Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Rijwan MohammadCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Rijwan MohammadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Rijwan MohammadCopyright:

Available Formats

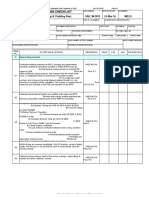

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.

01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General requirements

All weld documents shall be submitted to SA for technical approval

prior to start of work (per SAEP-352). The Welding documents

SAES-W-010,

include the Welding Procedure Specifications (WPS), Qualification

A1 Section 7.1.1 &

Test Records (PQR), Weld Description & Weld Map (Attachment 3)

7.1.9

See Attachment 1.

Originals of all test records, mill certificates, etc. including records

SAES-W-010,

A2 from independent test laboratory shall be made available for review

Para. 7.1.11

by Saudi Aramco upon request.

WPSs, PQRs, Weld Maps, & Weld Descriptions shall be available at SAES-W-010,

A3

work site for verification at any time by authorized SA inspector. Para. 7.1.8

For shop fabrication In-Kingdom and all field fabrication and

installation, the Welding Procedure Specifications (WPSs) and

Procedure Qualification Records (PQRs) shall be prepared as per

SAES-W-010,

A4 format of ASME Section IX (NMA App. B). See Attachment 2.

Para. 7.1.3

Commentary Note: Standardized PQR forms from an approved

independent test laboratory are acceptable. Equivalent WPS form

from a contractor may be acceptable if approved by CSD.

All corrosion-resistant weld overlays, including clad restoration, shall

conform with ASME SEC VIII reqts (Div. 1 or Div. 2) & W-014. SAES-W-014,

A5

Commentary Note: Refer to ASME SEC VIII D1, Part UCL and Para. 4.1

ASME SEC VIII D2, Article F-5 for specific requirements.

Repairs to integrally clad material shall not be done without the

SAES-W-014,

A6 specific approval of CSD. Any weld repairs to the cladding shall

Para. 4.7

meet the requirements for weld overlays.

The minimum deposit thickness shall be specified in the engineering

SAES-W-014,

A7 design but shall not be less than 3 mm for corrosion-resistant

Para. 4.2

overlays.

The direction of overlay deposition shall be circumferential unless

otherwise approved by CSD.

SAES-W-014,

A8 Commentary Note: Some components and geometries, such as

Para. 4.3

small diameter nozzles, or special applications may not permit

welding in a circumferential direction.

Single layer overlays require prior approval by CSD. Additional

SAES-W-014,

A9 qualification and production tests may be required, as determined by

Para. 4.9

CSD.

Ferrite measurements shall be performed in accordance with AWS SAES-W-014,

A10

A4.2 Para. 4.8

SAES-W-014,

A11 All chemical analysis methods shall conform to ASME/ASTM A751.

Para. 4.11

Saudi Aramco: Company General Use

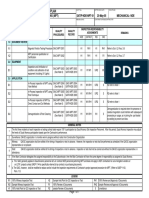

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B Overlay Procedure Qualification Requirements

All weld overlays shall be qualified in accordance with ASME SEC SAES-W-014,

B1

IX. Para. 5.1

The WPS shall indicate the minimum deposit thickness qualified and

the minimum number of layers required. The number of layers used

SAES-W-014,

B2 for the Procedure Qualification Record (PQR) shall be recorded and

Para. 5.2

shall be the minimum number of layers specified on the WPS and

used in production.

For all processes and all layers, the heat input specified on the WPS

SAES-W-014,

B3 shall not exceed the heat input recorded on the PQR by more than

Para. 5.3

10%.

For the SAW and Electro-slag processes, any change in the flux

SAES-W-014,

B4 brand, trade name, or designation shall be considered an essential

Para. 5.4

variable.

For single layer weld overlays, any decrease in overlap (As stated in

PQR) between adjacent beads needs requalification. SAES-W-014,

B5

Note: The overlap or spacing must be measured and recorded on Para. 5.5

the PQR and specified on the WPS.

The following elements shall be analyzed and specified for the

deposit chemistry for all stainless steel and nickel-based alloy weld

metal overlays:

SAES-W-014,

B6 C, Ni, Cr, Cu, Mo, Mn, Fe, plus any other significant elements that

Para. 5.6

are intentionally added to either the base metal or filler metal (e.g.,

Nb or Ti for stabilized stainless steel grades).

The chemistry of the overlay shall be measured at 1.5 mm below the

minimum specified overlay thickness. This is regardless of the SAES-W-014,

B7

thickness of the as-welded deposited thickness in the procedure Para. 5.7

qualification.

Inconel Alloy N06625 overlays shall have a maximum iron content of

SAES-W-014,

B8 10%.

Para. 5.7

Monel overlays shall have a maximum iron content of 4.5%.

The chemical composition of weld deposit shall be within the range

SAES-W-014,

B9 specified for the UNS number of the CRA clad material except for

Para. 5.8

the iron.

For PMI, the chemistry shall be checked on the final finished surface

of the production weld overlay.

SAES-W-014,

B10 Commentary Note:

Para. 5.9

Note: For overlay materials other than those listed above, the

elements to be analyzed shall be specified by CSD.

For austenitic stainless steel weld overlays, the ferrite content shall

SAES-W-014,

B11 be checked in the as-welded condition and shall be between 3 and

Para. 5.10

10 FN.

PQR hardness testing is required for weld overlays in:

a) Hydrogen service components of any wall thickness.

b) Sour service components of any wall thickness. SAES-W-014,

B12

c) For pressure vessels in any service if the base metal wall Para. 5.11

thickness is greater than 38 mm.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Hardness testing shall be in accordance with Standard Drawing AB-

036386. The maximum allowable hardness is VHN 250 for the base

metal and HAZ of all overlays and for the weld metal deposit of

austenitic stainless steel corrosion-resistant overlays.

Note: The hardnesses for the weld deposit of hardfacing overlays

SAES-W-014,

B13 and nickel-based corrosion-resistant overlays will depend on the

overlay material and the application. For sour service applications, Para. 5.11

NACE MR0175/ISO 15156 requirements for the weld metal overlay

must be met.

Hydrogen disbonding tests are additionally required to qualify weld

overlay procedures when both the design temperature exceeds

SAES-W-014,

B14 350°C and the hydrogen partial pressure exceeds 5 MPa. (Also see

Para. 7.1.1

SAIC-W-2020)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

C Qualification of Welders & Welding operators for Weld Overlays

SAES-W-014,

All welders & welding operators for weld overlays shall be qualified

C1 Para. 4.10;

per ASME SEC IX QW-380.

ASME Sec IX

REMARKS:

REFERENCE DOCUMENT: 1. SAES-W-010, Welding Requirements for Pressure Vessels, (08 September 12.)

2. SAES-W-014, Weld Overlays and Welding of Clad Materials, (11 March 2013)

3. ASME SEC VIII D1 Pressure Vessels (2013 Edition)

4. ASME SEC VIII D2 Pressure Vessels, Alternative Rules (2013 Edition)

5. ASME SEC IX Welding and Brazing Qualifications (2013 Edition)

6. AWS A4.2 Std Proc for Calibrating Magnetic Instr to Measure Delta Ferrite Content of Austenitic & Duplex Austenitic-Ferritic SS Weld Meta

ATTACHMENTS:

Attachment 1 - SAES-W-010, Attachments A & B Weld Map & Weld Description Table

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 1 - SAES-W-010, ATT. 3 Weld Map

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, Additional Forms (Info Only)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, Additional Forms (Info Only)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Saudi Aramco: Company General Use

You might also like

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldDocument9 pagesSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldIrshad IqbalNo ratings yet

- 09 Samss 035Document8 pages09 Samss 035Moustafa Bayoumi100% (1)

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- 09 Samss 030Document8 pages09 Samss 030Kalanithi KasirajanNo ratings yet

- 1 SATIP-NDE-MPT-01 Magnetic Particle Testing-Rev 1Document1 page1 SATIP-NDE-MPT-01 Magnetic Particle Testing-Rev 1KirubhakarPooranamNo ratings yet

- SAIC-W-2043 Rev 0Document3 pagesSAIC-W-2043 Rev 0philipyapNo ratings yet

- Saep 323Document12 pagesSaep 323rafatNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 NdeDocument3 pagesSaudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 Ndenadeem shaikhNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- Saep 306Document15 pagesSaep 306nadeem shaikh100% (1)

- 175 010710Document2 pages175 010710Abu Anas M.Salaheldin100% (1)

- 20554E04Document5 pages20554E04Mohamed GhonaimNo ratings yet

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Satr-W-2020Document1 pageSatr-W-2020Joni Carino SuniNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Sabp W 002Document7 pagesSabp W 002zoopladoNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- SAIC-L-2074 Rev 0Document1 pageSAIC-L-2074 Rev 0philipyapNo ratings yet

- SATIP-Q-011-01 Epoxy Grout For Machinery SupportDocument2 pagesSATIP-Q-011-01 Epoxy Grout For Machinery SupportAbdul HannanNo ratings yet

- 175 011000 PDFDocument2 pages175 011000 PDFAbu Anas M.SalaheldinNo ratings yet

- Satip A 000 01 Rev 7 (Final)Document2 pagesSatip A 000 01 Rev 7 (Final)faisalNo ratings yet

- 175 012300Document2 pages175 012300Abu Anas M.SalaheldinNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Satip - S-050-01Document4 pagesSatip - S-050-01LIJINNo ratings yet

- 1 Scope: SAEP-302Document8 pages1 Scope: SAEP-302nasirNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- Saep 1101Document50 pagesSaep 1101mathew.genesis.inspNo ratings yet

- Saep 1116Document5 pagesSaep 1116Anonymous 4IpmN7OnNo ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan Mohammad100% (1)

- 175 014301 PDFDocument2 pages175 014301 PDFVivek S SurendranNo ratings yet

- Saic LPT 2010Document4 pagesSaic LPT 2010Arjun RawatNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Saep 324 PDFDocument13 pagesSaep 324 PDFArvind ShakyaNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeDocument11 pagesSaudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaNo ratings yet

- Saep 1105 PDFDocument7 pagesSaep 1105 PDFbalajiNo ratings yet

- Challenges in Corrosion: Costs, Causes, Consequences, and ControlFrom EverandChallenges in Corrosion: Costs, Causes, Consequences, and ControlNo ratings yet

- Adw TR RTCF QP Me 002, Rev.1Document38 pagesAdw TR RTCF QP Me 002, Rev.1Rijwan MohammadNo ratings yet

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechDocument3 pagesSaudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechRijwan MohammadNo ratings yet

- Purchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Document1 pagePurchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan Mohammad100% (1)

- D43 15C 51666 12 - 0 PDFDocument1 pageD43 15C 51666 12 - 0 PDFRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan Mohammad100% (1)

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Satr W 2019Document3 pagesSatr W 2019Rijwan MohammadNo ratings yet

- Satip G 115 01Document7 pagesSatip G 115 01Rijwan MohammadNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- Saep 29Document10 pagesSaep 29Rijwan MohammadNo ratings yet

- SAIC-H-2001 NewDocument4 pagesSAIC-H-2001 NewRijwan MohammadNo ratings yet

- RCC Rectangular Overhead Water TankDocument19 pagesRCC Rectangular Overhead Water TankSRINIVAS DNo ratings yet

- Orientation Luminaires: Mounting InstructionsDocument2 pagesOrientation Luminaires: Mounting InstructionsAbdelrahman HassanNo ratings yet

- Archived: Construction of Pavement Subsurface Drainage SystemsDocument118 pagesArchived: Construction of Pavement Subsurface Drainage SystemsAjay SinghNo ratings yet

- Basic Plumbing System Design - DS - V2b.2015.0525Document10 pagesBasic Plumbing System Design - DS - V2b.2015.0525Dimaz ragaNo ratings yet

- Roxtec GH BG™ Frame - RoxtecDocument5 pagesRoxtec GH BG™ Frame - RoxtecStreesNo ratings yet

- Experimental Investigation On Bricks by Using Various Waste MaterialsDocument10 pagesExperimental Investigation On Bricks by Using Various Waste MaterialsGhyvz ElquirevaltNo ratings yet

- Porta Cabin For NGNDocument1 pagePorta Cabin For NGNRashmi Ranjan MohantyNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Mull HawassDocument7 pagesMull HawassMulugeta BezaNo ratings yet

- Induction Furnace Working Principle - Mechanical EngineeringDocument5 pagesInduction Furnace Working Principle - Mechanical Engineeringjalilemadi0% (1)

- Bobot PDFDocument2 pagesBobot PDFMoses TumenoNo ratings yet

- PARIS Et Al-2002-Fatigue & Fracture of Engineering Materials & StructuresDocument7 pagesPARIS Et Al-2002-Fatigue & Fracture of Engineering Materials & StructuresFrancesco MontagnoliNo ratings yet

- SERVICE MANUAL - lg+LC1200 PDFDocument27 pagesSERVICE MANUAL - lg+LC1200 PDFPaulo LaraNo ratings yet

- Fosroc Fibreboard - DtsDocument2 pagesFosroc Fibreboard - Dtsaljhun_1966No ratings yet

- CR Back To Back: 50/60 HZ CR, CRI, CRN 1, 3, 5Document11 pagesCR Back To Back: 50/60 HZ CR, CRI, CRN 1, 3, 5Tadeusz MatułaNo ratings yet

- 100 Seated Hostels Building SaharpadaDocument136 pages100 Seated Hostels Building SaharpadaMohammed Shahbaz100% (1)

- SS 316Document3 pagesSS 316Deepak SinghNo ratings yet

- RAILWAYS, Rails - PPTDocument75 pagesRAILWAYS, Rails - PPTZohaibShoukatBaloch0% (1)

- Sirocol Autobuz WEBASTODocument37 pagesSirocol Autobuz WEBASTOMihai MartonNo ratings yet

- SMC Structural Drawings 2020-06-29Document52 pagesSMC Structural Drawings 2020-06-29Musa AliNo ratings yet

- Prof. SuwarnoDocument24 pagesProf. SuwarnoJariniNo ratings yet

- BOQ Petron Clark (1.10.19)Document4 pagesBOQ Petron Clark (1.10.19)Mark Lester MolinoNo ratings yet

- Material Submittal-P6 Abha - SCSDocument131 pagesMaterial Submittal-P6 Abha - SCShabeebmudassir7677No ratings yet

- Air Release in PVC PlastisolsDocument5 pagesAir Release in PVC PlastisolsTrương Việt ThựcNo ratings yet

- Energy Theory of Rubber AbrasionDocument5 pagesEnergy Theory of Rubber Abrasionadriano_rods100% (1)

- Ejercicios - Resueltos - Diagramas de Momento y CortanteDocument11 pagesEjercicios - Resueltos - Diagramas de Momento y CortanteEstebanVasquezNo ratings yet

- Proportioning Concrete Mixtures With Graded AggregatesDocument86 pagesProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (2)

- FDASDocument15 pagesFDASPie Bernas100% (1)

- BOQ Shaliheen (1) .XLSX Rev-05Document2 pagesBOQ Shaliheen (1) .XLSX Rev-05dr.ppparikhNo ratings yet

- Several Criteria and Constraints For Flare Network - ProcessDocument2 pagesSeveral Criteria and Constraints For Flare Network - ProcessKamil Marszałek100% (1)