Single Core Thermosetting Insulated LSF Wiring Cables

Single Core Thermosetting Insulated LSF Wiring Cables

Uploaded by

Ognjen BiočaninCopyright:

Available Formats

Single Core Thermosetting Insulated LSF Wiring Cables

Single Core Thermosetting Insulated LSF Wiring Cables

Uploaded by

Ognjen BiočaninOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Single Core Thermosetting Insulated LSF Wiring Cables

Single Core Thermosetting Insulated LSF Wiring Cables

Uploaded by

Ognjen BiočaninCopyright:

Available Formats

SINGLE CORE THERMOSETTING INSULATED LSF WIRING CABLES

Type H05Z-U , H07Z- U, HO7Z- R Applications These types of Cables are having

self-extinguishing behaviour

Reference BS 7211: 98 without halogenidric acids emission.

Standards Furthermore toxic and corrosive gases

and smoke evolution is reduced to

Construction 1) Oxygen Free Electronic very low level. These characteristics

Copper Conductor make this ideal for usage where safety

2) Thermosetting / LSF behaviour is important at public places SINGLE CORE THERMOSETTING INSULATED SHEATHED LSF CABLES

Insulation in case of fire.

Reference BS 7211: 98 Applications These types of Cables are having

Technical Max. Operating Temperature: 90ºC Standards self-extinguishing behaviour

without halogenidric acids emission.

Data Rated Voltage: 300/500 V H05Z-U

Construction 1) Oxygen Free Electronic Furthermore toxic and corrosive gases

Packing In rolls of 100 yards, spools, 450/750 V H07Z- U, HO7Z- R, and smoke evolution is reduced to

drums or as per customer Copper Conductor very low level. These characteristics

requirements. Requirements Oxygen index - Minimum 30 2) Thermosetting / LSF make this ideal for usage where safety

for LSF Cables Smoke density - Maximum 60% Insulation behaviour is important at public places

Acid gas - Maximum 0.5% by 3) LSF Sheath in case of fire

weight

Technical Max. Operating Temperature: 90ºC

Data Rated Voltage: 300/500 V

Packing In rolls of 100 yards, spools,

NOMINAL CROSS CLASS OF INSULATION MAX. OVERALL APPROX. NET STANDARD drums or as per customer Requirements Oxygen index - Minimum 30

SECTION COPPER THICKNESS DIAMETER WEIGHT LENGTH requirements. for LSF Cables Smoke density - Maximum 60%

CON-

DUCTOR Acid gas - Maximum 0.5% by

(mm2) (mm) (mm) (kg/km) weight

H05Z-U 300/500 V Yards

0.50 1 0.6 2.3 9 100

0.75 1 0.6 2.5 11 100 NOMINAL

CLASS OF COPPER INSULATION SHEATH MAX. OVERALL APPROX.

1.00 1 0.6 2.7 14 100 CROSS

CONDUCTOR THICKNESS THICKNESS DIAMETER NET WEIGHT

H07Z-U 450/750 V SECTION

1.5 1 0.7 3.2 21 100

(mm2) (mm) (mm) (mm) (kg/km)

2.5 1 0.8 3.9 32 100

4.0 1 0.8 4.4 47 100 1.0 1 0.7 0.8 4.8 28

6.0 1 0.8 5.0 66 100 1.0 2 0.7 0.8 4.9 28

H07Z-R 450/750 V 1.5 1 0.7 0.8 5.0 36

1.5 2 0.7 3.3 21 100 1.5 2 0.7 0.8 5.2 36

2.5 2 0.8 4.0 32 100 2.5 1 0.7 0.8 5.5 50

4.0 2 0.8 4.6 47 100

2.5 2 0.7 0.8 5.6 51

6.0 2 0.8 5.2 66 100

4 1 0.7 0.8 6.0 72

Meters

10 2 1.0 6.7 110 300 4 2 0.7 0.9 6.4 75

16 2 1.0 7.8 170 300 6 1 0.7 0.9 6.8 95

25 2 1.2 8.2 255 1000 6 2 0.7 0.9 7.1 98

35 2 1.2 9.3 345 1000 10 2 0.7 0.9 8.1 150

50 2 1.4 10.9 470 1000 16 2 0.7 0.9 9.2 220

70 2 1.4 12.6 665 1000 25 2 0.9 1.0 11.4 300

95 2 1.6 14.7 920 1000

35 2 0.9 1.1 12.8 400

120 2 1.6 16.2 1150 1000

150 2 1.8 17.8 1415 1000

185 2 2.0 20.1 1765 1000

240 2 2.2 22.8 2310 1000

300 2 2.4 25.3 2890 1000

400 2 2.6 29.0 3685 1000

500 2 2.8 32.2 4700 1000

630 2 2.8 35.4 6000 500

10 11

You might also like

- ICICI Business Model and InnovationDocument28 pagesICICI Business Model and InnovationVenkatesan Jayaraman33% (3)

- BS PhysicsDocument37 pagesBS Physicsmustafaphy100% (1)

- Kablovi Katalog 5Document1 pageKablovi Katalog 5Ognjen BiočaninNo ratings yet

- Price List (SQ) PDFDocument12 pagesPrice List (SQ) PDFjamil100% (2)

- Online Catalogue PDFDocument4 pagesOnline Catalogue PDFmnmNo ratings yet

- FirestopFS110FlexibleSDI 1Document3 pagesFirestopFS110FlexibleSDI 1pcctschNo ratings yet

- Surface Mount - 200W SMF SeriesDocument6 pagesSurface Mount - 200W SMF Seriesm3y54mNo ratings yet

- Instrumentation Cable Gen. To EN 50288-7Document4 pagesInstrumentation Cable Gen. To EN 50288-7Shashank SaxenaNo ratings yet

- Fire Stop Fs 110 Stranded Conductor SdiDocument3 pagesFire Stop Fs 110 Stranded Conductor SdipcctschNo ratings yet

- Instrumentation Cable Gen. To EN 50288-7Document4 pagesInstrumentation Cable Gen. To EN 50288-7Shashank SaxenaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Cable Profibus DP ABBDocument8 pagesCable Profibus DP ABBEdwin GallegosNo ratings yet

- Cable Ls SFTPDocument2 pagesCable Ls SFTPLuis Alberto YarangaNo ratings yet

- Catalog Leoni CableDocument2 pagesCatalog Leoni CablesubodhNo ratings yet

- Pg060 - Coaxial RG LSHF Series & 540 Trunk Cable LSHFDocument1 pagePg060 - Coaxial RG LSHF Series & 540 Trunk Cable LSHFDolyNo ratings yet

- Astel Digital RG179Document3 pagesAstel Digital RG179Faiz BajwaNo ratings yet

- 12 Topcable Toxfree ZH RZ1MZ1-K AsDocument2 pages12 Topcable Toxfree ZH RZ1MZ1-K AsGabriel A. Gabriel MarmolejosNo ratings yet

- Listed Gel Free LSZH LT Cable LL SeriesDocument2 pagesListed Gel Free LSZH LT Cable LL SeriesAmir SalahNo ratings yet

- B&K Cables and Accessories For AcceleromtersDocument21 pagesB&K Cables and Accessories For AcceleromtersCleidimar NardiNo ratings yet

- SM6T Series: Rans ORBDocument5 pagesSM6T Series: Rans ORBАлексейNo ratings yet

- Disable System AlternativeDocument7 pagesDisable System AlternativeIbrahim MohamedNo ratings yet

- Cu-XLPE-IS or OS or IS OS-LSZH-TCWB or GSWB-LSZH 150-250 VDocument2 pagesCu-XLPE-IS or OS or IS OS-LSZH-TCWB or GSWB-LSZH 150-250 VAntzela ThimoNo ratings yet

- SM6T Series: Rans ORBDocument5 pagesSM6T Series: Rans ORBasam youssefNo ratings yet

- FPPLUSFlexPrysmian Cablu Tabel Si NR - TelefonDocument2 pagesFPPLUSFlexPrysmian Cablu Tabel Si NR - TelefonMircea Stefan IovNo ratings yet

- Power Splitter/Combiner: PSC-3-1W+ PSC-3-1WDocument1 pagePower Splitter/Combiner: PSC-3-1W+ PSC-3-1WRedNo ratings yet

- Heat Shrink Joints To Suit Low Voltage Cables Type XLPE SWA PVC 0.6 3.3kVDocument1 pageHeat Shrink Joints To Suit Low Voltage Cables Type XLPE SWA PVC 0.6 3.3kVAl HakkimNo ratings yet

- Cu Mica Xlpe Os Swa LSHFDocument2 pagesCu Mica Xlpe Os Swa LSHFNabeelNo ratings yet

- Hoja Tecnica RG 58 BeldenDocument2 pagesHoja Tecnica RG 58 Beldenapi-19911369No ratings yet

- Auto 125 CableDocument1 pageAuto 125 CableKristaNo ratings yet

- RCF12-50JFN (Becker Smartcom 450 Cable)Document3 pagesRCF12-50JFN (Becker Smartcom 450 Cable)Erich KnoopNo ratings yet

- GTP For 1CX300sqmmDocument4 pagesGTP For 1CX300sqmmpriyanka236No ratings yet

- Category 6 250Mhz Gel Filled Outdoor Lan CableDocument2 pagesCategory 6 250Mhz Gel Filled Outdoor Lan Cablesoulkidnyc4920No ratings yet

- Brosur Kabel Data BeldenDocument2 pagesBrosur Kabel Data BeldenwongantengharryNo ratings yet

- Multi Pair Fiber Cable Technical Data SheetsDocument3 pagesMulti Pair Fiber Cable Technical Data Sheetsprasadi.ariyadasaNo ratings yet

- Instrumentation Cable Gen. To EN 50288-7Document4 pagesInstrumentation Cable Gen. To EN 50288-7Shashank SaxenaNo ratings yet

- Bohler Uddeholm Brochure PDFDocument4 pagesBohler Uddeholm Brochure PDFMilos StoisavljevicNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 300 VDocument3 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 300 VRijo RajanNo ratings yet

- Is 17048Document34 pagesIs 17048Ashish bhattNo ratings yet

- Cat7 SFTP Cable CC7SFBLL5Document5 pagesCat7 SFTP Cable CC7SFBLL5andrei.iooNo ratings yet

- SXL CableDocument1 pageSXL CableVijay KarthikeyanNo ratings yet

- Flexible Single Core Cables: SeriesDocument1 pageFlexible Single Core Cables: SeriespcctschNo ratings yet

- WP9C611TDocument1 pageWP9C611TChristian Camilo Suarez RodriguezNo ratings yet

- Os1 Os2 Single Mode Enhanced PigtailDocument5 pagesOs1 Os2 Single Mode Enhanced PigtailAli KamelNo ratings yet

- SAM5Document40 pagesSAM5Itimatdelici MakinalarNo ratings yet

- S3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorDocument4 pagesS3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General Semiconductormahbub metulNo ratings yet

- RK CableDocument1 pageRK CableKristaNo ratings yet

- Topcable Catalogue Eng 2018-138-140Document3 pagesTopcable Catalogue Eng 2018-138-140Kevin RojasNo ratings yet

- Belden P/N 50106F: Industrial CAT 6 F/UTPDocument2 pagesBelden P/N 50106F: Industrial CAT 6 F/UTPAsep heriyanaNo ratings yet

- Chemtuff Sdi BFX: Flexible Single Core CablesDocument1 pageChemtuff Sdi BFX: Flexible Single Core CablespcctschNo ratings yet

- S5000 Data Sheet PDFDocument2 pagesS5000 Data Sheet PDFAnonymous X3PnFL6No ratings yet

- 50106U Category 6 UTP TDS - Belden - V2Document2 pages50106U Category 6 UTP TDS - Belden - V2Sugeng WahyudiNo ratings yet

- Av02 1508en - Ds - HFBR Rxxyyyz - 2016 02 18Document11 pagesAv02 1508en - Ds - HFBR Rxxyyyz - 2016 02 18Anonymous dGFqrw5vONo ratings yet

- Ul 1569 Awg 26 Atc WireDocument1 pageUl 1569 Awg 26 Atc WireDheerendra KumarNo ratings yet

- 2c +e (Flame Retardant)Document3 pages2c +e (Flame Retardant)raviroj SOMVADEENo ratings yet

- Auto 100 CableDocument1 pageAuto 100 CableVijay KarthikeyanNo ratings yet

- Rs3A, Rs3B, Rs3D, Rs3G, Rs3J, Rs3K: Vishay General SemiconductorDocument4 pagesRs3A, Rs3B, Rs3D, Rs3G, Rs3J, Rs3K: Vishay General Semiconductormainastanely317No ratings yet

- Unicon WiresDocument12 pagesUnicon WiresRzeus AdigueNo ratings yet

- RE-2X(ST)YSWAY-flDocument3 pagesRE-2X(ST)YSWAY-flabhishekNo ratings yet

- Cu Mica Xlpe Is Os Swa LSHFDocument2 pagesCu Mica Xlpe Is Os Swa LSHFNabeelNo ratings yet

- Kerpen 10px1 5 Is-Os En50288-7Document3 pagesKerpen 10px1 5 Is-Os En50288-7Rijo RajanNo ratings yet

- CSC 312 System Modelling Using UML Practice Exercises: Case Study: A Video Rental SystemDocument4 pagesCSC 312 System Modelling Using UML Practice Exercises: Case Study: A Video Rental SystemKc MamaNo ratings yet

- From Sylvinite by Fractional Crystallization (Keyes)Document6 pagesFrom Sylvinite by Fractional Crystallization (Keyes)nikaiNo ratings yet

- E-Mail Indeminty FormDocument2 pagesE-Mail Indeminty Formabdullahimuhammad2580No ratings yet

- Time Definite: DHL ExpressDocument4 pagesTime Definite: DHL ExpressAdventcia Tesha ParamithaNo ratings yet

- How To Prepare General Awareness For SSC CGLDocument7 pagesHow To Prepare General Awareness For SSC CGLreshmaNo ratings yet

- DLL World Religion 2nd Grading 6Document2 pagesDLL World Religion 2nd Grading 6Ruth Baguhin100% (1)

- Intermediate Microeconomics - Summary FKDocument27 pagesIntermediate Microeconomics - Summary FKFrédéric KrögerNo ratings yet

- Final BBA (CA) - Structure - UpdatesDocument8 pagesFinal BBA (CA) - Structure - UpdatesYogeshNo ratings yet

- Installing and Configuring Avaya Wireless Handsets 3700 in Avaya Aura Sip Environment 5-11-2023Document38 pagesInstalling and Configuring Avaya Wireless Handsets 3700 in Avaya Aura Sip Environment 5-11-2023Prin MayaoNo ratings yet

- Elect Eng CoursesDocument2 pagesElect Eng CoursesJohnsonNo ratings yet

- JWC PDFDocument8 pagesJWC PDFJH_ProjectNo ratings yet

- Nature Magazine - 12 February 2015Document265 pagesNature Magazine - 12 February 2015kamasanisNo ratings yet

- Andinet CV For SurveyorDocument3 pagesAndinet CV For Surveyorandinet044No ratings yet

- Settlement of Circular Footing On SandDocument26 pagesSettlement of Circular Footing On SandninoronaldNo ratings yet

- Depository Financial InstitutionsDocument3 pagesDepository Financial Institutionssamuel kebedeNo ratings yet

- Biology For Engineers Important QuestionsDocument15 pagesBiology For Engineers Important QuestionsNeelam PavanNo ratings yet

- Coilgun BlueprintsDocument9 pagesCoilgun Blueprintsjumpupdnbdj100% (1)

- NOTICE and LETTER TO EDITORDocument7 pagesNOTICE and LETTER TO EDITORRitika KharbandaNo ratings yet

- Wrkout Brand GuideDocument157 pagesWrkout Brand Guidererollaccgame2No ratings yet

- Internalisasi Core Value BerAKHLAK BPSDM Jatim - HODocument48 pagesInternalisasi Core Value BerAKHLAK BPSDM Jatim - HOBudi Susanto100% (1)

- Paper GHS formENDocument4 pagesPaper GHS formENF RNo ratings yet

- Unit-3 - Transport LayerDocument65 pagesUnit-3 - Transport LayerPrit PatelNo ratings yet

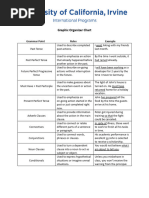

- Graphic Organizer ChartDocument1 pageGraphic Organizer Chartcode.ayechanNo ratings yet

- 100DSV CatalogueDocument8 pages100DSV CatalogueMachani OmkarNo ratings yet

- 4 - Conceptual Framework: Elements of Financial StatementsDocument7 pages4 - Conceptual Framework: Elements of Financial Statementsagm25No ratings yet

- Chapter One: Introduction To Survey EngineeringDocument51 pagesChapter One: Introduction To Survey EngineeringStudy ChillNo ratings yet

- CV+Atos+Syntel+2 2+yrsDocument2 pagesCV+Atos+Syntel+2 2+yrsTHE UNCHANGED ONENo ratings yet

- Hsslive XI 1 +1 Physics Full Chapters-2025Document16 pagesHsslive XI 1 +1 Physics Full Chapters-2025Fizan Bin FaisalNo ratings yet