Gap Analysis Checklist

Gap Analysis Checklist

Uploaded by

Julius MuhimboCopyright:

Available Formats

Gap Analysis Checklist

Gap Analysis Checklist

Uploaded by

Julius MuhimboCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Gap Analysis Checklist

Gap Analysis Checklist

Uploaded by

Julius MuhimboCopyright:

Available Formats

SELF- INSPECTION REPORT FORM

Meat and Meat Products

Date of Self-Inspection:

Name of the Establishment:

Address of premises:

Tel. No.:

Fax No.:

Category of licence (Central/ State)

License No.:

E-mail Address:

Name of the Manager / Authorized

Signatory:

No. of Shifts:

No. of Employees:

Kind of business:

Type of business ownership: Limited/ Private limited/ Public sector

undertaking/ Co-operative/ Partnership/

proprietorship/other.

FSMS Program Page 36

Please mark as Status as appropriate

In order X not in order

√

* If Status is marked not in order, please provide target completion date

1. LOCATION AND LAYOUT OF FOOD ESTABLISHMENT Status

a) The factory is ideally located away from industries which are emitting harmful

gases, obnoxious odour, chemical etc.

b) The nature of ceiling roof is of permanent nature (Iron sheet/Asbestos sheet/

R.C.C).

c) The floor of building is cemented, tiled or laid in stone/ pakka floor.

d) The production area walls are smooth, made with impervious material up to a

height of not less than five feet and the junction between the walls and floors are

curved.

e) The premises of the factory is adequately lighted and ventilated, properly white

washed or painted.

f) Provision for disposal of refuse and effluents is available.

g) The food production/ food service area provided with adequate drainage

facility.

h) In case cooking is done on open fire, proper outlets for smoke/ steam etc, like

chimney, exhaust fan etc are installed and the fans installed at a suitable

height.

i) Doors are provided with automatic door closer.

j) Doors, Windows and other openings are fitted with net or screen to prevent

insects etc.

k) Antiseptic/ disinfectant foot bath is provided at the entrance.

l) Sufficient number of latrine and urinals for worker are provided and located

outside the processing hall.

m) All the machinery is installed in such a manner which may allow continuous

flow of production and do not occupy more than 50% of the total production and

permits hygienic production and easy movement.

2. EQUIPMENT AND FIXTURES

a) Equipments kept clean, washed, dried and free from molds and fungi.

b) No such Container/ Vessel/ Equipments in use likely to cause metallic

contamination.

FSMS Program Page 37

c) The table tops used for food preparation are made of close joint and

impervious material.

d) The equipments are made of stainless steel /galvanised iron/ non corrosive

materials.

e) Appropriate facilities for the cleaning and disinfecting of equipments and

instruments and preferably cleaning in place (CIP) system are adopted;

wherever necessary.

3. STORAGE SYSTEMS

a) Appropriate arrangement for storage of food & food ingredients provided and

adequately segregated and labelled.

b) Systems to adequately maintain time- temperature control at the time of storage.

c) Raw material, food additives and ingredients, wherever applicable are conforming to

regulations laid down under the act.

d) Containers used for storage are made of non toxic material.

e) Cold Storage facility, wherever necessary/ provided.

4. PERSONAL HYGIENE

a) Suitable aprons, head cover, disposable gloves & footwear are provided.

b) Adequate facilities for toilets, hand wash and footbath, with provision for

detergent/bactericidal soap, hand drying facility and nail cutter are provided.

c) No person suffering from any infection or contagious disease.

d) Arrangements are made to get the staff medically examined once in six

months to ensure that they are free from infectious, contagious and other diseases.

e) The staff working in such factory are inoculated against the enteric group of disease

and vaccinated.

f) No employee of such factory who is suffering from a hand or face injury, skin

infection or clinically recognizable infectious disease.

5. WATER SUPPLY

a) Adequate supply of potable water.

b) Appropriate facilities for safe & clean storage of water.

c) The water is examined chemically and bacteriologic ally by a NABL Accredited

laboratory.

d) Ice and steam wherever in use during processing is made from potable water.

a) Identifying marks have been applied to the pipelines for easy identification of

potable and non-potable water.

FSMS Program Page 38

6. PEST CONTROL SYSTEM

a) Treatment with permissible chemical, physical or biological agents within the

permissible limits are carried out.

b) Adequate control measures are in place to prevent insect and rodents from

the processing area.

7. CONVEYANCE AND TRANSPORTATION

a) Conveyance & transportation of food being done in an appropriate

state of

cleanliness, particularly if the same vehicle has been used to carry

non-food items.

b) The conveyance and transportation are provided with temperature

control

system.

8. CLEANING AND MAINTENANCE

a) Cleaning and sanitation programme is drawn up, observed and the

record of

the same is properly maintained.

b) Food preparation areas are cleaned at regular intervals, with

water, and detergent and with the use of a disinfectant.

9. OPERATIONAL FEATURES

a) The source and standards of raw material used are of optimum

quality and as per Regulation and standards laid down under the

Act.

b) Test report from own or NABL accredited/ FSSAI notified labs

regarding microbiological contaminants in food items are

c) available.

Arrangements for monitoring Temperature & Relative Humidity

10. AUDIT/ DOCUMENTATION AND RECORDS

a) Records of daily production, raw material utilized and sales are

available.

b) A periodic audit of the whole system according to the Standard

Operating

Procedure conducted regarding Good Manufacturing Practices/Good

c) Hygienic

Appropriate records of food processing/ preparation, food quality,

laboratory

Practices (GMP/ GHP) system.

test results, pest control etc. for a period of 1 year or the shelf -

d) life

Records

of the of sale and

product; purchaseisthat

whichever the food product sold to registered/

more.

licensed vendor and raw material purchased from registered/

licensed supplier.

e) Recall plan.

11. PRODUCT INFORMATION AND CONSUMER AWARENESS

a) All packaged food products carrying label and requisite information as

per

Regulations are made.

12. TRAINING

FSMS Program Page 39

a) Food production personnel and production floor managers/

supervisors underwent appropriate food hygiene training.

13. ADDITIONAL REQUIREMENTS FOR MEAT AND MEAT PRODUCTS

1) Condition of animal house, holding pens, quarantine pens

(Hygienic/

unhygienic) and their adequate distance from the processing plant.

2) Incinerator or burial pits for disposal of condemned carcasses wastes

exists.

3) The raw meat department, filling department and cooked meat

department

4) are

Meat (Source of

partitioned Supply) and have separate entry and exit.

adequately

a) No. of animals to be slaughtered per day

b) Method of Slaughter (Halal /Jhatka etc.)

c) Adequate facilities/ equipments are available for slaughter

according to

d) production

Adequate facilities

capacityfor ante /post mortem examination

e) No. of VETs, their name and VCI registration number etc.

f) Record keeping (arrival and raw meat examination )

arrangements are adequate

5) Integration with Slaughter House; if any.

6) Arrangement for meat inspection - a qualified Vet or services of

technically qualified person are provided

7) Are the equipments at a sufficient height to check for any leftover

of meat

8) products

Clean and sufficient drums or receptacles, provided for storing the

glands, waste, tissues, bones blood clots etc. are available

separately in each department (Slaughter hall, deboning, cooking

and filling departments etc.)

9) Trolleys/ suitable arrangements provided for quick transportation

/removal of the above material

10) The storage receptacle/trolleys are properly marked for slaughter ,

clean and

unclean etc. to avoid cross contamination and easy identification

11) Separate cold storage provided for raw and cooked meat.

12) Condition of cold storage

i) (clean/unclean)

ii) meat properly stored or not

13) The additives, curing agents etc., are properly labelled and packed

to avoid access and contamination by rodents and insects.

FSMS Program Page 40

Sample Flowchart for Meat Production

1. Receiving Live Cattle

2. Stunning / Bleeding

OR Shooting/Bleeding

4. Head 3. Head / Shank

Processing Removal

5. Skinning

9. Trim Zero

Toerance 6. Evisceration 7. Variety Meats

(Performed Processing

concurrently

with step 4)

8. Splitting

9. Trim Zero

9. Trim

Tolerance

Zero Tolerance

(Performed

concurrently with

step 7)

10. Final Wash

11. Organic Acid Spray

11. Organic

11. Organic Acid

Acid Spray 12. Chilling

Spray

FSMS Program Page 41

Sample FSMS Plan for Slaughtering Units

Operational Monitoring Responsibilit

Step Hazard Control Measure Critical Limit Method Corrective Action y Record

Carcass fecal material, Carcass washing w Zero visible perform a Re-process to Vet In-charge Slaughter

Trimming ingesta, present material visual remove deviation. Log

inspection of No product that is

each carcass injurious to health Corrective

or otherwise Action Log

adulterated as a

result of the

deviation will be

permitted to enter

commerce.

Hot Water / Microbial Each carcass half or Temperature of visually Re-process to Vet In-charge Slaughter

Organic contamination quarter is sprayed water confirm that remove deviation. Log

Acid Spray from thoroughly with an Concentration each carcass, No product that is

evisceration organic acid solution of Organic Acid carcass half is injurious to health Organic

prepared according to thoroughly or otherwise Acid Spray

the Organic Acid Spray sprayed with adulterated as a SOP Log

SOP or 150F hot water hot water or result of the

an organic deviation will be Corrective

acid solution permitted to enter Action Log

commerce.

Re-process to

remove deviation.

No product that is

injurious to health

or otherwise

adulterated as a

result of the

deviation will be

Microbiological Chiller Carcass permitted to enter Chiller

Chilling Growth 7C for 12 hours temperature temperatures commerce Vet In-charge Temp lpogs

Re-process to

Check remove deviation.

cleanliness of No product that is Despatch

Trucks injurious to health Log

Check ice or otherwise Ice Quality

Transport is in clean, quality adulterated as a Checks

covered trucks and use Time and Monitor result of the GMP

Physical and of potable ice where temperature of duration of deviation will be checklist for

Transport Microbiological necessary transport transporting permitted Vet In-charge Transporter

FSMS Program Page 42

You might also like

- Archipelago Food & Beverages Inc.: Site Master FileDocument14 pagesArchipelago Food & Beverages Inc.: Site Master FileQuality Assurace Team100% (2)

- Handbook of Microbiological Criteria for FoodsFrom EverandHandbook of Microbiological Criteria for FoodsNo ratings yet

- Layers Feed Formulation Handboo1Document13 pagesLayers Feed Formulation Handboo1Gichuru K Riria100% (10)

- Non Conforming ProcedureDocument2 pagesNon Conforming ProcedureDanielNo ratings yet

- Hazard Analysis and Critical Control Point (Haccp) : A Food Protection SystemDocument13 pagesHazard Analysis and Critical Control Point (Haccp) : A Food Protection SystemNino Michael Pagcaliwagan100% (2)

- Quality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodDocument1 pageQuality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodMia AgustinNo ratings yet

- Confidential Company: Quality Assurance ManagerDocument2 pagesConfidential Company: Quality Assurance Managermmammer100% (1)

- Rca Report Form - 0Document9 pagesRca Report Form - 0Quality DeptNo ratings yet

- Dosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceDocument5 pagesDosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceMahin patelNo ratings yet

- 4.9.1 Personnel TrainingDocument8 pages4.9.1 Personnel TrainingTylerNo ratings yet

- Doh Revised Guidelines On Current Good ManufacturingDocument25 pagesDoh Revised Guidelines On Current Good Manufacturingcharlimagne100% (3)

- sSOP Post Production: ScopeDocument4 pagessSOP Post Production: ScopeAlfred RangelNo ratings yet

- Personal Hygiene Program (FDA)Document5 pagesPersonal Hygiene Program (FDA)Alfred RangelNo ratings yet

- Comparing HACCP and HARPCDocument3 pagesComparing HACCP and HARPCIndri MardiyanaNo ratings yet

- Good Storage & Distribution PracticesDocument10 pagesGood Storage & Distribution PracticesAftab ManiyarNo ratings yet

- Food Safety CultureDocument1 pageFood Safety Cultureh.limNo ratings yet

- OPRP 2 Management of Pest ControlDocument2 pagesOPRP 2 Management of Pest ControlAnggerNo ratings yet

- Supplier Seclection Procedure-SOPDocument4 pagesSupplier Seclection Procedure-SOPSinthia Akter SnigdhaNo ratings yet

- SQF Storage and Distribution Ed8 With DeskDocument77 pagesSQF Storage and Distribution Ed8 With DeskMiguel Ernesto Lacayo ChávezNo ratings yet

- EXP 3 DesignDocument52 pagesEXP 3 DesignnasuhaNo ratings yet

- HACCP Review Meeting TemplateDocument2 pagesHACCP Review Meeting TemplateLee Sye100% (2)

- FishCrustFarm Issue 2 App Rev 5 November 2016 PT 2Document12 pagesFishCrustFarm Issue 2 App Rev 5 November 2016 PT 2DeddyKurniawanNo ratings yet

- Severe Weather Preparation Checklist: Key Focus AreasDocument2 pagesSevere Weather Preparation Checklist: Key Focus Areaszam110No ratings yet

- Philippine National Philippine National Philippine National Philippine National Standard Standard Standard StandardDocument19 pagesPhilippine National Philippine National Philippine National Philippine National Standard Standard Standard StandardAngelica DuevoNo ratings yet

- Sop 11Document2 pagesSop 11tary_nuryana100% (2)

- Scope of A SMETA AuditDocument2 pagesScope of A SMETA AuditJohn ParkNo ratings yet

- Employee Food Safety Training RecordDocument1 pageEmployee Food Safety Training RecordSulaiman Ahmat100% (1)

- Haccp SopDocument20 pagesHaccp SopNor Adila Norhasmie hassanNo ratings yet

- Supplier Approval 1636626211Document3 pagesSupplier Approval 1636626211Amparo BagnisalNo ratings yet

- Halal - Internal Auditor Training: Syed Noor Mustafa ShahDocument77 pagesHalal - Internal Auditor Training: Syed Noor Mustafa ShahSaid SaidiNo ratings yet

- QM 014 Purchasing, Orders and Verification of Purchased MaterialsDocument5 pagesQM 014 Purchasing, Orders and Verification of Purchased MaterialsFood Safety Poke & CoNo ratings yet

- Registration FormDocument2 pagesRegistration FormAlex Maverick WhittakerNo ratings yet

- Hygiene Audit ChecklistDocument1 pageHygiene Audit ChecklistSharif Fayiz AbushaikhaNo ratings yet

- Bakels MSDSDocument4 pagesBakels MSDSMd. Hafijur Rahman PlabonNo ratings yet

- Types of RecordsDocument16 pagesTypes of RecordsGurpreet KaurNo ratings yet

- HACCPDocument8 pagesHACCPKaye NicolasNo ratings yet

- OPRP 4 Management of Cleaning ValidationDocument1 pageOPRP 4 Management of Cleaning ValidationJuan Pablo Azcuña C.No ratings yet

- Mock RecallDocument1 pageMock RecallKeive BritoNo ratings yet

- Haccp Plan TemplateDocument4 pagesHaccp Plan Templateana choi100% (1)

- SOP For Handling Scrap and Disposal in PharmaceuticalDocument4 pagesSOP For Handling Scrap and Disposal in Pharmaceutical王仁宏No ratings yet

- Book BFTestFlip TestDocument2 pagesBook BFTestFlip TestTaylorShannon100% (1)

- Haccp& FSMSDocument3 pagesHaccp& FSMSSelvamani RamanNo ratings yet

- SynopsisDocument3 pagesSynopsisrajeevtyagi41No ratings yet

- Haccp SOP 2015 TUVDocument61 pagesHaccp SOP 2015 TUVbrurNo ratings yet

- Guideline Processing Meat and Meat Products 01.01.2024Document39 pagesGuideline Processing Meat and Meat Products 01.01.2024tekolahailu3No ratings yet

- SOP For Product RecallDocument14 pagesSOP For Product Recall王仁宏100% (1)

- Food Safety Management System 1721277130Document33 pagesFood Safety Management System 1721277130Niaz KhanNo ratings yet

- GMP Checklist: Location and SurroundingsDocument29 pagesGMP Checklist: Location and SurroundingsBrian WilliamsNo ratings yet

- Sugar and Its By-Products (Important)Document28 pagesSugar and Its By-Products (Important)Prateek ChitambareNo ratings yet

- Potato Chips Processing Flow ChartDocument1 pagePotato Chips Processing Flow ChartHiba BakriNo ratings yet

- SOP For Receiving and StorageDocument2 pagesSOP For Receiving and StorageErdinan SetiawanNo ratings yet

- Pre Requisite Programs Main PresentationDocument19 pagesPre Requisite Programs Main PresentationASIF EJAZNo ratings yet

- FSSAI Vaccination Form - Tybar 2.5mlDocument2 pagesFSSAI Vaccination Form - Tybar 2.5mlanandsivNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Good Manufacturing Practices: By: Carolina Gallango-Brun Sana Khan Vedrana SahovicDocument19 pagesGood Manufacturing Practices: By: Carolina Gallango-Brun Sana Khan Vedrana SahovicGina AuliaNo ratings yet

- Quality Management Systems A Complete Guide - 2021 EditionFrom EverandQuality Management Systems A Complete Guide - 2021 EditionNo ratings yet

- Understanding International Harmonization of Pesticide Maximum Residue Limits with Codex Standards: A Case Study on RiceFrom EverandUnderstanding International Harmonization of Pesticide Maximum Residue Limits with Codex Standards: A Case Study on RiceNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- Food Defense A Complete Guide - 2020 EditionFrom EverandFood Defense A Complete Guide - 2020 EditionRating: 1 out of 5 stars1/5 (1)

- Procurement Advert 1 22-23Document1 pageProcurement Advert 1 22-23Julius MuhimboNo ratings yet

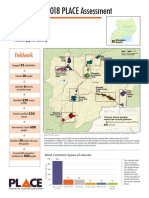

- Ntungamo: 2018 PLACE Assessment: PL CEDocument4 pagesNtungamo: 2018 PLACE Assessment: PL CEJulius MuhimboNo ratings yet

- Form - CAR FormDocument6 pagesForm - CAR FormJulius MuhimboNo ratings yet

- SPD Solar Flood Lights SpecificationsDocument1 pageSPD Solar Flood Lights SpecificationsJulius MuhimboNo ratings yet

- Manu PresentationDocument31 pagesManu PresentationJulius MuhimboNo ratings yet

- Solcourse Polythene DPM V005 TDSDocument3 pagesSolcourse Polythene DPM V005 TDSJulius MuhimboNo ratings yet

- Newterra Quality Plan - Uganda WWTP - PWTPDocument1 pageNewterra Quality Plan - Uganda WWTP - PWTPJulius MuhimboNo ratings yet

- TDS - Technical Data SheetsDocument1 pageTDS - Technical Data SheetsJulius MuhimboNo ratings yet

- MSDS - Smoke Detector Test SprayDocument15 pagesMSDS - Smoke Detector Test SprayJulius MuhimboNo ratings yet

- MTC Fabrication SystemDocument1 pageMTC Fabrication SystemJulius MuhimboNo ratings yet

- Rose FoamDocument4 pagesRose FoamJulius MuhimboNo ratings yet

- Material Safety Data Sheet: Wet Chemical Dry Charge (Portable Fire Extinguisher Agent)Document6 pagesMaterial Safety Data Sheet: Wet Chemical Dry Charge (Portable Fire Extinguisher Agent)Julius MuhimboNo ratings yet

- Anchor Bolt Detail 1Document1 pageAnchor Bolt Detail 1Julius MuhimboNo ratings yet

- SF01 Food Application Form With All AnnexesDocument11 pagesSF01 Food Application Form With All AnnexesJulius MuhimboNo ratings yet

- GWC24AGDXE-K3DNA1A - Spec SheetDocument5 pagesGWC24AGDXE-K3DNA1A - Spec SheetJulius MuhimboNo ratings yet

- ToolBox MeetingDocument1 pageToolBox MeetingJulius MuhimboNo ratings yet

- Sika Monotop 610 MsdsDocument14 pagesSika Monotop 610 MsdsJulius MuhimboNo ratings yet

- 01 35 16 Alteration Project ProceduresDocument8 pages01 35 16 Alteration Project ProceduresJulius MuhimboNo ratings yet

- Case Study ON MR - Vijay AgrawalDocument28 pagesCase Study ON MR - Vijay Agrawalmahesh003No ratings yet

- Simple Past Present Perfect?: A Bite Sized English LessonDocument13 pagesSimple Past Present Perfect?: A Bite Sized English LessonLucian DilgociNo ratings yet

- Cooking TermsDocument2 pagesCooking TermsYara CheaitoNo ratings yet

- 49827Document27 pages49827homesnonohNo ratings yet

- Container GardeningDocument36 pagesContainer GardeningLakshya SrivastavaNo ratings yet

- Macronutrients PPT 1416heDocument47 pagesMacronutrients PPT 1416heMA. DOMINIQUE CLORESNo ratings yet

- Turan 2015 HF MethodsDocument8 pagesTuran 2015 HF Methodsirem emine demirNo ratings yet

- Lesson Plan 5 Elements and CompoundsDocument4 pagesLesson Plan 5 Elements and CompoundsjingvillaruelNo ratings yet

- TLE6 Diagnostic TestDocument3 pagesTLE6 Diagnostic TestZeny San JuanNo ratings yet

- Agmark Acts & Rules PDFDocument7 pagesAgmark Acts & Rules PDFMadhu PrasadNo ratings yet

- Tienganh9 hk2Document144 pagesTienganh9 hk2Nguyễn Hòn ĐáNo ratings yet

- Food Safety in A Nutshell (2020)Document68 pagesFood Safety in A Nutshell (2020)Ken ChiuNo ratings yet

- Procedure Text Examples: How To Charge Hand Phone BatteryDocument3 pagesProcedure Text Examples: How To Charge Hand Phone BatteryNonna WiddaNo ratings yet

- MALUNGGAY: It's Like Growing Multi-Vitamins at Your DoorstepDocument15 pagesMALUNGGAY: It's Like Growing Multi-Vitamins at Your DoorstepPierre Anthony D. JovenNo ratings yet

- Harleen Saki 2041319034 F&B Sem 2Document16 pagesHarleen Saki 2041319034 F&B Sem 2Imran KhanNo ratings yet

- Grade - Agric, Science N Tech - Paper 2 Mid YearDocument2 pagesGrade - Agric, Science N Tech - Paper 2 Mid Yearsikitenifarai97No ratings yet

- The Cultural Evolution of HumansDocument20 pagesThe Cultural Evolution of HumansCatalinus SecundusNo ratings yet

- TOEFL - Activator - Advanced Listening PDFDocument158 pagesTOEFL - Activator - Advanced Listening PDFZsu Juhász67% (3)

- Konsumsi NO Uraian Satuan Harga Satuan Jumlah KETDocument3 pagesKonsumsi NO Uraian Satuan Harga Satuan Jumlah KETDwi AdityaNo ratings yet

- Present Continuous 5202Document2 pagesPresent Continuous 5202sara s.mendesNo ratings yet

- Worksheet Going Places LsDocument2 pagesWorksheet Going Places LsnadiaNo ratings yet

- Dampak Kenaikan Harga Kedelai Terhadap Industri Tahu Dan Tempe Di Kota Pekanbaru Oleh: Oktaria Ningsih Pembimbing: Azwar Harahap Dan Toti IndrawatiDocument10 pagesDampak Kenaikan Harga Kedelai Terhadap Industri Tahu Dan Tempe Di Kota Pekanbaru Oleh: Oktaria Ningsih Pembimbing: Azwar Harahap Dan Toti Indrawatiessi herwikaNo ratings yet

- DCA ReflectionDocument3 pagesDCA ReflectionCamille PoloNo ratings yet

- Name: Class: - Read The Text Carefully and Answer The Questions!Document1 pageName: Class: - Read The Text Carefully and Answer The Questions!hydeist zainiNo ratings yet

- ProductionDocument4 pagesProductionShashi ReddyNo ratings yet

- English 5 Q1 W1 D1Document29 pagesEnglish 5 Q1 W1 D1kriella hyacinthNo ratings yet

- Social Organization of The TainosDocument16 pagesSocial Organization of The TainosJudaNo ratings yet

- Zomato The Digital Dining DisruptorDocument10 pagesZomato The Digital Dining Disruptorabhishek chaharNo ratings yet

- TOEFL Practice Quiz 1-Study For The TOEFL: Choose The Correct Letter To Fill The BlankDocument13 pagesTOEFL Practice Quiz 1-Study For The TOEFL: Choose The Correct Letter To Fill The BlankGabriela HernandezNo ratings yet