ForkliftDocument3 pagesITP ForkliftAris100% (2)

- Stc600 Truck Crane 60 Tons Lifting Capacity: Quality Changes The WorldDocument9 pagesStc600 Truck Crane 60 Tons Lifting Capacity: Quality Changes The WorldFelipe50% (2)

- Truck Crane stc500 PDFDocument9 pagesTruck Crane stc500 PDFMohamed FathyNo ratings yet

- Manuale Carrello A Gas 1.5-3.5 Tonnellate GRENDiA ESDocument17 pagesManuale Carrello A Gas 1.5-3.5 Tonnellate GRENDiA ESryo asg3No ratings yet

- Grendia Ex New-Generation Internal Combustion 3.5-5.5-Ton Forklift TruckDocument3 pagesGrendia Ex New-Generation Internal Combustion 3.5-5.5-Ton Forklift Truckryo asg3No ratings yet

- Counterbalanced Forklift 5,000/7,000 Lb. Capacity: D+ Series LPG Forklift Truck KBG25/35Document4 pagesCounterbalanced Forklift 5,000/7,000 Lb. Capacity: D+ Series LPG Forklift Truck KBG25/35ryo asg3No ratings yet

- Truck Loader Crane: For Heavy-Duty VehicleDocument2 pagesTruck Loader Crane: For Heavy-Duty Vehicleryo asg3No ratings yet

- Truck Loader Crane: For Heavy-Duty VehicleDocument2 pagesTruck Loader Crane: For Heavy-Duty Vehicleryo asg3No ratings yet

- BR-CX50 Emi-002 201803Document12 pagesBR-CX50 Emi-002 201803ryo asg3No ratings yet

- Spesifikasi TadanoDocument10 pagesSpesifikasi Tadanoryo asg3No ratings yet

- Toyota 7-FD35 PDFDocument12 pagesToyota 7-FD35 PDFryo asg350% (2)

- Kobelco Rough Terrain Cranes Spec F6aba9Document12 pagesKobelco Rough Terrain Cranes Spec F6aba9ryo asg3No ratings yet

- Highlights ESI (Tronic) 2.0 Vehicle Coverage ESI (Tronic) 2.0 UpdatesDocument2 pagesHighlights ESI (Tronic) 2.0 Vehicle Coverage ESI (Tronic) 2.0 UpdatesYogendra DwivediNo ratings yet

- Motorcycle Aerodynamics - Canada Moto GuideDocument17 pagesMotorcycle Aerodynamics - Canada Moto GuideangelthingNo ratings yet

- Scorpio Case Study: Prepared by - Samir Lad, Nilesh Gokhale, Vinod Seelan, Noel Crasta, Babu Anthony & Alok NagDocument21 pagesScorpio Case Study: Prepared by - Samir Lad, Nilesh Gokhale, Vinod Seelan, Noel Crasta, Babu Anthony & Alok Nagjatinmevada1No ratings yet

- War Field Spying Robot With Night Vision Wireless CameraDocument3 pagesWar Field Spying Robot With Night Vision Wireless CameraMaruthi JacsNo ratings yet

- Analysis of Fleet Replacement Lifecycle: Project #12-14Document19 pagesAnalysis of Fleet Replacement Lifecycle: Project #12-14Juan Carlos Briceño GuevaraNo ratings yet

- 4 W MFCS Frachise Concept CDocument29 pages4 W MFCS Frachise Concept CMahendra Tyre Works RaigarhNo ratings yet

- Radia PioneeerDocument2 pagesRadia PioneeersdfgfghgfgbNo ratings yet

- List Gear MotorDocument1 pageList Gear MotorSuyantoNo ratings yet

- Essex Industries Platform-Controls-Aircraft-Components-CatalogDocument11 pagesEssex Industries Platform-Controls-Aircraft-Components-CatalogRJ AdamsNo ratings yet

- British Endurance Machinery ManualDocument288 pagesBritish Endurance Machinery ManualCarlos Henrique SouzaNo ratings yet

- Vechile Price DetailsDocument1 pageVechile Price Detailsvikky.tphNo ratings yet

- JLG 800S Manual de PartesDocument456 pagesJLG 800S Manual de PartesfernandoNo ratings yet

- Exedy Product ListDocument8 pagesExedy Product Listguillermo bravoNo ratings yet

- Complete The Puzzle. The Answers Are All Words From This UnitDocument2 pagesComplete The Puzzle. The Answers Are All Words From This UnitPhạm Quang DuyNo ratings yet

- Petunjuk Pengisian Lampiran Work OrderDocument7 pagesPetunjuk Pengisian Lampiran Work OrderDony ArifNo ratings yet

- G 1.1 Sohc-01Document1 pageG 1.1 Sohc-01Luis GarcíaNo ratings yet

- MiscellaneousDocument59 pagesMiscellaneousมาโนช ซิ่งตู้No ratings yet

- Full-Floating vs. Semi-Floating - Axle TechDocument13 pagesFull-Floating vs. Semi-Floating - Axle TechvamsiNo ratings yet

- Answer KeyDocument5 pagesAnswer Keyyuvaraja sNo ratings yet

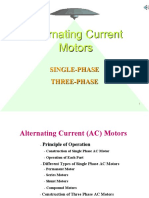

- Alternating Current Motors: Single-Phase Three-PhaseDocument56 pagesAlternating Current Motors: Single-Phase Three-Phaseeyd bartulabaNo ratings yet

- KNEX Star Wars Millennium FalconDocument44 pagesKNEX Star Wars Millennium FalconfrankiemassinghamNo ratings yet

- Module 5-Multi-Stage Air CompressorDocument26 pagesModule 5-Multi-Stage Air Compressoramit3184No ratings yet

- Textran TDH Premium: Universal Tractor Transmission OilDocument3 pagesTextran TDH Premium: Universal Tractor Transmission OilRobert RobertsNo ratings yet

- Tasplgd6346 1 V.KDocument8 pagesTasplgd6346 1 V.KPragnesh PrajapatiNo ratings yet

- Ot5304 Subsea Construction & Operational Support Assignment 1 Research of Autonomous Underwater Vehicles TechnologiesDocument40 pagesOt5304 Subsea Construction & Operational Support Assignment 1 Research of Autonomous Underwater Vehicles TechnologiesWeilun OngNo ratings yet

- Catalogo Pfi 2016 PDFDocument611 pagesCatalogo Pfi 2016 PDFConrado InsignaresNo ratings yet

- 4runner 1998Document350 pages4runner 1998Felix SimãoNo ratings yet